Professional Documents

Culture Documents

Pocket Lighter Patent from 1936 Describes Zippo Design

Uploaded by

Rakesh0 ratings0% found this document useful (0 votes)

66 views3 pagesThis document is a 1936 patent for an improved pocket lighter design. It describes a lighter with a hinged cover that is held closed by a concealed lever mechanism. The lever is pivotally mounted and has a toe portion that interacts with a spring-biased plunger to lock the cover in the open or closed position, without any exposed latches. This provides a simpler and more durable lighter design that prevents accidental opening while maintaining a large fuel capacity within a compact size.

Original Description:

novel pocket lighter

Original Title

Lighter

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a 1936 patent for an improved pocket lighter design. It describes a lighter with a hinged cover that is held closed by a concealed lever mechanism. The lever is pivotally mounted and has a toe portion that interacts with a spring-biased plunger to lock the cover in the open or closed position, without any exposed latches. This provides a simpler and more durable lighter design that prevents accidental opening while maintaining a large fuel capacity within a compact size.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

66 views3 pagesPocket Lighter Patent from 1936 Describes Zippo Design

Uploaded by

RakeshThis document is a 1936 patent for an improved pocket lighter design. It describes a lighter with a hinged cover that is held closed by a concealed lever mechanism. The lever is pivotally mounted and has a toe portion that interacts with a spring-biased plunger to lock the cover in the open or closed position, without any exposed latches. This provides a simpler and more durable lighter design that prevents accidental opening while maintaining a large fuel capacity within a compact size.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

March 3, 1936.

G, GIMERA ET AL

2,032,695

POCKET LIGHTER

Filed May 1'7, 1954

INVENTORS

Err-Easels

Ma. Ma -

' @&?7hii?%

2,032,695

Patented Mar. 3, 1936

UNITED STATES PATENT OFFICE

2,032,695

POCKET LIGHTER

George Gimera and George G. Blaisdell, Brad

'

ford, Pa., assignors to Zippo Manufacturing

Company, Bradford, Pa., a partnership con

sisting of- George G. Blaisdell, W. G. Blaisdell,

Frank W. Calkins, George Gimera, and George

B. Morris

Application May 17, 1934, Serial No. 726,022

lClaim. (crew-7.1)

curved sides are likewise provided with integral

This invention relates to pocket lighters of the extensions

or lugs l and 8 disposed in pairs at

hinged/cover type.

the front and rear, respectively, of the wind

Pofzket lighters having covers hinged on their

upper endsmust have means for holding them

closed it they are to be satisfactory, and it is

also desirable that they have means for prevent

ing the covers from closing prematurely and ex

tinguishing the ?ame after they are opened. In

lighters known heretofore these means take the

ll) form of exposed latches and interior springs and

levers which take up space in the lighters and

reduce their storage capacity for in?ammable

lighter ?uid. Furthermore, the exposed latches

are apt to catch in and wear the clothing, to be

accidentally actuated in the pocket, and to ac

cumulate dirt. Such lighters are complex and

frequently get out of order, while they must be

constructed in a cheap manner in order to be

salable at a low price.

It is among the objects of this invention to

:0

provide a pocket lighter having a minimum of

projections from its closed case, and in which

movement of the cover from either its fully open

or its fully closed position is restrained by sim

ple means concealed when the lighter is closed.

Further objects are to provide such a lighter

having large storage capacity for lighter fuel,

which is easy to ?ll, is strong and durable, and is

simple in design and construction with a mini

mum of moving parts.

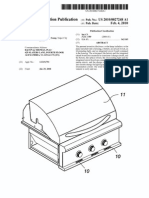

The preferred embodiment of the invention is

illustrated in the accompanying drawing, of which

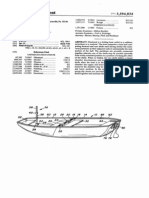

Figs. 1, 2 and 3 are, respectively, perspective, side

and top views with the cover open; Fig. 4 is a

central vertical section through the lighter with

its cover closed; and Fig. 5 is a side view with the

cover closed.

Referring to the drawing, a casing is provided

consisting of two telescopically disposed hollow

40

members, the inner member I being substantially

coextensive with the outer member 2 and having

a very snug sliding fit therewith.

The outer

member is closed at its lower end. A top plate 3

closes the upper end of inner member I, which

is preferably formed from a section of seamless

tubing. This forms in the casing a reservoir for

in?ammable lighter fuel, such as gasoline, which

is carried by a stui?ng of saturated cotton waste.

