Professional Documents

Culture Documents

Mixer Theory

Uploaded by

Sheikh Nouman Mohsin RamziCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mixer Theory

Uploaded by

Sheikh Nouman Mohsin RamziCopyright:

Available Formats

TYPES OF CONCRETE MIXER AND THEIR

SPECIFICATION

1: Standard Transit Concrete Mixer:

A Standard Transit Concrete Mixer is

a concrete delivery vehicle used for jobs where large pour volumes are

required. Transit Mixer Trucks come in a variety of sizes, ranging from 2

cubic metres to 8 cubic metres wet concrete output, making them the

ideal choice for ready-mix concrete operations

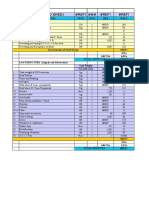

Specification:

Available in 6 cubic meters capacity.Driven by

Kirloskar Air Cooled Diesel Engine Model 494 with hydrostatic

transmission and oil cooler.Mounting on Ashok Leyland Taurus / Tata

2516 OR any other equivalent truck chassis.Fully imported oil bath

planetary gear system is proven when traveling in rough terrain

with full power of the engine required.Harden rollers increase the

reliability of the performance.Cover provides safety and protection

against dirt.The drum and spirals are made of highly wear resistant

steel so that it increases stability and reduces the wear out.volume

of drum with more water line capacity.Operation is userfriendly.Excellent quality of materials and components gives long

life with less economThe design of devices allow concrete

consistently with high speed.Constant discharges of concrete.High

mixing capacity and maximum discharge output thanks to the

optimal position of the spiral blades in the drum.Fully Imported

Hydraulic Pump, Motor and Oil Cooler.Efficient and reliable after

sale-service, round the clock.

2: Rough terrain concrete mixrers:

Utranazz range of Rough Terrain

Concrete Mixers are 4x4 wheel drive self-loading concrete mixers fitted

with a front operators cab. They can climb, fully loaded with concrete,

over the most precarious terrains at gradients of up to 30o. They can

load, mix, produce and discharge over 100m3 of concrete per day, and

its electronic weigh batching equipment ensures precise mixes of any

grade of concrete with an accuracy of +/- %. For ease of operation,

Utranazz Rough Terrain Concrete Mixers are joystick-controlled and

fitted with a 300o slewing drum, allowing concrete to be discharged at

every side of the vehicle at heights of over 2m. Simple to use and easy

to maintain, the mixer is suited to all types of job-sites from congested

city

centres

to

remote

villages.

Specification: Utranazz Rough Terrain Concrete Mixers are available

in the following sizes: 1.0, 2.0, 2.5, 3.5 and 5.5 cubic metre outputs.

The drum is fixed on the 1.0, 2.0 and 5.5 models and slews through

300o on the 2.5 and 3.5 models. All models have hydrostatic

transmission with T way steering and are fitted with Perkins, Cummins

or

Deutz

engines.

3: Volumetric concrete mixers:

Barrel: Designed adopting Euro-Style, beautiful and hardness.

Mixing System: Adopting wearable cast alloy steel, long working life,

high efficiency

Unloading System: Hydraulic control, 3 sticking dots, easy operation

Transmission System: Planetary gear, twin shaft homocentric working

Lubrication System: Advanced centralized oil lubrication system

Sealing System: Triple shaft sealing system

Significance and Use

These tests and requirements are used to evaluate loading and

operating procedures; verify the accuracy of proportioning and

indicating systems; and determine if mixing uniformity has been

degraded by excessive wear or by accumulations of hardened

concrete, or both .

Scope

This specification covers concrete made from materials continuously

batched by volume, mixed in a continuous mixer, and delivered to the

purchaser in a freshly mixed and unhardened state as hereinafter

specified. Requirements for quality of concrete shall be either as

hereinafter specified or as specified by the purchaser. When the

requirements of the purchaser differ from this specification, the

purchaser's specification shall govern. This specification does not cover

the placement, consolidation, finishing, curing, or protection of the

concrete after delivery to the purchaser. Tests and criteria for batching

accuracy and mixing efficiency are specified herein.

4: Hand fed site concrete mixer

Our clients can avail from us Tilting Hand-Fed Concrete Mixer, which

is extensively used in building and road construction. Manufactured

using quality raw material, these mixers are reckoned for sturdy

construction, user friendliness, optimum durability and high

performance. These are available in various specifications and can be

customized as well.

