Professional Documents

Culture Documents

HydrocarbonProcessMkt BR Us

Uploaded by

kavehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HydrocarbonProcessMkt BR Us

Uploaded by

kavehCopyright:

Available Formats

HYDROCARBON PROCESSING

OUR KNOWLEDGE AND EXPERTISE

YOUR SUCCESS

Storage

Reactors

Mixer

Separator

Furnace

Feedstock clean

Oxidation or reduction

Process heater

Separation or fractionation

Product storage

Waste product disposal

Generic process schematic

SERVOTOUGH

SpectraExact (2500)

2

Customized high performance systems designed to meet your needs

YOUR GAS ANALYSIS PARTNERS

ADDING VALUE TO YOUR PROCESS

Servomex is one of the world's largest specialist manufacturer

of gas analyzers and systems all of which are used extensively

in the hydrocarbon processing industry, due both to their

superior performance and to the fact that they are specifically

designed to match the needs of all stages of plant operation.

Servomex understands that reliable analysis and measurement of

gases is only one aspect of maintaining proper control of the total

hydrocarbon process. By providing you with products that use

stable, long-life and low maintenance sensors, along with hazardous

area analyzers that do not require purging or reference gases, we

ensure that our equipment will help you to achieve the highest

efficiency, yield and quality for your product.

Working with plant and process designers, constructors and

systems integrators we provide expert guidance on the best

methods of gas analysis even before a facility is built.

Operating alongside your own process engineers, Servomex

personnel can help you to define exactly the different types of

gas measurement that are required and where in the process

they should be located for optimum plant performance.

Servomex is already recommended as the supplier of choice

on over 50 licensed chemical processes worldwide and by

working closely with key research and development, and

engineering process specialists, we can ensure that the best

gas analysis solution is used for your process.

Our experience in gas analysis, built over more than 50 years,

combined with a detailed knowledge of its application in oil and

gas extraction, refining, chemical processing and delivery, is

your guarantee of safe operation of plant, product quality and

process efficiency.

Servomex produces reliable solutions for more than 100 chemical

and petrochemical processes. Applications where we have extensive

experience and are known for our class leading analyzers are:

-

Catalytic regeneration

Continuous emissions monitoring

Fractionation

High boiling point solvents

Process heaters

Product purity

Safety critical process control

Solvent recovery

Storage

Vent/flare headers

Servomexs goal is to help you achieve lower cost of ownership, by

ensuring your gas analyzers and systems are robust, reliable and

economical to operate, giving you minimum downtime and

optimum performance for continuous plant operation.

Superior gas analysis

performance for all

stages of plant operation

SERVOTOUGH OxyExact (2200)

Servomex offers a range of analyzers that use a

combination of intrinsic safety and flameproof

enclosures, providing the ideal combination of

safety, reliability and cost-of-ownership.

SERVOTOUGH Oxy (1900) - Leading the way with intrinsic safety

TECHNOLOGY THAT MEETS YOUR NEEDS

SPECIALIST KNOWLEDGE - WORLDWIDE SUPPORT

Identifying the right gas measurement for your process is never

simple. Servomexs experts will work with you throughout every

stage of this important decision so you can be sure your plant will

operate at its highest level of efficiency and maximum safety.

Today's complex plant, advanced systems engineering and sensitive

chemical handling, requires a high level of expertise to operate and

maintain. With a Servomex analyzer on your plant, you can be sure

that the best available analysis and measurement technology is at

work 24 hours a day.

Oxygen Measurement (Magnetodynamic paramagnetic type)

Operating at high temperatures and in demanding environments

requires both robust detection technology and electronics that are

designed to meet all appropriate national and international safety

standards. Servomex's oxygen analyzers use non-depleting, autocalibrating paramagnetic sensor cells, using the first sensor

developed to achieve up to 110C providing the ultimate in

reliability and repeatability of measurement with high payback on

initial investment.

