Professional Documents

Culture Documents

Optimization of Machinig

Uploaded by

khujistamahmoodCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimization of Machinig

Uploaded by

khujistamahmoodCopyright:

Available Formats

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.2, No.

4, November 2013

OPTIMIZATION OF MACHINING

PARAMETERS IN HIGH SPEED END

MILLING OF AL-SiC USING GRAVIATIONAL

SEARCH ALGORITHM

Vikas Pare1, Geeta Agnihotri2, C.M. Krishna3

Department of Mechanical Engineering,

Maulana Azad National Institute of Technology Bhopal,India

ABSTRACT

Surface roughness is very important criteria for evaluation in end milling operation. It is very important to

predict surface roughness to maintain or improve quality of the components and soft computing techniques

help in optimizing the machining parameters required to predict surface roughness. Many researchers

developed models in order to achieve minimum surface roughness in metal cutting operations at low cost.

However, very few researchers worked in the area of high speed machining for minimizing surface

roughness using gravitational search algorithm (GSA). In this paper, GSA which is inspired by Law of

gravity, is used for optimization of surface roughness. Speed, feed, depth of cut and step over ratio are

taken as the input parameters and Aluminum silicon carbide composite material is used as work material.

Experiments are conducted by varying the input parameters at two levels each except for speed at three

levels. These experiments are conducted on high speed CNC vertical machine and portable Taylor Hubson

surface roughness tester is used for measuring surface roughness. A Non linear regression equation is

used to establish relationship between surface roughness and the input parameters. MATLAB software has

been used for writing code for GSA and results indicate that GSA proves to be effective in this optimization

problem.

KEYWORDS

GSA, Surface Roughness, Composite Material, Non Linear Regression Equation, MATLAB Code.

1. INTRODUCTION

Metal matrix composite is world class engineering material with improved mechanical and

thermal properties having application in automotive, aircraft and related industries. Now a days,

aluminum silicon carbide composite (Al-SiC) is predominantly used in various applications in

industries. The material retains machinability characteristics of aluminum and at the same time

increases hardness of the material. In real life optimization problems with a high-dimensional

search space, the conventional optimization algorithms do not give a feasible solution because of

the continuously increasing search space with the problem size. Over the last decades, there has

been a strong inclination in using algorithms inspired by the behaviors of natural phenomena.

Various heuristic approaches have been applied by researches, such as, Genetic Algorithm (GA),

Simulated Annealing (SA), Artificial Bee colony Algorithm (ABC), Particle Swarm Optimization

(PSO) etc. These algorithms can be used to solve different optimization problems. However,

there is no specific algorithm to solve all optimization problems. Some algorithms provide a

better solution in particular case in comparison to other algorithms and thus they are very much

problem specific. In this study, a new optimization algorithm inspired by the law of gravity,

namely Gravitational Search Algorithm (GSA) is applied. This algorithm is influenced on

Newtonian gravity: Every particle in the universe attracts every other particle with a force that is

45

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.2, No.4, November 2013

directly proportional to the product of their masses and inversely proportional to the square of the

distance between them. Heuristic algorithm are based upon either physical or biological

processes.

1.1 Gravitational Search Algorithm (GSA)

In this algorithm, agents are correlated with the objects and their output is measured by their

masses. Due to gravity, all these objects attract each other and it also produces a global

movement of all objects towards the objects with heavier masses. Hence, gravitational force is

medium of communication between masses. The big and heavy masses represents good solutions

and it move significantly slower than lighter ones. This ensures the exploitation step of the

algorithm. In GSA, each mass holds four stages, namely position, inertial mass, active and

passive gravitational mass. The positions of the mass identify a solution of the problem and it is

solved by using a fitness function. The algorithm is governed and directed by properly adjusting

the gravitational and inertia masses. In due course of time, other small masses are attracted by the

heaviest masses. This mass will present an optimum and feasible solution in the search space. The

GSA virtually acknowledges it as an isolated system of masses in which masses are governed by

the Newtonian laws of gravitation and motion. These laws are: law of gravity: each particle

attracts every other particle and the gravitational force between two particles is directly

proportional to the product of their masses and inversely proportional to the distance between

them. Law of motion: the current velocity of any mass is equal to the sum of the fraction of its

previous velocity and the variation in the velocity. Variation in the velocity or acceleration of any

mass is equal to the force acted on the system divided by mass of inertia. The inertia mass causes

obstacles in the motion and causes the mass movement to be slow. Therefore, agents with heavy

inertia mass move slowly and it searches the space more effectively. GSA is a memory-less

algorithm but as good as other algorithms with memory.

