Professional Documents

Culture Documents

SY-8100 Manual Operacion

Uploaded by

JOse ArmentaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SY-8100 Manual Operacion

Uploaded by

JOse ArmentaCopyright:

Available Formats

Users Handbook

For

SY-8100 HPLC System

and

software of workstation

SY-8100 HPLC Chromatograph

CONTENT

CHAPTER ONE

PREFACE

SOPs in this manual...............................................................................................1

Unpacking ...............................................................................................................1

Packing list..............................................................................................................1

CHAPTER TWO

HPLC PUMP

Brief descriptions of HPLC Pump ..........................................................................2

1. Front view of HPLC Pump ..............................................................................2

2. Rear panel view of the HPLC pump ................................................................3

Operation of HPLC pump.......................................................................................4

1. Connection of power supply ............................................................................4

2. Users page characteristics and operation........................................................4

Simple Maintenance: ..............................................................................................7

1. Replacing and purging the pump head.............................................................7

HPLC pump technical parameters ........................................................................10

CHAPTER THREE

UV DETECTOR

Brief descriptions of UV Detector ........................................................................ 11

1. General description ........................................................................................ 11

2. Optical path of the UV detector ..................................................................... 11

Preparation of UV detector before the operation:.................................................12

1. Front view of UV detector .............................................................................12

2. Rear view of UV detector ..............................................................................14

3. Power supply, ON/OFF, and self-test.............................................................14

Operation of UV detector......................................................................................15

1. Internal software structure and menu explanation .........................................15

2. Installation of flow cell ..................................................................................17

1

SY-8100 HPLC Chromatograph

Simple Maintenance..............................................................................................18

1. Lamp maintenance .........................................................................................18

2. Cleaning the flow cell ....................................................................................18

3. Flow cell.........................................................................................................19

Technical data of UV detector ..............................................................................20

CHAPTER FOUR

CONNECTION

Connection of detector to HPLC system ..............................................................21

Connection of UV detector with computer ...........................................................22

CHAPTER FIVE

WORK STATION controlled instrument

Brief instructions of work station .........................................................................23

1. Characteristics of work station.......................................................................23

2. Running environment of work station software.............................................23

3. Integral environment of work station.............................................................24

Operation of work station .....................................................................................25

1. Preparation of work station before the operation...........................................25

2. Operation procedures of work station............................................................27

SY-8100 HPLC Chromatograph

CHAPTER ONE PREFACE

Thanks for purchasing Model SY-8100 Liquid Chromatograph developed by our company.

This device includes HPLC Pump,UV detector and software of work station. Read this manual

carefully before the operation.

SOPs in this manual

The Standard Operation Procedures (SOP) provided with this manual offer a convenient way of

structuring complex tasks in the operation of your HPLC pump and UV detector. They include

step-by-step instructions leading the user through all routine tasks during the operation. They can

be used for documentation purpose and be copied, applied signed, and filed in order to document

the performance of the instrument.

Please operate the instrument and all accessories according to instructions and SOPs in this

manual. This ensures proper results and longevity of the instrument.

Unpacking

Unpack the instrument and check the device and accessories thoroughly for any damage that may

have occurred during transport. If necessary, put forward any claim for damages to the carrier

and inform of your local dealer immediately.

Use packing list to check the device delivery is complete. Please contact your local dealer if you

miss something or if you need support. Please fill out the guarantee registration card and return it

to the local dealer immediately.

Remove the transport protections from the display.

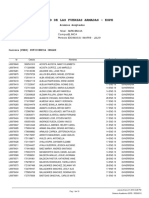

Packing list

Packing list (Standard delivery)

Quantity

HPLC Pump

1Set

UV Detector

1Set

Standard flow cell

1Pc.

Start-up kit,analytical

1Set

Operation manual

1Copy

Power cable 220V/10A

2Pcs.

RS232 Cable

1Pcs.

Software of work station

1Set

SY-8100 HPLC Chromatograph

CHAPTER TWO

HPLC PUMP

Brief descriptions of HPLC Pump

1. Front view of HPLC Pump

Fig. 1

Front view of Pump

1-Display information area

2- Foil key area

Display area and key area (1 and 2 in Fig.1)

Fig 2 Display area and key area

1-Display information area

2.1 Pump START/STOP

2.2-Purge START/STOP

2.3-Numeric key pad

2.4-Arrow keys and ENTER key

3-Pump front door

SY-8100 HPLC Chromatograph

Connections of piping (3 and 4 in Fig, 1)

Fig.3

Piping connection of Pump head with pressure transducer

3.1-Backflushing capillaries

3.3-Head set screws

3.5-Eluent outlet

4.2-Peek screws by hands

4.4-Eluent outlet

3.2-Outlet valve housing

3.4-Inlet valve housing

4.1-Inlets to transducer

4.3-De-areation screw

2. Rear panel view of the HPLC pump

Fig. 4 Rear panel view of the HPLC pump

4.1 Power connector

4.2 Fuse compartment

4.3 ON/OFF Switch

4.4 12V Ventilator

4.5 12V Ventilator

4.7 Gradient program trigger

4.8 Plug for solvent organizer

4.9 RS-232 Interface

SY-8100 HPLC Chromatograph

Operation of HPLC pump

HPLC pump is controlled by keyboard and work station of the computer control. The following

describes the operation of the keyboard. The work station of the computer control is described in

the Chapter four.

1. Connection of power supply

HPLC Pump is equipped with a universal power supply for input voltage 22020V Ac,

frequency 50 0.5Hz. 1KVA stabilizer is required. Connect the power cable to the socket on

the rear panel of the instrument and switch on the device with the ON/OFF key, see (4.1) and

(4.3) in Fig.4.

CAUTION: Make sure that the main power supply is properly grounded and a

correct three-pronged power cable is used. Connecting the instrument to faulty power

sockets can cause damages.

2. Users page characteristics and operation

Press the key in 2.2 of Fig.2 at any time to make system purge, again press this key to stop

purging.

CAUTION: If the purge is required, first loose PEEK screw by hands, see 4.2 in

Fig3, otherwise chromatographic column will be damaged!

Self-test page

After switching on the instrument, firstly enter into the self-test status, display the self-test page

as shown the follows:

BFRL

SY-8100 HPLC PUMP

RAM TEST OK

BFRL SY-8100 HPLC PUMP

EEPROM TEST OK

Page of switching on

FLOW0.00ml P.max 19.0 MPa

A

PRES 0.0mPa P.min 0.0 MPa STOP

Turn on the switch of the pump on this page. After completing the self-test of the pump, the

above page is appeared. Press 2.1 key in Fig.2 to make the pump START/STOP.