Infrared Measurements

Servomex's unique infrared gas analyzers and sampling systems are

used extensively in applications requiring trace analysis of solvents

and liquids. The SERVOTOUGH SpectraExact (2500) series of

analyzers utilises single beam, dual wavelength IR, GFC or soft UV

technology, depending upon the application. This technique

minimizes cross interference and maximizes sensitivity.

Combustion analysis (O2 and combustibles)

The rigorous measurements required for combustion control require

long life sensors that are resistant to SO2 and CO. Servomex provides

fast in-phase analysis and dynamic response: giving lower cost of

ownership with rapid payback of investment costs.

Laser

Tuneable diode laser is a well proven and reliable technology for

demanding industrial applications. The SERVOTOUGH Laser (2900)

employs the single line spectroscopy technique which reduces cross

interference from other gases and enables very low concentrations of

gas to be detected. With an immediate response to concentration

changes and insitu measurements this makes laser technology a viable

option for a number of different applications.

Servomex is well known throughout the hydrocarbon processing

industry for working with our customers to solve their problems. Our

global support network includes teams of maintenance engineers,

chemical engineers and systems specialists to ensure a high level of

technical expertise is always on hand.

To meet your support needs exactly, we offer a number of services

that have been customized specifically to suit your own plant

requirements. Whether you need an emergency response, training

for your personnel, a replacement analyzer solution while your own

equipment is serviced, or simply a planned maintenance programme,

Servomex can match the needs of your plant and personnel.

Ultimately, our aim is to help you maximize your investment by

providing a gas analysis capability that is unrivalled by any other

manufacturer.

CUSTOMERS INCLUDE

Aker Kvaerner

BASF

Conoco Philips

Dow

Exxon Mobil

FPC

Lyondell

Mitsui

Reliance

SABIC

Saudi Aramco

Shell

Shin Etsu

Sinopec

Shanghai Petrochemical

Technip

SERVOTOUGH Fluegas (2700)

SERVOTOUGH Laser (2900)

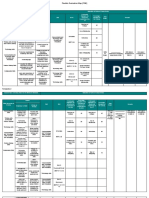

Servomex range of products for the Hydrocarbon Process Industry

EMISSIONS ANALYSERS

SERVOTOUGH

(Hazardous Area)

SERVOTOUGH

2500 - SERVOTOUGH SpectraExact

2900 - SERVOTOUGH Laser

SERVOPRO

(Safe Area)

SERVOTOUGH

SERVOTOUGH

2700 - SERVOTOUGH Fluegas

2900 - SERVOTOUGH Laser

1900

1900

2200

2500

2900

1800

Digital - SERVOTOUGH Oxy

IR - SERVOTOUGH Spectra

- SERVOTOUGH OxyExact

- SERVOTOUGH SpectraExact

- SERVOTOUGH Laser

SERVOPRO

SERVOPRO

5400 - SERVOPRO MultiExact

4100

4900

SERVOFLEX

PROCESS ANALYSERS

COMBUSTION ANALYSERS

SERVOFLEX

SERVOFLEX

(Portables)

5100 i.s - SERVOFLEX Micro i.s

BUSINESS CENTRES

TECHNICAL CENTRES

EUROPEAN (Europe, Middle East, Africa and India):

Servomex Group Limited

Jarvis Brook

Crowborough

East Sussex, UK

TN6 3FB

Tel: +44 (0)1892 652181

Fax: +44 (0)1892 662253

+31 (0) 79 3301581

Fax: +31 (0) 79 3420819

Toll Free from UK/France/Germany/Netherlands:

00800 7378 6639

AMERICAS:

+1 281 295 5800

5100 i.s - SERVOFLEX Micro i.s

5100 Marine - SERVOFLEX MicroMarine

Servomex Canada

1076 Johnson Street,

Thetford Mines,

Qc Canada,

G6G 5W6

Tel: +1 418 3340990

Fax: +1 418 3340660

Fax: 1 281 295 5899

Toll Free from US:

1 800 862 0200

ASIA PACIFIC:

+86 (0) 21 6489 7570

Fax: +86 (0) 21 6442 6498

WWW.SERVOMEX.COM

Servomex has a policy of constant product improvement and reserves the right to change specifications without notice.

