Professional Documents

Culture Documents

High Mast Spec

Uploaded by

rkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Mast Spec

Uploaded by

rkCopyright:

Available Formats

ANNEXURE 'B'

Annexure to Our Tender NO. 0799-12/FMT/PEG

Technical Specifications for High Mast Lighting system

Sl.No

Description

Scope of Supply, Erection and commissioning of High Mast Lighting

System as per the specifications.

The scope of this specification covers the manufacture, transport,

installation, testing and commissioning of the complete lighting

system, using Raising and Lowering type of High mast Towers,

including the Civil Foundation Works.MPM will only provide the

supply point and the feeder cable of the required size, up to the

bottom of the high mast.However, all items required for the safe and

efficient operation and maintenance of the lighting system, including

the high mast, whether mentioned below or not, shall be included by

the Vendor.

Supply of 30 Meters High Mast system with all accessories

including but not restricted to the following.

a) Mast shaft hot dipped galvanized and suitable for wind velocity as

per IS 875 part 3.

b) Head frame,steel wire rope of suitable dia., double drum winch.

c) Galvanised Lantern carriage arrangement suitable for 12 nos.

luminaires & its control gear boxes and Lightning finial.

d) Integral power tool installed inside base compartment for its

operation.

Supply of foundation bolts manufactured from special steel

along with nuts, washers, anchor plate and templates

Design, supply and casting of suitable shallow foundation

with M-15 concrete for the High mast considering safe soil

bearing capacity at the site.

Supply of 8 nos. non - integral 2x400watts High Pressure Metal

Halide floodlight lumininaire with two nos 400 W Metal Halide lamps

in each luminaire and required control gear boxes suitable for

operation on 230V, 50HZ, a.c. supply.

Supply of 4 nos. non - integral 1x400watts High Pressure Metal

Halide focus light lumininaire with one no. 400 W Metal Halide lamp

in each luminaire and required control gear boxes suitable for

operation on 230V, 50HZ, a.c. supply.

Supply of control panel housing suitable control circuit for the

operation of the mast, precision timer for automatic On/Off control

and required controls for the power tool motor.

Erection/ installation and commissioning of the High Mast system

comprising of foundation, mast and its accessories, earthing,

luminaires, control panel etc. with the help of suitable equipments.

3 sets of, wiring/ connection diagram, O&M manual to be supplied

along with the high mast.

10

The type and make of the luminaire and lamp to be furnished in the

offer. Technical leaflet giving the dimensions, features to be attached

with the offer. The fitting and control gear boxes offered should be

suitable for outdoor application and properly sealed to prevent rain

water entry.

10.1 The luminaire and lamp should be of Philips, Bajaj, CromptonGreaves

Surya, makes.

10.2 The electrical works should be carried out by a licenced electrical

contractor.

11

Reference List/ Qualifying Condition:

11.1 Only those vendors who have supplied and commissioned similar or

higher capacity/ size high mast and working satisfactorily for at least

one year after commissioning should quote.

11.2 Information about the companies where similar equipments have been

supplied, certificate about satisfactory performance are to be

submitted.

12.0 General Features:

12.1 Winch

The winch shall be of completely self sustaining and self lubricating

type, without the need for brake shoe, springs or clutches. Each

driving spindle of the winch shall be positively locked when not in use.

Individual drum also should be operated for fine adjustment of

lantern carriage. The capacity, operating speed, safe working load,

recommended lubrication and serial number of the winch shall be

clearly marked. The winch drums shall be grooved toensure

perfect seat for stable and tidy rope lay, with no chances of rope

slippage. The rope termination in the winch shall be such that

distortion or twisting is eliminated and at least 5 to 6 turns of rope

remains on the drum even when the lantern carraiage is fully lowered

and rested on the rest pads. It should be possible to operate the

winch manually by a suitable handle by an integral power tool.

12.2

Head Frame

The head frame, which is to be designed as a capping unit of the

mast, shall be of welded steel construction, galvanised both internally

and externally after assembly. The top pulley shall be of appropriate

diameter, large enough to accommodate the accommodate the

stainless steel wire ropes and the multi-core electric cable.The pulley

block shall be made of non-corrodable material, and shall be of die

cast Aluminium Alloy.Pulleys made of synthetic materials such as

Plastic or PVC are not acceptable. Self-lubricating bearings and

stainless steel wire ropes and the multi-core electric cable.The

maintenance free operation for a long period. The pulley assembly

shall be fully protected by a canopy galvanised internally and

externally. Close fittings guides and sleeves shall be provided to

ensure that the ropes and cables do not get dislodged from their

respective positions in the grooves. The head frame shall be provided

with guides and stops with PVC buffer for docking the lantern

carriage.