CAUTION: Never run the HPLC Pump without liquid in the pump head or in the piston

backflushing compartment. Operating the pump without solvent may lead to damage of the

pump seals

SOP 1:

4

SY-8100 HPLC Chromatograph

Press ENTER key, move the triangle cursor among Flow, P. max. and P. min.

As shown in Fig., the triangle cursor points Flow, use the numeric key for flow input, again

press ENTER key to confirm the setting. Therefore, the system flow is transferred to the flow

value of setting.

As the same operation, press ENTER key to move the cursor to P. max. and P. min.

The data value enables to be renewed with the same operation.

Press the arrow andkeys to enter into the other pages.

Vocabulary explanation:

Flow

Current flow of pump

P. max. Maximum pressure allowable for the system

A Pump Series number of Pump

Pressure Current pressure of pump

P. min.

Minimum pressure of system

Stop

Running status of pumpWhen pump stops, displayStop, when

running, displayRun

Gradient mode page

GE MODE: High-Pressure Gradient A

1: HP. GE A 2: HP. GE B

3: LP. GE

This page is the selection page of the gradient mode of the current pump

Press the numerical keys 1, 2 or 3, again press ENTER key to select the corresponding gradient

mode.

SOP 2

Press 1, 2 or 3 keys, again press ENTER key to select the corresponding gradient mode.

Press andkeys to enter into the other pages.

Vocabulary explanation:

HP. GE A Pump located in A pump system of binary high pressure system

HP. GE B B pump in binary high pressure system

LP. GE

Pump in quarter low pressure gradient system.

During the operation of high pressure gradient and low pressure gradient, the corresponding

setting is required in SY8000 chromatograph work station to realize the work station to fully

control the instrument.See the control section in the operation manual of data work station of

chromatograph.

Pressure zeroing page

Pressure zero Adj

ENTER to zero adj

This page is the pressure zeroing page. There is no need for the user to operate it. User can press

ENTER key to adjust the pressure zeroing unless PEEK screw is loosen and the pressure

value does not display the zero in the page of switching on the instrument.

SOP 3

5

SY-8100 HPLC Chromatograph

Press ENTER key to adjust the pressure to be the zero.

Pressandkeys to enter into the other pages.

Vocabulary explanation:

Pressure zero Adj Current pressure display value in the system is adjusted

to be the zero.

Status page

SN: 815299

Total time

Total volume

0.1 (H)

0.1 (L)

This page is a using status page of current pump, the user can not operate it any more.

SOP 4

Pressandkeys to enter into the other pages.

Vocabulary explanation:

SN Production series of the instrument, not series No. of the delivery

Total time

Accumulated using time of current pump.

Total volume Accumulated transfusion volume of current pump.

Remark page

BFRL HPLC PUMP

SN. 815299

Rev: 1.7

This page shows Model of HPLC Pump, Series No and Version No. It is not necessary for

the user to operate it.

SOP 5

PressandKeys to enter into the other pages.

Vocabulary explanation:

BFRL HPLC Pump

SN. 815299

Rev: 1.7

Model of instrument

Production number of instrument

Software version No.

SY-8100 HPLC Chromatograph

Simple Maintenance:

1. Replacing and purging the pump head

1.1 Disassembling the pump head

CAUTION: If the organic residential is remained in the pump head, it may cause the

skin irritation..

Use proper cleaning reagent to purge the pump head, and then to purge it with the distilled water.

After so, `the replacement for the pump head is made.

SOP 6:

1. LoosenEluent outlet, see Fig.33.5

Loosen inlet valve housing, see Fig. 3(3.4).

2. Use 3#3mmhexagonal spanner to loose fixing screws of pump head on the two

slanting angles, see Fig. 3 (3.3). Remove them.

3. Carefully loosen the rest two screws about half a turn, alternating from one to the other

to avoid the damaging the pump head. Unscrew the two screws strictly alternating due

to strong force of springs, it may be help to either clamp the pump head or to press one

of its side surfaces against a table with one hand and remove it.

4. Carefully remove the pump head

Disassembling and Check piston

SOP 7

1. Detach the pump head.

2. The piston is shown as Fig.511. A clipper (nipper) is available for detaching it.

Use the clipper to clamp the metal material part of the piston end and carefully pull it out along

on the straight line.

CAUTION:

If the piston is broken, the pump head must be thoroughly checked for the damage.

1.2 Detaching the pump head

1) Detach the pump head.

2) Detach the piston.

3) Loosen the two retaining plate screws as shown in Fig.520half a turn,

alternating from one to the other to avoid damaging the retaining plate.

4) Because the two screws are very tight, it may be help to either clamp the pump head or

to press one of its side surfaces against a table with one hand while loosening the

screws.

5) Unscrew the screws strictly alternating due to strong force of the spring behind the plate

as shown in Fig. 510and remove them.

6) Dismount the retaining plate, see Fig.512.

7) The moment, remove spring guide sleevesee Fig.519and spring:.

8) Use the spinner to loosen retaining nut as shown in Fig.59, half a turn alternately.

9) Remove Rear pump head as shown in Fig 517and take out15 and16.

10)Insert the piston into high pressure seal ring, and then pull it out. The moment, the

seal ring is adhered on the piston and take it out.

SY-8100 HPLC Chromatograph

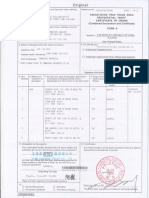

Disassemble diagram of the pump head and parts sequence.

Ser. No

Parts Name

Retaining screw of pump head

Front pump head

Front connection tube

High pressure seal ring

Stainless steel block ring

O- ring

Rear purge tube

Low pressure seal ring

Retaining bolt

10

Spring

11

Piston

12

Retaining plate

13

Valve sleeve

14

Single way valve

15

Plastic baffle ring

16

Rear purge tube

17

Rear pump head

18

Bushing

19

Guide for spring

20

Screw of retaining plate

Table 1

Pump head

SY-8100 HPLC Chromatograph

1.3 Assembling the pump head

All positions of components of the pump head refer to Fig 5

SOP 8

1. Detach the pump head to check it. After solving the problems, mount it into (4

15

and5at the front pump head in regular sequence.

2. After mounting the pump head, piston the head in a straight line onto the pump

housing (9and then take the piston out .

3. Mount spring guide sleeve and spring, see Fig.519and (10).

4. Install retaining plate, see Fig.512.

5. Insert and tighten the two screws strictly alternating due to strong force of the spring

behind the plate.

6. Alternating from one to the next, tighten two screws half a turn at a time on the

retaining board so as not to damage it.

