Professional Documents

Culture Documents

FileDownLoad, 32908, en PDF

Uploaded by

정진교Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FileDownLoad, 32908, en PDF

Uploaded by

정진교Copyright:

Available Formats

WICKLOW COUNTY COUNCIL

ARKLOW SEWERAGE SCHEME

OUTLINE METHOD STATEMENT FOR SEA OUTFALL CONSTRUCTION

DECEMBER 2012

Arklow Sewerage Scheme

Outline Method Statement for Sea Outfall Construction

1.0 INTRODUCTION

This outline method statement is prepared on behalf of Wicklow County Council in response to

queries from the Department of the Environment, Community and Local Government (DECLG)

regarding a foreshore application for the proposed marine sea outfall at Seabank as part of the Arklow

Sewerage Scheme.

This method statement shall not be interpreted as a detailed construction method statement for these

works as this will be dependent on the exact methods of construction by the DBO Contractor.

1.1

Arklow Sewerage Scheme

Currently, the existing sewerage system within the town discharges raw sewage to the River Avoca

via a number of different outlets. The new scheme is required to meet all national and EU

environmental legislation.

The design philosophy for the scheme is outlined as follows; All foul/combined discharges are to be

collected by proposed interceptor sewers constructed along both banks of the Avoca River with flows

conveyed to the proposed North Quay Pumping Station and pumped onwards for treatment to the

proposed WWTW at Seabank located approx. 2.5km to the north east of the town. Flows from the

south of the river are to be conveyed via a proposed siphon under the river bed to the North Quay.

The proposed WWTW includes the construction of a marine sea outfall with a diffuser system at the

end. The sea outfall forms an integral part of the works and is designed to cater for the future

expansion of the WWTW up to a PE of 36,000.

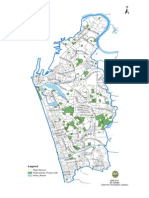

The proposed location of the Sea Outfall is shown in Figure 1.1 below.

20121213 Method Statement for Sea Outfall Construction

December 2012

Arklow Sewerage Scheme

Outline Method Statement for Sea Outfall Construction

Figure 1.1 Proposed Sea Outfall Location

20121213 Method Statement for Sea Outfall Construction

December 2012

Arklow Sewerage Scheme

Outline Method Statement for Sea Outfall Construction

2.0 ACCESS TO PROPOSED WORKS

The EIS for the proposed WWTW requires a no-dig section of the sea outfall from the WWTW under

the existing sand dunes. The no-dig technique shall be used to put the landward end of the outfall

pipe into position so that the surface of the dunes will not be disturbed. This will involve sinking a 17m deep shaft at the WWTW site and drilling out to a temporary reception pit at the exit point on the

state foreshore.

In considering tenders submitted for the design of the Works, no construction

techniques that involve excavation through the dunes will be acceptable. This temporary reception

shaft will be removed upon completionand the foreshore will be fully reinstated to the original

condition post construction. Suitable no-dig techniques include tunnelling (conventional tunnelling,

micro-tunnelling, pipe-jacking) and drilling. This will be decided by the DBO Contractor.

It is estimated that the temporary reception shaft will cover an area approximately 5m x 5m. Options

available to the contractor will be sheet piled cofferdam construction or precast concrete caisson type

construction. Under the EIS no vehicular access to the privately owned sand dune and beach area is

permitted. Construction plant and materials will be brought to site using marine transport.

Material will be excavated, stockpiled and backfilled by marine access only. Upon completion of

construction, the temporary reception shaft will be backfilled with the selected excavated material and

compacted in layers to avoid any future depressions or soft spots. A protective concrete matt

protection will be constructed in the foreshore to prevent damage to the pipe due to wave action and

scouring. The seabed will be fully restored to its original condition using excavated backfilled material

upon completion. All plant and reception shaft material will be removed from site by marine transport

only.

20121213 Method Statement for Sea Outfall Construction

December 2012

Arklow Sewerage Scheme

Outline Method Statement for Sea Outfall Construction

3.0 PROPOSED SEA OUTFALL AND DIFFUSER SYSTEM

2.13.1 General

Formatted: Bullets and Numbering

The 500mm ID Sea Outfall pipe will have a diffuser section at its extremity. The constituent material

of the outfall pipe could be welded steel, welded polyethylene or some other equivalent material that

can be formed into a continuous length. The diffuser section will terminate in deep water approx.

990m from the low water mark. Details of the proposed outfall in plan and longitudinal section are

shown on Drawing No. 466/EIS/004 of the EIS. The pipe will run in a south-westerly direction from

the treatment works, skirting the north-eastern end of the concrete sea wall at Porters Rocks.