12.3 Stainless Steel Wire Ropes :

The suspension system shall essentially be without any intermediate

joint and shall consist of only non-corrodable stainless steel of AISI

316 or better grade. The stainless steel wire ropes shall be of suitable

size, the central core being of the same material. The overall diameter

of the rope shall not be less than 6 mm. The thimbles shall be secured

on ropes by compression splices. Two continuous lengths of

stainless steel wire ropes shall be used in the system and no

intermediate joints are acceptable in view of the required safety. No

No intermediate joints / terminations, either bolted or else, shall be

provided on the wire ropes between winch and lantern carriage.

12.4

Electrical System, Cable and Cable Connections.

A suitable terminal box shall be provided as part of the contract at the

base compartment of the high mast for terminating the incoming cable.

The electrical connections from the bottom to the top shall be made

by special trailing cable. Suitable size copper cable to be used. At the

top there shall be weather proof junction box to terminate the trailing

cable. Connections from the top junction box to the individual

luminaries shall be made by using 3 core 1.5 sq.mm. copper flexible

PVC cables of reputed make. The system shall have in-built facilities

for testing the luminaries while in lowered position. Also suitable

provision shall be made at the base compartment of the mast to

facilitate the operation of internally mounted, electrically operated

power tool for raising and lowering of the lantern carriage assembly.

The trailing cables of the lantern carriage rings shall be terminated by

means of metal clad, multipin plug and socket provided in the base

compartment to enable easy disconnection when required.

12.5

Power Tool for the Winch:

A suitable, high-powered, electrically driven, internally mounted

power tool, with manual over ride shall be supplied for the raising and

lowering of the lantern carraige for maintenance purposes. The speed

of the power tool shall be to suit the system. The power tool shall be

single speed, provided with a motor of the required rating. The Power

tool shall be supplied complete with suitable control. The capacity and

speed of the elelctric motor used in the power tool shall be suitable

for the lifting of the design load installed on the lantern carraige. The

power tool mounting shall be so designed that it will be not only self

supporting but also aligns the power tool perfectly with respect to the

winch spindle during the operations. Also, a handle for the manual

operation of the winches in case of problems with the electrically

operated tool shall be provided.

12.6

Lightning Finial:

One number heavy duty hot dip galvanised lightning finial shall be

provided for each mast. The lightning finial shall be minimum 1.2 M in

length and shall be provided at the centre of the head frame. It shall

be bolted solidly to the head frame to get a direct conducting path to

the earth through the mast.

12.7 Earthing Terminals :

Suitable earth terminal shall be provided at a convenient

location on the base of the Mast, for lightning and electrical earthing

of the mast.

12.8 Feeder Pillar:

Each mast shall be provided with a feeder pillar fabricated out of 14

SWG CRCA sheet and finished with two coats of red oxide primer

and grey enamel paint. The feeder pillar shall comprise of incoming

TPN Switch Fuse Unit with HRC fuses or MCCB of suitable current

rating, incoming / outgoing terminals and control for the power motor.

Feeder pillar shall be mounted near to the mast. Suitable digital timer

of reputed make, with necessary contactors, wiring etc.for ON/OFF

control of the lamps should be provided and connected in the circuit.

12.9

Power Cable:

Suitable four core Armoured Aluminium cable for power supply and

suitable armoured Copper conductor cable for motor supply shall be

provided from feeder pillar to the base compartment of the highmast.

Cable shall be taken to the base compartment of the highmast

through the provision made in the foundation. Power cable of suitable

size up to the feeder pillar from supply point shall be provided by

MPM.