7. Carefully insert the piston rod, see Fig.511without bending or quenching the rod..

8. Both the spacing bolts and retaining board screws must be tightened securely

as before.

1.4 Installing the pump head

SOP 9:

1. Make sure that the pump head has been correctly assembled.

2. Piston the head in a straight line onto the pump housing..

3. Tighten all four pump head set screws a few turns by hand, see Fig.510.

4. Alternating from one to the next, tighten two diagonally opposed screws half a turn at a

Time until the pump head is correctly seated

5. Tighten the two remaining screws. Make sure that all four pump head set screws are

Securely tightened, see Fig. 5 (1).

6. Mount the capillary connection between the pump head outlet and the pressure

transducer.

SY-8100 HPLC Chromatograph

HPLC pump technical parameters

Flow rate range:

Structure of Pump:

0.019.99 ml/min

Dual piston rod, series type oscillating

displacement pump

Flow accuracy

<1%

Flow reproducibility 0.5%

Pressure pulsation

<0.04MPa

Pressure range

042MPa

Remote control

RS-232 interfaceComputer control

System protection

Available for protection of minimum and

maximum pressures

Display

LCD 216

Dimension

350190210 mmLWX H

10

SY-8100 HPLC Chromatograph

CHAPTER THREE UV Detector

Brief descriptions of UV Detector

1. General description

BFRL UV detector is a valuable new type detectorespecially developed for the routine analysis.

The deuterium lamp is used as the light source of the instrument.

UV detector selects the flow cell of standard typeOptical path:10mmvolume:10Lthe flow

rate range of eluent phase of UV detector is available from 0.0019.999mL/min.

After powering up, the UV detector performs the self test and calibration automatically.

z The internal software includes an auto-calibration of the wavelength scale. The

position of the grating reflection (0. order) will be located automatically.

z The deuterium lamp with the wavelength of 656nm is used to check and to calibrate

the display.

The distance of the wavelength passed through the monochromator should be 1nm for per

step, arbitrary setting can be made in the range of 190nm to 740nm. Accuracy is 2nm.

In addition, UV detector still have the function of the whole wavelength or the wavelength

range set by user to process stopping the flow scanning.

UV detector provides with very low noise210-5AUand shift1510-5AU/havailable

for auto-zeroing of the full scale.

Key pad is clear, clean film, convenient for completing the operation.

The control and data acquisition of the UV detector is digitalization to secure running

without the trouble.

2. Optical path of the UV detector

1. Deuterium lamp

2. Slit

3. Filter

4. Concave mirror

5. Plane grating monochromator

6. Half transparent mirror

7. Flow cell

8. Photodiode (Sample)

9. Photodiode (Reference)

9.

Optical Path of UV detector

Instructions for optical path

A beam of emitted light from the deuterium lamp1is faded out by a slit2. After passing a

filter3 it is focused by a concave mirror4on a plane grating monochromator 5so

as to obtain a beam light of characteristic wavelength. The bream is then split by a half

transparent mirror6. One part beam delivers the reference signal9and the other after

pathing the flow cell7irradiates to photodiode (8) to produce the measurement signal.

11

SY-8100 HPLC Chromatograph

Preparation of UV detector before the operation:

1. Front view of UV detector

1.Display information area

Fig.7

2.Foil key pad

3.UV detcector front door

Front panel of UV detector and flow cell

Display area and foil key pad

Fig. 8

Display area and foil key pad

1. Display area

2. Control function key

3.Input key

4. Arrow key and ENTER key

Information display area

ABS0.0001 AU

LAMP IS LIT

WAVE

254 nm

Fig. 9

Display information area

Information display area displays real time parameters and result data of UV detector.

Foil key pad area

Foil key pad includes control function keyAuto-zeroing key and running program key,Data

12

SY-8100 HPLC Chromatograph

input key, arrows keys and ENTER key.

Auto

Zero

Prog

Auto-zeroing

Press this key to adjust the baseline of the instrumentbaseline returns to zero.

Normally press this key before the analysis. Use sampling valve of signal cable

(7725i) equipped with the instrument for sampling, the work station will

automatically control to process the zeroing adjustment for once at the same time

the valve is changed over. The moment, there is no need for user to press this key

again.

Running program

Press this key to run the wavelength scanning program set by user.

Data input key

As shown in Fig.83. Data input key is used to modify the operation parameters.

At the same time, CE key is set at the key areaCANCEL key. It is used to

cancel error parameters being input.

Arrow keys and ENTER key

As shown in Fig.84. Arrow keys are used to turn over the pages. Enter key is

used to confirm currently entered or selected parameters.

Flow cell area

Fig. 10

Flow cell area and flow cell

1. Knurled cell screw

2. Flow cell cradle

3. Inlet liquid

4. Cell body

5. Outlet liquid

Inlet liquid of the flow cell is connected to column, outlet liquid is connected to waste liquid

bottle or collecting device. Every constituent separated by the column is entered into the flow

cell to make the determination.

13

SY-8100 HPLC Chromatograph

2. Rear view of UV detector

Fig. 11

Rear view of

UV detector

1.RS232 interface

2.Remote terminal

3. Analog output

4. 24V ventilator

5.12V ventilator

6. Power switch

7., power socket

8. Slow melting fuse1A

3. Power supply, ON/OFF, and self-test

UV detector operates with 22020V AC of 500.5Hz. 1A slow melting fuse is used. The

setting is done by the manufacture on custom request. The actual setting is indicated on the

rear panel of the instrument (Fig. 12).

Caution:

Cut off power supply before opening cover.

22020V 500.5 Hz

100VA

FUSE: 1A SLOW

Fig. 12 Indication of the input voltage

CAUTION: Make certain that the correct voltage has been set on the rear panel of the

instrument, the power supply is reliably grounded and a corresponding 3-pole power cable

is used.

Connect the detector to the power supply. Switch on the instrument. Power switch is on the rear

part of the instrument.

After switching on, the instrument first performs the self-test as follows:

BFRL

RAM

UV/VIS

TEST

DETECTOR

OK

14

SY-8100 HPLC Chromatograph

BFRL UV/VIS

EEPROM TEST

DETECTOR

OK

>

Afterwards, display model of instrument and simultaneously the deuterium lamp is lit.

BFRL UV/VIS

Pre-heating

DETECTOR

Power on the instrument a time, the wavelength should be calibrated for once, display as

follows:

BFRL UV/VIS

Check Home Pos

DETECTOR

After a certain period of zeroing calibrationabout one minute, display as follows

BFRL UV/VIS

Wave calib

DETECTOR

The detector enters into the following page afterward. This page is also a acquiesce page of

UV detector

ABS

WAVE

0.0001 AU

254 nm

LAMP IS LIT

15 minutes later, UV detector is ready for the analytical determination.

