Professional Documents

Culture Documents

Suzlon S88 Wind Turbine Technical Description

Uploaded by

ismailbejCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Suzlon S88 Wind Turbine Technical Description

Uploaded by

ismailbejCopyright:

Available Formats

Technical Documentation

TECHNICAL DESCRIPTION

S88-2.1 MW

Project:

Standard WTG

Document Number:

WD00122

Document Class:

2 [3, 4 = Confidential]

Issue:

08

[2008-09-05]

SUZLON Windkraft GmbH

Doberaner Str. 115

18057 Rostock | Germany

+49 381 203578-0

+49 381 203578-10

germany-documentation@suzlon.com

www.suzlon.de

TECHNICAL DESCRIPTION | S88-2.1 MW

Overview Technical Documentation

The grey marked image indicates the description which follows on the next pages.

Technical Data

Technical

Description

Safety

Transportation /

Package /

Storage

Installation

Commissioning

Operation /

Logbook

Maintenance

SCADA

Appendix

SC-Plant Netw ork

SC-PPC

SC-MetStation

Gen eral Safety

Safety in a WTG

M ech anical

Electrical

Troubleshooting

Procedures

Checklists

Charts

Spare Parts

Drawings

Electrical

Documentation

Sing le Line Diag .

Electr. Data an d

Settings

The information contained in this documentation is the property of Suzlon R&D Germany. This documentation and extracts thereof may

only be duplicated or forwarded to third parties following explicit written approval by Suzlon R&D Germany. We reserve the right to

make changes and improvements to this documentation as well as the hardware and software features at any time and without prior

notification.

All product names used in this documentation are trademarks or otherwise protected by law, even if not specifically indicated.

2007-2008 by Suzlon R&D Germany | All rights reserved.

Issue 08 | 2008-09-05

WD00122 | Class 2

2/43

TECHNICAL DESCRIPTION | S88-2.1 MW

Table of Contents Technical Description

1

Notes on manual .............................................................................. 5

1.1

Scope...................................................................................................................... 5

1.2

Warranty ................................................................................................................. 6

1.3

Copyright................................................................................................................. 6

Technical overview .......................................................................... 7

Foundation and tower ...................................................................... 9

3.1

Lift (optional) ..........................................................................................................10

Nacelle ........................................................................................... 11

4.1

4.1.1

Drive train ..............................................................................................................13

Gear box ................................................................................................................13

4.2

Generator system ....................................................................................................15

4.3

4.3.1

4.3.2

SUZLON FLEXISLIP SYSTEM ......................................................................................16

System description...................................................................................................16

System behaviour ....................................................................................................17

4.4

On-board hoist ........................................................................................................20

4.5

Yaw system.............................................................................................................21

Rotor.............................................................................................. 22

5.1

Pitch system ...........................................................................................................22

Cooling systems ............................................................................. 24

6.1

Gear box cooling......................................................................................................24

6.2

Generator cooling ....................................................................................................24

6.3

Cabinet cooling ........................................................................................................24

Brake system and rotor lock .......................................................... 25

7.1

Aerodynamic brake ..................................................................................................25

7.2

Mechanical brake .....................................................................................................25

7.3

Rotor lock ...............................................................................................................26

Hydraulic and lubrication system ................................................... 27

8.1

Hydraulic system .....................................................................................................27

8.2

Lubrication system ...................................................................................................28

Wind measurement and aviation light............................................ 29

10

Grid connection.............................................................................. 31

10.1

Compensation .........................................................................................................31

3/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

10.2

10.2.1

Medium voltage cabinet and transformer .....................................................................31

Power in tower (optional) ..........................................................................................32

11

Lightning and surge protection system .......................................... 33

11.1

11.1.1

Lightning protection zones.........................................................................................33

Rolling sphere simulation ..........................................................................................35

11.2

11.2.1

11.2.2

11.2.3

11.2.4

11.2.5

Lightning protection outside WTG ...............................................................................35

Lightning rods and receptors .....................................................................................36

Spark gaps .............................................................................................................36

Lightning arrester cables ...........................................................................................37

Nacelle ...................................................................................................................37

Hub construction......................................................................................................37

11.3

Lightning protection inside the WTG............................................................................38

11.4

Equipotential bonding system ....................................................................................38

11.5

Subterranean earthing system (optional).....................................................................38

12

Condition Monitoring System (optional) ........................................ 39

13

SUZLON CONTROL SYSTEM ............................................................ 40

13.1

SC-Turbine .............................................................................................................41

13.2

SC-Commander .......................................................................................................41

13.3

13.3.1

13.3.2

SC-Service Terminal (optional) ..................................................................................41

SC-Terminal-fixed ....................................................................................................41

SC-Terminal-portable ...............................................................................................41

13.4

SC-Power Plant Controller (optional) ...........................................................................41

13.5

SC-MetStation (optional)...........................................................................................42

14

Annotations ................................................................................... 43

4/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Notes on manual

Notes on manual

This manual is part of the Technical Documentation of a SUZLON wind turbine

generator (WTG). It describes the Technical Description of a WTG and/or wind farm.

The document is meant for authorised and qualified staff only. It has to be carefully read and

understood before performing the tasks.

The text contains abbreviations. When used for the first time the term is written in full

notation. The abbreviation stands in brackets behind the full notation term, e.g.: wind

turbine generator (WTG).

Pages, tables and figures are cross references and numbered consecutively. The document

contains further cross references and bookmarks intended to guide the reader to more

detailed information.

Figures may come with positioning numbers explaining determined components. The

positioning number appears again behind the explained component in the text as follows:

Figure 31/5

Positioning number

Serial number

Chapter

Dimensions and weights are given according to the "International System of Units" (SI).

Photos in this manual illustrate examples. Equipment and procedures may differ regarding

the specific projects. Therefore, the content of the photos is not to be considered as

generally applicable. Contact the responsible logistic manager for project specific

information.

If any suggestions or improvements are required please forward your comments to

germany-documentation@suzlon.com.

As the SUZLON WTGs are continually improved and further developed, we reserve the right

of modifications.

1.1

Scope

This Manual is valid for the S88-2.1 MW WTG in following variants:

V1/V2

V3

50 Hz

60 Hz

Standard Temperature Version (STV)

SUZLON CONTROL SYSTEM (SCS)

Tubular Tower

5/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Notes on manual

1.2

Warranty

This document is based on the technical and product-specific parameters of the supplied

WTG. Nevertheless, the manufacturer reserves the right to add complementary information

to this document.

The manufacturer only accepts warranty and liability as they are defined in the "General

Terms of Sale and Delivery".

The manufacturer does not accept any warranties or liabilities for personal injuries or

damage to property, if they refer to one or several of the following causes:

The described product was

1.3

damaged by "force majeure"

used non-intendedly

not operated according to the instructions given in the documentation

operated after technical safeguards have been put out of service

operated with inadmissible materials or equipment

subject to modifications of its design, controlling and/or functionality without prior

consultation of the manufacturer

equipped with replacement parts not supplied or approved by the manufacturer

repaired improperly.

Copyright

The manufacturer has the copyright for this document.

Reproduction, copying, propagation or any other use by or information of a third party of this

documentation whether in parts or as a whole for competition purposes requires prior

written consent by the manufacturer.

All rights reserved.

Address of the manufacturer:

SUZLON Energy Ltd

5TH Floor

Godrej Millenium

9 Koregaon Park Rd.

Pune 411 001

www.suzlon.com

INDIA

|

info@suzlon.com

6/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Technical overview

Technical overview

In particular, the WTG is designed for climatic conditions described in Manual "Technical

Data". Its robust design and uniform weight distribution ensures high levels of safety,

reliability and enhanced energy yields throughout its lifespan.

