Professional Documents

Culture Documents

Lower Guide Man Mill

Uploaded by

wiccanwaysCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lower Guide Man Mill

Uploaded by

wiccanwaysCopyright:

Available Formats

AR-15 Lower Receiver Completion Guide

Manual Mill

Please carefully read these instructions in entirety before beginning.

Overview:

These instructions are meant to give you some direction in completing your Optimus Defense 80%

Lower Receiver. To complete the lower you will be drilling three holes and machining two pockets. To

keep the lower receiver within tolerance, pay close attention to the tolerances as you machine. We offer

recommended speeds, depths of cuts, and stick out lengths on the final page of this manual. This guide

will cover manually machining your lower. It is possible to use drill jigs or a CNC machine if you so

choose.

Cutters:

These tools are included in the Optimus Defense tool kit

available for purchase:

7/16 Endmill with a 3/8 shank

5/16 Endmill with a 3/8 shank

3/8 Stub split tip drill bit

5/32 Stub split tip drill bit

1/4 Precision ground rod for part zero

Other Tools:

Mill with Vise (needs to be squared)

Edge Finder or suitable touch off method

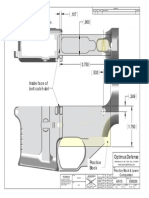

Figure 1

Safety Glasses

Cutting Fluid (recommended but not required) such as A-9 or Tap Magic Aluminum

Dykem (blue dye) or dark color Sharpie

Manual Mill Drawings and Inspection Drawings (available at optimusdefense.com/documents)

Procedure:

Hammer and Trigger pin holes

1. Clamp the lower in the vise with the Lowers left side

facing up.

Note: Place the lower on parallels or a sacrificial parallel block to avoid

drilling the vise.

2.

Zero X and Y; Place the 1/4 precision rod in a tool

holder and center the rod over the take down hole.

Adjust the table until the rod drops smoothly and

easily into the take down pin hole. See Figure 2.

Note: A high quality 1/4 drill bit can be used instead of the 1/4

precision rod.

3.

Figure 2

Using the 5/32 drill bit, drill the hammer and trigger pin holes.

Selector Hole

4. Using the 3/8 drill bit, drill the selector hole.

5.

After drilling all three holes remove the lower from the vise and carefully inspect it using the

inspection drawing.

2014 Optimus Defense

Rev. 1

Page: 1

AR-15 Lower Receiver Completion Guide

Manual Mill

Fire Control Pocket

6. Place the lower in the vise in the upright position,

with the trigger guard flat on the bottom of the vise.

Note: Make sure that the lower is sitting flat. Check with a square or

dial indicator.

7.

Insert the 1/4 precision rod in the take down hole

and touch off on one side. The rod is precision

ground to diameter 0.250. The center of the rod is

your X Zero. See Figure 3.

Note: Remember to adjust for the precision rod and edge finder

radiuses.

Figure 3

8.

Touch off the left side of the lower, this will be

your Y Zero. See Figure 4.

Note: Remember to adjust for the edge finder radius.

Figure 4

9.

Using the 7/16 endmill, zero Z off the top surface

of the lower. See Figure 5.

10. Machine the fire control pocket to a depth of

approximately .020" deep. Then use Dykem (blue

dye) or a dark color Sharpie to color the fire control

pocket. This provides a visual reference for

roughing.

Figure 5

2014 Optimus Defense

Rev. 1

Page: 2

AR-15 Lower Receiver Completion Guide

Manual Mill

11. Visually rough out the large pocket of the fire

control pocket, but not the rear slot, to a depth of

1.250. Leave an allowance of about 0.010 to

0.020 around the pocket. This allowance will be

machined during the finish pass. See Figure 6.

12. Perform a full depth finish pass to bring the

pocket to its finished dimensions.

Note: Due to tool deflection, conventional milling tends to cut a

slightly larger pocket. You may want to cut slightly undersized. You

can always remove more material.

Figure 6

13. Machine the rear slot of the fire control pocket.

See Figure 7.

Note: No finish pass. Just slot in and out at the same depth of cuts

as rough milling the fire control pocket.

Figure 7

Trigger Slot

14. Using the 5/16 endmill, machine the trigger slot.

See Figure 8.

Note: Ensure the tool is sticking out enough to avoid any collisions

with the mill head and/or tool holder.

15. After milling both pockets take some

measurements and compare it to the inspection

drawing. All dimensions should be within the

tolerance noted on the drawing. If out of

tolerance, carefully consider how it will affect

the function of your lower.