Operation of UV detector

1. Internal software structure and menu explanation

The software is divided into several menus. Settings and operation modes are made on every

menu. Useand keys to enter into each menu as shown in Fig.13.

ABS

WAVE

0.0001 AU

254 nm

RESPONSE

LAMP IS LIT

1.00

0.0510S

Press [ENTER] TO Change

15

SY-8100 HPLC Chromatograph

D2 LAMP ENERGY

USED TIME 50.3 h

SMPL 0.794583

REF.

0.401205

SERIAL

825365

1:D2 OFF 2WAVE CALIB

Option

[Enter]

BFRL UV/VIS DETECTOR

SN. 825282

Rev: 1.70

Fig. 13

Menu sequence of UV detector

Describe every menu in details as follows. When the parameter on the menu is required to

modify, use the data input key to modify the setting of the corresponding parameter. Thus press

the ENTER keythe moment the value just input is confirmed. If error parameter is input, use

CEkey to delete it, then input the correct one according to the procedures mentioned above.

Signal menu

ABS

-0.0001AU

WAVE

254nm

LAMP IS LIT

Signal menuor main menuincludes: absorbancesignal intensityD2 lamp status and

wavelength. Absorbance is in unit of AU. D2 lamp status shows ON and OFF. The

wavelength is in unit ofnm.

The signal value for real measurement displays in four digits. The wavelength range is from 190

to 740nm for arbitrary setting.

Response time menu

RESPONCE

1.00 0.0510S

Press [Enter] TO Change

Use the response time (time constant) to make the signal smooth. Press ENTER key to select the

input. Respectively set: 0.050.100.150.200.250.300.350.400.450.500.55

0.600.650.700.750.800.850.900.951.001.502.002.503.003.504.00

4.505.006.007.008.009.0010.00sec. The value is more bigger, the signal is more smooth.

Time constant of 1second. is satisfied with the most of the analysis requirements.

D2 lamp energy and using time menu

D2 LAMP ENERGY

USED TIME 50.3 h

SMPL 0.794583

REF 0.401205

D2 lamp energy menu displayed is the energy values of ultraviolet light received from the

16

SY-8100 HPLC Chromatograph

photodiode on the reference signal board and the sample of the detector. These two energy

values can be directly known the energy of the deuterium lamp. If these energy values show too

small, replace D2 lamp on time.

The used time means the ignition time of D2 lamp.

Series No. and operation function menu

SERIAL 825365

1D2 OFF 2WAVE CALB

Option

[Enter]

Series No. means production series No. of the detector, not delivery series No.

Operation function menu includes:1OFF lamp

, 2Wavelength calibration. Respectively

input the numeric number corresponded to the operation function under this menu. Press

Enterkey to complete the corresponding function. For example: Complete the operation of

switching off the lamp, press the corresponding digit1under this menu and then pressEnter

key to finish the operation of OFF lamp. As the same, complete the operation of the wavelength

calibration, press the corresponding digit2on this menuafter so, pressEnterkey to finish

the operation of the wavelength calibration.

Identification menu

BFRL UV/VIS DETECTOR

SN. 825282

Rev: 170

Identification menu displays model and name of the instrument simultaneously display

production series number of the instrument and software version No. It is not necessary for the

user to modify any item in the identification menu.

2. Installation of flow cell

The flow cell of UV detector has not been delivered during transport. There is a dummy flow cell

without any of optics equipped with the instrument. Before the detector is used, a proper

standard flow cell must be installed.

CAUTION: There is no need to change the status of the instrument and the lamp

during the replacement of the flow cell.

SOP 1 Installation of flow cell

This instruction refers to UV detector as shown in Fig10 flow cell area and flow cell (see the

preparation of UV detector before the operation in the concerned section).

a) Loosen the two knurled cell screws (1) by hand and remove them.

b) Pull out the flow cell cradle (2).

c) Take the cell or dummy cell with two figures and remove it upward.

d) Insert the new flow cell and make sure engraved specification towards the user

(.can be read) and the fixing hole on the back side of the cell meets the

corresponding metal pin.

e) Now push the complete system towards the housing, insert the two screws and

tighten them manually.

17

SY-8100 HPLC Chromatograph

Simple Maintenance

1. Lamp maintenance

The deuterium used with UV detector has an extended lifetime to ensure long-time functionality

and reliable measurements with low noise and baseline drift as well as high sensitivity. (life time

about 2000 hours). The actual using time of the deuterium lamp depends on different factors, like

the number of lamp starts, the average burning time and your requirements concerning noise and

sensitivity.

To check the functionality of the lamp, the two intensity values of sample and referenceseeD2

lamp energy and used time menuthe help information for D2 lamp can be found there. The

reference value refers to the intensity of the light measured in the reference channel and be used

for checking the quality of the lamp.

We recommend to check the reference value at regular intervals under the conditions mentioned

abovedummy cell, = 240nm. This applies especially in case higher noise levels or decreased

sensitivity is observed on working with UV detector. In these observations coincide with a

reference value of approx. 0.1 or less, or used time is over 2000h, a new deuterium lamp should

be installed.

2. Cleaning the flow cell

Noisy baselines and low sensitivities may be due to a dirty flow cell. This may also be indicated

by a low absorbance value in the signal menu when flushing the cell with pure solvent. That

shows the flow cell has been polluted. In most cases it is sufficient to purge the flow cell

according to the following SOP.

SOP 1 Purging the flow cell

This instruction applies to the flow cell delivered with UV detector

a) Purge the flow cell using one of following solvents: sodium dodecyle sulfate

(SDS), 1m HCL, 1m NaOH, ethanol, or acetone.

b) Run the solvent through the flow cell using a syring and leave for approximately 5

minutes.

c) Rinse extensively with water and the blow dry using a gentle stream of pure

nitrogen.

CAUTION: Never dry with compressed air to blow the flow cell, this will contain

microdroplets of oil that will coat the cell.

CAUTION: When the optics module is not in use, disconnect the flow cell and clean

outer traces of salt and protein with a syringe filled with distilled water.

Before storing the flow cell inject a dilute solution (10-25%) of ethanol or

i-propanol to prevent microbial growth.

CAUTION: In case the flow cell purging do not provide sufficient success, all flow cells

can easily be disassembled for cleaning the lenses.