In this paper, in addition to introduction in this section, the literature review is given in section-2.

The experimental work is explained in section-3. The data obtained from experiments and results

and discussions are explained in section-4. The conclusions drawn about the work are explained

in section-5.

2. LITERATURE REVIEW

The literature review on this topic reveals that very few researchers worked in parameter

optimization of metal cutting process under high speed machining conditions for composite

materials. The researchers mostly applied a few conventional optimization techniques, such as,

goal programming, feasible direction method, etc. to solve the problems of optimization but

subsequently, researchers could not achieve optimum values for the output variables by these

conventional techniques. These techniques are very cumbersome and often not result oriented. To

overcome the limitation of conventional optimization techniques, researchers attempted the

advanced optimization techniques, such as, GA and its versions, SA, PSO and ABC algorithms.

In the category of new optimization techniques, gravitational search algorithm (GSA) is a recent

one and very result oriented for optimization problems.

Zubaidi et al (2013) deployed the gravitational search algorithm for the optimization of cutting

conditions for end milling of Ti6Al4V Alloy and compared the results with the results obtained

by applying genetic algorithm and particle search algorithm. They proved that GSA is more

effective as compared to GA and PSO techniques. R.Arokiadass et al., (2012) studied the

machining properties of LM25 Al/SiCp composite under high speed end milling conditions. They

deployed the RSM and developed a mathematical model to estimate the high speed end milling

process parameter.

46

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.2, No.4, November 2013

Esmat rashadi et al., (2009) introduced a new optimization algorithm viz., gravitational search

algorithm which is based on the law of gravity and mass interactions. This algorithm has been

compared with some well-established heuristic search methods and best result is achieved as

compared to other techniques for their case. Yusup et al (2012) have given the overall view and

compared various evolutionary optimization techniques which are applied in optimization of

cutting conditions for machining processes. They applied five techniques for comparison namely:

genetic algorithm (GA), simulated annealing (SA), particle swarm optimization (PSO), ant colony

optimization (ACO) and artificial bee colony (ABC) algorithm. The authors concluded that, in

comparison to other machining processes, the most prominently used algorithm is genetic

algorithm which was deployed mostly for multi pass turning operation. The performances of these

techniques have been used widely in minimization of surface roughness.

Mahyar Khorasani et al.(2012) studied the parameters that influence the surface roughness in

metal cutting processes in a significant way. They categorized the different machining

parameters into six groups namely: tool properties, machine tool , cutting conditions, thermal and

dynamic properties and work material. Ozcelik and Bayramoglu (2006) deployed a statistical

model for surface roughness prediction in a high-speed flat end milling process considering wet

cutting conditions, by applying machining variables, namely, spindle speed, feed rate, depth of

cut, and step over ratio.

3. EXPERIMENTAL WORK

The experimental study was carried out in dry cutting conditions on a high-speed CNC vertical

milling machine (Model-Agni-BMV-45-T-20-Year 2008) with a maximum spindle speed of

10,000 rpm, clamping area of 450 x 900 mm2 , feed rate of (1-10000) mm/min, 15-kW drive

motor capacity, and a table Size of 800x500x550 mm3. CNC part programs for tool paths were

prepared. Aluminum silicon carbide composite material is used in the form of a 52mm x 52mm x

22mm block. A flat end mill (25mm diameter, 451 helix angle, 4-flutes) of make Addison was

used in the tests. In this paper, linear and non-linear relationship has been established between

input and output parameters and applied GSA to minimize surface roughness. Figure-2 shows the

working of surface roughness tester and High Speed CNC vertical milling machine as used in

experimental work.

Figure 2 Surface roughness tester and its working

4. RESULT AND DISCUSSION

Based on the selected range, data is collected by varying the selected combinations of speed, feed,

depth of cut and step over ratio. In this experiment, coolant was not used and other indirect

factors such as, machine vibration and its tolerance, operator efficiency and environmental

condition are assumed to have negligible effect on surface roughness. Table 1 shows the selected

range of input parameter and Table 2 shows the experimental results. The range is chosen from

47

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.2, No.4, November 2013

5000 to 7000 for speed in order to study the influence of speed on surface roughness at higher

ranges. This is attempted by very few researchers. Similarly the feed range is also higher in

contract to conventional ranges as higher range of feed value assures higher productivity. For

depth of cut, relatively wider range is chosen so as to ensure the best value of depth of cuts as the

objective. The step over ratio is chosen such that the surface obtained is smooth.

Following are the ranges of input parameters used in this study.

