Professional Documents

Culture Documents

Impact Electrosurgical Heat On Optical Force Feedback Sensors

Uploaded by

rssbaratoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impact Electrosurgical Heat On Optical Force Feedback Sensors

Uploaded by

rssbaratoCopyright:

Available Formats

The impact of electrosurgical heat on optical force feedback sensors

J.A.C. Heijmans1, M.P.H. Vleugels2,3, E. Tabak1, T.v.d. Dool1, M.P. Oderwald1

1

TNO Science and Industry/Advanced Precision and Production Equipment, Delft, Netherlands

2

EFI BV, Maastricht, Netherlands

3

Rivierenland Hospital, Netherlands

Abstract Electrosurgery enables cutting and coagulation

(desiccation) of tissue for Minimally Invasive Surgery.

Measurements performed by TNO with an infrared camera

showed that the forceps of an endoscopic instrument can be

over 300C in temperature. During electro-surgery the

surgeon relies on the power control and endoscopic images to

perform the procedure successfully.

Manipulation of tissue with the present forceps does not

give accurate tissue information due to the presence of friction

in the transmission mechanism and in turn force, control of the

operating surgeon is poor. The latest developed instruments

incorporates sensors and actuators that enable better control

of force application on the tissue and give a better feeling of

the tissue to the surgeon. TNO works for EFI BV on the

development of a surgical instrument that senses and controls

the gripping force even during electrosurgery.

Electric sensors and actuators experience Electro Magnetic

Interference during the use of electro-surgery, making it

impossible to control the force. The high temperature that

arises at the forceps influences and possibly destroys the

sensors when positioned nearby the heat source. Based on the

experience with optical fiber sensors TNO has developed an

instrument that is immune to EMI and withstands

temperatures up to 200C. This optical sensor is based on a

Fiber Bragg Grating (FBG). The FBG read out system, named

the interrogator, transfers the optical fiber signal from the

mechanical local strain. By this way the force exerted on the

tissue and its resistance can be measured. However this sensor

system is also sensitive to temperature changes. To control

accurately he gripping force, the measurement must be

independent of temperature. Therefore the thermal load at the

forceps were measured and analyzed. The results are used for

the instrument design and location of sensors.

Keywords Electrosurgery,

coagulation,

Minimally

Invasive Surgery, Fiber Bragg Grating, optical force sensor

instruments has started. The majority of these instruments

are based on existing instruments, used in conventional

surgical procedures. These evaluated into devices which are

difficult in handling and which lost force control. Moreover

information of the force created by the tissue resistance on

the tip of the instrument is absent. These disadvantages

added to the poor visualization of the area of operation,

decrease the usability performance of the instruments and

hampers the introduction of minimal invasive surgery into

areas with higher demands on accuracy. By introducing

novel technologies from the field of robotics into the

instruments, the mechanical disadvantages of the current

instruments can be tackled. Innovation in medical

technology is rather difficult due to the harsh environment

in which the instrument must operate. However, thorough

understanding of the medical problem and the issues related

to human interfacing is just as important [1]. The

cooperation of medical company EFI BV with TNO Science

and Industry covers both the medical and technical field.

The concept for this next generation of surgical

instrumentation comes from EFI BV, (Endoscopic Forcereflecting Instrument). The control issues related to haptic

feedback, the mechatronical and fiber optic (FO) issues are

all dealt with by TNO.

II. SYSTEM OVERVIEW

A. Instrument overview

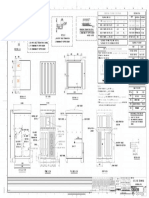

Figure 1 shows the design of an endoscopic instrument

for surgery with haptic feedback. It consists of forceps for

gripping tissue, a shaft with a rod inside for moving the

I. INTRODUCTION

Minimally Invasive Surgery is performed with instrumentation that enables surgery through small incisions. This type

of surgery enables faster recovery of the patient and reduces

the change on postoperative complications. The surgeon,

however, makes sacrifices on its perception and ergonomics.