18

SY-8100 HPLC Chromatograph

3. Flow cell

Fig.17

Sectional view of

flow cell

SOP 2 Cleaning the flow cell

This instruction applies to the flow cells enclosed in UV detector.

a) Unscrew the outer threads with 3mm hexagonal spanner enclosed in the flow

cells delivery.

b) Remove the black gasket that carries the lenses with a pair of tweezers or by

gently tapping it on a clean surface. The lens is embedded in the gasket and sealed

against the flow path with PTFE seal. This seal should be changed every time

when assembling the flow cell.

c) Take out the lenses and clean them by wiping them with a soft cloth or with an

appropriate solvent in an ultrasonic bath. Be careful not to touch the lenses

with the figures.

d) Reassemble the cell in the reverse manner, making sure that PTFE seal does not

block the light path.

e) Tighten the outer threads carefully with the spanner in order not to damage the

lenses.

19

SY-8100 HPLC Chromatograph

Technical data of UV detector

Wavelength

Lamp

Wavelength accuracy

Scan function

Measurement range

Sensitivity

Noise

Baseline drift

Time constant

Integrator output

Auto-zero range

Display

Control

Power supply

Weight

Dimensions

190~740nm

Deuterium lamp

2nm

Spectral scanning

0~2AU

410-5AU at 240nm and time constant 1.0S

210-5AUat 240nm and time constant 1.0S

1510-5AUat 240nm and time constant 1.0S

0.0510.00

1.0V

Full scale

216Digits

RS232interface, analog output, remote connector

22020 V500.5Hz100VA

8Kg

350190210mm (LWH

20

SY-8100 HPLC Chromatograph

CHAPTER FOUR

Connection

Connection of detector to HPLC system

CAUTIONBefore taking a measurement cell filled with fluid into operation, please

make certain that the reagent used is miscible with that one used

previously. Or purge the flow cell with a medium miscible and two

miscible reagents.

The connection of the fluid piping in the isocratic system is shown in the following Fig.

Convenient for the instruction, the pump head represents HPLC pump and UV detector shows as

flow cell.

15

Isocratic HPLC system

Brief description of fluid system

a) Flow path of fluidAs shown above the Fig, Fluid is aspirated from sampling inlet

by HPLC pump, then flow into the sampling valve (2) from the fluid outlet,

afterwards, from the sampling valve (3) to the column. The fluid is entered into

the flow cell of the detector coming from the column. At last enter into the waste

liquid bottle or collection device.

b) Flow path of sampleAs shown in Fig 16, see the operation mode of the 7725i

sampling valveThe operation of 7725i sampling valve is divided into two parts:

preparation status and sampling status.

Preparation status

Fig. 16

Sampling status

Operation mode of 7725i sampling valve

Preparation status: The pump is directly connected with the columnconnection

of hole 2 with hole 3and the needle hole is connected with the sample ring. The

moment, use the sampling needle to aspirate 2-3 times sample (or more, to

21

SY-8100 HPLC Chromatograph

achieve the higher accuracy) of sample ring volume to inject it into the sample

ring. The residual sample is drained off through the discharge tube which is

connected with the hole 6.

Sampling status: The pump is connected with the sample ring (hole 1 and hole

2)Purge all of samples from the sample ring to the column. Needle port is

connected with the discharge tube (hole 5).

The sample under the sampling status is brought into the column by the fluid for

the separation.

Connection of UV detector with computer

UV detector is connected with computer by RS232 interface. The analytical result enables to

display in the software of HPLC chromatograph by this interface. The software of HPLC

chromatograph can be also realizing the modification of the detection parameters by this

interface..

RS-232 series interface is located on the back of the instrument as shown in Fig.11see the

section described in the preparation of UV detector before the operation. Use this interface to

connect the computer installed the software of HPLC chromatograph with UV detector.

The series interface of the computer is directly connected with this interface.

22

SY-8100 HPLC Chromatograph

CHAPTER FIVE

Work station controlled instrument

Brief instructions of work station

The work station controlled SY-8000 series HPLC Chromatograph is a specialized instrument

controlled software. To realize full control of the instrument, user can input control parameters of

the instrument in the work station for controlling running of the instrument so as to avoid the

operation on the instrument panel manually.

The section only describes how the work station to control the instrument, the data processing of

the work station refers to operation manual of SY-8000 Chromatograph work station.

1. Characteristics of work station

All in one data file structure: including method file, data file, report module file and sample

queuing file.

Method file---- including peak integral parameter, quantitative parameter, constituent table,

calibration curve, report format, method information and instrument conditions, etc. File

expended namemth, file path as work station directory\mth.

Data file--------- including chromatogram data, sample information, peak table, analytical result

and method. File extended name DAT, file path at will.

Report module file---Save the required parameters for printing the specialized report. File

extended name flm, file path as work station directory\REP.

Sample queuing file----Save sample name, multiplier and divisor, etc. File extended nameSDL,

file path at will. It is available for analyzing the batch sample continuously.

There are another three files including in the data file. Those three files are respectively

independent file. It is very convenient for user to recall the required file freely. The structure of

all in one data file can be able to open the file from the method file, or from the sample data file.

Custom report tool: The custom report editor provides the user for self designing the report

content and the required format. It is similar to the character treatment program. Therefore, the

characters, color and margin for page can be changed and available to drive block (the block is

copied to the cut and paste board, and then the block is adhered to word or wps file). Insert the

chromatogram, graphics, system information and format, etc to let user flexible edit the required

report, adjust its appearance, contents and location.

The report module is used to control the printing format file in the chromatograph work station.

All of parameters required for printing the report are saved in the report module file and these

parameters will directly influence on the report appearance. The report module can be designed

by yourself with custom report (custom report editor). The report designed can also be saved

as a new module. The system is automatically acquiesced and the module file extended name

is flm , Saving path: installation directory of work station\REP.

Multi-chromatogram result report: The custom report editor still provides the analytical function

of multi-overlapped chromatogram. That means, If multi-parallel experiments are required for

testing the reproducibility and the average value, the report system will directly calculate result

mean value.

Prompt operation page: Pages are very clear, easy operation. Such as: editing page of all

parameters in the method file is saved in the window of the method file edition in form of cards.

2. Running environment of work station software

Hardware: Better 586, CPU

23

SY-8100 HPLC Chromatograph

Better 64M

One free series interface on the system board (COM1 and COM2)

VGA Color display (better use an accelerated card of graphics)

Optical drive

Mouth

Printer

Software: Better Windows 20000 operation system

3. Integral environment of work station

Double-click the graphic of chromatograph work station on the table to enter into the intergral

environmental page of work station.

Main menu

Prompt button

Running indicating lamp

Spectrogram display window

Information line

Fig 1

The main page of the integral environment consists of five parts: main menu, graphic display

window, prompt button, controlling menu, running indicating lamp and information line.

