Professional Documents

Culture Documents

# Pelabuhan 10

Uploaded by

Muhammad Abdul FattahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

# Pelabuhan 10

Uploaded by

Muhammad Abdul FattahCopyright:

Available Formats

FACILITIES REQUIREMENTS

Based on the queuing theory

Rules of thumb for annual throughput capacity :

* General cargo berth = 100.000 150.000 ton

* Container = 500.000 1.000.000 ton

Analytical solutions :

1. Berths :

* Exponential service time distribution (for general cargo

ports / larger ports)

* Constant service time distribution (for bulk carriers)

* Poisson distribution (for small general cargo ports)

2. Storage facilities : based on average throughput, stowage

factor & storage time. (uncertain)

3. Equipment : based on down-time, productivity, cargo

handling work force & maintenance. (uncertain)

GENERAL ASPECTS OF PLANNING PORT FACILITIES

Extreme high water (flooding of quays, damage of

cargo handling and fixed installations)

Extreme low water ( ships to leave berths not to

enter port)

Extreme wind conditions (Interruption of cargo

handling, Ships to leave berths, damage to building)

Extreme currents (Interruption of arrival & departure of

ships, erosion damage to structures)

Extreme wave actions (Damage to breakwaters interruption

of cargo handling, ships to leave berths, siltation of basins)

Aft

Forward

Bridge

Stem

Midships

Bow

Length between perps

Length overall

Port side

Astem

Ahead

Starboard side

Min freeboard

Moulded depth

Draf scantling

= max draft

Keel

Width or Beam

Figure. Ship Definitions

BERTH & TERMINAL DESIGN IN GENERAL

Weight, Fdist, size, manoeuvrability of Che

structures, foundations & pavement.

Existing fixed facilities

influences lay out & design of

influence the choice of CHE.

Cargo units

the choice of CHE & storage facilities.

Storage facilities & CHE system

General cargo berths

flexible.

require a continuos land area or

combination of

supported deck & land area immediately adjacent to

the ship along their entire length.

(Connected to berthing, mooring & CH).

Liquid bulk terminal

* CH talces place in mid-ships manifold.

* Need 1 loading platform.

* Need berthing & mooring platform.

Dry bulk terminal

* Loading / unloading through no. of haches along

the ship.

* Permanent conueying systems.

* Finger piers & offshore installations

land.

Container terminal

: Similar to drybulk terminals

Ro / Ro

: Similar to liquid bulk terminals need only one loading

platform (Ramp).

Calculation the required capacity terminal

to handle agiven traffic demand :

a)

For conventional break-bulk cargo : first.

* To ascertain the number of berthing point

to keep

ship waiting time down to economic level.

b)

For container cargo : first to determine the area needed to

handle the annual through put.

c)

For specialized bulk cargo : first to find the hourly rate of

dischage or loading

The calculation method requires

to handle the ship in accp.time.

:

Study of productivity.

No & size of facilities needed.

The level of service to be provided.

For development plans (basic feature) ; Terminal capacity X level

of service provided

Total No. of Boxes/year

No.TEU/year

=

% 40'

100

% 40'x Total No. of Boxes

100

No. of 40 Boxes

No. of 20 Boxes

= - No. of 40 + Total No. of Boxes

Length Berth

= LoA + 20 m

Nbr. Of Container Boxes/ship

Time At Berth for land or unload =

No. Ships per year

Ship. Capacity TEU

% 40'

100

No. of Cont / ship

No. of moves per gantry xNo.gantry/Berth

No. Total Boxes/ year

No.Cont Boxes / ship

No. Ships per week

= No. Ship / year

Ships call / week

= Round up

Required Berth time

= Time at berth x No. of ships / year

Available time/berth

= 365 x 24 x Max. berth occupation

52

Theorical required no of berth

No. ships / week

Requiredberth time

Available time per berth

Eff. No. of Berth

Requiredberth time

= Roundup

Available time per berth

Quay Length

= Eff. No. of Berth x Length of berth

Effective berth occupation

100 x Requiredberth time

365 x 24 x Eff. No of berth

365

No of cont through one storage unit =

Dwiil time (Cont. days in CY)

N0. of TEU / year

N0. of cont.through one storage unit

CY Capacity inTEU

Bottom area / stack

= Area ratio x 6 x 2,5

CY area for full berth

= CY Cap. in TEU x bottom area/stack

Stackingheight

CY capacity for gantry

= CY Cap. in TEU Full x % Empty TEU

Total CY area

100

Depth CY Empty

Quay length

For General Cargo :

