Professional Documents

Culture Documents

E16p 20phl en (5cf)

Uploaded by

Tomy Abad AbadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E16p 20phl en (5cf)

Uploaded by

Tomy Abad AbadCopyright:

Available Formats

TB_E16P-E20P_engl_C.

qxd

23.07.2008

14:59 Uhr

Seite 1 (2,1)

Features

Linde clearview ma

with top mounted til

seamless load contro

3 Excellent view o

surroundings thro

yet slim mast pro

3 Nominal capacity

maximum lift hei

3 High residual cap

all applications

3 Exceptionally sta

Electric Counterbalance Trucks

Capacity 1600 2000 kg

E 16, E 18, E 20

SERIES 386

Linde twin accelera

3 Seamless, rapid r

repositioning the

3 Short pedal trave

3 Fatigue-free wor

3 Increased throug

performance

Safety

Linde ProtectorFrame: The protective overhead guard and its

supporting frame together form a strong and completely

enclosed protective zone providing optimum structural

integrity, safety and protection for the operator. The top

mounted tilt cylinders provide seamless, smooth control of

the tilt movements for excellent load stability in all operating

conditions. This unique design also enables slimmer mast

profiles to be fitted for outstanding visibility.

Reliability

An electric fork lift truck depends on reliable electronic

Performance

systems. The Linde electronic control system provides a high

One would expect a high performance truck to have a high

level of reliability because of its dual circuit monitoring system

performance traction system and that is exactly what the

and the sealed aluminium housing which provides total

Linde compact drive axle and lift system delivers. Powerful

protection for the electronics from the ingress of dust and

motors, maintenance-free brakes and intelligent electronic

moisture. For additional adaptability a simple programming

control form an impressive power pack to deliver the highest

system enables the performance parameters to be adjusted

levels of efficiency and productivity.

to meet individual application requirements.

Comfort

Productivity

Consistently high levels of performance and efficiency for

Effective in operation, efficient in reducing costs: the unique

extended periods is only possible if the operator is comfortable.

Linde energy management system ensures intelligent and

The ergonomic layout of all the controls, the adjustability

economical consumption of energy. Energy can also be

the armrest and seat, Linde Load Control, and twin accelerator

obtained quickly utilising the optional built-in charging unit

pedals provide the best possible intuitive interface between

or one of the five simple and rapid battery changing methods.

the truck and the operator.

The result: more uptime and increased productivity.

Linde operators co

3 Ergonomically d

fatigue-free wor

3 Spacious operat

with generous f

3 Cushioned comf

axle are isolated

and cab by a un

suspension syst

shock loadings

Linde Material Handl

Phone +49.60 21.99-0

TB_E16P-E20P_engl_C.qxd

23.07.2008

14:58 Uhr

Seite 1 (1,1)

Standard and optional equipment

Standard equipment

Truck

Comprehensive digital instrument display

Hydrostatic power steering

Superelastic tyres

Linde twin accelerator pedals for all vehicle movements

Generous storage facilities for writing materials and

Four wheeled configuration

miscellaneous items

Dual axis fingertip joystick controls (Linde Load Control)

Battery capacity for flat version (height h6=1,970 mm)

integrated into the adjustable arm rest

E 16 P = 24 V/575 Ah, E 20 PL = 24 V/690 Ah

2 x 5.0 kW maintenance free AC drive motors

Raised version for greater battery capacity (height h6 = 2,130mm)

11kW AC maintenance free lift motor

E 16 PH = 48 V/700 Ah, E 18 PH = 48 V/700 Ah,

Proportional reduction of travel speed when cornering

E 20PH = 48 V/700 Ah, E 20 PHL = 48 V/840 Ah

(Linde Driver Assistant)