Specification:

5/7cu ft (200xv140 litres)

Type: Tilting type

Ideal for small job

Capacity: 200 lt. (7 cuft.) unmixed. 140 lt (5 cuft) mixed power

unit

5 h. P. Kirloskar / power pack air/water cooled

Diesel engine or 5 h. P. 440/3/50 a c. Electric motor

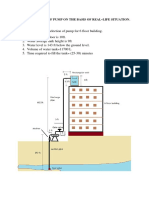

5: Self loading concrete truck mixer

Utranazz Hydromix SRY350G Self-Loading Concrete Truck Mixer is

designed to work as a ready-mix concrete delivery vehicle and is suited

to work in all types of areas, from busy city centres to remote villages.

With a 3.5m3 wet concrete output it can handle all types of concrete

deliveries, from large pour volume jobs to small deliveries for the DIY

markets. It can even work on-the-job as an on-site batching unit.

Technical information:

The SRY350G Self-Loading Concrete Truck Mixer is fitted with electronic

weighbatching equipment, which shows the exact weight of raw

materials going into the drum and the exact amount of concrete that is

discharged. This allows the operator to split loads of any quantity and

enables multiple deliveries. A further advantage is that it can re-load

with raw materials from any builders merchants or satellite depot, as it

has its own batching equipment, self-loading equipment, on-board

water system and auxiliary engine. It can be fitted to any cab/chassis,

with the correct specifications, or even onto a trailer.

frame Structure

A farame structure is defined as A structure which transfers load through beams and

columns only is called a frame structure.

Piles constructed as a retaining wall

Shuttering

Steel Scaffolding

You might also like

- Load Distribution From Slab To BeamsDocument18 pagesLoad Distribution From Slab To BeamsMudasir HussainNo ratings yet

- Two Way Slab BestDocument25 pagesTwo Way Slab BestErnest Christian Nanola100% (1)

- (Engineersdaily - Com) RCC62 Retaining WallDocument12 pages(Engineersdaily - Com) RCC62 Retaining WallMuhammad WaqasNo ratings yet

- Stetter Truck Mixer BrochureDocument12 pagesStetter Truck Mixer Brochuregsm.nkl6049No ratings yet

- Suspension ReportDocument10 pagesSuspension ReportAlbin SibyNo ratings yet

- Screening: Che-205 Particle TechnologyDocument31 pagesScreening: Che-205 Particle TechnologyInsiram NaveedNo ratings yet

- ScreeningDocument16 pagesScreeninganthony ijigaNo ratings yet

- Asphalt Batch Type Portable PlantDocument8 pagesAsphalt Batch Type Portable Plantfisco4rilNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Structural Design Review of Tailing Thickener by Finite Element Analysis (FEA) - Summary PresentationDocument5 pagesStructural Design Review of Tailing Thickener by Finite Element Analysis (FEA) - Summary PresentationEnrique Aguilar100% (1)

- Mix Design and Pumped ConcreteDocument13 pagesMix Design and Pumped ConcreteLimbu Niwa Lawahang100% (1)

- Mobile Virtual Network EnablerDocument27 pagesMobile Virtual Network Enablerk.vishnu vardhan100% (2)

- For Highest Concrete Qualities: Ring-Pan MixerDocument8 pagesFor Highest Concrete Qualities: Ring-Pan MixerGeetesh Makadia100% (1)

- CDCAS3.0 User ManualDocument77 pagesCDCAS3.0 User ManualHari HaryantoNo ratings yet

- DB Schedule PDFDocument9 pagesDB Schedule PDFMohamed FaragNo ratings yet

- Is 15466 (2004)Document16 pagesIs 15466 (2004)slamienkaNo ratings yet

- Construction Methodology For Test PIle NPBDocument8 pagesConstruction Methodology For Test PIle NPBSheikh Nouman Mohsin RamziNo ratings yet

- World Record in Long Distance Pumping - Case Study V1Document28 pagesWorld Record in Long Distance Pumping - Case Study V1Kaleeswari GNo ratings yet

- FIDIC Question & Answer - 2Document59 pagesFIDIC Question & Answer - 2segar12382% (17)

- Lime-Dosing Wam Inc Brochure 0114 EDIT PDFDocument4 pagesLime-Dosing Wam Inc Brochure 0114 EDIT PDFWidiyanto WidiyantiNo ratings yet

- Research On A Multi-Story Car ParkDocument11 pagesResearch On A Multi-Story Car ParkAnna MendozaNo ratings yet

- Quotation of Hzs90 Concrete Batching PlantDocument5 pagesQuotation of Hzs90 Concrete Batching PlantZarko LazicNo ratings yet

- Mixers and Flowakers (GB)Document24 pagesMixers and Flowakers (GB)Magin Idelfonso TorreblancaNo ratings yet