The power output is controlled by three different systems working together:

SUZLON FLEXISLIP SYSTEM (SFS, see Chapter 4.3 on page 16)

Pitch system (see Chapter 5.1 on page 22)

SUZLON CONTROL SYSTEM (SCS, see Chapter 13 on page 40)

The main parts of the WTG have been designed in line with approved industry standards to

guarantee operational safety and efficient operation.

The minimum outside temperature describes the limit to which temperature the durability of

the WTG is guaranteed during non-operating condition. The working temperature range

describes at which temperatures the WTG can operate by producing electrical power.

To keep the WTG in constant operation status all significant temperatures are measured, e.g.

the temperature outside and inside the WTG as well as temperatures of pitch accumulators

and oil sump of gear box.

All highly stressed parts, which are made of steel, were investigated in terms of strength and

suitability.

7/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Technical overview

Figure 2-1:

Main parts of the WTG

Rotor (with rotor blades)

Nacelle

Tubular tower

Foundation

8/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Foundation and tower

Foundation and tower

The WTG comes with a tubular steel tower.

The tower can be climbed from the inside

and consists of 4 several steel tube

sections connected with each other by

means of bolted flanges. The tower is

connected to the foundation by anchor

bolts, which are set into concrete at the

foundation.

There are various working platforms inside

the tower as well as a ladder with climbing

protection and hinged rest stay plates. As

an optional attachment, an electric

passenger lift can be installed inside the

tower in addition to the ladder.

The bottom cabinets are arranged on the

lowest tower platform. They are connected

to the generator and the top cabinet inside

the nacelle via power and control cables.

The cables are guided through the tower

by special cable clamps that relieve the

cable tension. At the top, the cables are

routed through a cable loop to allow the

nacelle to turn several times in each

direction without cable damage. The yaw

sensor prevents over twisting and initiates

automatically unwinding when necessary.

The power cables between WTG and grid

are routed through conduits set into the

foundation. The WTGs electrical

connections are in the power section of the

bottom cabinet.

Figure 3-1:

Tubular tower with 4 tower segments and foundation

Tubular tower section (shown transparent)

Foundation above ground

Example of a tower entry with ladder

Platform

The tower is protected against corrosion by sandblasting and applying an epoxy resin coating

to the tower surface in accordance with ISO 12944.

The foundation construction for the tower is site-specific, depending on the ground conditions

and the local codes and regulations. In the majority of cases, the foundation is prepared by

the customer on its own. Therefore, the foundation loads need to receive attention.

9/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Foundation and tower

3.1

Lift (optional)

The lift is installed inside the tower of the WTG and is meant to transport people and their

equipment up and down easily. The lift is constructed for permanent installation in one

specific WTG.

The transportation takes place by means of a pressure system with an automatic safety

control device. The automatic safety control device is placed on a panel inside the cabin.

The cabin is made of aluminium and is closed with a double door. Thus, the cabin allows a

maximum space for transport of people and tools; additionally a fast driving tempo is

guaranteed

Upward and downward travel can be controlled by an electrical control box from inside the

cabin or from outside the cabin trough an open window. A lifting force limiter prevents

upward travel in case of an overload of the cabin. Two guide wires on both sides of the cabin

prevent the lift from swinging.

[1]

[2]

[3]

Figure 3-2:

Cabin overwiev (Example of Avanti)

Electrical control box

Cabin door

Cabin

10/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

Nacelle

The nacelle consists of a cast main frame with a bolted-on girder system and a nacelle cover.

The main frame is connected to the tower via the yaw bearing. It carries the main

components of the WTG, shown in Figure 4-2 on page 12.

The nacelle cover is made of glass-fibre reinforced plastic (GRP) and designed in such way

that the internal components are fully protected against various ambient conditions. The

nacelle is also equipped with an on-board hoist for lifting or unloading material into or from

the nacelle (see Chapter 4.4 on page 20). There are two access hatches on top of the nacelle

to provide access to the measuring instruments, the resistors of the SUZLON FLEXISLIP

SYSTEM (SFS) on the roof and to the hub.

The nacelle cover is made in sandwich construction to avoid a quick cool down.

The temperature inside the cabinets is controlled by temperature sensors. The heaters are

connected directly to the grid and will be activated via thermostats.

[1]

[2]

[3]

[2]

[4]

Figure 4-1:

Nacelle exterior view with transparent displayed nacelle cover

Access hatch on top to wind measurement equipment and SFS resistor boxes

Vent

Access hatch on top for the hub

Access hatch for the on board hoist

11/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

[1]

[2]

[3]

[4]

[7]

Figure 4-2:

[6]

[5]

Nacelle interior view without nacelle cover

Top cabinets

Rotor lock disc

Drive train (see Chapter 4.1 on page 12)

Main frame (for mounting the drive train)

Yaw bearing (see Chapter 4.5 on page 21)

Generator (see Chapter 4.2 on page 15)

Girder system (for mounting the generator)

12/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

4.1

Drive train

The main components of the drive train are shown in Figure 4-3.

The main shaft is made of high grade heat-treated steel. On the rotor side, it is supported by

the main bearing, which is a robust spherical roller bearing. A shrink disk connects the main

shaft to the gear box (see Chapter 4.1.1 on page 13). Inside the gear box, the main shaft is

supported by a cylindrical roller bearing. To reduce weight without losing strength and for

guiding the hub cables, the main shaft is hollow.

[1]

[2]

[7]

Figure 4-3:

4.1.1

[6]

[5]

[4]

[3]

Main components of drive train

Rotor lock disc

Main bearing

Main shaft

Gear box (see Chapter 4.1.1 on page 13)

Mechanical rotor brake (see Chapter 7.2 on page 25)

Coupling

Generator

Gear box

The gear box (Figure 4-4 on page 14) is a compact design, single stage planetary/ multi

stage helical spur gear gear box that ensures the highest possible mechanical efficiency and

power. The first planetary gear stage takes up the slow rotor rotation and distributes the

high torque input into subsequent planetary gears. High precision manufacturing and Finite

Element Methodology (FEM) calculations of the planet carrier ensures optimal load

distribution to the helical gears. Reduced torque values and increased rotational speeds are

optimally converted to the high-speed operation of the generator.

The helical stage is responsible for a low sound power level, which is further reduced by

impact sound isolation via rubber bushings between gear box and main frame.

13/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

The gear box is equipped with two independent oil circulations. The internal mechanical oil

pump supplies the gear box with oil during idling mode.

The external electrical lubrication system is for operation mode. With this system the oil is

filtered by a micro-filter and comprises an oil-cooling device rendering temperature

optimization.

The internal oil heating is equipped with heating rods. It operates when the oil sump

temperature is below freezing point.

[1]

[2]

[4]

[5]

Figure 4-4:

[3]

Gear box (Example of Hansen Transmissions)

Gear box oil cooling

Inspection cover

Slip ring adapter

Valve for oil sample and oil change

Oil filter pump

14/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

4.2

Generator system

The WTG is equipped with a single-fed asynchronous three-phase generator. During

operation, the stator side of the generator is permanently connected to the grid. On the rotor

side, a slip ring connects the generator to the SFS (see Chapter 4.3 on page 16). The

generator is kept at optimum operational temperature by a robust air cooling system (see

Chapter 6.2 on page 24).

An anti-condensation heating element is integrated into the generator, it is operated via the

SCS.