Main menu

As same as the other application program, according to the different requirement of treating data,

all of the function commands are classified, after so, respectively put them into eight menus, so

every menu has own group commands.

Prompt button

Some common used functions in the main menu are marked on these buttons with display

presentation. Therefore, these functions in common use can be directly selected by pressing the

concerned button without selecting it from the menu in order to speed up the operation.

Spectrogram display window: including plotting area, time coordinate scale, level coordinate

scale and peak hold time.

Plotting areaActively display the real time spectrogram area, the sizes can be automatically

adjusted with the size change of the spectrogram display window. When the user makes the

spectrogram display window shortening to a certain extent, the system automatically delete the

24

SY-8100 HPLC Chromatograph

plotting coordinate scale and display of the hold time to secure observing the graphics clearly

even in a small size window.

Time coordinate scaleIt is used as X axle coordinate scale, in unit: Min. The initial value is

automatically adjusted with the change of the sampling time. Modify the full time difference on

screen plotting parameter edition, minimum time is 1min.

Level coordinate scaleIt is used as Y axle coordinate scale of the spectrogram plotting, in

unit : Mv. Modify the full scale maximum value and minimum value on screen plotting

parameter.

Peak hold time During starting sampling, automatically display the hold time after

appearing the chromatograph peak top. In the screen plotting parameter edition, select no

display the hold time to close it.

Running indicating lamp

The red lamp is flash when the data is acquiring, while the green lamp is lit under the state of

preparation

Information line

It displays currently inputting level, sampling time, current sample name and current time.

As the main page mentioned above, when you select some command in the main menu or

single-click some of prompt button, the corresponding window or dialogue block will be

appeared.

Operation of work station

1. Preparation of work station before the operation

Before operating the work station, SY-8000 series HPLC Chromatograph should be connected

with the computer installed the work station software. Power the instrument on. When

completing the self test of the instrument, the computer displays the following page, That shows

the connection of the computer is successful.

Current Wavelength

Success for the connection

Current

setting

flow

Fig 2

25

Current

pressure

of

SY-8100 HPLC Chromatograph

After success for the connection of the instrument with the computer, the operation page of the

work station simultaneously display current setting flow speed and current pressure of pump and

current wavelength of UV detector.

If the instrument failed to connect to the instrument, under instrument control menu, make

setting of communicating terminal and let the terminal number of the setting be in accord with

the terminal number connected with the instrument shown as the following figure:

Setting of communicating terminal

Fig. 3

After success for the connection of the instrument with work station, firstly click Pump or

Detector on the work station, check the setting of working parameters of the pump and

detector as shown in the following:

Setting of pump

Fig. 4

26

SY-8100 HPLC Chromatograph

Setting of detector

Fig. 5

The pump requires to set the control mode (control mode divides: single pump, double pump

running independently, double pump high pressure gradient and single pump low pressure

gradient), If using gradient table, pump flow and up limit and down limit of pressure; Detector

requires to set the wavelength and deuterium lamp status, if using the wavelength program table,

etc. The sensitivity of the detector is set by the acqueuiescence. The spectral scanning is set

according to the concerning conditions when it is required.

2. Operation procedures of work station

Use the work station software to do the experiment after the settings mentioned above. As

example for outer standard method as follows:

Operation procedures of outer standard method

1. Create a new method file parameter to do the experiment. Its procedures are as follows:

1) Start HPLC chromatograph and work station software;

Fig. 6

27

SY-8100 HPLC Chromatograph

2) Record parameters of editing data

Signal-click the graphic of data record parameter to appear the window of the method editing,

set the position of file storage.

Fig.7

3) Editing integral parameter

Single-click the graphic of integral parameter to appear the window of the method edition.

Where set the integral parameter value and edit time program table, If it is not set any, only

press the acquiescent value.

Fig. 8

4) Edit sample information table

Click the graphic of sample information, edit sample information table, define the name of

the experimentalized data file as sample name as shown in the following:

28

SY-8100 HPLC Chromatograph

Fig.9

5) Standard sample anslysis

When running the chromatograph stable, input the standard sample. During valve sampling, at

the same time, the program automatically process the data acquisition to the spectragram, and

remark the hold time. When all of peaks are appeared, stop the program manually, or set stop

time in integral parameter table to stop it automatically.

6) Sample analysis

Input the unknown sample. As same as the procedures 5. (this step can be made at last.) Data file

obtained from the procedures 5 and 6 will be saved automatically by the system.. The data files

are automatically, continuously named. Such as: Test001.dat, Test002.dat, Test003.dat..

7) Draft the calibration curve

a. Edit the quantitative parameter

Click the graphic of the quantitative parameter to appear the window of the method

edition:

Fig. 10

Set well quantitative mode, quantitative method (outer standard method), standard

( eight concentration standard sample, select eight points), standard concentration

unit and sample result unit.

b. Filling in constituent table

Click the graphic of constituent table to appear the window of the method edition, fill in

the analytical sample constituent table name, hold time and series standard concentration.

29

SY-8100 HPLC Chromatograph

Fig.11

c. Definition calibration curve

a) Click the graphic of calibration curve to appear the window of the method edition.

Fig.12

b) Definite spectrogram peak file required at every point. Firstly use the mouth to move

to the point number of the standard sample, then click the right key, this number is

covered by blue frame, again click the left key to select the menu:

Fig.13

c) Select Add item (this operation shows at the same concentration point, add the data

30

SY-8100 HPLC Chromatograph

of several parallel experiment to calculate the mean value), the window of

spectrogram selection is appeared.

Fig.14

Here select the corresponding spectrogram file. + appears before the file of sequence

number point. After completing the definition foe every points, click re-read peak file to

display the calibration curve.

8) Check sample result

Enter re-treatment page, click the graphic of open data file to appear the window of

spectrogram selection, select the sample spectrogram file here as follows:

Fig.15

And then click the button of re-calculate, Again click the graphic of screen report to look at

the screen report table.

31

SY-8100 HPLC Chromatograph

Fig.16

9) Printing report

2. Recall the method file parameters originally saved to do the experiment.

1) Use the mode of open method

Select open method in file menu of work station, appear the window of method file

selection, select the method file here as shown as follows:

Fig.17

Sampling is directly made after recalling the method file without the operation procedures from

1-7. After the experiment, the step 8 is made directly to look at the sample content.

2) Use mode of open method from data

Select open method from data in file menu of work station (it is another mode for recalling

the method file, only recall the method file with the date), appear the window of spectrogram

selection, the moment, select the method file here as shown as the follows:

32

SY-8100 HPLC Chromatograph

Fig.18

The descriptions as same as the method above mentioned, Sampling analysis can be made after

recalling the method file without the operation procedures from 1-7 steps. The procedure of step

8 is made after completing the experiment in order to directly obverse the sample content.