- Waste To FuelDocument8 pagesWaste To Fueljosean_246No ratings yet

- Fire Safety Audit ReportDocument9 pagesFire Safety Audit ReportSheikh Nouman Mohsin RamziNo ratings yet

- Fire Safety Audit ReportDocument9 pagesFire Safety Audit ReportSheikh Nouman Mohsin RamziNo ratings yet

- Procedure For Control of Documents and RecordsDocument3 pagesProcedure For Control of Documents and RecordsmrugeshjNo ratings yet

- Tender Boq - xls139170140Document12 pagesTender Boq - xls139170140Sheikh Nouman Mohsin RamziNo ratings yet

- Control of Flakiness & Elongation Indices With Selection of Crusher TypeDocument12 pagesControl of Flakiness & Elongation Indices With Selection of Crusher Typevenkateswara rao pothinaNo ratings yet

- Bitumen TablesDocument6 pagesBitumen Tablessattha3330% (1)

- Belt FilterDocument18 pagesBelt FilterNaik LarkaNo ratings yet

- Measurement Uncertainty PresentationDocument18 pagesMeasurement Uncertainty PresentationStefan KonyanNo ratings yet

- Volumetric Concrete Mixer Proposal For Ready Mix CompaniesDocument6 pagesVolumetric Concrete Mixer Proposal For Ready Mix CompaniesHabtamu Sedie0% (1)

- Mvcp-4555-Pp Part Manual For BP - MaxmechDocument51 pagesMvcp-4555-Pp Part Manual For BP - MaxmechKrm Chari100% (1)

- Atca MGW WorkshopDocument106 pagesAtca MGW Workshopgaussyn100% (2)

- AMOS MGW-V4-V3 Commands BisDocument2 pagesAMOS MGW-V4-V3 Commands BisKhalidox SolitaireNo ratings yet

- HFC-227ea Design Manual by BettatiDocument39 pagesHFC-227ea Design Manual by BettatiIppi100% (3)

- Concrete Recycling Systems: The Choice of ProfessionalsDocument6 pagesConcrete Recycling Systems: The Choice of ProfessionalsSanjay BaidNo ratings yet

- Pump Final New ModelDocument9 pagesPump Final New ModelAnukoolNo ratings yet

- Transit MixerDocument2 pagesTransit MixerbhargavipulivarthiNo ratings yet

- Elkomix-60 Quickmaster With Conveyor - StojanovicDocument5 pagesElkomix-60 Quickmaster With Conveyor - StojanovicBorivoje StojanovicNo ratings yet

- Cat Impianti EDocument12 pagesCat Impianti EWilliam HenryNo ratings yet

- PuztmeisterDocument3 pagesPuztmeisterEdgar Quispe LaricoNo ratings yet

- Stationary Pump BP350XTDocument4 pagesStationary Pump BP350XTRithan BNo ratings yet

- Prospect Kredmash 2014 EnglishDocument32 pagesProspect Kredmash 2014 EnglishMuhaimin100% (1)

- FEECO Complete OfferingsDocument8 pagesFEECO Complete OfferingsawfahNo ratings yet

- 4634 PDFDocument7 pages4634 PDFMuthu KumarNo ratings yet

- Fds Series: Fiber Dosing-Feeding SystemDocument15 pagesFds Series: Fiber Dosing-Feeding SystemPaul Ticla PuenteNo ratings yet

- Hot Mix PlantDocument19 pagesHot Mix PlantRiya Tripathi100% (1)

- Advanced Construction EquipmentsDocument25 pagesAdvanced Construction EquipmentsEfrem BeyeneNo ratings yet

- Wear ProtectionDocument6 pagesWear ProtectionRafael CortezNo ratings yet

- 1 PDFDocument41 pages1 PDFChan Peng SwanNo ratings yet

- Field CompactionDocument5 pagesField CompactionG-ann DatarioNo ratings yet

- Mechtcherine (2013) - Testing Pumpability of Concrete Using Sliding Pipe Rheometer PDFDocument12 pagesMechtcherine (2013) - Testing Pumpability of Concrete Using Sliding Pipe Rheometer PDFManu K Mohan100% (1)

- DM 30 Asphalt PlantDocument4 pagesDM 30 Asphalt PlantTheodore Teddy KahiNo ratings yet

- EMCO Electro - Hydraulic Drum BrakeDocument7 pagesEMCO Electro - Hydraulic Drum Brakehardik033No ratings yet

- Greasing Points of Transit MixerDocument7 pagesGreasing Points of Transit MixerNishant SinhaNo ratings yet