Servomex Group Limited. 2009. A Spectris company. All rights reserved.

HCPMB Rev. 1 07/09 A

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Nebosh Oil Gas Content 2Document8 pagesNebosh Oil Gas Content 2kavehNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Oil and Gas Summary SyllabusDocument5 pagesOil and Gas Summary Syllabusnedian1982100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Igc 2Document201 pagesIgc 2shadabNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- HACCP FormsDocument10 pagesHACCP FormskavehNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- NEBOSH Brochure EngDocument2 pagesNEBOSH Brochure EngArman Ul NasarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- IOG1 Element 5Document10 pagesIOG1 Element 5kaveh100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- NGC Practice Papers 1nov2012 PDFDocument12 pagesNGC Practice Papers 1nov2012 PDFPradeep Aneja100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Melissa 2Document51 pagesMelissa 2kavehNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Archive of SID: Analysis of Accidents in Nine Iranian Gas Refineries: 2007-2011Document6 pagesArchive of SID: Analysis of Accidents in Nine Iranian Gas Refineries: 2007-2011kavehNo ratings yet

- IOG1 Element 3Document22 pagesIOG1 Element 3kaveh100% (2)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- IOG1 Element 1Document18 pagesIOG1 Element 1kaveh100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- IOG1 Element 2Document12 pagesIOG1 Element 2kaveh100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- IOG1 Element 4Document12 pagesIOG1 Element 4kavehNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- NCC 3rd EdnDocument5 pagesNCC 3rd EdnkavehNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- NEBOSHDocument5 pagesNEBOSHkaveh50% (2)

- 77113900403Document14 pages77113900403kavehNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- NHC 1st EdnDocument5 pagesNHC 1st EdnkavehNo ratings yet

- Emergency Medical Services ToolkitDocument31 pagesEmergency Medical Services ToolkitkavehNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- NURS 330 May 9, 2011Document66 pagesNURS 330 May 9, 2011kavehNo ratings yet

- First Aid in The WorkplaceDocument28 pagesFirst Aid in The Workplacejay_rajeshirkeNo ratings yet

- Decision Tree For Eye Exposures: Yes ContinueDocument1 pageDecision Tree For Eye Exposures: Yes ContinuekavehNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- N Sms I 55681392841800Document13 pagesN Sms I 55681392841800kavehNo ratings yet

- Safety IN LPG Storage, Bottling & TransportationDocument28 pagesSafety IN LPG Storage, Bottling & TransportationkavehNo ratings yet

- Well Plugging and Abandonment Paper From A National Petroleum Council Study (9.15.11)Document21 pagesWell Plugging and Abandonment Paper From A National Petroleum Council Study (9.15.11)Westchester GasetteNo ratings yet

- Sex Dysfunc TDocument28 pagesSex Dysfunc TkavehNo ratings yet

- Sex at The Anatomical LevelDocument46 pagesSex at The Anatomical LevelkavehNo ratings yet

- 2009 MODU Code A.1023Document148 pages2009 MODU Code A.1023Praveen BalachandranNo ratings yet

- 6.EER Analysis ExternalDocument8 pages6.EER Analysis ExternalkavehNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Entrepreneurial Method - Co-Create The Future!Document11 pagesThe Entrepreneurial Method - Co-Create The Future!kavehNo ratings yet

- Practical Java Machine LearningDocument46 pagesPractical Java Machine Learningeazpil01No ratings yet

- ISO - ISO 3452-1 2013 - Non-Destructive Testing - Penetrant Testing - Part 1 General PrinciplesDocument3 pagesISO - ISO 3452-1 2013 - Non-Destructive Testing - Penetrant Testing - Part 1 General PrinciplesKline LineNo ratings yet

- Chapter 10 AnswersDocument6 pagesChapter 10 AnswersJohn HoltNo ratings yet

- JIO Mini-ProjectDocument26 pagesJIO Mini-ProjectAliNo ratings yet

- Hexagon PPM Caesar II Fundamentals Info Sheet 1Document2 pagesHexagon PPM Caesar II Fundamentals Info Sheet 1Muhammad Zahir ShahNo ratings yet