You might also like

- Annexure I Technical Specifications For Lighting High MastDocument5 pagesAnnexure I Technical Specifications For Lighting High MastManish Gupta100% (1)

- High MastAug07Document27 pagesHigh MastAug07Leena ChoudharyNo ratings yet

- High Mast SpecsDocument10 pagesHigh Mast SpecsBhanu PratapNo ratings yet

- Tender For High Mast Lighting SystemDocument8 pagesTender For High Mast Lighting SystemArchishman BhattacharyaNo ratings yet

- General Specification For Radial Type Motorised Cable ReelersDocument5 pagesGeneral Specification For Radial Type Motorised Cable ReelersIon Logofătu AlbertNo ratings yet

- KT - Specs High Power Busbar Trunking Metal Enclosure 1000 To 6300A Cu V20180607Document5 pagesKT - Specs High Power Busbar Trunking Metal Enclosure 1000 To 6300A Cu V20180607N_LocusNo ratings yet

- Safety For Wiring Methods: By: Komarul FausiyahDocument16 pagesSafety For Wiring Methods: By: Komarul FausiyahJeffrey ArandiaNo ratings yet

- Tech Spec. of EOT CraneDocument7 pagesTech Spec. of EOT CraneSuresh MuttaNo ratings yet

- Specifications For Motor Control CentersDocument5 pagesSpecifications For Motor Control CentersNATHANNo ratings yet

- S-20 Railroad Highway Crossing Gate: Instruction & MaintenanceDocument28 pagesS-20 Railroad Highway Crossing Gate: Instruction & MaintenanceThanh Bình VũNo ratings yet

- Technical Specifications For Power Distribution Board (PDB)Document14 pagesTechnical Specifications For Power Distribution Board (PDB)sri_lnt0% (1)

- Ganztrans TransformersDocument13 pagesGanztrans TransformersaidedthunderNo ratings yet

- Low Voltage Switchgear: Maxsg SpecificationsDocument18 pagesLow Voltage Switchgear: Maxsg SpecificationssuvarnapreyasNo ratings yet

- 1 SECTION 16425 Switchboards (600 V and Below)Document4 pages1 SECTION 16425 Switchboards (600 V and Below)Ahmed AliNo ratings yet

- 5 - SMDBDocument4 pages5 - SMDBKhyle Laurenz DuroNo ratings yet

- Overhead Busbar SystemsDocument4 pagesOverhead Busbar Systemsgianfutol1No ratings yet

- Spec of High Mast Tower 30 MtrsDocument11 pagesSpec of High Mast Tower 30 MtrsNagesh Rao0% (1)

- MNS-MCC LV SpecificationDocument16 pagesMNS-MCC LV SpecificationRaju MbkNo ratings yet

- Honeywell Office, Gurgaon HVAC System: Particular Conditions & Technical SpecificationDocument16 pagesHoneywell Office, Gurgaon HVAC System: Particular Conditions & Technical SpecificationAmitSamadiyaNo ratings yet

- نسخة من 1كهDocument16 pagesنسخة من 1كهRashad AlqatniNo ratings yet

- Low Voltage 480 VSwitchgear 1Document11 pagesLow Voltage 480 VSwitchgear 1Abhilash BvNo ratings yet

- Busbar Shortform PDFDocument28 pagesBusbar Shortform PDFHunter XhunterNo ratings yet

- S&C Custom Metal-Enclosed Switchgear: (Select Values From Table On Page 2.)Document29 pagesS&C Custom Metal-Enclosed Switchgear: (Select Values From Table On Page 2.)Luis CabimasNo ratings yet

- CraneDocument19 pagesCranedeua2004No ratings yet

- Low Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationDocument16 pagesLow Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationCharles RobiansyahNo ratings yet

- Disconnectors DesignDocument14 pagesDisconnectors DesignTravis WoodNo ratings yet

- Actom High Voltage Outdoor DisconnectorsDocument8 pagesActom High Voltage Outdoor Disconnectorsjoydeep_d3232No ratings yet

- 2TDC490003 MNS-SG NON AR Guideform Specification Rev. ADocument15 pages2TDC490003 MNS-SG NON AR Guideform Specification Rev. ALokesh BabuNo ratings yet

- LVSG SpecificationsDocument10 pagesLVSG SpecificationsperijoyNo ratings yet

- Earthing & Bonding 2Document11 pagesEarthing & Bonding 2nautelNo ratings yet

- 6.8.6 Ground Bus Safety Ground Bus Bar: CE/416/NPCIL/24VDC/TR Rev 00 Page 13 of 20Document1 page6.8.6 Ground Bus Safety Ground Bus Bar: CE/416/NPCIL/24VDC/TR Rev 00 Page 13 of 20Satyasrinivas PulavarthiNo ratings yet