[3]

stator side /

nacelle front

rotor side /

nacelle back

[2]

[1]

[4]

Figure 4-5:

Drawing of the generator system transparent

Generator

Adapter to coupling

Generator cooler

Rotor terminal box (slip ring inside)

15/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

4.3

SUZLON FLEXISLIP SYSTEM

The SUZLON FLEXISLIP SYSTEM (SFS) is a robust generator system for WTG. It has been

developed to be cost efficient, to reduce mechanical WTG loads and to be suitable to feed

electrical energy under different grid conditions into electricity networks.

4.3.1

System description

The WTG optimises the power output from the available wind by a combination of the

pitch system and the SFS, which is a generator control. The pitch system can operate

over a wide wind speed range to maximise aerodynamic efficiency.

The SFS works with a single fed induction generator with slip rings. The slip of the generator

is flexible because its rotor current is being controlled by power electronic components. Slip

means the difference between synchronous speed and actual speed of the machine divided

by the synchronous speed. This gives positive values for motor operation and negative

values for generator operation.

[1]

Figure 4-6:

[2]

[3]

Scheme of the SFS

Rectifier

Surge protection

IGBT-switch

In an asynchronous machine with slip rings, the slip can be adjusted. As it is not possible to

change the natural rotor resistance, external resistors can be used additionally. That can be

used to get a constant torque and respectively constant power over a wide range of

generator speed. In the SFS the rotor resistance can be adjusted. This is achieved by

switching on and off external resistors in the rotor circuit. The switching is controlled by

opening and closing an Insulated Gate Bipolar Transistor (IGBT) in the DC link, which is

parallel to the external resistors. That leads to the same behaviour as continuous adjustment

16/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

of the rotor resistance and so regulates the rotor current. The range which can be realised

only depends on the capability of the rotor resistors.

The surge protection is connected in parallel to the IGBT unit. The surge protection consists

of a thyristor unit which short circuits the DC link in special faults like overvoltage and

overcurrent in the rotor circuit. In this cases the current flows through the surge protection

and protects the IGBT.

4.3.2

System behaviour

The WTG is controlled via two separate systems working together:

1.

The pitch regulation (see Chapter 5.1 on page 22) controls the maximum speed to given

setpoints. Below and above this setpoints the pitch angle will be adjusted. This

regulation is comparable to the SFS control "slow". It also controls the generator speed

without load.

2.

The SFS regulates among others the power output to a defined stepoint. The regulation

is "fast" in comparison to the pitch system.

Table 4-1: Overview of the different operational states of the SFS

Operation state

IGBT switch

condition

Rotor resistance

Region Figure 4-7

on page 19

Cut in

Permanently off

Rotor resistance plus

full external resistors

0 to 100% power

Switching on-off

Little increase of the

rotor resistor, drive

train damping

I+II

Constant nominal

power

Switching on-off

Varying resistance.

Rotor resistance plus

switched external

resistors

III

With an interaction of this two regulation systems the SFS has the following system

behavior:

During the cut in of the WTG the pitch regulation tries to keep the generator speed close to

synchronous speed. The IGBT is switched off. This leads to an operation characteristic with a

very high slip (Figure 4-7/A on page 19). The WTG is connected to the grid by a soft starter

module. Because of the high rotor resistance during cut in the inrush current is small.

After a successful "cut in" the pitch system gets a new setpoint, which is higher than the

synchronous speed. The SFS begins to control the rotor current and thus controls the power

output. Up to a rated power the SFS gives a small additional slip to the WTG to reduce loads

and power fluctuation.

When the reference current, respectively the power is reached, the SFS limits the

current/power output. The pitch system control ensures that the rotation speed of the WTG

is within the given setpoints.

17/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

The operation area of the system is limited by the following boundaries:

Characteristic A is given by the external resistors on the roof

Characteristic B is given by the natural slip of the generator

There is a limitation to the maximum power output of the system (see Figure 4-7/Pmax

on page 19)

There are given two additional areas between the boundaries (see Figure 4-7 on page 19,

shaded areas). These areas are defined due to the losses of the external resistors and thus

given by the power which can be overtaken permanently (see Figure 4-7/D on page 19). In

the left shaded area the system works continuously. The right diagonal shaded area is for

dynamic operation at higher rotation speeds due to gusts. The nominal working point of the

WTG is given in Figure 4-7 on page 19.

Between nominal current and maximum current is a 11.1% range left. The WTG is able to

produce 100% power also when the grid voltage is 10% lower then normal voltage because

of a available reserve in the power electronic components. The power output of the WTG is

limited to nominal power due to the mechanical loads.

18/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

Figure 4-7:

Working areas of SFS

Characteristic with max. resistors, IGBT switched off, full external resistors are added

Characteristic with natural slip of generator, IGBT switched on continuously, external

resistors short circuited

Power curve

Border between region of continuous and short-time operation. In the area left of this

line, the system can work continuously, in the area right of the line, it can work for a

short time only (e.g. for gusts).

Nominal working point of

Possible working region continuously

Possible working region for dynamic use (e.g. strong gusts)

19/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

4.4

On-board hoist

The on-board hoist is situated inside the nacelle to lift small items into and out of the nacelle

through a bottom hatch at the rear of the nacelle. The on-board hoist is an electrical chain

type and is mounted on a frame. The rail is secured to the main frame of the nacelle cover

underneath the roof.

[1]

[2]

[3]

[4]

[5]

[6]

Figure 4-8:

Position and parts of the on-bord hoist

Frame

Motor

Chain bag

Hook

Pendant control

Bottom hatch (open)

20/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Nacelle

4.5

Yaw system

The nacelle is mounted to the tower with a torque adjustable friction-type yaw bearing

consisting of polyamide slide bearings, which transmit the loads from the nacelle to the

tower.

The bearing is of a strong, solid construction to avoid damage. All parts of the yaw bearing

are manufactured with high grade steel. The yaw system is equipped with a lubrication

system for greasing the rotating/moving yaw components. Additionally it avoids noise and

vibration during yaw tracking.

The WTG uses a reliable and proven yaw system to ensure optimal alignment of the rotor to

the wind. The wind direction is sensed by two anemometers on the nacelle roof (see Chapter

9 on page 28), which send the information to the controller. The yaw tracking is performed

and controlled by three electrical gear motors, which are activated as soon as the system

recognises a certain predefined difference between the rotor axis and the current wind

direction. The yaw drives turn the nacelle into the wind by rotating it via a friction type

bearing against a fixed gear rim sitting on the top section of the tower. A sensor located on

the gear rim registers the number of turns the nacelle performs in the given direction to

avoid over twisting the cables. If the nacelle turns more than a predefined number of times

in the same direction, the WTG is temporarily shut down and automatic unwinding starts.

Afterwards the WTG restarts automatically.

The system ensures with a precise yaw a high energy yield and reduces mechanical load on

the WTG caused by changes in wind direction.

[1]

[2]

[3]

Figure 4-9:

Yaw system

Main frame

Yaw drives with integrated brakes

Gear rim

21/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Rotor

Rotor

The rotor consists of a high strength cast iron hub supporting three pitch able rotor blades.

The blades are connected to the hub via ball bearings. They can be turned with the pitch

system (see Chapter 5.1 on page 22). The hub is directly connected to the main shaft and

transmits the rotation of the rotor via the drive train to the generator. The hub is housed in a

nose cone that is made of GRP and covers the hub cabinet.

The rotor blades are aerodynamically optimised to provide high lifting forces and low airresistance values to produce high performance. The rotor blades are made of high grade GRP

and manufactured by using Resin Infusing Moulding (RIM) technology. The blades are

lightweight but at the same time possess a high degree of stiffness and mechanical strength.

Their low weight to diameter ratio results in low stresses on the drive train, thus enhancing

the life and efficiency of the WTG.