- ArevaDocument10 pagesArevamkbpgcilNo ratings yet

- Imm Star l10 08 07 17 v06Document4 pagesImm Star l10 08 07 17 v06Risto GodevNo ratings yet

- Yamaha Enticer II Et410tr Br250tf Et410trf Vk540ef 2000 Owners ManualDocument103 pagesYamaha Enticer II Et410tr Br250tf Et410trf Vk540ef 2000 Owners ManualS. H. JAWALE100% (1)

- HVDC Converter Station Layout PDFDocument37 pagesHVDC Converter Station Layout PDFmgkvprNo ratings yet

- CS SP Prraaccttiiccaall F Fiille e Se Essssiio On n2 20 02 233 - 2 24 4 Clla AS SS S 112 2Document30 pagesCS SP Prraaccttiiccaall F Fiille e Se Essssiio On n2 20 02 233 - 2 24 4 Clla AS SS S 112 2piyushkumar155900No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2 SK 170Document6 pages2 SK 170Robert GabrielNo ratings yet

- Auto CAD Civil 3DDocument2 pagesAuto CAD Civil 3DCadd CentreNo ratings yet

- 3-EASY FPGA Development Board Users ManualDocument26 pages3-EASY FPGA Development Board Users ManualTeoKissNo ratings yet

- Christine Jocson - EFAA1 - FEM - TemplateDocument3 pagesChristine Jocson - EFAA1 - FEM - TemplateRomano Jocson100% (1)

- Expert System Design For Fault Diagnosis in Diesel EnginesDocument10 pagesExpert System Design For Fault Diagnosis in Diesel EnginesevanNo ratings yet

- M32195F4TFPDocument1,044 pagesM32195F4TFPnorbertoNo ratings yet

- American Series ManualDocument26 pagesAmerican Series ManualIsael HernandezNo ratings yet

- Network Device Drivers in Linux Sub1Document3 pagesNetwork Device Drivers in Linux Sub1hrushiNo ratings yet

- Cost Comparison For Business Decision-Makers: Oracle Exadata Database Machine vs. IBM Power SystemsDocument30 pagesCost Comparison For Business Decision-Makers: Oracle Exadata Database Machine vs. IBM Power SystemsGautham SampathNo ratings yet

- Bosch Voice Alarm Systems: Contributing To A Safer WorldDocument8 pagesBosch Voice Alarm Systems: Contributing To A Safer WorldSaad KhNo ratings yet

- COVERLETTER (Rig Mechanic)Document1 pageCOVERLETTER (Rig Mechanic)shehryar khanNo ratings yet

- Hannstar Product Specification: Model: Hsd101Pfw2Document26 pagesHannstar Product Specification: Model: Hsd101Pfw2massipoedNo ratings yet

- Performance Analysis of Statistical Time Division Multiplexing Systems PDFDocument16 pagesPerformance Analysis of Statistical Time Division Multiplexing Systems PDFshofi nur aisyahNo ratings yet

- Eee-Vii-high Voltage Engineering U8Document14 pagesEee-Vii-high Voltage Engineering U8ACE PROFILESNo ratings yet

- Aberdeen Research Report Big Data AnalyticsDocument11 pagesAberdeen Research Report Big Data AnalyticsRosie3k90% (1)

- TTT Accreditation ProcessDocument1 pageTTT Accreditation ProcessnhishamNo ratings yet

- KK2.1.X Instruction Manual V1.19S1 ProDocument38 pagesKK2.1.X Instruction Manual V1.19S1 ProAnonymous Gcqk4Pry3rNo ratings yet

- Chapter 2 - Key Roles and Responsibilities - UpdatedDocument27 pagesChapter 2 - Key Roles and Responsibilities - Updatedferran fangNo ratings yet

- User Guide Vodafone Mobile Wi-Fi R205Document24 pagesUser Guide Vodafone Mobile Wi-Fi R205Koliko TogaNo ratings yet

- Contour CraftingDocument43 pagesContour CraftingTEMY PETERNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)