Seamless electronic control of all traction and hydraulic

Mast

movements

Clearview standard mast 3,110 mm lift

Standard chassis suitable for working in ISO containers with

Fork length 1,000 mm

appropriate mast

Fork carriage width 1,040 mm

Hydraulically adjustable full suspension PVC operators seat

with armrest

Options

Single pedal accelerator with forward/reverse selector in

Super-comfort seat with air suspension, heater and

the armrest

backrest extension

Safety

Standard mast lifts up to 5,610 mm

Swivelling seat

Linde Protect

Duplex mast lifts (full free lift) up to 3,825 mm

Integrated charger unit, 2-phase and 3-phase versions,

supporting fr

Triplex mast lifts (full free lift) up to 6,075 mm

optionally with electrolytic recirculation

enclosed pro

Integrated sideshift

Individual hydraulic control joysticks

integrity, saf

Integrated fork spreader

Scanner terminal docking port

mounted tilt c

Tilt cylinder protection

Truck lighting/flashing amber beacon/working lamps

the tilt movem

Load guard

Driving mirror

conditions. Th

Single and double additional hydraulics for attachments

Full road lighting

profiles to be

Alternative fork lengths

Audible reversing alarm

Alternative fork carriage widths

Clipboard

Performan

Polycarbonate top screen on overhead guard

Cold store protection

One would e

Front and rear screens, wipers and top screen

Alternative colour schemes

performance

Full cab with hinged doors

Linde Fleet Management (LFM)

Linde compac

Overhead guard sun blind

Alternative tyre types

motors, main

Heating (with pollen protection filter)

control form a

Radio with cassette player

levels of effic

Fabric covered comfort seat

Other options available on request

Comfort

Consistently h

extended peri

The ergonom

the armrest a

pedals provid

the truck and

TB_E16P-E20P_engl_C.qxd

23.07.2008

14:59 Uhr

Seite 2 (1,1)

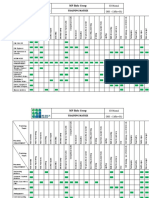

Technical data

Addition data

Electric-engine

Performance data

Dimensions

Tyres, chassis

Weight

Distinguishing mark

Model group

E 16 P

E 18 P

1.1

Manufacturer (abbreviation)

LINDE

LINDE

LINDE

LINDE

1.2

Manufacturers type designation

E 16 P

E 16 PH

E 18 PH

E 20 PL

1.3

Drive: electric (battery or mains), diesel, petrol, fuel gas

Battery

Battery

Battery

Battery

1.4

Operator type: hand, pedestrian, standing, seated, order-picker

Seated

Seated

Seated

Seated

1.5

Load capacity/rated load

Q (t)

1.6

1.6

1.8

2.0

1.6

Load centre distance

c (mm)

500

500

500

500

1.8

Load distance, centre of drive axle to fork

x (mm)

365

365

370

374

1.9

Wheelbase

y (mm)

1429 1)

1481 1)

1481 1)

1537 1)

2.1

Service weight

kg

3015

3360

3385

3360

2.2

Axle loading, laden front/rear

kg

4090/525

4260/755

4565/625 1)

4785/575

2.3

Axle loading, unladen front/rear

kg

1525/1490

1670/1690

1705/1680 1)

1646/1710

17

3.1

Tyres: solid rubber, superelastic, pneumatic, polyurethane

SE

SE

SE

SE

3.2

Tyre size, front

18 x 7 8 2)

18 x 7 8 2)

200/50 10 5)

200/50 10 5)

3.3

Tyre size, rear

16 x 6 8 4)

16 x 6 8 4)

16 x 6 8

16 x 6 8

3.5

Wheels, number front rear (x = driven wheels)

2x/2

2x/2

2x/2

2x/2

3.6

Tread, front

b10 (mm)

930

930

965

965

3.7

Tread, rear

b11 (mm)

807

807

807

807

4.1

Tilt of mast/fork carriage forward/backward

Grad

5/ 7

5/ 7

5/ 7

5/ 7

4.2

Height, mast lowered

h1 (mm)

2019 6)

2194 4)

2194 6)

2019 6)

4.3

Free lift

h2 (mm)