- V20 120kW Product DescriptionDocument4 pagesV20 120kW Product DescriptiongarmeloNo ratings yet

- 3885 SpecDocument2 pages3885 Specm_engineer09No ratings yet

- 11 KV Switch Board - Specification DetailsDocument18 pages11 KV Switch Board - Specification DetailsssbNo ratings yet

- Specs For Lighting SystemDocument8 pagesSpecs For Lighting SystemEloy NateNo ratings yet

- Marathahalli Project - BlankDocument12 pagesMarathahalli Project - BlankSajad ManjadikkalNo ratings yet

- QFW Series SteamDocument8 pagesQFW Series Steamnikon_fa50% (2)

- Document No PCPL-0532-4-407-04-08 MV Switchgear Section - 4 PAGE: 1 of 13 ScopeDocument13 pagesDocument No PCPL-0532-4-407-04-08 MV Switchgear Section - 4 PAGE: 1 of 13 ScopetceterexNo ratings yet

- DLTC 2011 LowresDocument8 pagesDLTC 2011 LowresSalvador FayssalNo ratings yet

- Copper Bus Duct SpecDocument135 pagesCopper Bus Duct SpecChilamkurti Siva Sankara Rao100% (2)

- Operation Manual For Automatic Girth Welder Model Agw-1Document29 pagesOperation Manual For Automatic Girth Welder Model Agw-1mdk50No ratings yet

- NGC3+Low Voltage+Switchgear,+Withdrawable+TypeDocument8 pagesNGC3+Low Voltage+Switchgear,+Withdrawable+TypedmugalloyNo ratings yet

- Part - 6 Distribution Boards: 1.0 GeneralDocument5 pagesPart - 6 Distribution Boards: 1.0 GeneralKhyle Laurenz DuroNo ratings yet

- Advc N SeriesDocument16 pagesAdvc N SeriesMeghan Garrett0% (1)

- 1.-33 KV VCBDocument14 pages1.-33 KV VCBPasupuleti007No ratings yet

- Stinger Technical SpecificationDocument8 pagesStinger Technical Specificationrickbushido100% (1)

- Technical Specification of 11Kv 630A VCB Panel With 5 Nos 11Kv Lbs O/GDocument9 pagesTechnical Specification of 11Kv 630A VCB Panel With 5 Nos 11Kv Lbs O/GShayarrn KhatiwodaNo ratings yet

- 16480Document5 pages16480Ahmed AliNo ratings yet

- CE232 - Alternator Flameproof PDFDocument6 pagesCE232 - Alternator Flameproof PDFbutaberusNo ratings yet

- Dhuvaran Gujarat 75MW Solar Power Poant Tendernotice - 1 - Compressed-26-50Document25 pagesDhuvaran Gujarat 75MW Solar Power Poant Tendernotice - 1 - Compressed-26-50Yash YadavNo ratings yet

- Lecture 10 Electrical Design Considrations For Residential BuildingDocument11 pagesLecture 10 Electrical Design Considrations For Residential BuildingBUKENYA BEEE-2026100% (1)

- CatalogDocument48 pagesCatalogAhmad AshrafNo ratings yet

- Generador KatoDocument20 pagesGenerador KatoVelasquez DavisNo ratings yet

- Motor Controller CenterDocument17 pagesMotor Controller CenterSimbu ArasanNo ratings yet

- Alimak Super Scando FC ManualDocument71 pagesAlimak Super Scando FC Manualdsn_sarma100% (1)

- GGas Insulated Switchgear - Ganz Transelektro Electric Co.Document20 pagesGGas Insulated Switchgear - Ganz Transelektro Electric Co.KARAM ZAKARIANo ratings yet

- Cable LayingDocument6 pagesCable LayingPramod B.WankhadeNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Amie Syllabus Sec B ElectricalDocument19 pagesAmie Syllabus Sec B ElectricalTechnical boxNo ratings yet

- High Performance Team Neelraman BookDocument60 pagesHigh Performance Team Neelraman Bookrk100% (1)

- Navavaranam LyricsDocument11 pagesNavavaranam LyricsSriramRengarajanNo ratings yet

- Schneider Electric Innovation Summit Paris 2018: Research ReportDocument36 pagesSchneider Electric Innovation Summit Paris 2018: Research ReportrkNo ratings yet