- 1 Comparison of SANY and SINO HOWO 10m3 Transit MixerDocument1 page1 Comparison of SANY and SINO HOWO 10m3 Transit MixerAdeelNo ratings yet

- 3.concrete - ProductionDocument24 pages3.concrete - ProductionSUMANT KUMARNo ratings yet

- Linnhoff Presentation Cold & Hot Recycling - 2009Document27 pagesLinnhoff Presentation Cold & Hot Recycling - 2009willypraviantoNo ratings yet

- Designing Silo Walls For Flow Patterns : Aci Structural Journal Technical PaperDocument10 pagesDesigning Silo Walls For Flow Patterns : Aci Structural Journal Technical PaperJuan Cruz CoronelNo ratings yet

- Ahlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentDocument28 pagesAhlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentARYAN_FATHONI_AMRINo ratings yet

- Cde Sand Washing ProductsDocument1 pageCde Sand Washing ProductsSaumil SharmaNo ratings yet

- Mechanical Properties of Polymer ConcreteDocument12 pagesMechanical Properties of Polymer ConcreteSamuelSzeNo ratings yet

- DesignDocument4 pagesDesignJigneshkumar PatelNo ratings yet

- HVAC Catalogue 2016Document233 pagesHVAC Catalogue 2016Vincent GabrielNo ratings yet

- First Fill LubricantsDocument1 pageFirst Fill LubricantsAnubhav ChandraNo ratings yet

- Sluice Gate With Manual Gearbox - Sereco S.R.LDocument2 pagesSluice Gate With Manual Gearbox - Sereco S.R.LMuhammad EhtshamNo ratings yet

- JS1000 Concrete MixerDocument5 pagesJS1000 Concrete MixerErik100% (1)

- Suspension Gear PaperDocument27 pagesSuspension Gear PaperSteve PennNo ratings yet

- Fresh Cement Concrete BanfillDocument70 pagesFresh Cement Concrete BanfillBatepola BacNo ratings yet

- Michael M. Calistrat: Safety, Application, and Service Factors As Applied To Shaft Couplings byDocument8 pagesMichael M. Calistrat: Safety, Application, and Service Factors As Applied To Shaft Couplings byronny_fernandes363No ratings yet

- Placing Systems CT4524 AUSDocument14 pagesPlacing Systems CT4524 AUSemadnaguibNo ratings yet

- 02 Rashi Resources KabraiDocument3 pages02 Rashi Resources KabraiAkhileah PalNo ratings yet

- Cascade BrochureDocument2 pagesCascade BrochureEzequiel FavelukesNo ratings yet

- M1 Bro2013Document12 pagesM1 Bro2013Akshat Rastogi100% (3)

- Different Types of Asphalt Paver Machines in IndiaDocument3 pagesDifferent Types of Asphalt Paver Machines in Indiakhaled nawazNo ratings yet

- 8 Equipment: Concrete PlantsDocument18 pages8 Equipment: Concrete PlantsLoed Baruis SamsonNo ratings yet

- Metrobus Card Selling Point For Feeder Bus ServiceDocument2 pagesMetrobus Card Selling Point For Feeder Bus ServiceSheikh Nouman Mohsin RamziNo ratings yet

- View Topic - Flat Slab Under Wall LoadingDocument6 pagesView Topic - Flat Slab Under Wall LoadingSheikh Nouman Mohsin RamziNo ratings yet

- EfschlstDocument6 pagesEfschlstmisteriterbangNo ratings yet

- Quantify Dead Loads Acting On StructureDocument41 pagesQuantify Dead Loads Acting On StructureKem RaiNo ratings yet

- Building ... Ring Other Technical Topics - Eng-TipsDocument3 pagesBuilding ... Ring Other Technical Topics - Eng-TipsSheikh Nouman Mohsin RamziNo ratings yet

- Building Information Modeling Assignment No, 01Document5 pagesBuilding Information Modeling Assignment No, 01Sheikh Nouman Mohsin RamziNo ratings yet

- 1B Fidic-Selection PDFDocument1 page1B Fidic-Selection PDFSheikh Nouman Mohsin RamziNo ratings yet

- New Item Coding Implementation in AccpacDocument2 pagesNew Item Coding Implementation in AccpacSheikh Nouman Mohsin RamziNo ratings yet

- FarDocument1 pageFarSheikh Nouman Mohsin RamziNo ratings yet

- Detailed Design of Hullar BridgeDocument28 pagesDetailed Design of Hullar BridgeSheikh Nouman Mohsin RamziNo ratings yet

- Slab 2-WayDocument13 pagesSlab 2-WaySheikh Nouman Mohsin Ramzi0% (1)