33

You might also like

- Manual Phmetro Altronix PDFDocument22 pagesManual Phmetro Altronix PDFMatias OliveraNo ratings yet

- P - Block Elements 12th (All)Document63 pagesP - Block Elements 12th (All)Kaveeth Ariyha0% (1)

- Tutorial # 1 - KineticsDocument7 pagesTutorial # 1 - KineticsbebsybiswezNo ratings yet

- 6211 MetanoDocument3 pages6211 MetanoPenelope MeloNo ratings yet

- Conceptos Basicos CronocoulomDocument3 pagesConceptos Basicos Cronocoulombettypaz89No ratings yet

- RMN ProblemsDocument7 pagesRMN ProblemsAnonymous llSDP0tNo ratings yet

- Synthesis of Isobutyl AcetateDocument7 pagesSynthesis of Isobutyl AcetateRandy DavenportNo ratings yet

- Functional Group TestsDocument2 pagesFunctional Group TestsSalman HusainNo ratings yet

- Electrochemical Study of A Commercial SoapDocument4 pagesElectrochemical Study of A Commercial Soap12jagNo ratings yet

- Problem Set 1Document3 pagesProblem Set 1Lu JunqueiraNo ratings yet

- The Significance of The 260 230 Ratio in Determining Nucleic Acid PurityDocument2 pagesThe Significance of The 260 230 Ratio in Determining Nucleic Acid Purityraubn1110% (1)

- POGIL Intermolecular ForcesDocument7 pagesPOGIL Intermolecular Forcesdemyeets64No ratings yet

- C.G. Granqvist Eds. Materials Science For Solar Energy Conversion SystemsDocument208 pagesC.G. Granqvist Eds. Materials Science For Solar Energy Conversion SystemsmedelaidNo ratings yet

- The Acid Base Titration of A Very Weak Acid: Boric Acid: M. Celeste C. Azevedo and Ana M. V. CavaleiroDocument4 pagesThe Acid Base Titration of A Very Weak Acid: Boric Acid: M. Celeste C. Azevedo and Ana M. V. CavaleiroAitor PastorNo ratings yet

- C01 14PDocument33 pagesC01 14PTiffany LiuNo ratings yet

- Application of ANOVADocument19 pagesApplication of ANOVAabhay_prakash_ranjan100% (2)

- Lecture5 - Chemical Oxygen Demand PDFDocument40 pagesLecture5 - Chemical Oxygen Demand PDFgagileNo ratings yet

- 1-Phenylethanol H-NMR PDFDocument2 pages1-Phenylethanol H-NMR PDFkobir960% (1)

- CH20Document88 pagesCH20Zakria ToorNo ratings yet

- Problema 5Document2 pagesProblema 5PepeArandaNo ratings yet

- Urea PhenolDocument21 pagesUrea PhenolMarthaLuceroPerezNo ratings yet

- ESS LAB REPORT Online SimulationDocument7 pagesESS LAB REPORT Online SimulationhanirveshNo ratings yet

- CHM 132 Journal 1Document12 pagesCHM 132 Journal 1Michelle TagalogNo ratings yet

- VinegarDocument14 pagesVinegarLynn HeimatotoNo ratings yet

- Thermodynamics of The Ionization ofDocument2 pagesThermodynamics of The Ionization ofNicolás PeñaNo ratings yet

- HPLC Simulator Exercise - VithaDocument5 pagesHPLC Simulator Exercise - Vitharodrigue yanNo ratings yet

- Chromatography: The Separation Technique of The 20th CenturyDocument11 pagesChromatography: The Separation Technique of The 20th CenturyAnonymous qOxE6C7kNo ratings yet

- Diapositiva de Recursos Humanos 1: Total Synthesis of CoprinolDocument22 pagesDiapositiva de Recursos Humanos 1: Total Synthesis of CoprinolAngelOrtegaZarcoNo ratings yet

- Especific HeatDocument18 pagesEspecific HeatRafaela RibeiroNo ratings yet

- Development of Solvay Clusters of Chemical Reactions PDFDocument11 pagesDevelopment of Solvay Clusters of Chemical Reactions PDFJordan Lopez FernandezNo ratings yet

- Book of Abstracts RAA2011Document241 pagesBook of Abstracts RAA2011Vornicu NicoletaNo ratings yet

- Thermodynamic & Chemical Equil PDFDocument710 pagesThermodynamic & Chemical Equil PDFbitconcepts9781No ratings yet

- Campus El IncaDocument10 pagesCampus El IncaEddy FernandoNo ratings yet

- Thermodynamics TutorialDocument2 pagesThermodynamics TutorialMuhamad Hazim Zaaba0% (1)

- Espectrofotómetro Ftir C103-E076a Iraffinity-1Document28 pagesEspectrofotómetro Ftir C103-E076a Iraffinity-1Gustavo RuizNo ratings yet

- CPP Assignment 1Document2 pagesCPP Assignment 1AmandaEdwinNo ratings yet

- Partial Molar Volumes From Refractive Index MeasurementsDocument4 pagesPartial Molar Volumes From Refractive Index MeasurementsFelipe Antonio Vasquez CarrascoNo ratings yet

- TonicityDocument2 pagesTonicityamethyst grandeNo ratings yet

- Air Stripping of AcetoneDocument19 pagesAir Stripping of AcetoneGabe100% (1)

- Randles-Sevcik Equation - WikipediaDocument6 pagesRandles-Sevcik Equation - WikipediaRoger GonçalvesNo ratings yet

- Homework 2-S15 (1) Chem E 178Document1 pageHomework 2-S15 (1) Chem E 178siegeddNo ratings yet

- EJERCICIOS DISTR ContinuasDocument3 pagesEJERCICIOS DISTR ContinuasJulio IbarraNo ratings yet

- Organic Chemistry QuizDocument7 pagesOrganic Chemistry QuizCarlo Jay BasulNo ratings yet

- Cyanide Spectroquant 114561 WW Method 1999 PDFDocument20 pagesCyanide Spectroquant 114561 WW Method 1999 PDFSantos Edwin Cari ApazaNo ratings yet

- Worksheet 2Document2 pagesWorksheet 2Abrhsh100% (1)

- Semibatch UniDocument22 pagesSemibatch UniMelgi159100% (1)

- Sma2217 Stat WS1 PDFDocument7 pagesSma2217 Stat WS1 PDFQuantNo ratings yet

- AOAC 971.27. Sodium Chloride in Canned VegetablesDocument1 pageAOAC 971.27. Sodium Chloride in Canned VegetablesGerman AyalaNo ratings yet