- NFPA70EDocument58 pagesNFPA70EYousuf Ibrahim100% (1)

- An Interview With John Grinder 1996 - InspiritiveDocument10 pagesAn Interview With John Grinder 1996 - InspiritiverkNo ratings yet

- Re-Registration in Section A of AMIE ExamsDocument6 pagesRe-Registration in Section A of AMIE ExamsAMIE Study Circle, RoorkeeNo ratings yet

- 7 Hormone Imbalances That Fuel Fatigue, Weight Gain, & Moodiness - Dr. Will ColeDocument11 pages7 Hormone Imbalances That Fuel Fatigue, Weight Gain, & Moodiness - Dr. Will Colerk100% (1)

- Father Suddodhana Mother MayadeviDocument1 pageFather Suddodhana Mother MayadevirkNo ratings yet

- Chapter 8 Proposal of TariffDocument43 pagesChapter 8 Proposal of TariffrkNo ratings yet

- Blew Minds Ashish Vidyarthi - Blew MindsDocument2 pagesBlew Minds Ashish Vidyarthi - Blew MindsrkNo ratings yet

- Fire Safety ManualDocument59 pagesFire Safety Manualjomonabraham100% (6)

- Combo ChartDocument3 pagesCombo ChartrkNo ratings yet

- 7 - 200 315 630 kVA X-Mer - Spec No 32 PDFDocument22 pages7 - 200 315 630 kVA X-Mer - Spec No 32 PDFRaghav GhateNo ratings yet

- English Vishnu SahasranamaDocument55 pagesEnglish Vishnu SahasranamarkNo ratings yet

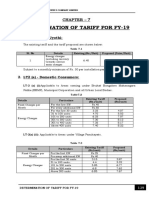

- Determination of Tariff For Fy-19: Chapter - 7Document13 pagesDetermination of Tariff For Fy-19: Chapter - 7rkNo ratings yet

- Understanding Emotional Competence WorkshopDocument20 pagesUnderstanding Emotional Competence WorkshoprkNo ratings yet

- Energy Conservation Building Code (ECBC)Document19 pagesEnergy Conservation Building Code (ECBC)rkNo ratings yet

- Atma Shatkam - Wikipedia, The Free Encyclopedia PDFDocument4 pagesAtma Shatkam - Wikipedia, The Free Encyclopedia PDFrkNo ratings yet

- Training Needs Analysis (TNA) GuideDocument13 pagesTraining Needs Analysis (TNA) GuideMungunkhishig BatbaatarNo ratings yet

- 03ECBC LightingDocument15 pages03ECBC LightingrkNo ratings yet

- 4 3 Inch Color VDP - FinalDocument3 pages4 3 Inch Color VDP - FinalrkNo ratings yet

- 03ECBC LightingDocument15 pages03ECBC LightingrkNo ratings yet

- Atma Shatkam - Wikipedia, The Free Encyclopedia PDFDocument4 pagesAtma Shatkam - Wikipedia, The Free Encyclopedia PDFrkNo ratings yet

- 3.5 Meditation sp58Document11 pages3.5 Meditation sp58rkNo ratings yet

- 2 Kerc Supply Code Reguln.2004Document13 pages2 Kerc Supply Code Reguln.2004B G Vijaya KumarNo ratings yet

- Fluke 2042 Cable LocatorDocument28 pagesFluke 2042 Cable Locatorbogdy00733054No ratings yet

- Energy Yields Up To 10 KWDocument8 pagesEnergy Yields Up To 10 KWrkNo ratings yet

- 3.2 Joints GlandsDocument10 pages3.2 Joints GlandsrkNo ratings yet

- PsychometricDocument13 pagesPsychometricfouad0% (1)

- Asus N550jk E-ManualDocument140 pagesAsus N550jk E-Manualzlaja3011No ratings yet

- Impact of Storage Devices On The EnviromentDocument4 pagesImpact of Storage Devices On The Enviromentalfredsamsele2100% (1)

- 022501-164L - GeoXT 3000 Series - DS - 0712 - MGIS - HR - NCDocument2 pages022501-164L - GeoXT 3000 Series - DS - 0712 - MGIS - HR - NCArief Yoga PratamaNo ratings yet

- RHR 1000 Dok LokDocument28 pagesRHR 1000 Dok LokThomas MillerNo ratings yet

- SCX2 190BB PDFDocument2 pagesSCX2 190BB PDFIvan José Campos MadridNo ratings yet