Figure 8

Debur

16. Using a suitable debur tool or sandpaper, carefully take down any sharp edges.

Warning: Once you have machined any of the hammer, trigger and selector holes or the fire control pocket and trigger slot,

you have what is legally considered a firearm. This firearm can not be traded, gifted or sold without the assistance of a

FFL. Optimus Defense assumes no liability for the actions of the user of this product. You are responsible for knowing all

laws and regulations in your area relating to this product. We are not lawyers, and this is not legal advice.

2014 Optimus Defense

Rev. 1

Page: 3

AR-15 Lower Receiver Completion Guide

Manual Mill

Recommended Cutting Parameters

Calculations

7/16 Endmill

Speed: 1750 RPM

Stick Out: 1-3/4

Roughing Depth of Cut: 0.220

Definitions

RPM Revolutions per Minute

SFM Surface Feet per Minute

Dia Diameter of cutter

5/16 Endmill

Speed: 2450 RPM

Stick Out: 1-1/2

Roughing Depth of Cut: 0.150

Formulas

RPM = SFM * 3.82 / Dia

3/8 Drill

Speed: 2000 RPM

Stick Out: 1-1/2

Peck Drill: 0.190

SFM for High Speed Steel cutting Aluminum is

200. (conservative cutting)

Recommended RPMs are based off the above

calculation. You can use a slower RPM and

compensate by lowering your feed rate as well.

5/32 Drill

Speed: 4800 RPM

Stick Out: 1-1/2

Peck Drill: 0.080

Other Information:

Climb vs Conventional Milling:

Conventional milling is recommended for manual

machining since it keeps pressure against the table of the

mill. For the fire control pocket, it is recommended to

machine in a conventional pattern. This is generally

moving the cutter clockwise around the inside of the

pocket.

Tool Chatter:

Tool chatter may occur due to the long length of these

cutters. If you are experiencing excessive chatter or

getting a bad surface finish, reduce the spindle RPM.

Cutting Fluid:

Using a cutting fluid that is made for machining

aluminum, such as A-9 or Tap Magic Aluminum, will greatly improve the machining finish, reduce tool

chatter, and improve tool life.

Warning: Manual machining can be dangerous. You should know how to safely operate the tools and equipment before

attempting to complete an AR-15 Lower Receiver. Always were safety glasses. This Guide is for informational and

educational purposes only. Optimus Defense is not liable for an property damage, personal injury, or death, as a result of

using this Guide.

2014 Optimus Defense

Rev. 1

Page: 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- m16 Receiver Ordnance PrintDocument3 pagesm16 Receiver Ordnance Printdownload1414100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manufacturing Execution System - MESDocument276 pagesManufacturing Execution System - MESDexter100% (5)

- Altima Wiring ConnectorsDocument4 pagesAltima Wiring ConnectorswiccanwaysNo ratings yet

- AR-15 Practice BlockDocument1 pageAR-15 Practice Blockwiccanways100% (2)

- Inventory Reorder MethodsDocument26 pagesInventory Reorder MethodsmragarwalNo ratings yet

- Altima WiringDocument7 pagesAltima WiringwiccanwaysNo ratings yet

- Altima FusesDocument8 pagesAltima FuseswiccanwaysNo ratings yet

- Lower Guide Drill JigDocument5 pagesLower Guide Drill Jigwiccanways100% (1)

- Digital Patterns: Designed by Steve GoodDocument3 pagesDigital Patterns: Designed by Steve GoodwiccanwaysNo ratings yet

- PSL 10 Signal CODESDocument1 pagePSL 10 Signal CODESwiccanwaysNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument4 pagesDigital Patterns: Designed by Steve GoodwiccanwaysNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument4 pagesDigital Patterns: Designed by Steve GoodwiccanwaysNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument5 pagesDigital Patterns: Designed by Steve GoodwiccanwaysNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument3 pagesDigital Patterns: Designed by Steve GoodwiccanwaysNo ratings yet

- Optimus AR-15 Man MillDocument2 pagesOptimus AR-15 Man Millwiccanways50% (2)

- Digital Patterns: Designed by Steve GoodDocument9 pagesDigital Patterns: Designed by Steve GoodwiccanwaysNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument4 pagesDigital Patterns: Designed by Steve GoodwiccanwaysNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument5 pagesDigital Patterns: Designed by Steve GoodwiccanwaysNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument3 pagesDigital Patterns: Designed by Steve Goodwiccanways100% (1)

- Digital Patterns: Designed by Steve GoodDocument5 pagesDigital Patterns: Designed by Steve GoodwiccanwaysNo ratings yet