At their roots, the rotor blades have a flange that is bolted to the hub via double-row ball

bearings. Each blade is equipped with a lightning receptor. The lightning is guided from the

receptors to the hub and thus to the rotor shaft (see Chapter 11 on page 33). From the rotor

shaft, the lightning is conducted to the grounded main frame with the help of spark gaps

(see Chapter 11.2.2 on page 36).

[1]

[2]

[3]

[4]

Figure 5-1:

5.1

Rotor

Rotor blade

Handrail

Exit hatch (there are 3 hatches to enter the hub 2 are shown in figure)

Lightning protection

Pitch system

The pitch system has been designed with a triple redundancy, which means that each blade

has its own drive system consisting of a motor with gear box, a frequency converter and a

backup system. The pitch angle of each blade is accurately adjusted to the requirements of

the SCS. With this, it is possible to turn the rotor blades more than the needed 90. The SCS

22/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Rotor

transmits the required set point for the blade position, which is controlled for each blade

separately by the respective frequency converter.

The pitch system operates in the following way: Below nominal wind speed, the pitch angle is

constant at 0 position. Once the wind speed reaches nominal speed, the pitch regulation

starts to regulate the pitch angle to limit the rotational speed of WTG to the nominal speed.

In comparison to the SFS this regulation is "slow".

Each pitch drive has its own battery backup to ensure its functionality, even when the

electrical grid is not available. In this case the WTG stops immediately by rotating the blades

into feathering position with the energy of the battery backup. The SCS, which is equipped

with an uninterruptible power supply (UPS), checks the status of the backup systems

periodicly and will shut down the WTG in case the energy of the pitch batteries drops below a

predefined value.

The pitch motors are fastened inside the hub. Their drive pinions are interlocked with the

inner gear wheel of the blade bearings, which supports the rotor blades. The pitch motors

are equipped with an internal brake, which holds the blade position when the pitch is not

active. To guarantee high performance the blade bearings are made of high tensile doublerow ball-bearing slewing rings. The pitch control system and the emergency battery backup

systems are located in suitable control cabinets inside the hub. The supply and

communication cables to the nacelle are passed through the low speed hollow main shaft. A

slip ring behind the gear box transmits the electrical signals and supply from a static to a

rotational condition.

The pitch drive is equipped with an extra strong motor featuring with an extra high

brake down moment to deal with higher loads in case of icing. The seals for the gear and the

drive are made of special Nitrile-Butadiene-Rubber (NBR).

The pitch system is equipped with 1 heater within every battery box. It warms up the

accumulators and prevents humidity inside the boxes. The heating is operated by

thermostats, which are integrated in the battery boxes. A temperature sensor is installed in

each battery box. It will shut down the WTG safely in case of low temperature.

[1]

[2]

[3]

Figure 5-2:

Hub without blades; view into the pitch system

Pitch drive

Pitch bearing

Pitch cabinet

23/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Cooling systems

Cooling systems

The gear box, generator and each control cabinet are equipped with cooling systems.

All cooling systems are designed in such a way, that the optimum operation temperature will

not be exceeded. The components to be cooled are monitored by a sensors system and the

information is processed by the SCS.

6.1

Gear box cooling

The gear box (see Chapter 4.1.1 on page 13) is cooled via the oil flow that is passed through

the oil/air heat exchanger. A thermal choke shuts off the oil circulation during start-up until

the minimum operational temperature of the oil has been reached. An oil pump brings the oil

directly to the relevant gear box components.

Additionally, the SCS monitors the gear box temperature by means of temperature sensors

fitted to the gear box bearings and in the oil sump.

6.2

Generator cooling

The generator (see Chapter 4.2 on page 15) is cooled by two separate cooling air circuits

(Figure 4-5/1 on page 15).

The inner, closed cooling air circuit is fed by the rotor cooling ducts. Special air guiding

devices provide effective cooling of all moving parts. The air to air heat exchanger, a part of

the stator housing, transfers the heat to the outer cooling circuit.

The outer cooling circuit has its air intake at the drive end side. One axial-flow bladed fan,

located at the drive end side, sucks the air in, blows it through the axially placed cooling

tubes and discharges it at the non drive end side. The cooling air for the slip ring is

introduced by an air guiding device into the slip ring housing and discharged through an

opening in the bottom of the nacelle.

Additionally, the SCS monitors the generator temperature by means of temperature sensors

fitted to the generator bearings and inside the windings.

6.3

Cabinet cooling

The cabinets are cooled by a fan system.

The fans blow cool air through filters and into the cabinets. Warm air leaves the cabinets via

filtered outlets. A sensor system with programmed minimum and maximum values for the

control cabinet temperature switches the fans on and off on demand.

Humidity sensors activate fans and heaters if the humidity inside the cabinets reaches a

certain limit.

Additionally, the SCS monitors the cabinet temperature by means of temperature sensors.

24/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Brake system and rotor lock

Brake system and rotor lock

The brake system stops the rotation of the rotor and the main shaft. It consists of two

independent systems:

The aerodynamic brake (see Chapter 7.1 on page 25) is operated by the pitch system of

the three blades. It is used as the standard brake during automatic operation.

The mechanical brake (see Chapter 7.2 on page 25) is an active brake only for

supporting the aerodynamic brake. It works with hydraulic pressure.

7.1

Aerodynamic brake

The aerodynamic brake is operated by pitching the rotor blades. For braking, the pitch

system turns the leading edge of the rotor blades to the 90 position wind wards (also called

feathering position). The rotor blades lose their lift and increase their drag, which is utilise

for braking.

The aerodynamic brake is equipped with a safety system ensuring the blades can be pitched

even in the event of a grid failure. In this case, each pitch motor is supplied with power by

an individual battery box, which delivers the necessary energy for pitching back to the

feathering position.

Each of the three blades have an independent pitch drive to ensure safe operation. The

system is then comprised of three aerodynamic brakes.

7.2

Mechanical brake

The mechanical brake is located on the high speed shaft between gear box and coupling.

Hydraulic pressure prevents pressing the brake pads against the brake disc. It is applied by

hydraulic pressure (active brake). The brake pads are pressing against the brake disc, thus

braking the shaft.

The mechanical brake is only used to stop the WTG when it has already been decelerated by

the aerodynamic brake. That means, the mechanical brake operates at a very low rotational

speed and hence it is used only as a parking brake while applying the rotor lock pin or in

emergency case.

gear box connection

(Drive End DE)

[1]

generator connection

(None Drive End NDE)

Figure 7-1:

[2]

Mechanical brake

Brake pads

Brake disc

25/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Brake system and rotor lock

7.3

Rotor lock

The mechanical rotor lock prevents the rotor from moving during service and maintenance

work. It is fitted to provide additional personal safety when working inside the hub and on

the nacelle/hub roof.

The rotor lock disc is positioned on the main shaft inside the nacelle. The rotor lock pin is

located underneath the main bearing and is operated by the hydraulic system (see Chapter

8.1 on page 27) during a standstill condition of the rotor. It is only allowed to use the rotor

lock pin under certain circumstances (see Manual "Operation").

[1]

[2]

Figure 7-2:

[3]

[4]

Rotor lock disc with main shaft

Main shaft

Rotor lock pin

Main bearing

Rotor lock disc

26/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Hydraulic and lubrication system

Hydraulic and lubrication system

There are two systems to ensure a permanent and essential operation of the separate

components and of the WTG. Both systems ensure a sufficient oil or lubrication supply for all

components (where needed).

8.1

Hydraulic system

The hydraulic system provides the oil

pressure that is required for the mechanical

rotor brake and for applying the the rotor

lock pin. It can be controlled manually by

using the brake and rotor lock buttons.

Additionally it can be used to operate the

rotor lock pin by using the hydraulic hand

pump.