- Lloyds Ship Vibration and Noise Guidance NotesDocument54 pagesLloyds Ship Vibration and Noise Guidance NotesYegor Luchenkov100% (3)

- Pocket Sized Soldering Kit Cold Heat HackDocument18 pagesPocket Sized Soldering Kit Cold Heat HackDraganNo ratings yet

- Kawai CN34 Owner's ManualDocument132 pagesKawai CN34 Owner's ManualFlorin AlexeNo ratings yet

- Drunken Drive Protection SystemDocument5 pagesDrunken Drive Protection SystemIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Swap Magic Code R ManualDocument3 pagesSwap Magic Code R ManualkorrakorraNo ratings yet

- Chapter 3 - Combinational Logic Circuits (Part 1) - Digital ElectronicsDocument12 pagesChapter 3 - Combinational Logic Circuits (Part 1) - Digital ElectronicsRakesh KumarNo ratings yet

- CPE400 Lab8 ARCONADO DEVELLES 2 PDFDocument10 pagesCPE400 Lab8 ARCONADO DEVELLES 2 PDFKimNo ratings yet

- Inertial Navigation IntroductionDocument10 pagesInertial Navigation Introductionedwin_killedlaw100% (1)

- The Process of Measurement: An Overview: Mechanical Measurements.1 Measurand. Measurand ResultDocument13 pagesThe Process of Measurement: An Overview: Mechanical Measurements.1 Measurand. Measurand ResultFelipe MoreraNo ratings yet

- GSM Fundamental Principle: Radio Network Planning & Optimization Dept Mobile DivisionDocument80 pagesGSM Fundamental Principle: Radio Network Planning & Optimization Dept Mobile Divisiondiar_asNo ratings yet

- 15 Switching Dissipation and Power LossesDocument28 pages15 Switching Dissipation and Power LossesSwifty SpotNo ratings yet

- NUS ME Core Modules 20190925 PDFDocument3 pagesNUS ME Core Modules 20190925 PDFHammadAzizNo ratings yet

- RAN Signaling Analysis Guide (RAN10.0 - 02)Document245 pagesRAN Signaling Analysis Guide (RAN10.0 - 02)Juan Camilo GalvisNo ratings yet

- 1 Basics of Heat Transfer (ENSC 14a)Document27 pages1 Basics of Heat Transfer (ENSC 14a)Aldwin Angelo Culing MontañezNo ratings yet

- Automatic Street Light Control by Detecting Vehicle MovementDocument5 pagesAutomatic Street Light Control by Detecting Vehicle MovementBhupendra(Rahul...) kumarNo ratings yet

- Product Overview UK BDDocument28 pagesProduct Overview UK BDNaser Jahangiri100% (1)

- Filtering BasicsDocument83 pagesFiltering BasicsDikshitJainNo ratings yet

- Design2 CalculationDocument11 pagesDesign2 Calculationangelo dedicatoriaNo ratings yet

- Delta-Q IC Series: User Manual: Important Safety and Operating InstructionsDocument5 pagesDelta-Q IC Series: User Manual: Important Safety and Operating InstructionsGaryNo ratings yet

- EE592 Lab Manual Power Sytem LabDocument48 pagesEE592 Lab Manual Power Sytem LabCiczmockingbird TsvkAdmNo ratings yet

- Olevia LT26HVX LCD TV Service ManualDocument35 pagesOlevia LT26HVX LCD TV Service Manual33bNo ratings yet

- Panasonic TX-p42u30e TX-p42ux30e TX-p42u30j TX-pr42u30 TX-pr42u31 Chassis Gpf14d-EDocument113 pagesPanasonic TX-p42u30e TX-p42ux30e TX-p42u30j TX-pr42u30 TX-pr42u31 Chassis Gpf14d-ESorin DanielNo ratings yet

- Wireless CommunicationDocument31 pagesWireless CommunicationGurpreet SinghNo ratings yet

- Development of Indigenous Smart Energy Meter Adhering Indian Standards For Smart GridDocument5 pagesDevelopment of Indigenous Smart Energy Meter Adhering Indian Standards For Smart GridK3L ULP KSPNo ratings yet

- LF412Document11 pagesLF412Alexandru CaracosteaNo ratings yet