Table1 Selected Range of Input Parameters

Parameter

Lower Higher

Speed (x1)(m/min)

5000

7500

Feed/tooth(x2)

200

300

Depth of cut (x3)

0.2

0.4

Step over ratio(x4)

0.6

0.7

Table 2 Data high speed CNC milling

S.N0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

X1

2500

2500

2500

2500

2500

2500

2500

2500

5000

5000

5000

5000

5000

5000

5000

5000

7500

7500

7500

7500

7500

7500

7500

7500

X2

100

100

100

100

200

200

200

200

100

100

100

100

200

200

200

200

100

100

100

100

200

200

200

200

X3

0.2

0.2

0.3

0.3

0.2

0.2

0.3

0.3

0.2

0.2

0.3

0.3

0.2

0.2

0.3

0.3

0.2

0.2

0.3

0.3

0.2

0.2

0.3

0.3

X4

0.5

0.6

0.5

0.6

0.5

0.6

0.5

0.6

0.5

0.6

0.5

0.6

0.5

0.6

0.5

0.6

0.5

0.6

0.5

0.6

0.5

0.6

0.5

0.6

Ra

0.3096

0.3714

0.3362

0.4001

0.3459

0.4098

0.3745

0.4364

0.1689

0.2328

0.1976

0.2594

0.2072

0.2691

0.2339

0.2978

0.0882

0.1501

0.1149

0.1787

0.1245

0.1884

0.1532

0.2151

48

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.2, No.4, November 2013

General form of non linear equation is

Ra = K.x1a1 .x2a2 .x3a3 .x4a4

(4.1)

By taking logarithmic on both sides

Log(Ra)= Log(K)+a1*log(x1) + a2*log(x2) + a3*log(x3) + a4*log(x4)

(4.2)

RA= a1*log(x1) + a2*log(x2) + a3*log(x3) + a4*log(x4) + C,

(4.3)

where RA=log(Ra) and C=log(K)

With the help of Minitab software using 24 experimental data values, non-linear regression

equation is developed, which is given equation 4.4.

RA= 1.9863 -0.2014.log(x1) +0.05382. log(x2) + 0.0682.1og(x3) +0.3447. log(x4)

(4.4)

This non-linear equation is based on Gauss Newton having tolerance .00001 and 200 iteration. In

this paper, GSA applied. The result of GSA techniques in terms of surface roughness and

corresponding parameters are x1, x2, x3 and x4 shown in table 5.

Table 5 Optimum Result as obtained by GSA method

Parameter

GSA

X1(rpm)

7132

X2(mm/min)

120.8

X3(mm)

0.3

X4

0.6

Result

.1986

(Ra in micron)

Iteration

4.1 Summary of non-linear regression analysis

In this study, non-linear regression analysis performed with experimental data is given in Table-7.

Four input parameters, a1, a2, a3, and a4 are chosen and their estimates are given in table.

Standard error estimates are very low for all five parameters including constant, C. This

indicates that this model is fit for prediction of surface roughness.

49

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.2, No.4, November 2013

Table6 parameter constraints

Table 7 ParameterEstimates

Parameter Value

Constraints

Parameter

Estimate

SE Estimate

a1

-10 < a1 < 10

a1

0.20151

0.0000511

a2

-10 < a2 < 10

a2

0.05385

0.0000663

a3

-10 < a3 < 10

a3

0.06818

0.0001133

a4

-10 < a4 < 10

a4

0.34483

0.0002593

1.98650

0.0029059

Table 8 Summary

Item

Value

Iterations

Final SSE

DFE

MSE

S

3

0.0000

19

0.0000003

0.0005620

5. CONCLUSION

Application of the heuristic algorithms has been the latest trend by researchers to find out best

solution in optimization problems related to selection of metal cutting conditions. Most of these

algorithms are influenced by physical law and the natural behavior of organisms. GSA is

introduced as a heuristic algorithm which utilizes the law of gravity and motion. GSA emerges as

a most promising option now for the researchers to solve metal cutting optimization problems. In

our study, we adopted this algorithm for optimizing process parameters at the higher ranges of

speed using CNC machine. Out of the four input parameters selected for study, it is found that all

the four parameters have significant influence on surface roughness and GSA is found to be an

effective tool to solve complex computational problems. The method may be extended by future

researchers for optimization of machining time and metal removal rate using GSA. If necessary,

some more input parameters may be tested for their influence on surface roughness at higher

speed ranges of metal cutting.

REFERENCE

50

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.2, No.4, November 2013

[1]

Zubaidi Salah Al, Ghani Jaharah A. , Hassan Che, Haron Che (2013) Optimization of cutting

conditions for

end milling of Ti6Al4V Alloy by using a Gravitational Search

Algorithm(GSA).Springer DOI 10.1007/s11012-013-9702-2.