With the introduction of minimally invasive surgical

procedures, the development of a new range of surgical

Fig. 1

Conceptual design of the endoscopic instrument

J. Vander Sloten, P. Verdonck, M. Nyssen, J. Haueisen (Eds.): ECIFMBE 2008, IFMBE Proceedings 22, pp. 914917, 2008

www.springerlink.com Springer-Verlag Berlin Heidelberg 2009

The impact of electrosurgical heat on optical force feedback sensors

915

forceps, and a handle that moves the rod relative to the

shaft. This instrument is connected through a cable with an

external controller (not shown).

A regular handle is shaped like a simple pair of scissors.

This handle has been replaced by a type that houses two

actuators, one for actuating the forceps and one for

actuating the trigger. In the present regular instruments for

Minimally Invasive Surgery (MIS) the surgeon has little

feeling of the tissue which he is gripping due to friction in

the handle, the rod inside the shaft, and hinges in the

forceps. The newly developed forceps has fiber optic FBG

sensors that accurately measure the gripping force. This

force is relayed to the controller which in turn sends signals

to the actuators in the handle such that the desired force is

exerted on the tissue and an exact scaled force is exerted on

the trigger at the same time which enables the surgeon to

feel the tissue characteristics. Also the force can

automatically be limited to safe values that prevent tissue

damage. The measuring range of the clamping force is up to

20N with a resolution of 10mN.

A further advantage of a wired MIS instrument is that it

allows for independent scaling of force and displacement.

This enables highly accurate operation of delicate tissue as

is the case in an extreme degree for neuro- and eye surgery.

One of the challenges for the endoscopic instrument is the

need to perform electrosurgery. This requires the instrument

to accurately measure the force while the forceps is charged

with electric signals with frequencies in between 350kHz

and 3.3MHz. Besides the EMC the instrument must be reusable and therefore allow demounting, cleaning and

sterilizing by autoclavation.

Multiple sensors can be used inside one fiber, known as

multiplexing. The length of the grating is typically 1 to

10mm in length. The diameter of the sensor is generally in

between 10^m up to 100^m that corresponds with the fiber

core and cladding respectively.

The signal can be monitored with an optical instrument

which is named an interrogator. This instrument analyses

the signal with interferometry or spectroscopy. To create a

realistic haptic feedback system, an interrogator is used with

a bandwidth of 19kHz. This relatively high bandwidth is

commercially available nowadays [3].

B. Fiber optic sensor, FBG

Fiber optic (FO) sensors are a relatively new type of

sensors and their application fields rapidly grow. Medical

technology is one of these applications. Here fiber optics is

very attractive due to their insensitivity to electromagnetic

fields, their small dimensions and their intrinsic electrical

safety [2].

The FBG sensor used for this application is used for force

measurement at the distal end of a surgical instrument. The

functionality is quite identical to an electrical strain gauge

with the difference that no electrical signal comes from the

sensor. A grating situated in the fiber reflects a small band

of wavelength from the light that is sent in the fiber. A

change in the grating results in a change of the reflected

wavelength. This is in general a length difference of the

sensor (strain) or a temperature difference. The sensitivity

of an FBG sensor expressed in wavelength shift for these

parameters is typically 10pm per Kelvin, 1.2pm per strain

(1 strain = 110-6 [-]).

_______________________________________________________________

III. EXPERIMENT

As the FO FBG sensor is sensitive to temperature

changes an experiment has been performed to determine the

thermal effects of electrosurgery. In order to obtain the

required force measurement accuracy the temperature must

be known within 2C. Even without electrosurgery the

temperatures vary from 20C to 37C, clearly indicating the

need for temperature compensation. Therefore a second

FBG is used that only measures the temperature at the

forceps. However, the temperature gradient in the forceps

should be sufficiently homogenous. Since the aim is that the

instrument can be used at all times, even during

electrosurgery, experiments have been carried out in order

to measure thermal effects during electrosurgery. In figure 2

a schematic representation is given of the experimental

setup.

The Valleylab Force 30 (1) is used for both electrical

cutting and desiccation. A handheld device (2) is used to

initiate the electrosurgery. The device is electrically

(1)

(2)

(3)

(4)

(7)

(5)

IFMBE Proceedings Vol. 22

(6)

Fig. 2 Schematic representation of the test setup

_________________________________________________________________

916

J.A.C. Heijmans, M.P.H. Vleugels, E. Tabak, T.v.d. Dool, M.P. Oderwald

connected (3) to the endoscopic instrument (4).