The upper edges of the side walls of the inner

member are provided with upright integral exten

sions, the central portion 4 of each having its

sides curved inward over the top plate toward

the opposite extension to form a generally ellipti

cal wind screen in which a plurality of draft

openings 6 are punched (Figs. 1 and 3), These

screen, the lugs of each pair being disposed in

spaced parallel relation longitudinally of top ,

plate 3.

In the front pair of lugs I there is journalled

a toothed wheel 9 which engages the upper end

of an elongate ?int H slidably disposed in an

opening through top plate 3. The ?int is con- 10

stantly held in frictional engagement with the

toothed wheel by a coil spring l2 (Fig. 4) com

pressed between the bottom of the ?int and a

set screw l3 threaded in the lower end of a tube

l4 depending from top plate 3. The toothed 15

wheel is adapted to throw sparks, when rotated

by the thumb, from the ?int to a wick l6 sur

rounded by the wind screen and projecting into

the fuel reservoir through a hole in top plate 3.

In order to protect the projections at the top 20

of the casing, as well as the clothing, the casing is

provided with a cover l8 which is connected at

its rear wall to the rear wall of outer telescop- '

ing member 2 by means of a small hinge l9. As

will be observed in Fig. 5 of the drawing, there 25

are no projections from the lighter other than

this hinge when the cover is closed. However,

as it is desirable that the cover remain closed ex

cept when the operator opens it, means is pro

vided for accomplishing this object without ex 30

posing anything which might catch in and wear

the pocket or he accidentally actuated.

Accordingly, a lever 21 is plvotally mounted

at one end between the rear pair of lugs 8 so

that it can be swung from an upright position, 35

as shown in Fig. 4, to a substantially horizontal

position, as shown in Fig. 2, and vice versa.

The lever resists movement from both its up

right and horizontal position because its pivot

ed end is provided with a laterally projecting 40

toe portion 22 which must depress a spring-bi

ased plunger 23, slidably disposed in an opening

through top plate 3, as the lever moves from one

of said positions to the other. The spring 24,

which biases the plunger against the pivoted end 45

of the lever radially of its pivot axis, is com

pressed between the bottom of the plunger and

the lower end of a closed tube 26 secured in the

inner telescoping member I. When the lever is

substantially upright the pressure of the plunger 50

against the under side of toe 22 biases the lever

toward the wind screen (Fig. 4).

When the cover is closed it is held in that po

sition by the upright lever bearing against the

rear side of a cross member 21 secured in the 65

2,032,695

cover transversely thereof adjacent its rear wall

(Fig. 4). As the cover is swung open by the

thumb, cross member 21 swings the lever back

ward and downward, toe 22 depressing the plung

er against the resistance of spring 24 as the toe

slides over the plunger. Continued movement

of the lever causes the end of the toe to slip of!

the plunger, whereupon the latter quickly rises

and snaps the lever togtsrhorizontal position, as

10 shown in Fig. 2, the outer end of the lever snap

ping against the rear wall of the cover which

is thereby thrown wide open.

Self-closing or premature closing of the cover

is prevented by this rear wall striking the end of

the lever whose upward and forward movement

the plunger and toe 22 cooperate in restraining.

However, the cover is easily closed by the opera

tor by applying su?icient pressure to it to cause

the toe to overcome the resistance of spring 24

20 when the lever is swung upward by the rear

wall' of the cover.

Once again, as the end of the

toe slips off the plunger the latter is forced up

ward against the under side of the toe and snaps

the lever against cross member 21 which causes

the cover to swing shut (Fig. 4).

Besides being a lighter which has a cover op

member, and not separate parts soldered in place

and apt to break off. This integral structure

also simpli?es the manufacture of the lighter and

decreases its cost. Finally, this lighter is pro

vided with a minimum of moving parts, thereby

obviating the possibility of its getting out of

order.

According to the provisions of the patent

statutes, we have explained the principle and

operation of our invention, and have illustrated

and described what we now consider to represent

its best embodiment.

However, we desire to have

it understood that, within the scope of the ap

pended claim, the invention may be practiced

otherwise than as speci?cally illustrated and

described.