150

150

150

150

4.4

Lift

h3 (mm)

2800

3150

3150

2800

4.5

Height, mast extended

h4 (mm)

3401

3751

3751

3401

4.7

Height of overhead guard (cabin)

h6 (mm)

1970

2130

2130

1970

4.8

Seat height/stand height

h7 (mm)

908

1065

1065

908

4.12

Coupling height

h10 (mm)

538

602

602

538

3045

20

16

4.19

Overall length

l1 (mm)

2929

2978

2983

4.20

Length to face of forks

l2 (mm)

2029

2078

2083

2145

4.21

Overall width

b1 / b2 (mm)

1090/1050 7)

1090/1050 7)

1172/1050 7)

1172/1050

4.22

Fork dimensions

s/e/l (mm)

40 x 80 x 900

40 x 80 x 900

45 x 100 x 900

45 x 100 x 900

4.23

Fork carriage DIN 15 173, class/type A, B

4.24

Fork-carriage width

4.31

Ground clearance, laden, below mast

m1 (mm)

97

97

97

97

4.32

Ground clearance, centre of wheelbase

m2 (mm)

103

103

103

103

4.33

Aisle width for pallets 1000 x 1200 crossways

Ast (mm)

3355

3404

3409

3470

4.34

Aisle width for pallets 800 x 1200 lengthways Ast (mm)

3479

3528

3533

3595

4.35

Turning radius

Wa (mm)

1664

1713

1713

1771

4.36

Internal turning radius

b13 (mm)

5.1

Travel speed, laden/unladen

20/20

20/20

20/20

20/20

5.2

Lift speed, laden/unladen

m/s

0.5/0.6

0.5/0.6

0.5/0.6

0.5/0.6

5.3

Lowering speed, laden/unladen

m/s

0.58/0.5

0.58/0.5

0.58/0.5

0.58/0.5

5.5

Drawbar pull, laden/unladen

2300/2300

2300/2300

2300/2300

2300/2300

23

100

b3 (mm)

km / h

2A

2A

2A

2A

1040

1040

1040

1040

5.6

Max. drawbar pull, laden/unladen

10000/10000

10000/10000

10000/10000

10000/10000

5.7

Gradeability, laden/unladen

6.8/10.4

6.6/9.9

6.1/9.4

5.8/9.2

5.8

Max. gradeability, laden/unladen

22.6/36.9

21.9/34.1

20.3/32.1

19.3/31.6

5.9

Acceleration time, laden/unladen

4.5/4.0

4.5/4.0

4.5/4.0

4.6/4.0

Hydraulic/mechanical

Hydraulic/mechanical

Hydraulic/mechanical

Hydraulic/mechanical

2x5

2x5

2x5

2x5

5.10

Service brake

6.1

Drive motor rating S2 60 min

kW

6.2

Lift motor rating at S3 15 %

kW

6.3

Battery acc. to DIN 43 531/35/36 A, B, C, no

6.4

Battery voltage, nominal capacity K5

6.5

Battery weight

6.6

Energy consumption acc. to VDI cycle

8.1

Type of drive control

8.2

Operating pressure for attachments

8.3

Oil volume for attachments

V / Ah

11

11

11

11

43531 A

43531 A

43531A

43531A

48/550 (575)9)

48/700 (700) 9)

48/700 (700) 9)

48/660 (690) 9)

856

1118

1118

1013

6.8

7.1

7.4

7.6

kg

kWh / h

bar

170

170

170

170

32 8)

32 8)

32 8)

32 8)

8.4

Sound level at the drivers ear according to DIN 12053 dB (A)

< 65

< 65

< 65

< 65

8.5

Towing coupling, type DIN

With lifting mast vertical

Optional: pneumatic tyres, 18 x 7-8 7 16PR or wrap-around

Optional: pneumatic tyres, 15x4 1/2-8/12PR

Optional: pneumatic tyres, 16 x 68 / 10PR

According to VDI 2198

Hydrau

48/

digital control/stepless digital control/stepless digital control/stepless digital control/stepless digital c

l / min

1)

2)

3)

4)

11

45 x

5)

6)

7)

8)

Optional: wrap-around tyres

With 150 mm free lift

With wrap-around tyre, 18 x 6 b1 1074

At 80% nominal pressure (8.2)

9)

Data between brackets are taken from the ZV

instruction leaflet on Use of European-series

DIN-standard batteries (July 2002 edition).