[2]

Rashedi Esmat ,Hossein Nezamabadi-pour , Saryazdi Saeid (2009) GSA: A Gravitational Search

Algorithm, Journal of Information Sciences 179 2232 2248

[3]

Yusup N, Zain AM, Hashim SZM (2012) Evolutionary techniques in optimizing machining

parameters: review

and recent applications (20072011). Expert Syst Appl 39(10):99099927.

doi:10.1016/j.eswa.2012.02.109.

[4]

Khorasani AM, Yazdi MRS, Safizadeh MS (2012) Analysis of machining parameters effects on

surface

roughness: a review. Int J Comput Mat Sci Surf Eng 5(1):6884.

doi:10.1504/ijcmsse.2012.049058

[5]

Ozcelik B. and Bayramoglu M.( 2006), The statistical modeling of surface roughness in high-speed

flat end milling, International Journal of Machine Tools & Manufacturing, Vol. 46, pp. 1395-1402

51

You might also like

- Press BHMCTDocument2 pagesPress BHMCTkhujistamahmoodNo ratings yet

- Pre PHD - Resheduled O.UDocument1 pagePre PHD - Resheduled O.UkhujistamahmoodNo ratings yet

- Oriental Exams - OuDocument3 pagesOriental Exams - OukhujistamahmoodNo ratings yet

- PHD ProspectusDocument32 pagesPHD ProspectuskhujistamahmoodNo ratings yet

- Physical Education P.HDDocument3 pagesPhysical Education P.HDkhujistamahmoodNo ratings yet

- UGC NET Dec 2014 NotificationDocument43 pagesUGC NET Dec 2014 NotificationSanthosh GuduruNo ratings yet

- Revised Fee Structure 11march2015Document23 pagesRevised Fee Structure 11march2015khujistamahmoodNo ratings yet

- Synopsis Full TimeDocument3 pagesSynopsis Full TimekhujistamahmoodNo ratings yet

- Thesis Part TimeDocument3 pagesThesis Part TimekhujistamahmoodNo ratings yet

- Thesis Full TimeDocument3 pagesThesis Full TimekhujistamahmoodNo ratings yet

- Synopsis Part TimeDocument3 pagesSynopsis Part TimekhujistamahmoodNo ratings yet

- PHD ApplicationDocument7 pagesPHD ApplicationkhujistamahmoodNo ratings yet

- Tax Procedure & Practices - I, II, III - 2009-10Document46 pagesTax Procedure & Practices - I, II, III - 2009-10khujistamahmoodNo ratings yet

- Ugc Travel GuidelinesDocument1 pageUgc Travel GuidelineskhujistamahmoodNo ratings yet

- National Science Day Celebration 2015Document1 pageNational Science Day Celebration 2015khujistamahmoodNo ratings yet

- Venu Govinda Raju (PROF) Lecture Jntu HydDocument1 pageVenu Govinda Raju (PROF) Lecture Jntu HydkhujistamahmoodNo ratings yet

- Academic Rules Regulations Updated To Jan-2015 Jawaharlal NehruDocument181 pagesAcademic Rules Regulations Updated To Jan-2015 Jawaharlal NehrukhujistamahmoodNo ratings yet

- Ugc India Degrees To Be ConferredDocument2 pagesUgc India Degrees To Be ConferredkhujistamahmoodNo ratings yet

- 42 Orientation Course: University Grants CommissionDocument2 pages42 Orientation Course: University Grants CommissionkhujistamahmoodNo ratings yet

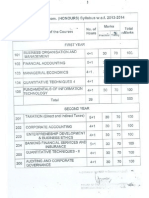

- (Honours) Syllabus 2013-14Document38 pages(Honours) Syllabus 2013-14khujistamahmoodNo ratings yet

- Foreign Trade Practices - I, II, III - 2009-10Document48 pagesForeign Trade Practices - I, II, III - 2009-10khujistamahmoodNo ratings yet

- B.SC I Year ElectronicsDocument15 pagesB.SC I Year ElectronicskhujistamahmoodNo ratings yet

- Advertising I, II, III 2009-10Document46 pagesAdvertising I, II, III 2009-10khujistamahmoodNo ratings yet

- Indian Society For Technical Education Jntu HydDocument1 pageIndian Society For Technical Education Jntu HydkhujistamahmoodNo ratings yet

- Computers I, II, III 2009-10Document51 pagesComputers I, II, III 2009-10fujijuju100% (1)

- Creation of Indian Manuscripts DatabaseDocument7 pagesCreation of Indian Manuscripts DatabasekhujistamahmoodNo ratings yet