The pressure vessel of the electric oil pump

system is fitted with a membrane suitable

for low temperatures.

Figure 8-1:

Hydraulic aggregate

27/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Hydraulic and lubrication system

8.2

Lubrication system

In the WTG a couple of lubrication systems are present. There are two kinds of systems:

Closed system or

Opened system

The closed systems were lubricated only

once for the life time and closed afterwards.

It is used for some kind of roller bearings in

the WTG.

For the opened systems lubrication

reservoirs exist, to supply the components

at all times. Such a system is used for

example for the yaw system (see Chapter

4.5 on page 21).

Figure 8-2:

Lubrication reservoirs for

the yaw system (LINCOLN)

28/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Wind measurement and aviation light

Wind measurement and aviation light

The wind measurement equipment is mounted on top of the nacelle roof and measures the

wind direction and the wind speed. It consists of two anemometers and two wind vanes fitted

to the wind measurement pole. The sensors are surrounded by a protection cage to protect

them against electromagnetic fields. The sensors are equipped with integrated heaters.

The SCS works with one of the anemometers. It permanently tests for plausibility and

chooses the correct working sensor. The SCS uses the higher wind speed of the two wind

sensors because they act downwind and the turbulence from the blades affects them. The

wind direction is averaged between the two wind sensors.

It is possible to fit an aviation light on top of the nacelle. The light is placed at the wind

measurement mast. It operates independently. The aviation light will be according to the

national requirements.

The lights were attached on rotatable arms. To prevent light pollution at the public eye level

an aviation light covering can be fitted. So the red light is still visible for pilots from above.

[1]

[2]

[3]

[4]

[5]

[6]

Figure 9-1:

Wind measurement with lightning protection on the roof of the nacelle

Lightening protection

Protection case

Wind vane

Anemometer

Metal rack

Example of an aviation light

29/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Wind measurement and aviation light

[1]

[2]

[3]

Figure 9-2:

Aviation light with cover (optional)

Light

Cover

Metal rack

30/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Grid connection

10

Grid connection

The WTG is directly connected to the grid. The WTG needs to transform the voltage from

medium voltage to high voltage by means of a transformer. The transformer also minimizes

the electrical losses.

The WTG starts up by turning the rotor blades to an optimum blade angle, thus accelerating

the rotor. When the generator speed has reached synchronous speed, it is connected to the

grid via a soft starter controlling the inrush current. After this, the bypass contactor switches

on and bypasses the soft starter. The generator is directly connected to the grid.

10.1

Compensation

The usable electrical power is the active power. By its technical nature, each asynchronous

electrical generator needs a certain amount of reactive power. This form of electrical power

places additional load on the electrical supply system, e.g. the cables. To compensate this

effect and to reduce the reactive power, the WTG has a compensation mechanism.

The reactive power required by the WTG is compensated by using a 16 step capacitor bank.

The reactive power of the WTG is constantly measured during operation. Capacitors are

switched on and off according to whether or not additional capacity is needed. The individual

capacitor bank is switched according to the short-time-average-value of the measured

reactive power. If the supply system requires to much reactive power, one additional

capacitor bank is switched on. If the reactive power is too low, one bank is switched off. The

system always switches on the capacitor bank, which has the lowest individual operation

time and switches off the banks with the highest individual operation time.

10.2

Medium voltage cabinet and transformer

The medium voltage (MV) cabinet and the step up transformer are included in an area

outside the WTG. Therefore a separate building is necessary. It is part of the owner to realise

the construction.

The transformer transfers electrical energy from one voltage level to another, e.g. from the

grid to the WTG or vice versa.

31/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Grid connection

10.2.1

Power in tower (optional)

An optional possibility is to include the MV

cabinet and the step up transformer in the

tower. It is called "power in tower" (PIT). In

this case, the transformer is positioned at

the tower bottom in special frames. The MV

cabinet is installed on the second rack level

above the transformer. The MV cables from

the wind park are installed through the

foundation of the WTG to the MV cabinet.

From the MV cabinet the step up

transformer is connected. Protection of the

transformer is realized by relay in

combination with circuit breaker. The

bottom cabinet is installed on the third rack

level and connected to the low voltage side

of the transformer.

[1]

[2]

[3]

[4]

[5]

Figure 10-1:

Power in tower with 3 rack levels transparent tower sections

Bottom cabinet

Medium voltage (MV) cabinet

Tower door

Transformer

Foundation

32/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Lightning and surge protection system

11

Lightning and surge protection system

The lightning protection in WTGs has to be designed in accordance with the active standard

IEC TR 61400-24 "wind turbine generator systems part 24: lightning protection". The

standard requires a full protection against direct lightning strikes and the effects of lightning

strikes. The lightning protection is designed according to lightning protection level I (LPL I),

the highest existing level.

The lightning protection system of the WTG is divided into four main parts:

11.1

Exterior lightning protection

Interior lightning protection

Equipotential bonding system

Earthing system

Lightning protection zones

The creation of lightning protection zones (LPZ) of the WTG was realised by national and

international standards. An overview of the LPZ is shown in Figure 11-1 on page 34.

Furthermore, the efficiency of the LPZ was tested by applying the rolling sphere simulation

(Chapter 11.1.1 on page 35).

The LPZ 1 in the nacelle is realised by a meshstructure for damping the electromagnetic

influences. For the tower is used a metal tube construction. All cabinets inside the tower,

nacelle and hub are classified as LPZ 2.

33/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Lightning and surge protection system

Figure 11-1:

Overview lightning protection zones (LPZ)

34/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Lightning and surge protection system

11.1.1

Rolling sphere simulation

The lightning protection system is designed

in accordance with the rolling sphere

simulation on the geometry of the WTG.

The rolling sphere simulation is used to

place and dimension the lightning rods to

afford the highest level of lightning

protection against the nacelle.

[1]

[2]

Figure 11-2:

11.2

During simulation the rolling sphere with a

radius of 20 m is runnig across the

geometry of the WTG. To guarantee the

LPZ 1 (inside WTG) and LPZ 0B (outside

WTG) the rolling sphere is not allowed to

contact a part of the nacelle or the hub but

the lightning rods. The LPZ 0B is not

endangered by direct lightning strikes.

As shown in Figure 11-2 the rolling sphere

does not contact the nacelle cover but the

lightning rod. Hence, the LPZ 0B is

guaranteed. In case the lightning rod is not

dimensioned correctly the rolling sphere

would contact the nacelle cover. Hence, the

LPZ 0B is not guaranteed.

Rolling sphere modell

Rolling sphere

Lightning rod

Lightning protection outside WTG

The lightning protection outside the WTG includes the following parts:

Lightning rods at nose cone and nacelle

Receptors at rotor blades

Copper cables, spark gaps and carbon brushes

Wire mesh inside the nacelle cover and metal hub construction

Copper busbars for connection of cables and arresting devices

One task of the lightning protection outside the WTG is to avoid direct lightning strikes into

the mechanical and electrical operation systems of the WTG. A second task is to avoid the

endangerment of free leading down of lightning currents. The electromagnetic field must be

reduced to a LPL according to the LPZ 1 by the nacelle cover.

The blade of the WTG includes two lightning receptors, one in the tip and one in the middle

of the blade. The receptors are connected to the spark gap at the blade root, where the

lightning current will be lead onto the hub construction. From there, the lightning current will

be lead over spark gaps at the rotor lock disc on an isolated arresting path to the top section

of the tower and then into the ground.

35/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Lightning and surge protection system

11.2.1

Lightning rods and receptors

The rotor blades are equipped with receptors. The receptors avoid damages of the rotor

blade by a direct lightning strike.