Thermocouples (not depicted) are glued to the forceps of

the instrument that are monitored with a multimeter (5). A

piece of chicken meat (6), which is connected to the return

electrode (7), is used to simulate human tissue. When

electrosurgery is performed heat is generated at the contact

area of the forceps with the tissue.

Figure 3 depicts the actual setup. The temperature

distribution is measured using an infrared camera (7), which

is placed just above the tissue. At first, the thermocouples

(8) are calibrated offline. Secondly, the results from the

camera are calibrated using the thermocouples.

IV. RESULTS

Measurements show that cutting results in slightly higher

temperature than desiccation. Figure 4 depicts a typical

temperature distribution during cutting. Maximum

temperatures of 160C are measured at the tip of the

forceps.

(7)

(8)

Fig. 4

Temperature distribution in the forceps and tissue

during cutting with representative settings

The result of the second experiment (increased power) is

depicted in figure 5. The maximum temperature at the tip is

approximately 300C.

Fig. 3

The actual test setup in which the temperature distribution is

measured using an infrared camera (7). A detail of the forceps and

thermocouples (8) are depicted at the corner, far right

In order for the experiments to be representative, the

measurement procedure is formulated in consultation with a

surgeon (M.Vleugels2,3). Both (monopolair) cutting and

desiccation is performed. Cutting is done by applying a cut

of approximately 3 to 4 centimeters. Next, a waiting period

is introduced of 3 seconds and than another cut is made. In

the measurements four cuts are made. The power used for

the desiccation and cutting is depicted in figure 2.

A second experiment is carried out in which a high load

situation has been examined. In this case the power is

increased by a factor of 2 and is applied for 20 instead of 3

seconds continuously. It must be noted that the heat load is

depending on the power, the contact area between tissue and

forceps and the amount of moisture in the tissue.

A third experiment is carried out with a FBG sensor

fixed to the forceps. When applying cutting and desiccation

to this sample, the FBG signal is read out simultaneously.

The purpose is to show the thermal effects experimentally

and to verify that the sensor and interrogator are indeed

insensitive to electromagnetic fields.

_______________________________________________________________

Fig. 5 Temperature distribution in the forceps and

tissue during cutting with increased heat load

The result of the third experiment is shown in figure 6,

showing the response of the FBG sensor to the heat that

arises from electrosurgery. After nine seconds the forceps

cuts in the tissue for three seconds. This is repeated for four

times. The FBG signal is clearly affected and therefore a

IFMBE Proceedings Vol. 22

_________________________________________________________________

The impact of electrosurgical heat on optical force feedback sensors

917

simultaneous temperature measurement must be taken to

decouple the clamping force from the rise in temperature.

Note that the signal from the FBG sensor is not affected by

the EMC but is only sensitive to temperature changes.

the FBG sensor. Therefore the temperature must be

measured separately and subtracted from the force

measurement. Correct fixation of the FBG sensor is

essential to make the characterization reproducible. The

cooperation between medical company EFI BV and

research institute TNO has been vital for the successful

development of this high tech surgical instrument.

1550.1

Optical strain [nm]

Wavelength

[nm]

1550

1549.9

VI. FUTURE DEVELOPMENTS

1549.8

1549.7

1549.6

1549.5

1549.4

1549.3

10

20

30

time [s]

40

50

60

Fig. 6 Optical signal due to heating when performing electrosurgery

Finally, a study to different sensor fixations has been

performed. Results from this study showed the impact of the

geometry and materials to the reproducibility of the sensor

signal in time and after autoclavation. This has led to the

design of a stable fixation with a reproducibility error of

less than 0.9% after 10 cycles of cleaning and autoclavation.

The FBG sensors, including the adhesive that is used to

fix them, need to be able to withstand the high mechanical,

chemical, and thermal loads due to coagulation, cleaning

and sterilization. Tests will therefore be conducted with

washing (100 cycles) and sterilization (1000 cycles) to see

if any degradation occurs.

A first prototype of this MIS instrument is being realized.