- 2008 Bear Archery SpecsDocument7 pages2008 Bear Archery SpecswiccanwaysNo ratings yet

- 2011 Bear Archery SpecsDocument8 pages2011 Bear Archery SpecswiccanwaysNo ratings yet

- 2012 Bear Archery SpecsDocument9 pages2012 Bear Archery SpecswiccanwaysNo ratings yet

- Smoking BookDocument55 pagesSmoking Bookjtbark100% (1)

- 2010 Bear Archery SpecsDocument10 pages2010 Bear Archery SpecswiccanwaysNo ratings yet

- TR - Heat TreatmentDocument48 pagesTR - Heat TreatmentAMIT PRAJAPATINo ratings yet

- Design and Analysis of A Concrete Modular Housing System Constructed With 3D PanelsDocument80 pagesDesign and Analysis of A Concrete Modular Housing System Constructed With 3D PanelsNeven Ahmed HassanNo ratings yet

- Chapter 19-Bulk Deformation Processes IDocument67 pagesChapter 19-Bulk Deformation Processes IMohsin AliNo ratings yet

- ISO - 15156-1 - 2009 - Technical Circular - 1 - 2014-01-27Document4 pagesISO - 15156-1 - 2009 - Technical Circular - 1 - 2014-01-27manuelazo78No ratings yet

- Agile Learning DesignDocument11 pagesAgile Learning Designmegan7130100% (1)

- Matdan BCS Series CatalogDocument2 pagesMatdan BCS Series Catalogsatheez3251No ratings yet

- Chain Wheels ChainconveyorDocument9 pagesChain Wheels ChainconveyorPedro RBNo ratings yet

- IOCL InsulationDocument43 pagesIOCL InsulationYogi17350% (2)

- NSK Cat E1267Document9 pagesNSK Cat E1267Anonymous 5RUnMVLMPNo ratings yet

- Masonry Support Systems and LintelsDocument36 pagesMasonry Support Systems and LintelsAchilleas21No ratings yet

- FQP PileDocument18 pagesFQP PileGoanengineer100% (1)

- BS 4504 FlangeDocument11 pagesBS 4504 FlangeAlon BalonNo ratings yet

- List of Welding Processes - Wikipedia, The Free EncyclopediaDocument6 pagesList of Welding Processes - Wikipedia, The Free EncyclopediasumitNo ratings yet

- Vaccum Box Test ProcedureDocument3 pagesVaccum Box Test ProcedureAJOJOY009No ratings yet

- CompReg 8NOVEMBER2019Document1,671 pagesCompReg 8NOVEMBER2019Solidworks Reseller Chennai InNo ratings yet

- Piping FundamentalsDocument12 pagesPiping FundamentalsKurian JoseNo ratings yet

- Southern Company/MHI Ltd. Plant Barry CCS DemonstrationDocument23 pagesSouthern Company/MHI Ltd. Plant Barry CCS Demonstrationrecsco2100% (1)

- Singeing Fundamentals: By: Tanveer HussainDocument12 pagesSingeing Fundamentals: By: Tanveer HussainPushpanjali VermaNo ratings yet

- Flexible Manufacturing System (FMS)Document19 pagesFlexible Manufacturing System (FMS)purushothamkr100% (1)

- Induction Hardening of Gears Part 2Document5 pagesInduction Hardening of Gears Part 2Pratap SahooNo ratings yet

- Operations Management: Course Instructor: Mansoor QureshiDocument37 pagesOperations Management: Course Instructor: Mansoor QureshiPrince ZiaNo ratings yet

- Lean Manufacturing in A Mass Customization Plant: Improvement of Kanban Policy and ImplementationDocument64 pagesLean Manufacturing in A Mass Customization Plant: Improvement of Kanban Policy and ImplementationMohammed SirelkhatimNo ratings yet

- Logistics Services SindhuDocument86 pagesLogistics Services SindhubandichaituNo ratings yet

- VA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1Document20 pagesVA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1MungNguyenDinhNo ratings yet

- RMW3 08 Morita HDocument50 pagesRMW3 08 Morita Hnovas88No ratings yet

- Project On Utkal Signature Official BuildingDocument3 pagesProject On Utkal Signature Official BuildingspruhatechNo ratings yet

- Fencing Catalogue UKDocument28 pagesFencing Catalogue UKVisoiu TiberiusNo ratings yet

- Green Electronics: Save Environment, It Will Save You!!! We Are Doing Our Bit What About YOU???Document19 pagesGreen Electronics: Save Environment, It Will Save You!!! We Are Doing Our Bit What About YOU???ayeshasweet100% (1)