TB_E16P-E20P_engl_C.qxd

23.07.2008

14:59 Uhr

Seite 2 (2,1)

E 20 P

LINDE

LINDE

LINDE

E 20 PL

E 20 PH

E 20 PHL

Battery

Battery

Battery

Seated

Seated

Seated

2.0

2.0

2.0

500

500

500

374

374

374

1537 1)

1481 1)

1589 1)

3360

3520

3600

4785/575

4890/630

4905/695

1646/1710

1705/1815

1805/1795

SE

SE

SE

200/50 10 5)

200/50 10 5)

200/50 10 5)

16 x 6 8

16 x 6 8 5)

16 x 6 8 5)

2x/2

2x/2

2x/2

965

965

965

807

807

807

5/ 7

5/ 7

5/ 7

2019 6)

2194 6)

2194 6)

150

150

150

2800

3150

3150

3401

3751

3751

1970

2130

2130

908

1065

1065

538

602

602

3045

2987

3095

2145

2087

2195

1172/1050

1172/1050

1172/1050

45 x 100 x 900

45 x 100 x 900

45 x 100 x 900

2A

2A

2A

1040

1040

1040

97

97

97

103

103

103

3470

3412

3520

3595

3537

3645

1771

1713

1821

Safety distance a = 200 mm

Standard mast (in mm)

20/20

20/20

20/20

Lift

0.5/0.6

0.5/0.6

0.5/0.6

Overall height, retracted

(to 150 mm free lift)

0.58/0.5

0.58/0.5

0.58/0.5

2300/2300

2300/2300

2300/2300

10000/10000

10000/10000

10000/10000

5.8/9.2

5.7/8.9

5.7/8.9

19.3/31.6

18.8/30.3

18.8/30.3

4.6/4.0

4.6/4.0

4.7/4.1

Hydraulic/mechanical

Hydraulic/mechanical

Hydraulic/mechanical

2x5

2x5

E 16 PH/ E 18 PH/E 20 PH/E 20 PHL

h3

2800

3150

4250

3150

4250

h1

2021

2196

2746

2196

2746

Overall height, extended h4

3363

3713

4813

3713

4813

Duplex mast (in mm)

E 16 PH/ E 18 PH/E 20 PH/E 20 PHL

2795

3145

3845

3145

3845

2x5

Overall height, retracted h1

1946

2121

2471

2121

2471

Overall height, extended h4

3377

3727

4427

3727

4427

Special free lift

1343

1518

1868

1518

1868

11

11

11

43531A

43531A

48/660 (690) 9)

48/700 (700) 9)

48/840 (840) 9)

1013

1118

1309

7.6

7.6

7.9

digital control/stepless digital control/stepless digital control/stepless

170

170

170

32 8)

32 8)

32 8)

< 65

< 65

< 65

Lift

E 16 P/ E 20 PL

h3

43531A

ween brackets are taken from the ZVEI

on leaflet on Use of European-series cells in

dard batteries (July 2002 edition).