C=

Starting from; Q (tons)

Qt

375

Vol =

Loading Capacity

= Q.sf

ton

year

Surface =

Vol

h

For Ro / Ro :

Starting from; No. of caps N

N x Sf

Surface( m3 / car)

( m3 / car)

Loading Capacity; C =

N.t car

365 year

SHIPS & THEIR INFLUENCE ON PORT FACILITIES

SHIP CHARACTERISTICS

MAIN DIMENSIONS :

Length

Beam

Draft

GOVERNING /

DETERMINATION

Length & layout of

terminal, length of

quay, location of

transit sheds

The reach of CHE

Water depth along the

berth, in channels &

basins

INFLUENCE ON PORT

FACILITIES

Widtha & bends of

channels, the size of

port basins

Width of channels &

basins

CARGO CARRYING CAPACITY

Minimum storage

requirement for full ship

load

Handing rate

CARGO HANDLING GEAR

(CRANE & PUMPS)

Cargo handling rates

Types of CHE (quay

cranes & booster pumps)

TYPES OF CARGO UNITS

(BULK, CONTAINER, ETC)

Handling equipment &

storage

SHAPE OF HULL & MOTION

Mooring & fender design

MOORING EQUIPMENT

(ROPES & WIRES)

Motion of ships & their

mooring forces

MANOEUVRABILITY AT LOW

SPEED

Channels, port entrance,

basin layout & harbor tug

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Ijirae:: Tower Crne Mast Anchorage Tie DesignDocument8 pagesIjirae:: Tower Crne Mast Anchorage Tie DesignIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Tower Crane Footing Structural Design For All Cranes PDFDocument14 pagesTower Crane Footing Structural Design For All Cranes PDFmordidomi92% (71)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- D 420 - 98 Rdqymc05oa - PDFDocument7 pagesD 420 - 98 Rdqymc05oa - PDFJhony CotaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Contoh Cross ExcelDocument42 pagesContoh Cross ExcelMuhammad Abdul FattahNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- ABC ManualDocument347 pagesABC ManualsergiodelgadoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 2.4Ghz Wireless Optical Mouse: Your Inspirations. Our InnovationsDocument2 pages2.4Ghz Wireless Optical Mouse: Your Inspirations. Our InnovationsMuhammad Abdul FattahNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Producto Key AutocadDocument4 pagesProducto Key AutocadFrancisco Javier Hernández FloresNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- nrcs142p2 032035Document10 pagesnrcs142p2 032035Muhammad Abdul FattahNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Lampiran PageDocument5 pagesLampiran PageMuhammad Abdul FattahNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- AntekDocument96 pagesAntekMuhammad Abdul FattahNo ratings yet

- CV314-3 Cloverleaf Interchange DesignDocument26 pagesCV314-3 Cloverleaf Interchange DesignstradaricNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Lightweight Concrete Mix Design (Sekam+albument) CBR Unila 14Document2 pagesLightweight Concrete Mix Design (Sekam+albument) CBR Unila 14Muhammad Abdul FattahNo ratings yet

- Naruto ShippudenDocument109 pagesNaruto ShippudenMuhammad Abdul Fattah50% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- # Pelabuhan 1Document14 pages# Pelabuhan 1Muhammad Abdul FattahNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Situasi - Civil Engineering Building-Azimuth 0-ModelDocument1 pageSituasi - Civil Engineering Building-Azimuth 0-ModelMuhammad Abdul FattahNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

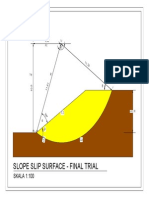

- Slope Slip Surface - Final Trial: SKALA 1:100Document1 pageSlope Slip Surface - Final Trial: SKALA 1:100Muhammad Abdul FattahNo ratings yet

- Statistik Untuk Hidrologi 14 Mei 2013Document30 pagesStatistik Untuk Hidrologi 14 Mei 2013Muhammad Abdul FattahNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Soal Statika 1Document1 pageSoal Statika 1Muhammad Abdul FattahNo ratings yet

- Soal Statika 3Document1 pageSoal Statika 3Muhammad Abdul FattahNo ratings yet

- Statistik Untuk Hidrologi 14 Mei 2013Document30 pagesStatistik Untuk Hidrologi 14 Mei 2013Muhammad Abdul FattahNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Soil ChartDocument1 pageSoil ChartMuhammad Abdul FattahNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Soal Statika 2Document1 pageSoal Statika 2Muhammad Abdul FattahNo ratings yet