The lightning rod on the nacelle protect the wind measurement equipment and the nacelle

against direct lightning strikes.

11.2.2

Spark gaps

To conduct the lightning current riskless into the ground it is necessary to protect the

bearings at the rotor blade and drive train by parallel current paths, which conduct and direct

the lightning current. This is realised by using spark gaps at the blade bearing, in the section

of the rotor lock disc in front of the main bearing and at the yaw bearing.

[1]

[2]

[3]

[4]

[5]

Figure 11-3:

Spark gap at the yaw bearing

Spark gap bolt

Lock nut

Yaw base/main frame

Gear rim

Adjustable spark gap between bolt and gear rim

36/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Lightning and surge protection system

11.2.3

Lightning arrester cables

[1]

[2]

[3]

Figure 11-4:

11.2.4

The lightning current will be conducted into

the ground by using copper cables. The

cables connect the spark gaps and the

lightning rods directly with the upper tower

shell. The connection between the tower

shells is bridged by three copper cable

bridges at the flange. The cross section of

the three cable bridges is identical to the

cross section of the tower shells. Hence, the

tower is used for conducting lightning

current without influences to inside installed

cables and wires.

Copper cable bridge at tower section connection interior view of the tower

Tower section

Earthing strap

Flange between tower sections

Nacelle

The glass fibre reinforced plastic (GRP) cover of the nacelle is divided into three parts. Each

part is provided with a mesh of galvanised steel. The meshes are interconnected to each

other in order to build a Faraday cage. Furthermore, the meshes are attached to the tower

by a copper cable to bleed off the lightning current.

11.2.5

Hub construction

The hub construction is made of cast iron.

All electric components have the required distance to the nose cone. So the hub complies

with the requirements for a faraday cage.

37/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Lightning and surge protection system

11.3

Lightning protection inside the WTG

The lightning protection inside the WTG includes surge current arresters and surge voltage

arresters. This components are also called surge protective devices (SPDs). The SPDs

protects the electrical and electronic systems against indirect effect of the lightning, which

strikes the WTG or the upstreamed net system.

The main advantage of the lightning protection inside the WTG is the subsequent design of

an all side protection of control systems (incoming and outgoing wires protected by SPDs).

Hence, the influences to the systems can be reduced enormously.

The bottom cabinet of the WTG includes three main surge arresters, which reduce the

influence of lightning current and surge voltage arrester by the upstreamed net system

(Figure 11-5 and Figure 11-6).

Figure 11-5:

11.4

Surge arrester in bottom

cabinet

Figure 11-6:

Surge volge arrester in

bottom cabinet

Equipotential bonding system

The task of the equipotential bonding system is the potential equalisation of all metal system

components like housings, handrails, ladders and cabinets.

The equipotential bonding system is based on the potential tree concept, which is especially

designed for the application in WTGs. The potential equalisation avoids the generation of

dangerous voltages, which can hazard people and technical systems.

The equipotential bonding system connects all metal components of the WTG. As a result,

the electric potential of all components is the same. Thus, in case of contacting two

components there is no danger of current flow for humans.

11.5

Subterranean earthing system (optional)

The subterranean earthing system connects the WTG with the transformer star point and all

outside installations. The earthing system has to avoid potential differences between the

WTG and the transformer station in case of lightning strike and the safeguarding of low loop

impedance, which is necessary for a fast and safe disconnection in case of electrical failures.

The subterranean earthing system is connected to the PAS busbar in the bottom of the WTG.

From this point, the earthing system is designed like a grid in the sub terrain.

38/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Condition Monitoring System (optional)

12

Condition Monitoring System (optional)

The intention of the Condition Monitoring System (CMS) is to prevent damages and loss of

components. It can predict damages and allow a minimum time for maintenances.

Additionally, it is possible to analyse damages, increase the reliability and mean time

between failures (MTBF).

The scope of the CMS is basic diagnostic by measuring vibration at drive train components

and automatic detection of relevant changes. Furthermore, it is possible for CMS experts in

CMS surveillance centre to diagnose damages and thus prepare instructions for operating

staff. The analysis of damage causes may help to develop possibilities of prevention.

The CMS components are as follows:

Measurement of vibration on drive train (main bearing, gear box, generator)

Communication to programmable logic controller (PLC)

Communication to CMS surveillance centre (remote control)

The CMS device is only able to recognize but not to react! On this account it is necessary to

have a CMS surveillance centre. Here the measurements of all joined WTGs are centralised

and CMS experts react accordingly.

It is possible to retrofit the CMS.

39/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

SUZLON CONTROL SYSTEM

13

SUZLON CONTROL SYSTEM

The SUZLON CONTROL SYSTEM (SCS) is a new generation of an innovative WTG and park

controlling and monitoring system. It consists of four parts to ensure an optimum level of

safety, stability and flexibility. Each part is designed for its specific task:

SUZLON Control-Turbine (SC-Turbine)

This is the pure WTG control. SC-Turbine can run the WTG independently.

SUZLON ControlCommander (SC-C)

For visualisation of WTG data and WTG remote control. SC-C is the gate to SC-Turbine

and SC-PPC.

SUZLON Control-Service Terminal (SC-Service Terminal)

This is a portable box for controlling and data request of a single WTG.

SUZLON Control-Power Plant Controller (SC-PPC)

Optional part for wind park management in close interaction with SC-Turbine.

SUZLON Control-MetStation

Optional part for wind park management to provide detailed weather conditions of the

wind park

Figure 13-1:

Interaction of the components of the SCS

40/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

SUZLON CONTROL SYSTEM

13.1

SC-Turbine

The SC-Turbine is the control system of a single WTG. Via different sensors and

measurements (e.g. electrical grid data, wind speed and direction, rotational speed, yaw and

blade angle and component temperatures) SC-Turbine ensures safe and stable operation and

power production of the WTG. Also statistical and operational data are stored on a flash

memory.

The innovative software solution runs on a robust industrial programmable logical controller

(PLC) and ensures safe and high performance of the WTG.

SC-Turbine can be monitored and controlled with the robust SC-Service Terminal or a normal

laptop directly at the WTG. Also in close interaction with SC-C it is possible to communicate

with the WTG and additionally to create reports and logs of the stored data of WTGs or the

whole wind park.

13.2

SC-Commander

The SC-Commander (SC-C) is designed as a user interface to WTGs. It manages access for

customers, service staff and other persons, according to defined access levels, to all wind

park devices, such as WTGs, meteorological masts and also to SC-PPC. At the same time it

collects, stores and distributes all required data. To see the WTG status, to carry out simple

operations like start, stop, reset and to create reports it is necessary to use SC-C. So SC-C is

the "gate" to SC-Turbine and SC-PPC.

The SC-C can be installed on any kind of operating system. The laptop/PC has to comply with

the requirements in "Hardware Specification SC-Commander".

13.3

SC-Service Terminal (optional)

With the SC-Service Terminal operation of a single WTG is possible.

13.3.1

SC-Terminal-fixed

The fixed SC-Terminal is placed in a cabinet door of the bottom cabinet. It consists of

processor, monitor and key pad.

13.3.2

SC-Terminal-portable

It is possible to connect a portable and compatible SC-Service Terminal to a WTG. The SCTerminal consists of processor, monitor and key pad in a single box and can be plugged to

every WTG.

13.4

SC-Power Plant Controller (optional)

The SC-Power Plant Controller (SC-PPC) is designed to control a complete wind park

according to specific requirements. The wind park will be controlled as a power plant. For

example it is possible to reduce the power output of the wind park which is in certain cases

necessary to meet the requirements of the utilities. It is also possible to stop individual WTGs

to avoid shadow flicker effects at particular areas.