E 16 P/ E 20 PL

h2

Triplex mast (in mm)

Lift

E 16 P/ E 20 PL

E 16 PH/ E 18 PH/E 20 PH/E 20 PHL

h3

4100

4625

5475

4625

5475

Overall height, retracted h1

1946

2121

2471

2121

2471

Overall height, extended h4

4702

5227

6077

5227

6077

Special free lift

1344

1519

1781

1519

1781

h2

Other lift heights on request

Minimum lift height does not apply to tall vehicle

TB_E16P-E20P_engl_C.qxd

23.07.2008

14:59 Uhr

Seite 2 (3,1)

PHL

4250

2746

4813

PHL

3845

2471

Lifting capacity diagrams

E16P

E 16 PH

1.600

1.500

mm

1.200

1.600

1.500

1.300

mm

1.100

1.000

900

800

700

1.000

900

800

700

4.500

5.500

600

6.500

600

6.500

500

7.000

500

7.000

6.000

400

500

4427

600

700

800

kg

900 1.000

5.000

5.500

6.000

400

500

600

700

800

kg

mm

900 1.000

mm

1868

E 18PH

E 20PL/E 20PH/E 20PHL

1.800

PHL

5475

2471

6077

1781

mm

1.500

1.300

1.200

1.100

1.000

900

800

700

4.500

5.500

6.000

6.500

6.800

7.000

600

500

500

kg

600

700

800

900 1.000

mm

2.000

1.800

mm

1.300

1.300

4.500

5.500

1.100

1.000

900

800

700

6.000

6.500

6.800

7.000

600

500

500

600

kg

700

800

900 1.000

mm

TB_E16P-E20P_engl_C.qxd

23.07.2008

14:59 Uhr

Seite 1 (3,1)

Features

Linde twin accelerator control

3 Seamless, rapid reversing without

repositioning the feet

3 Short pedal travel

3 Fatigue-free working

3 Increased throughput and

performance

Linde Load Control

3 Safe and seamless load handling

with millimetre accuracy

3 Effortless fingertip control of

all mast functions

3 Joystick controls integrated

into the armrest

Economical AC drive

3 Two powerful AC drive motors

integrated in the front axle

3 Seamless acceleration and variable

torque characteristics

3 Excellent structural integrity and

stability

3 Extremely quiet in operation

Linde operators compartment

3 Ergonomically designed for efficient,

fatigue-free working

3 Spacious operators compartment

with generous floor plate area

3 Cushioned comfort mast and drive

axle are isolated from the chassis

and cab by a unique resilient

suspension system that absorbs

shock loadings

Linde compact drive axle

3 Twin drive design with high

performance Linde AC technology

3 Integrated AC lift motor

3 Optimum energy efficiency

3 Maintenance-free oil-bath vane brake

3 Electronic components housed in

sealed unit for complete protection

Linde energy management

3 Optimised energy consumption

3 Accurate battery condition

indicator

3 Simple horizontal or vertical

battery changing options

3 Optional built-in high frequency

charger for convenience and

flexibility

3 Record of battery usage

Linde Material Handling GmbH, Postfach 10 0136, 63701 Aschaffenburg, Germany

Phone +49.60 21.99-0, Fax +49.60 21.99-15 70, www.linde-mh.com, info@linde-mh.de

The manufacturer reserves the right to alter specifications without notice.

All dimensions are subject to manufacturing tolerances.

Linde combi axle

Unique Linde combi axle

offers total flexibility

3 Combi axle gives this

four wheeled truck the

maneuvrability of a three

wheeler

3 Excellent four wheeled

stability and safety on

hard uneven surfaces

3 The perfect flexible

combination for inside/

outside working

Printed in Germany 078 e 5 0708 Ind.C Ca

Linde clearview mast design

with top mounted tilt cylinders for

seamless load control and stability

3 Excellent view of load and

surroundings through the robust

yet slim mast profiles

3 Nominal capacity retained to

maximum lift heights

3 High residual capacities in

all applications

3 Exceptionally stable

You might also like

- Load Capacity Diagrams Show Lifting Capacities of ForkliftsDocument2 pagesLoad Capacity Diagrams Show Lifting Capacities of ForkliftsYogi YoiNo ratings yet

- E20 25 30 35 en (F5a)Document2 pagesE20 25 30 35 en (F5a)Tomy Abad AbadNo ratings yet