- Cad DrawingDocument53 pagesCad DrawingAvish Gunnuck100% (3)

- Date Dia Quantity Length of Each (M)Document5 pagesDate Dia Quantity Length of Each (M)Sheikh Nouman Mohsin RamziNo ratings yet

- One Way & Two Way SlabDocument1 pageOne Way & Two Way SlabSheikh Nouman Mohsin RamziNo ratings yet

- Plan With Coffer DamDocument1 pagePlan With Coffer DamSheikh Nouman Mohsin RamziNo ratings yet

- SAP FICO Interview Questions Answers ExplanationsDocument130 pagesSAP FICO Interview Questions Answers ExplanationsSheikh Nouman Mohsin RamziNo ratings yet

- Flat Slab DesignDocument17 pagesFlat Slab DesignSheikh Nouman Mohsin RamziNo ratings yet

- 16.02-GuideLines For Preparing Weekly Project Performance Report (Rev-8)Document8 pages16.02-GuideLines For Preparing Weekly Project Performance Report (Rev-8)Sheikh Nouman Mohsin RamziNo ratings yet

- 03 - How To Update ACCPAC 7.3 Latest ProgramDocument1 page03 - How To Update ACCPAC 7.3 Latest ProgramSheikh Nouman Mohsin RamziNo ratings yet

- Lrmts PlanDocument1 pageLrmts PlanSheikh Nouman Mohsin RamziNo ratings yet

- 16.02-GuideLines For Preparing Weekly Project Performance Report (Rev-7)Document8 pages16.02-GuideLines For Preparing Weekly Project Performance Report (Rev-7)Sheikh Nouman Mohsin RamziNo ratings yet

- Reinforcement NotesDocument1 pageReinforcement NotesSheikh Nouman Mohsin RamziNo ratings yet

- Rochester Analog Transducer Data SheetDocument2 pagesRochester Analog Transducer Data SheetRick JordanNo ratings yet

- Training Calendar (2017) : School of Quality: Iso 9001:2015 - Quality Management SystemDocument1 pageTraining Calendar (2017) : School of Quality: Iso 9001:2015 - Quality Management SystemHasbullah MohdNo ratings yet

- Netfilter PaperDocument5 pagesNetfilter Paperravi_nakarmi20019650No ratings yet

- Upto 145kV 40ka 3150A Operating ManualDocument12 pagesUpto 145kV 40ka 3150A Operating ManualNiloy DebroyNo ratings yet

- Is 1474 1959Document23 pagesIs 1474 1959Ankita vaghelaNo ratings yet

- Chapter 9Document5 pagesChapter 9nicenightmareNo ratings yet

- T3S 250 MA200 Im 1200..2400 3p F F: General InformationDocument2 pagesT3S 250 MA200 Im 1200..2400 3p F F: General InformationYonas Dwiananta YuwonoNo ratings yet

- XML API Developer GuideDocument159 pagesXML API Developer GuidegirishpoojariNo ratings yet

- Plastiment® 100Document3 pagesPlastiment® 100Troy AustinNo ratings yet

- Pure Racing Performance.: All-New 2019 TVS Apache RTR 180 (BS IV)Document2 pagesPure Racing Performance.: All-New 2019 TVS Apache RTR 180 (BS IV)sandeep sehrawatNo ratings yet

- Advanced Motion Controls Sr30a40acDocument11 pagesAdvanced Motion Controls Sr30a40acElectromateNo ratings yet

- DEBEG 442X Installation ManualDocument55 pagesDEBEG 442X Installation Manualchristos1157100% (4)

- Chapter 5 ControllingDocument22 pagesChapter 5 ControllingWalaa ElsharifNo ratings yet

- Air PollutuionDocument3 pagesAir PollutuionMalvikasingh93No ratings yet

- IEng and CEng Applications WorkshopDocument2 pagesIEng and CEng Applications WorkshopmachinemanNo ratings yet

- Phoenix Contact 0311126 enDocument46 pagesPhoenix Contact 0311126 enGiorgi AbashidzeNo ratings yet

- Digital HV Insulation Tester 10KV KM 2804 inDocument1 pageDigital HV Insulation Tester 10KV KM 2804 inindustrialindiaNo ratings yet

- Manual - Video-PorteiroDocument127 pagesManual - Video-PorteiroLeonardo FigueiredoNo ratings yet

- User Manual SP-3360ADocument12 pagesUser Manual SP-3360AMarielaUgoliniNo ratings yet

- Fisher EWN Series and EW 1 Series Valves: Scope of ManualDocument24 pagesFisher EWN Series and EW 1 Series Valves: Scope of ManualMOUWAKILNo ratings yet