- Gen I, II, III 2008-09Document48 pagesGen I, II, III 2008-09Suresh KuncheNo ratings yet

- Aaina e Khud ShanasiDocument58 pagesAaina e Khud ShanasikhujistamahmoodNo ratings yet

- Venu Govinda Raju (PROF) Lecture Jntu HydDocument1 pageVenu Govinda Raju (PROF) Lecture Jntu HydkhujistamahmoodNo ratings yet

- Annual Report 2010-11Document129 pagesAnnual Report 2010-11khujistamahmoodNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Curva TD12F - 1000GPM@130PSI - 2950RPMDocument2 pagesCurva TD12F - 1000GPM@130PSI - 2950RPMHenry Hurtado ZeladaNo ratings yet

- Amines Plant PresentationDocument22 pagesAmines Plant Presentationirsanti dewiNo ratings yet

- Train Backyard ToyDocument12 pagesTrain Backyard ToyJim100% (17)

- Felsic 105 Tfrs v4Document12 pagesFelsic 105 Tfrs v4mohammad reza aghatiNo ratings yet

- JLC Online Article PDF - Letters To The EditorDocument1 pageJLC Online Article PDF - Letters To The EditoreeNo ratings yet

- User Manual of Joinchamp Dental Unit 2022Document54 pagesUser Manual of Joinchamp Dental Unit 2022Renjun hwangNo ratings yet

- Drilling Cost and Hole ProblemsDocument39 pagesDrilling Cost and Hole ProblemsArun Sharma100% (1)

- XPol 806-960MHz 90° Fixed Tilt Sector Panel AntennaDocument1 pageXPol 806-960MHz 90° Fixed Tilt Sector Panel AntennaArif Noviardiansyah100% (1)

- Karcher Operation ManualDocument60 pagesKarcher Operation ManualDadi SucahyonoNo ratings yet

- Perfect Gas Law Lab ReportDocument9 pagesPerfect Gas Law Lab ReportTan Zu Kuan50% (2)

- Expt 2 - Thevenin-NortonDocument10 pagesExpt 2 - Thevenin-NortonNitin KhetadeNo ratings yet

- HLP-A Series Operating ManualDocument117 pagesHLP-A Series Operating ManualComunicaciones RogeNo ratings yet

- ResumeDocument2 pagesResumekoduruabhinavNo ratings yet

- Sika AnchorFix 1 PDSDocument8 pagesSika AnchorFix 1 PDSAchilleas21No ratings yet

- Bridge Abutment Pier Design As Per IRCDocument41 pagesBridge Abutment Pier Design As Per IRCjibendra mishra88% (43)

- Bernini PDFDocument13 pagesBernini PDFChris AntoniouNo ratings yet

- Ece 230Document4 pagesEce 230JackNo ratings yet

- GM-MS45 hydraulic valve technical specificationsDocument21 pagesGM-MS45 hydraulic valve technical specificationsDUVAN GARNICANo ratings yet

- Concrete DurabilityDocument19 pagesConcrete Durabilityapi-3766593100% (2)

- Regal Raptor DAYTONA Euro IV Owner ManualDocument25 pagesRegal Raptor DAYTONA Euro IV Owner ManualKrzysztof Jakiś50% (2)

- Parts Catalog: 1270D Wheel Harvester (0001-0997)Document772 pagesParts Catalog: 1270D Wheel Harvester (0001-0997)NunesSergioNo ratings yet

- Jeppview For Windows: General Information General InformationDocument13 pagesJeppview For Windows: General Information General InformationEmerald Gr100% (1)

- A210-Handheld: Operating InstructionsDocument24 pagesA210-Handheld: Operating InstructionsAleksandarNo ratings yet

- 4unsafe Unhealthy Act Conditions PDFDocument41 pages4unsafe Unhealthy Act Conditions PDFej constantino100% (1)

- D2.07 Non Segregated Phase Bus DuctsDocument3 pagesD2.07 Non Segregated Phase Bus DuctsSaraswatapalitNo ratings yet

- Santosh ResumeDocument4 pagesSantosh ResumeSantosh KumarNo ratings yet

- PLG Script For Prison LifeDocument7 pagesPLG Script For Prison LifeXxcode 1No ratings yet

- BFC 31901 Structure LabsheetDocument11 pagesBFC 31901 Structure LabsheetAshyra JamilNo ratings yet

- Effect of Brick on Rubber Lining TemperatureDocument2 pagesEffect of Brick on Rubber Lining Temperaturetamago_fujiNo ratings yet

- TSC List of Correspondents 201711 PDFDocument180 pagesTSC List of Correspondents 201711 PDFbaroon1234No ratings yet