- Soal Statika 3Document1 pageSoal Statika 3Muhammad Abdul FattahNo ratings yet

- Soal Statika 3Document1 pageSoal Statika 3Muhammad Abdul FattahNo ratings yet

- Soal Statika 1Document1 pageSoal Statika 1Muhammad Abdul FattahNo ratings yet

- Soal Statika 2Document1 pageSoal Statika 2Muhammad Abdul FattahNo ratings yet

- Indian Evidence Act Renaissance Law College NotesDocument74 pagesIndian Evidence Act Renaissance Law College NotesDivya100% (6)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Bio-Bibliographical NoteDocument20 pagesBio-Bibliographical NoteRica EstandarteNo ratings yet

- Teqball Supporting Utah Refugees With Donated TablesDocument5 pagesTeqball Supporting Utah Refugees With Donated TablesPR.comNo ratings yet

- Rosales Street, Maasin City, Southern Leyte: MissionDocument11 pagesRosales Street, Maasin City, Southern Leyte: MissionJezzene Gail R. PalerNo ratings yet

- Letra de La Canción de AdeleDocument2 pagesLetra de La Canción de AdeleEli MirandaNo ratings yet

- 4rthsummativequizes 140317015553 Phpapp01Document19 pages4rthsummativequizes 140317015553 Phpapp01Edal SantosNo ratings yet

- 8Document4 pages8Anca Lucia MNo ratings yet

- Module V - ConsentDocument58 pagesModule V - ConsentAadhitya NarayananNo ratings yet

- Q16 Lecture PDFDocument34 pagesQ16 Lecture PDFtommy1232No ratings yet

- Unit 2 Higher TestDocument2 pagesUnit 2 Higher Testvanu1986No ratings yet

- Apologetics, Kreeft Chapter 8: The Divinity of ChristDocument32 pagesApologetics, Kreeft Chapter 8: The Divinity of ChristrichardNo ratings yet

- Letter of Pilates WifeDocument16 pagesLetter of Pilates WifeTeodoro CastilloNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Topic and SourcesDocument2 pagesTopic and Sourcescarter.henmanNo ratings yet

- Trial Technique - Ja (Collection of Sum of Money)Document3 pagesTrial Technique - Ja (Collection of Sum of Money)Olan Dave LachicaNo ratings yet

- EvidenceDocument3 pagesEvidenceEricha Joy Gonadan100% (1)

- W4 D1 Basic Grammar - Present Smple and ContinuousDocument14 pagesW4 D1 Basic Grammar - Present Smple and ContinuousDainty EnglishNo ratings yet

- Wayne's World / Austin Powers CrossoverDocument7 pagesWayne's World / Austin Powers CrossoverTom Ryan RyanNo ratings yet

- Daftar Lagu DisneyDocument13 pagesDaftar Lagu DisneyAngkasa KarimNo ratings yet

- Gender and EducationDocument8 pagesGender and EducationRosheil Ramos100% (1)

- Virtuoso V Municipal JudgeDocument2 pagesVirtuoso V Municipal JudgeCarlota Nicolas Villaroman100% (1)

- Brutus and Antonys SpeechesDocument10 pagesBrutus and Antonys SpeechesEmily CoppneyNo ratings yet

- DT 0120 20191113 BoardingpassDocument2 pagesDT 0120 20191113 BoardingpassEusebio DiembaNo ratings yet

- Manuel VS., PeopleDocument7 pagesManuel VS., PeopleAldrinmarkquintanaNo ratings yet

- Cory Aquinos SpeechDocument19 pagesCory Aquinos SpeechLuke Demate Borja100% (4)

- Los Pueblos de La Sierra. APÉNDICE 2 Encomiendas y EncomenderosDocument11 pagesLos Pueblos de La Sierra. APÉNDICE 2 Encomiendas y EncomenderosDenisse Bonilla ReynosoNo ratings yet

- The Legend of BanyuwangiDocument11 pagesThe Legend of Banyuwangibing printingNo ratings yet

- NepotismDocument2 pagesNepotismMay Larkspur TadeoNo ratings yet

- Christmas Carols Medley Guitar ChordsDocument3 pagesChristmas Carols Medley Guitar ChordsCarlo Emil100% (1)

- FinalDocument3 pagesFinalapi-317482441No ratings yet

- JESTROVIC, S. From Brecht To BelgradeDocument10 pagesJESTROVIC, S. From Brecht To BelgradeMarcela MariaNo ratings yet