The software runs on a robust industrial PLC in close interaction with SC-Turbine.

Visualisation and remote control of SC-PPC is possible via SC-C.

41/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

SUZLON CONTROL SYSTEM

13.5

SC-MetStation (optional)

The SC-MetStation is introduced to provide

a detailed and correct representation of

actual weather conditions of a wind park.

Additional forecasts and calculations are

possible.

The measured data are used for:

Production forecast

Free wind speed

Wind direction

Production loss calculation

Air density calculation

Turbulence intensity

The SC-MetStation is placed inside the wind

park it belongs to.

The SC-MetStation is equipped with a

standard scope of sensors, that means: one

anemometer and one wind vane. It is

possible to increase the scope of sensors up

to four anemometers and four wind vanes.

The sensors are installed at hub height.

Figure 13-2:

Example of a SC-MetStation

42/43

Issue 08 | 2008-09-05

WD00122 | Class 2

TECHNICAL DESCRIPTION | S88-2.1 MW

Annotations

14

Annotations

43/43

Issue 08 | 2008-09-05

WD00122 | Class 2

You might also like

- Suzlon S88 WT ManualDocument21 pagesSuzlon S88 WT ManualJavier Canosa IM FutureNo ratings yet

- V90 Turbine SpecificationsDocument38 pagesV90 Turbine SpecificationsTrevor ClineNo ratings yet

- 4 - V112-3.0MW - VestasDocument26 pages4 - V112-3.0MW - Vestasvasile78No ratings yet

- 2102 - 001 - 04 Introduction To V80-V90-V100 Mk.7 VCS-VCUS TurbineDocument34 pages2102 - 001 - 04 Introduction To V80-V90-V100 Mk.7 VCS-VCUS Turbinenils_erickssonNo ratings yet

- Anexo D E.T. v80-2mw-1Document17 pagesAnexo D E.T. v80-2mw-1riogadNo ratings yet

- Retrofit Vestas V47Document4 pagesRetrofit Vestas V47imadNo ratings yet

- Transport Manual V90Document28 pagesTransport Manual V90cungondaNo ratings yet

- Vestasv90 3MWDocument6 pagesVestasv90 3MWOviri Charles Umude-IgbruNo ratings yet

- V82-1,65 MW GB Exchange Compl. Us VersDocument62 pagesV82-1,65 MW GB Exchange Compl. Us VersAEDDG80% (5)

- Offshore Wind Operations and Maintenance - Eeke MastDocument17 pagesOffshore Wind Operations and Maintenance - Eeke MastSimon ChangNo ratings yet

- V112-3 MWDocument16 pagesV112-3 MWnikos_tsNo ratings yet

- 3.5 Foundation Design and Execution Information 109W4732 RDocument65 pages3.5 Foundation Design and Execution Information 109W4732 RJoão Batista Medeiros Gonçalves100% (1)

- Torque Wrench Settings: History of This DocumentDocument35 pagesTorque Wrench Settings: History of This Documentpatrick crowley100% (1)

- Connecting Rod Repair GuideDocument32 pagesConnecting Rod Repair GuideJorge Espinoza100% (1)

- Ecodiseno GAMESADocument2 pagesEcodiseno GAMESAMario YañezNo ratings yet

- VestasDocument16 pagesVestasΙωάννης Γεωργίου ΜάντηςNo ratings yet

- V47 UsDocument6 pagesV47 UsDaniel BatNo ratings yet

- Chinese WTG ManufacturesDocument9 pagesChinese WTG ManufacturesSpark NetworkNo ratings yet

- Cotas Vestas CT273 VRCC Processor Repair Solution PDFDocument6 pagesCotas Vestas CT273 VRCC Processor Repair Solution PDFDhatchina MoorthyNo ratings yet

- NordexDocument176 pagesNordexbben010100% (1)

- Gamesa G114 PDFDocument27 pagesGamesa G114 PDFAbdallah Mahmoud75% (4)

- {7CD09A1D-735D-418D-B6D5-B51AD0715B72}Document48 pages{7CD09A1D-735D-418D-B6D5-B51AD0715B72}Pei Xin CheongNo ratings yet

- Suzlon S9X SuiteDocument8 pagesSuzlon S9X SuiteJuanPabloSánchezNo ratings yet

- Wind EnergyDocument32 pagesWind EnergyJohn MillerNo ratings yet

- V80 2mw Turbina PDFDocument6 pagesV80 2mw Turbina PDFAmer ZagorcicNo ratings yet

- Ergänzungsheft Zur Betriebsanleitung: VMP 5000-SteuerungDocument23 pagesErgänzungsheft Zur Betriebsanleitung: VMP 5000-Steuerungisterii100% (1)

- Vestas V 100 BrochureDocument16 pagesVestas V 100 BrochureAnaApcarianNo ratings yet

- D2075735-004 SGRE ON 6.0-170 Standard CT and Power Curve, Rev 0, AM 0 - Air DensityDocument6 pagesD2075735-004 SGRE ON 6.0-170 Standard CT and Power Curve, Rev 0, AM 0 - Air DensityMarcelo Gonçalves0% (1)

- Processor: Processor Date: 2. Dec 1997 Class: 2 Item No.: 941877.R4 1 of 13Document13 pagesProcessor: Processor Date: 2. Dec 1997 Class: 2 Item No.: 941877.R4 1 of 13Jorge EspinozaNo ratings yet

- Ge 2.5 and 3 MW PMSGDocument28 pagesGe 2.5 and 3 MW PMSGdaniyalahNo ratings yet

- User Manual - MSIMMA - Rev5 PDFDocument130 pagesUser Manual - MSIMMA - Rev5 PDFiuliiulianNo ratings yet

- 71 OFFSHORE2011presentationDocument19 pages71 OFFSHORE2011presentationJACKNo ratings yet

- Wind Turbine Vestas - V47Document6 pagesWind Turbine Vestas - V47سامح الجاسمNo ratings yet

- BONUS Wind Turbine - How A Wind Turbine Works - The Theory & Design of Modern Wind TurbinesDocument25 pagesBONUS Wind Turbine - How A Wind Turbine Works - The Theory & Design of Modern Wind TurbinesSPYDERSKILL100% (2)

- Nordex N117-2,4Document142 pagesNordex N117-2,4Ardei IuteNo ratings yet

- Hydraulic System, V80/V90 - 1.8/2.0 MW: History of This DocumentDocument33 pagesHydraulic System, V80/V90 - 1.8/2.0 MW: History of This DocumentHUNGNo ratings yet

- Siemens G4 Plant, S36 - 23804 - G4 - Offshore - 8ppDocument8 pagesSiemens G4 Plant, S36 - 23804 - G4 - Offshore - 8ppwvsonqNo ratings yet

- How Vestas Manufacture Wind Turbine NacellesDocument67 pagesHow Vestas Manufacture Wind Turbine NacellestpzunigaNo ratings yet

- 4MW Platform Brochure Q4 2020Document20 pages4MW Platform Brochure Q4 2020HAROLD EDMUNDO CALVACHE VALLEJONo ratings yet

- Arbox Reliability Collaborative Phase 3 Gearbox 3 Test PlanDocument76 pagesArbox Reliability Collaborative Phase 3 Gearbox 3 Test PlannawadaoNo ratings yet

- Stanford Paper On Wake EffectDocument6 pagesStanford Paper On Wake Effectdulika_12No ratings yet

- V52-850 KW UKDocument12 pagesV52-850 KW UKpunotchaNo ratings yet

- Repower Mm82 (50 Hz/2050 KW) : Product DescriptionDocument28 pagesRepower Mm82 (50 Hz/2050 KW) : Product DescriptionHarold CarrascoNo ratings yet