We claim:

A pocket lighter comprising a hollow member

having a closed bottom and an open top, a sec

ond hollow member telescoped therein, and hav-

ing an open bottom, a plate permanently clos

ing the top of the inner member whereby ares

ervoir for in?ammable fuel is formed, the side

walls of the inner member projecting above said

plate and being formed to provide a wind screen 1-15

and front and rear pairs of lugs, a cover disposed

over the tops of said telescoping members and

parts projecting beyond the closed case except hinged at its rear wall to the outer of said mem

a hinge, it has a larger storage. capacity for

bers, a cross member secured in the cover trans

lighter fuel than lighters now known having the versely

thereof adjacent said rear wall, a .lever 30

same over-all area that this one has. Unob

pivotally mounted at one end between said rear

structed access to the fuel reservoir is readily pair of lugs with its opposite end projecting up

gained by merely grasping the wind screen and between said rear wall and cross member and

pulling the two telescoping.- members apart. engaging the latter, a spring biased plunger slid

erated in the above-described manner with no

There are no screw plugs to remove or become

lost, nor small openings through which to at

tempt to introduce the lighter fuel. The snug

sliding fit of the telescoping members insures a

40

leaf-proof reservoir.

The projections on top of the inner member I

are strong and well constructed, because the

wind screen and the wheel-supporting and lever

supporting lugs are all integral with the inner

ably disposed in said top plate for biasing the

lever against the cross member, whereby move

ment of the cover from its closed position is re

strained, and a flint-engaging toothed wheel piv

otally mounted between said front pair of lugs,

the lighter being free of external latch-manipu 40

lating means.

GEORGE GIMERA.

GEORGE G. BLAISDELL.

You might also like

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- June 6, 5 Ak) Et Al: Filed March 23, 1932Document2 pagesJune 6, 5 Ak) Et Al: Filed March 23, 1932david19775891No ratings yet

- Tow Target Release Mechanism (1927)Document5 pagesTow Target Release Mechanism (1927)CAP History LibraryNo ratings yet

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- United States PatentDocument5 pagesUnited States PatentJagannathan ArumugamNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- O/65ézá / /zzáez: Ozzezz67Document4 pagesO/65ézá / /zzáez: Ozzezz67TECUMCE GOMEZ PEREZNo ratings yet

- Get. 15, 1968 J. A. Gregoire 3,405,901: Filed July 5, 1966 3 Sheets-Sheet LDocument6 pagesGet. 15, 1968 J. A. Gregoire 3,405,901: Filed July 5, 1966 3 Sheets-Sheet LFercon DocenciaNo ratings yet

- Dec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LDocument5 pagesDec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LcheesewizzNo ratings yet

- Filed Sept. 8, l942Document4 pagesFiled Sept. 8, l942HaithemNo ratings yet

- Us1446763 PDFDocument7 pagesUs1446763 PDFJin SongNo ratings yet

- Us 3960084Document3 pagesUs 3960084rte678No ratings yet

- Dec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Document8 pagesDec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Rezicky ImamNo ratings yet

- Oct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Document5 pagesOct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Юрий РуденкоNo ratings yet

- H.M. Sprague's Folding Pistol Patent from 1912Document4 pagesH.M. Sprague's Folding Pistol Patent from 1912djsfNo ratings yet

- Browning Firearm PatentDocument8 pagesBrowning Firearm PatentСлэйтер Строительная компанияNo ratings yet

- Us2960824 PDFDocument5 pagesUs2960824 PDFgrigNo ratings yet

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- A Single ShontgunDocument3 pagesA Single ShontgunyuehanNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- Patented Oct. 27, 1896.: Gas Operated Magazine GunDocument14 pagesPatented Oct. 27, 1896.: Gas Operated Magazine GunСлэйтер Строительная компанияNo ratings yet

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- Us 1893840Document6 pagesUs 1893840Robert BercovitzNo ratings yet

- Lûëîßûäá., Patented July 8, 1913.: C6265 Z1' MEN@ MijnDocument6 pagesLûëîßûäá., Patented July 8, 1913.: C6265 Z1' MEN@ MijnyuehanNo ratings yet

- Compact Camera Cover Plate DesignDocument4 pagesCompact Camera Cover Plate DesignAndrei PoseaNo ratings yet

- US3200917Document5 pagesUS3200917张淼No ratings yet

- US36505Document5 pagesUS36505ReggieNo ratings yet

- United States Patent (191: SeecampDocument4 pagesUnited States Patent (191: Seecamp9aszerfNo ratings yet

- Mannlicher Us1008162Document6 pagesMannlicher Us1008162cll1968No ratings yet

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- Howell and Bunger's 1934 patented valve designDocument6 pagesHowell and Bunger's 1934 patented valve designJohn TLNo ratings yet