- E12 20l en (7de)Document8 pagesE12 20l en (7de)Tomy Abad AbadNo ratings yet

- E10 en (6b6)Document4 pagesE10 en (6b6)Tomy Abad AbadNo ratings yet

- B 620 B 625 B 625 L B 630 B 630 L B 635 en (2f1)Document5 pagesB 620 B 625 B 625 L B 630 B 630 L B 635 en (2f1)Tomy Abad AbadNo ratings yet

- c360 400 en (C5e)Document6 pagesc360 400 en (C5e)Tomy Abad AbadNo ratings yet

- c90 5 8 en (cd7)Document6 pagesc90 5 8 en (cd7)Tomy Abad AbadNo ratings yet

- E16p 20phl en (5cf)Document6 pagesE16p 20phl en (5cf)Tomy Abad Abad100% (1)

- E12 20l en (7de)Document8 pagesE12 20l en (7de)Tomy Abad AbadNo ratings yet

- E3.50 5.50xl enDocument7 pagesE3.50 5.50xl enTomy Abad AbadNo ratings yet

- B12 - 17 - 2 JP As ExDocument136 pagesB12 - 17 - 2 JP As ExTomy Abad AbadNo ratings yet

- Cat XE60-80Document4 pagesCat XE60-80Tomy Abad AbadNo ratings yet

- E1.50 2.00xms en (3c7)Document6 pagesE1.50 2.00xms en (3c7)Tomy Abad AbadNo ratings yet

- A10 13 en (0de)Document6 pagesA10 13 en (0de)Tomy Abad AbadNo ratings yet

- Cesab B300-B420 enDocument12 pagesCesab B300-B420 enTomy Abad AbadNo ratings yet

- Call For Yanmar Solutions: Midi-ExcavatorDocument8 pagesCall For Yanmar Solutions: Midi-ExcavatorTomy Abad AbadNo ratings yet

- Cesab B300-B420 enDocument12 pagesCesab B300-B420 enTomy Abad AbadNo ratings yet

- E 8 10n en (Efb)Document4 pagesE 8 10n en (Efb)Tomy Abad AbadNo ratings yet

- GB C50R-3CDocument8 pagesGB C50R-3CTomy Abad AbadNo ratings yet

- Call For Yanmar Solutions: CarrierDocument8 pagesCall For Yanmar Solutions: CarrierTomy Abad AbadNo ratings yet

- GB C12R-BDocument8 pagesGB C12R-BTomy Abad AbadNo ratings yet

- Compact Micro-Excavator for Confined SpacesDocument8 pagesCompact Micro-Excavator for Confined SpacesTomy Abad AbadNo ratings yet

- Call for Yanmar micro-excavator solutionsDocument8 pagesCall for Yanmar micro-excavator solutionsTomy Abad AbadNo ratings yet

- GB SV100-2 0714Document16 pagesGB SV100-2 0714Tomy Abad AbadNo ratings yet

- GB SV26 0114Document12 pagesGB SV26 0114Tomy Abad AbadNo ratings yet

- Compact Micro-Excavator for Confined SpacesDocument8 pagesCompact Micro-Excavator for Confined SpacesTomy Abad AbadNo ratings yet

- GB SV18 0714Document12 pagesGB SV18 0714Tomy Abad AbadNo ratings yet

- Compact Mini-Excavator for Confined SpacesDocument8 pagesCompact Mini-Excavator for Confined SpacesTomy Abad AbadNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 21734Document67 pages21734Jeef100% (4)

- Product Information: Traffic Management AccessoryDocument12 pagesProduct Information: Traffic Management AccessoryCORAL ALONSONo ratings yet

- Anotações - Seminários em Língua Inglesa - Discurso LiterárioDocument17 pagesAnotações - Seminários em Língua Inglesa - Discurso LiterárioAline MoraisNo ratings yet