This instrument will be used for experimental surgery on

cadavers to verify the advantages of such an instrument in

practice. With the experience and knowledge acquired, a

MIS product based on this technology will be realized.

REFERENCES

1.

2.

V. CONCLUSIONS

3.

The realized demonstrator has shown the achievability of

force sensing during electrosurgery with a fiber optic

sensor. Measuring the clamping force in the forceps with an

optical strain sensor requires that the temperature must be

taken into account. Tests have shown that during

electrosurgery temperatures can rise up to 160C and up to

300C for high load situations. This heat load at the forceps

causes a significant deviation in the strain read out signal of

_______________________________________________________________

Wieringa F, Poley M, Dumay A. et al. (2007). Avoiding pitfalls in

the road from idea to certified product (and the harsh clinical

environment thereafter) when innovating medical devices. In 7th

Belgian Day on Biomedical Engineering, Brussels, Belgium, 2007

Heijmans J, Cheng L, Wieringa F, Optical fiber sensors for medical

applications, IFMBE Proc., 4th European Congress on Med. &

Biomed. Eng., Antwerp, Belgium, 2008

Cheng L, Groote Schaarsberg J, Osnabrugge van, J, et al. (2001)

Novel Fiber Bragg Grating sensor system for high -speed structure

monitoring, 3rd Int. Workshop on Struct. Health Mon., Stanford,

2001.

Author:

Institute:

Street:

City:

Country:

Email:

IFMBE Proceedings Vol. 22

J.A.C.Heijmans

TNO Science and Industry

Stieltjesweg 1

Delft

Netherlands

teun.vandendool@tno.nl

_________________________________________________________________

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Instructions For Repairing AlternatorDocument3 pagesInstructions For Repairing AlternatordamoccaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Transmission - Approved List 26-09-2017Document554 pagesTransmission - Approved List 26-09-2017bkhNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Electronic - Schematic Circuits For The HobbyistDocument136 pagesElectronic - Schematic Circuits For The Hobbyistanon-916719100% (196)

- Cd300m Parts BreakdownDocument10 pagesCd300m Parts BreakdownAmanda FitzgeraldNo ratings yet

- 008 Cat-6060 Attachment Functions FSDocument37 pages008 Cat-6060 Attachment Functions FSenrico100% (3)

- MQ-4C TritonDocument2 pagesMQ-4C TritonLeakSourceInfoNo ratings yet

- Lane Departure Warning SystemDocument7 pagesLane Departure Warning SystemRavisingh RajputNo ratings yet

- Obturation Techniques and DevicesDocument29 pagesObturation Techniques and DevicesArivinthaan Tanigajalam100% (1)

- Review On Development of Polypropylene Manufacturing ProcessDocument11 pagesReview On Development of Polypropylene Manufacturing ProcessShweta Yadav100% (1)

- A Multi-Parameter Sensor PDFDocument10 pagesA Multi-Parameter Sensor PDFrssbaratoNo ratings yet

- Optical Fibre Sensors For Health Monitoring of Bonded Repair Systems PDFDocument12 pagesOptical Fibre Sensors For Health Monitoring of Bonded Repair Systems PDFrssbaratoNo ratings yet

- CDC - Bioseguridad en Laboratorios de Microbiología y Biomedicina 4taDocument196 pagesCDC - Bioseguridad en Laboratorios de Microbiología y Biomedicina 4tazodiac_38No ratings yet

- Optical Fibre Sensors For Health Monitoring of Bonded Repair SystemsDocument12 pagesOptical Fibre Sensors For Health Monitoring of Bonded Repair SystemsrssbaratoNo ratings yet

- Damage of Optical Fibers Under Wet EnvironmentsDocument10 pagesDamage of Optical Fibers Under Wet EnvironmentsrssbaratoNo ratings yet

- Characterization of A FBG StrainDocument9 pagesCharacterization of A FBG StrainrssbaratoNo ratings yet

- Fibras BraggDocument6 pagesFibras BraggrssbaratoNo ratings yet

- Medicion de Sensibilidad de La Presion HidrostaticaDocument9 pagesMedicion de Sensibilidad de La Presion HidrostaticarssbaratoNo ratings yet