- US2755738 Rocket Fuze 3.5 Inch Rocket M404 PatentDocument3 pagesUS2755738 Rocket Fuze 3.5 Inch Rocket M404 Patentrichardwb1No ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- Hamilton Rifle ConstructionDocument5 pagesHamilton Rifle Constructionposchul2003No ratings yet

- J.B. HALE'S 1920 BRAIDING MACHINE CARRIERDocument5 pagesJ.B. HALE'S 1920 BRAIDING MACHINE CARRIERsebastian escobarNo ratings yet

- March 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1Document5 pagesMarch 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1david19775891No ratings yet

- United States Patent (19) : VicardDocument4 pagesUnited States Patent (19) : Vicard155100% (1)

- Viewfinder ProjectDocument4 pagesViewfinder ProjectAndrei PoseaNo ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- Sept. 2, 1.930. W. Wxlson 1,774,955: Filed De'C. 7, 1929 2 Sheets-Sheet L ADocument5 pagesSept. 2, 1.930. W. Wxlson 1,774,955: Filed De'C. 7, 1929 2 Sheets-Sheet L Aاحمد عبدالكريمNo ratings yet

- Tow Target Cable Drag Mechanism (1941)Document4 pagesTow Target Cable Drag Mechanism (1941)CAP History LibraryNo ratings yet

- Deç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946Document3 pagesDeç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946david19775891No ratings yet

- Measure cheese with this compact dispenserDocument5 pagesMeasure cheese with this compact dispenserRodrigoPomaNo ratings yet

- US2128620 - Bending MachineDocument5 pagesUS2128620 - Bending MachinedevheadbotNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- Us 4676137Document6 pagesUs 4676137fghdfjerNo ratings yet

- Us 3823668Document4 pagesUs 3823668wewewewNo ratings yet

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Document7 pages??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- Cloth Tow Target Sleeve (1935)Document6 pagesCloth Tow Target Sleeve (1935)CAP History LibraryNo ratings yet

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedDocument7 pagesNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaNo ratings yet

- Wellhead Connector H4 TypeDocument9 pagesWellhead Connector H4 Typeste7ieNo ratings yet

- US5231917 - Wobble PistonDocument5 pagesUS5231917 - Wobble PistondevheadbotNo ratings yet

- United States Patent (191: ReilingDocument5 pagesUnited States Patent (191: ReilingTannyVaneNo ratings yet

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- Us2297693 PDFDocument8 pagesUs2297693 PDFJin SongNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Pen HolderDocument8 pagesPen HolderRakeshNo ratings yet

- Rechargable Cigrett LighterDocument6 pagesRechargable Cigrett LighterRakeshNo ratings yet

- Cooler Warm SeasonDocument13 pagesCooler Warm SeasonRakeshNo ratings yet

- Froth Flotation Deinking Process For PaperDocument16 pagesFroth Flotation Deinking Process For PaperRakeshNo ratings yet

- Llo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterDocument3 pagesLlo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterRakeshNo ratings yet

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- Cigar Holding ApparatusDocument1 pageCigar Holding ApparatusRakeshNo ratings yet

- Process For Surface Sizing PaperDocument7 pagesProcess For Surface Sizing PaperRakeshNo ratings yet

- Dynamic KeysDocument46 pagesDynamic KeysRakeshNo ratings yet

- Testing-Paper and Method of Making SameDocument2 pagesTesting-Paper and Method of Making SameRakeshNo ratings yet

- Ornamenting A PaperDocument2 pagesOrnamenting A PaperRakeshNo ratings yet

- Hybrid Topcoat Formulations For PaperDocument11 pagesHybrid Topcoat Formulations For PaperRakeshNo ratings yet

- Fountain Pen PatentDocument3 pagesFountain Pen PatentRakeshNo ratings yet

- Toothbrush HolderDocument7 pagesToothbrush HolderRakeshNo ratings yet

- Comb FilterDocument5 pagesComb FilterRakeshNo ratings yet

- Solar PlantDocument12 pagesSolar PlantRakeshNo ratings yet

- Vernier DesignDocument9 pagesVernier DesignRakeshNo ratings yet

- KniDocument5 pagesKniRakeshNo ratings yet

- Sol ShieldDocument9 pagesSol ShieldRakeshNo ratings yet

- MicDocument7 pagesMicRakeshNo ratings yet

- CalDocument48 pagesCalRakeshNo ratings yet

- PencilDocument1 pagePencilRakeshNo ratings yet

- Buddhism VolDocument36 pagesBuddhism VolRakesh100% (1)