- Wind Turbine TheoryDocument50 pagesWind Turbine Theoryrini44fNo ratings yet

- Erection Instructions Tubular Steel Tower Up To 100 MDocument116 pagesErection Instructions Tubular Steel Tower Up To 100 MenantioagaNo ratings yet

- WTG Modeling-V601Document41 pagesWTG Modeling-V601Alberto Jimenez100% (1)

- GE Wind TutorialDocument30 pagesGE Wind Tutorialkeikunbr100% (1)

- D2356502-001 SGRE ON SG 6.0-170 Standard CT and Power Curve, Rev 0, AM-2 - Air DensityDocument6 pagesD2356502-001 SGRE ON SG 6.0-170 Standard CT and Power Curve, Rev 0, AM-2 - Air DensityMarcelo GonçalvesNo ratings yet

- Modbus Sunspec STP60-10 en PDFDocument58 pagesModbus Sunspec STP60-10 en PDFabual3ezNo ratings yet

- G-Series GT-3xxx Analog Input Modules RTD - TC Rev. 1.01Document42 pagesG-Series GT-3xxx Analog Input Modules RTD - TC Rev. 1.01Orhan DenizliNo ratings yet

- Wago-I/O-System 750: ManualDocument368 pagesWago-I/O-System 750: ManualMircea AndoneNo ratings yet

- G120 Lista de Parametros CU230-2Document668 pagesG120 Lista de Parametros CU230-2Ricky MclaughlinNo ratings yet

- Ag0103 6047802 en 3023 DeskDocument60 pagesAg0103 6047802 en 3023 Deskolivier.bigouretNo ratings yet

- Technical Information and ConfigurationDocument13 pagesTechnical Information and ConfigurationAli DiabNo ratings yet

- Operating Manual: SUNNY TRIPOWER 20000TL / 25000TLDocument50 pagesOperating Manual: SUNNY TRIPOWER 20000TL / 25000TLakbar installNo ratings yet

- SINAMICS G130-G150 Drive ManualDocument1,510 pagesSINAMICS G130-G150 Drive ManualSubhendu JanaNo ratings yet

- 1KHW000890 en NSD570Document562 pages1KHW000890 en NSD570jckrishnah100% (1)

- B0193ax2 - An-Integrated Control Block Descriptions (Vol 2) - (ECB - MOVLV)Document922 pagesB0193ax2 - An-Integrated Control Block Descriptions (Vol 2) - (ECB - MOVLV)zamNo ratings yet

- YD101 UsermanualDocument97 pagesYD101 UsermanualReymar S. Banaag100% (2)

- CAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitFrom EverandCAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitNo ratings yet

- Fuel Cell 10 KW Inverter SystemDocument60 pagesFuel Cell 10 KW Inverter Systemismailbej100% (1)

- EN - TB001502 Rev2 - Repair For Gas Leakage - Combi Built-InDocument4 pagesEN - TB001502 Rev2 - Repair For Gas Leakage - Combi Built-InismailbejNo ratings yet

- Induction Generators For Wind PowerDocument128 pagesInduction Generators For Wind Powerismailbej100% (3)

- Full-Scale Converter ABBDocument104 pagesFull-Scale Converter ABBismailbejNo ratings yet

- All Tenses One Document PDFDocument46 pagesAll Tenses One Document PDFismailbejNo ratings yet

- Indesit - Single Door Built-In - Repair For Gas Leakage Through The Evaporation RingDocument4 pagesIndesit - Single Door Built-In - Repair For Gas Leakage Through The Evaporation RingismailbejNo ratings yet

- Notice 005LB Washing Machines and Wash Dryers Functionality Check of Electronic ComponentsDocument43 pagesNotice 005LB Washing Machines and Wash Dryers Functionality Check of Electronic ComponentsismailbejNo ratings yet

- Root Islamic EducationDocument96 pagesRoot Islamic EducationismailbejNo ratings yet

- PPR Techincal Data SheetDocument0 pagesPPR Techincal Data SheetKrish ChennaiNo ratings yet

- BIOCNGDocument23 pagesBIOCNGDhruva DNo ratings yet

- Dsd-060 Earthquake Shutdown Unit: DescriptionDocument2 pagesDsd-060 Earthquake Shutdown Unit: Descriptionmuhammad arifNo ratings yet

- Green Building Rating Systems ExplainedDocument42 pagesGreen Building Rating Systems ExplainedJake CerezoNo ratings yet

- Regulator Capacitor Manual PDFDocument8 pagesRegulator Capacitor Manual PDFKyle StairNo ratings yet

- Axera 5-126 - 6232sd PDFDocument4 pagesAxera 5-126 - 6232sd PDFOscar Acevedo MirandaNo ratings yet

- 793 F Air SystemDocument9 pages793 F Air SystemWilson ClaveriaNo ratings yet

- Submissions - MMC Safety Program, MBFHI & Breastfeeding in The Workplace Orientation - Learning CheckDocument1 pageSubmissions - MMC Safety Program, MBFHI & Breastfeeding in The Workplace Orientation - Learning CheckAbis JohnNo ratings yet

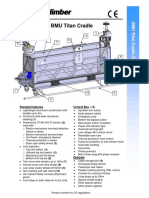

- BMU Titan Cradle: Standard Features Control BoxDocument2 pagesBMU Titan Cradle: Standard Features Control BoxKashyapNo ratings yet

- As-Built Drawing ListDocument14 pagesAs-Built Drawing Listsugeng wahyudi100% (1)

- Equity Research Report On Bajaj Finserv LTD Authored By: Mohammad Reza PoyaDocument6 pagesEquity Research Report On Bajaj Finserv LTD Authored By: Mohammad Reza Poyashraddha anandNo ratings yet

- Diagrama de Interconexion XL 200 PDFDocument9 pagesDiagrama de Interconexion XL 200 PDFjoseNo ratings yet

- Catalytic LEL SensorsDocument9 pagesCatalytic LEL Sensorsvibhor_748408347No ratings yet

- Response of Water Resources Systems To Climate ChangeDocument355 pagesResponse of Water Resources Systems To Climate ChangePat Prodanovic100% (5)

- Ючай каталог 1Document78 pagesЮчай каталог 1Евгений100% (1)

- CFBC Boilers & TG Set Auxillaries SpecificationsDocument18 pagesCFBC Boilers & TG Set Auxillaries SpecificationsJAY PARIKHNo ratings yet

- STW21NM50N MosfetDocument16 pagesSTW21NM50N MosfetrigowNo ratings yet

- Group 2 Financial Brick Case StudyDocument9 pagesGroup 2 Financial Brick Case StudyMDNo ratings yet

- r2 Hy-Optima 720as-Gc Technical Data SheetDocument1 pager2 Hy-Optima 720as-Gc Technical Data SheetMohammed SaberNo ratings yet

- Particulate Photocatalysts CRDocument67 pagesParticulate Photocatalysts CRYiou WangNo ratings yet

- Psychrometric Chart ReadingDocument10 pagesPsychrometric Chart ReadingEzakiman OtanimNo ratings yet

- Simulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel CellsDocument18 pagesSimulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel Cellswww.beatricechongNo ratings yet

- TM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceDocument221 pagesTM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceAdvocateNo ratings yet

- Green ConcreteDocument22 pagesGreen ConcreteQseem Khan100% (1)

- Thermiculite BrochureDocument8 pagesThermiculite BrochureXuan TruongNo ratings yet

- OCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Document12 pagesOCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Soham PatwardhanNo ratings yet

- Pompe Perkins 3340f261t PDFDocument2 pagesPompe Perkins 3340f261t PDFKamel BelhibaNo ratings yet