- Intensity Referencing in An Extrinsic Optical Fiber TemperatureDocument4 pagesIntensity Referencing in An Extrinsic Optical Fiber TemperaturerssbaratoNo ratings yet

- Fibras BraggDocument6 pagesFibras BraggrssbaratoNo ratings yet

- Fibras BraggDocument6 pagesFibras BraggrssbaratoNo ratings yet

- CDC - Bioseguridad en Laboratorios de Microbiología y Biomedicina 4taDocument196 pagesCDC - Bioseguridad en Laboratorios de Microbiología y Biomedicina 4tazodiac_38No ratings yet

- Practical ExampleDocument4 pagesPractical ExamplerssbaratoNo ratings yet

- Arduino X Bee ShieldDocument2 pagesArduino X Bee ShieldrssbaratoNo ratings yet

- FRAP AssayDocument2 pagesFRAP AssayMayank Tandon94% (17)

- 14 Upgrading of Safety Measures in The Arlberg Railway TunnelDocument10 pages14 Upgrading of Safety Measures in The Arlberg Railway TunnelvijyantbNo ratings yet

- C426Document5 pagesC426Rufo CascoNo ratings yet

- 01-09-04MIL On, DTCs P1545, P0121, P0123, P0221 or P0222 Stored in ECM Fault MemoryDocument7 pages01-09-04MIL On, DTCs P1545, P0121, P0123, P0221 or P0222 Stored in ECM Fault MemoryKilobyte202005No ratings yet

- Surtec 680: Protection UpgradedDocument7 pagesSurtec 680: Protection Upgradedyudhien4443No ratings yet

- Uh X PDFDocument20 pagesUh X PDFRepresentaciones y Distribuciones FAL100% (1)

- MAX32xx, Serial To TTLDocument17 pagesMAX32xx, Serial To TTLDecker JamesNo ratings yet

- Chemistry Lab 2 Flame TestsDocument7 pagesChemistry Lab 2 Flame Testshpcoutinho36No ratings yet

- AISC Properties ViewerDocument3 pagesAISC Properties ViewerrubenNo ratings yet

- BSS Steel Guide CataloguesDocument52 pagesBSS Steel Guide Cataloguessaber66No ratings yet

- Geopolymer Reinforced With Bamboo For Sustainable Construction MaterialsDocument7 pagesGeopolymer Reinforced With Bamboo For Sustainable Construction MaterialsSamyuktha SridharNo ratings yet

- Standard Test Procedures Manual: 1. Scope 1.1 Description of TestDocument5 pagesStandard Test Procedures Manual: 1. Scope 1.1 Description of TestAkshay TikooNo ratings yet

- CPAR Summary - WK 144Document6 pagesCPAR Summary - WK 144NagarajNo ratings yet

- VCS Commands Ease Coverage Efforts - Speed Simulation PDFDocument6 pagesVCS Commands Ease Coverage Efforts - Speed Simulation PDFAnonymous k2nUzQgO6HNo ratings yet

- Move Core Application: Fully Integrated 2D and 3D Model Building and AnalysisDocument2 pagesMove Core Application: Fully Integrated 2D and 3D Model Building and AnalysisAlfredo Iguaran AmayaNo ratings yet

- CE ESE-2015 Obj 2Document26 pagesCE ESE-2015 Obj 2rameshNo ratings yet

- Maz18 Maz38 ManualDocument5 pagesMaz18 Maz38 Manualheritage336No ratings yet

- Octagonal Blender PDFDocument4 pagesOctagonal Blender PDFMohsinShaikhNo ratings yet

- Pvu-L0880er GaDocument1 pagePvu-L0880er GaarunghandwalNo ratings yet

- PC Smart Ptsgob8wDocument11 pagesPC Smart Ptsgob8wJose LopezNo ratings yet

- Removal of SO2 From Low Sulfur Coal Combustion Gases by Limestone ScrubbingDocument12 pagesRemoval of SO2 From Low Sulfur Coal Combustion Gases by Limestone ScrubbingCaballero MarioNo ratings yet

- Intro To Neutron ScatteringDocument191 pagesIntro To Neutron ScatteringEleni MitsiNo ratings yet