- Sol LampDocument6 pagesSol LampRakeshNo ratings yet

- Sound Abs BarrDocument23 pagesSound Abs BarrRakeshNo ratings yet

- Solar PlantDocument12 pagesSolar PlantRakeshNo ratings yet

- Sol StovDocument11 pagesSol StovRakeshNo ratings yet

- Solar HarnDocument11 pagesSolar HarnRakeshNo ratings yet

- Interconnected Solar CellsDocument13 pagesInterconnected Solar CellsRakeshNo ratings yet

- Driving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorsDocument10 pagesDriving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorskellendadNo ratings yet

- Irctc Tour May 2023Document6 pagesIrctc Tour May 2023Mysa ChakrapaniNo ratings yet

- Political Reporting:: Political Reporting in Journalism Is A Branch of Journalism, Which SpecificallyDocument6 pagesPolitical Reporting:: Political Reporting in Journalism Is A Branch of Journalism, Which SpecificallyParth MehtaNo ratings yet

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Document8 pagesDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIONo ratings yet

- Translation EquivalenceDocument6 pagesTranslation EquivalenceJamal Anwar TahaNo ratings yet

- Radio Theory: Frequency or AmplitudeDocument11 pagesRadio Theory: Frequency or AmplitudeMoslem GrimaldiNo ratings yet

- WWW - Istructe.pdf FIP UKDocument4 pagesWWW - Istructe.pdf FIP UKBunkun15No ratings yet

- (Bio) Chemistry of Bacterial Leaching-Direct vs. Indirect BioleachingDocument17 pages(Bio) Chemistry of Bacterial Leaching-Direct vs. Indirect BioleachingKatherine Natalia Pino Arredondo100% (1)

- Key formulas for introductory statisticsDocument8 pagesKey formulas for introductory statisticsimam awaluddinNo ratings yet

- Guidelines Tax Related DeclarationsDocument16 pagesGuidelines Tax Related DeclarationsRaghul MuthuNo ratings yet

- (Variable Length Subnet MasksDocument49 pages(Variable Length Subnet MasksAnonymous GvIT4n41GNo ratings yet

- Development of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993Document14 pagesDevelopment of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993pghasaeiNo ratings yet

- FALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFDocument3 pagesFALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFJISHNU TKNo ratings yet

- WassiDocument12 pagesWassiwaseem0808No ratings yet

- How To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)Document19 pagesHow To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)hiwot kebedeNo ratings yet

- TransistorDocument1 pageTransistorXhaNo ratings yet

- Obligations and Contracts Bar Questions and Answers PhilippinesDocument3 pagesObligations and Contracts Bar Questions and Answers PhilippinesPearl Aude33% (3)

- General Separator 1636422026Document55 pagesGeneral Separator 1636422026mohamed abdelazizNo ratings yet

- Biomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCDocument125 pagesBiomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCAlpesh Jadhav100% (1)

- IMM Indian Oil Case Group 3Document13 pagesIMM Indian Oil Case Group 3Soniya AgnihotriNo ratings yet

- Lesson 2 Mathematics Curriculum in The Intermediate GradesDocument15 pagesLesson 2 Mathematics Curriculum in The Intermediate GradesRose Angel Manaog100% (1)

- Kahveci: OzkanDocument2 pagesKahveci: OzkanVictor SmithNo ratings yet

- For Coin & Blood (2nd Edition) - SicknessDocument16 pagesFor Coin & Blood (2nd Edition) - SicknessMyriam Poveda50% (2)

- Honors Biology Unit 2 - Energy Study GuideDocument2 pagesHonors Biology Unit 2 - Energy Study GuideMark RandolphNo ratings yet

- Vehicle Registration Renewal Form DetailsDocument1 pageVehicle Registration Renewal Form Detailsabe lincolnNo ratings yet

- Factsheet B2B PunchOut en 140623Document2 pagesFactsheet B2B PunchOut en 140623Curtis GibsonNo ratings yet

- Planview Innovation Management Maturity Model PDFDocument1 pagePlanview Innovation Management Maturity Model PDFMiguel Alfonso Mercado GarcíaNo ratings yet

- THE PEOPLE OF FARSCAPEDocument29 pagesTHE PEOPLE OF FARSCAPEedemaitreNo ratings yet

- The Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToDocument21 pagesThe Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToBik Bok50% (2)

- CL 5313 17021-1 Requirements Matrix-1458-5Document6 pagesCL 5313 17021-1 Requirements Matrix-1458-5Ana AnaNo ratings yet