- ASTM D 2726 - 05a Standard Test Method For Bulk Specific Gravity and DensityDocument4 pagesASTM D 2726 - 05a Standard Test Method For Bulk Specific Gravity and DensityAzlan AbdNo ratings yet

- Plant Seedling Classification Using CNNDocument12 pagesPlant Seedling Classification Using CNNYugal Joshi0% (1)

- Wattgate 381 Audio Grade Duplex Socket - y CableDocument20 pagesWattgate 381 Audio Grade Duplex Socket - y Cableapi-11530725100% (1)

- Alfa Laval Energy Balance Casestory enDocument2 pagesAlfa Laval Energy Balance Casestory enHélder FernandoNo ratings yet

- The Indonesian Food Processing Industry (Final)Document48 pagesThe Indonesian Food Processing Industry (Final)patalnoNo ratings yet

- Caffeine Extraction 1 PDFDocument25 pagesCaffeine Extraction 1 PDFShanay ShahNo ratings yet

- DD Cen TR 10347-2006Document14 pagesDD Cen TR 10347-2006prabagaran88% (8)

- 02 - AFT - Know Your Pump & System Curves - Part 2ADocument8 pages02 - AFT - Know Your Pump & System Curves - Part 2AAlfonso José García LagunaNo ratings yet

- Sea Cucumber PDFDocument171 pagesSea Cucumber PDFRebeccaSulivanNo ratings yet

- Environmental Law Handbook ExampleDocument20 pagesEnvironmental Law Handbook ExampleThomson Reuters Australia100% (5)

- Aspirasi MekoniumDocument17 pagesAspirasi MekoniumimanNo ratings yet

- University of Toronto Astronomy 101 Midterm Test QuestionsDocument6 pagesUniversity of Toronto Astronomy 101 Midterm Test QuestionsTrash RowzanNo ratings yet

- Answer Example Source Questio N Type Topic: Glish/Doanddoeshasandhave/Bjgd /post - HTMDocument92 pagesAnswer Example Source Questio N Type Topic: Glish/Doanddoeshasandhave/Bjgd /post - HTMFarhan HakimiNo ratings yet

- The UFO MonthlyDocument21 pagesThe UFO MonthlySAB78No ratings yet

- English Idea BookDocument2 pagesEnglish Idea Bookapi-551731988No ratings yet

- AC Circuit 2 (Three-Phase)Document2 pagesAC Circuit 2 (Three-Phase)marlon desaculaNo ratings yet

- Sir ClanDocument109 pagesSir ClanJames AbendanNo ratings yet

- 405 Econometrics Odar N. Gujarati: Prof. M. El-SakkaDocument27 pages405 Econometrics Odar N. Gujarati: Prof. M. El-SakkaKashif KhurshidNo ratings yet

- 28 2001 04 0007Document1 page28 2001 04 0007Fernando FanteNo ratings yet

- 1 5109354204116287644 PDFDocument336 pages1 5109354204116287644 PDFGerardoNo ratings yet

- FMDocument12 pagesFMGajera HarshadNo ratings yet

- MP Birla Group: Training MatrixDocument3 pagesMP Birla Group: Training MatrixAprilia kusumaNo ratings yet

- Crusher Type Part Number Description Weight (KG)Document3 pagesCrusher Type Part Number Description Weight (KG)Juvenal CorreiaNo ratings yet

- Ruby and Pink Sapphire - IntroDocument3 pagesRuby and Pink Sapphire - Introrazanym100% (1)

- Hanoi 2023 Peoples Picks AwardsDocument113 pagesHanoi 2023 Peoples Picks AwardsNguyen Anh VuNo ratings yet

- Finger Print Based Voting System For Rigging Free Governing SystemDocument2 pagesFinger Print Based Voting System For Rigging Free Governing SystemArvind TilotiaNo ratings yet

- Design and Analysis of Interleaved Boost Converter for Increased Renewable Energy OutputDocument18 pagesDesign and Analysis of Interleaved Boost Converter for Increased Renewable Energy OutputHarshitNo ratings yet