- Cryoscopic Constants For Calculation of Freezing Point DepressionDocument1 pageCryoscopic Constants For Calculation of Freezing Point DepressionantonioNo ratings yet

- Hydrolysis of Tert-Butyl Chloride and Solvent EffectDocument7 pagesHydrolysis of Tert-Butyl Chloride and Solvent EffectangelbenavidezNo ratings yet

- Tarea I FQ II SOLUCIÓN PDFDocument7 pagesTarea I FQ II SOLUCIÓN PDFRoberto Daniel Rivera CastroNo ratings yet

- DLAB Low Temp Circulator&vacuum Controller CatalogDocument3 pagesDLAB Low Temp Circulator&vacuum Controller CatalogasfsdfNo ratings yet

- Electrochemistry Exercises - SolutionsDocument19 pagesElectrochemistry Exercises - SolutionsHữu ĐứcNo ratings yet

- Tablas Alcoholimetricas BDocument3 pagesTablas Alcoholimetricas Bfgranobles100% (1)

- FLASH ADIABÁTICO - Separation Process Principles - SEADER - 3rdedDocument5 pagesFLASH ADIABÁTICO - Separation Process Principles - SEADER - 3rdedMaykkkowNo ratings yet

- Vapor Liquid Equilibrium Diagrams of Binary SystemsDocument2 pagesVapor Liquid Equilibrium Diagrams of Binary SystemsMaximus MishraNo ratings yet

- Experiment2 18052012Document3 pagesExperiment2 18052012Abhishek Shetty100% (1)

- SOP05-5002F Service Manual ProlyteDocument41 pagesSOP05-5002F Service Manual ProlyteRogger Ruffini100% (1)

- RT-7600-Service Manual PDFDocument39 pagesRT-7600-Service Manual PDFAlexey82% (11)

- DP CalibrationDocument12 pagesDP CalibrationGeorge AsuncionNo ratings yet

- Kids and Their Favourite Food Key Reading Comprehension Exercises - 34436Document2 pagesKids and Their Favourite Food Key Reading Comprehension Exercises - 34436MonicaMartirosyanNo ratings yet

- Hinomoto Tractor Parts Catalogue 2018 C144, C174, E150, E180, E230, E250, E280, E384Document63 pagesHinomoto Tractor Parts Catalogue 2018 C144, C174, E150, E180, E230, E250, E280, E384Monica Mascarenhas0% (1)

- MOE XT2-XT4 110... 125V Ac/dcDocument3 pagesMOE XT2-XT4 110... 125V Ac/dcLê Xuân ĐịnhNo ratings yet

- bNSG9000 Datasheet 2Document3 pagesbNSG9000 Datasheet 2RobertNo ratings yet

- Final Tana Beles - pdf2222Document72 pagesFinal Tana Beles - pdf2222Tiruneh Yeneneh100% (1)

- Wire Rope Forensics Letter PDFDocument50 pagesWire Rope Forensics Letter PDFAshley DeanNo ratings yet

- Formula SheetDocument16 pagesFormula SheetgwerNo ratings yet

- Type of TrucksDocument8 pagesType of TrucksYojhan VelezNo ratings yet

- Bleeding Disorders and Periodontology: P V & K PDocument13 pagesBleeding Disorders and Periodontology: P V & K PAdyas AdrianaNo ratings yet

- Therelek - Heat Treatment ServicesDocument8 pagesTherelek - Heat Treatment ServicesTherelek EngineersNo ratings yet

- AdsfatreewerwertgdsfDocument1 pageAdsfatreewerwertgdsfJhonel AguilarNo ratings yet

- Sperm Cell: Specialised CellsDocument2 pagesSperm Cell: Specialised CellsRhynnieNo ratings yet

- Factory Program Library List v1.0Document9 pagesFactory Program Library List v1.0Ronaldo DamattaNo ratings yet

- Nfpa 13d 2007 IndexDocument3 pagesNfpa 13d 2007 Indexsaladin1977No ratings yet

- N100 Rle Back MassageDocument24 pagesN100 Rle Back MassagerlinaoNo ratings yet

- Federal Bylaw 12 Air Pollution 2006 English Translation v2 OCRDocument63 pagesFederal Bylaw 12 Air Pollution 2006 English Translation v2 OCRIsmail SultanNo ratings yet

- Catalogo Smartline Transmitter Family Ferrum Energy 变送器Document12 pagesCatalogo Smartline Transmitter Family Ferrum Energy 变送器peng chaowenNo ratings yet

- Symmetry & Space GroupsDocument49 pagesSymmetry & Space GroupsfaysaljamilNo ratings yet

- 9trffi&hpr.! Ni-: Use E EDocument2 pages9trffi&hpr.! Ni-: Use E ERafi ZulfiNo ratings yet

- Hibon - SN Ingersoll Rand BlowerDocument7 pagesHibon - SN Ingersoll Rand BlowermarquezsiemNo ratings yet

- SCSM 2022 Runners Information GuideDocument36 pagesSCSM 2022 Runners Information GuideDollar SurvivorNo ratings yet

- Optimizing With eGaN FETsDocument6 pagesOptimizing With eGaN FETskhsniperNo ratings yet

- Architecture of HimalayasDocument3 pagesArchitecture of HimalayasAndrea CaballeroNo ratings yet

- Adsorption Processes For Water Treatment and Purification PDFDocument266 pagesAdsorption Processes For Water Treatment and Purification PDFVictor Rezende Moreira100% (1)

- Topic 2 P2: MarkschemeDocument58 pagesTopic 2 P2: MarkschemeZihil ShahNo ratings yet

- Street Design Manual NYCDocument312 pagesStreet Design Manual NYCgonleoNo ratings yet

- Vivo X5Pro Smartphone Specifications: Brand and ModelDocument4 pagesVivo X5Pro Smartphone Specifications: Brand and ModelEric AndriantoNo ratings yet

- Slidex StrepDocument9 pagesSlidex StrepLizeth Daniela RojasNo ratings yet

- Philippine Airlines Reservation New Timings Dep - 230314 - 193643Document7 pagesPhilippine Airlines Reservation New Timings Dep - 230314 - 193643sophia buiserNo ratings yet

- Interactions of Microplastic Debris Throughout The Marine Ecosystem Final Tracked-Galloway, TS Cole, M Lewis, CDocument22 pagesInteractions of Microplastic Debris Throughout The Marine Ecosystem Final Tracked-Galloway, TS Cole, M Lewis, CTrydawNo ratings yet