A surge tank will be constructed within the treatment works, at the head of the outfall pipe. A valving

arrangement at the surge tank will allow a regular flushing of the submarine pipe and will prevent

fouling of the diffuser section.

3.2

Construction of the Work

Construction of the outfall pipe will be carried out either prior to or simultaneously with the treatment

works. It will be the Contractors responsibility to assemble the pipeline and to find a location for

preparing it, but access to the beach and sand dune system will be prohibited for these purposes.

This will require assembling the pipeline at an alternative location and floating it into position. A typical

operation is shown in Figure 3.1.

Figure 3.1 Typical marine based transportation of pipes

20121213 Method Statement for Sea Outfall Construction

December 2012

Arklow Sewerage Scheme

Outline Method Statement for Sea Outfall Construction

The outfall pipe will be put into position by burying it in a trench excavated on the seabed. The trench

will be excavated either in one pass or section by section. The bedding material will be placed in

position and the pipeline will be dropped into the trench either all in one pre-fabricated length or

section by section. Surround material will then be placed around the pipe. The trench will also be

back-filled with the excavated material either all at once or section by section. Suitable modes of

construction of the outfall pipe include a bottom-tow method, lay-barge operations or drilling.

Construction of the sea outfall will be carried out during the months of May to October in a single year.

Should the DBO contractor decide on a lay-barge operations, this will require marine based

equipment similar to that in Figure 3.2.

Figure 3.2 Typical Lay-barge operations

A protective concrete mat made of Armorflex or some other equivalent product, will be placed over the

outfall pipe in shallow water (see drawing 466/EIS/004 of the EIS). The concrete mat could be

lowered by crane into position, but other modes of installation suggested by the Contractor will be

taken into consideration.

The mode of connection between the tunnel and outfall pipe is likely to be a proprietary fixing and may

involve welding, bolting or flanging. The method used will depend on the Contractors construction

method for the pipeline.

The end of the diffuser system will be marked with a yellow navigation buoy with a St. Andrews cross

and a flashing yellow beacon that will be in accordance with the requirements of Commissioners of

Irish Lights. This buoy will be connected to the end of the diffuser system via steel chains. Wicklow

County Council or their agents will be responsible for the maintenance of the buoy and the marine

structure.

20121213 Method Statement for Sea Outfall Construction

December 2012

Arklow Sewerage Scheme

Outline Method Statement for Sea Outfall Construction

4.0 PROGRAMME

Construction of the Sea Outfall, which is expected to take 6 months, will either be completed prior to

the commencement of work on the Treatment Works or will be carried out in conjunction with

construction of the Treatment Works.

Construction of the sea outfall will be carried out during the months of May to October in a single year.

The proposed works shall comply in full with the requirements of the Foreshore Act 1933.

20121213 Method Statement for Sea Outfall Construction

December 2012

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Operations Manual PDFDocument295 pagesOperations Manual PDF정진교No ratings yet

- 1.2 Org ChartDocument1 page1.2 Org Chart정진교No ratings yet

- Earthquake Resistant Design of Concrete Buildings According To Eurocode 8Document17 pagesEarthquake Resistant Design of Concrete Buildings According To Eurocode 8정진교No ratings yet

- AS 1170.4 - Earthquake Actions in Australia - 2007 PDFDocument57 pagesAS 1170.4 - Earthquake Actions in Australia - 2007 PDF정진교88% (8)

- Iceland - The Ultimate Road TripDocument15 pagesIceland - The Ultimate Road TripRMascilNo ratings yet

- VSWS Sample Questions AnswersDocument16 pagesVSWS Sample Questions AnswersWayaya2009100% (1)

- Dredging Management PlanDocument39 pagesDredging Management PlanBambang Permana100% (2)

- Geotechnical Design Based On Eurocode 7Document5 pagesGeotechnical Design Based On Eurocode 7정진교No ratings yet

- Ansi 9.8Document11 pagesAnsi 9.8alvaroaguinaga0% (1)

- Design of Pile Foundations Following Eurocode 7Document10 pagesDesign of Pile Foundations Following Eurocode 7정진교100% (1)

- Design of Diaphragm Walls According To Eurocode 7Document6 pagesDesign of Diaphragm Walls According To Eurocode 7정진교No ratings yet

- Shristi, Farm StructureDocument70 pagesShristi, Farm StructureShristi ShefaliNo ratings yet

- 14 Murray Roberts Marine Near Shore Subsea PipelinesDocument6 pages14 Murray Roberts Marine Near Shore Subsea Pipelines정진교No ratings yet

- Renderoc FC (1) Fairing Coat PDFDocument4 pagesRenderoc FC (1) Fairing Coat PDFPrashant MankarNo ratings yet

- SOFEC CALM BUOY FINAL 3page RedDocument3 pagesSOFEC CALM BUOY FINAL 3page RedJ. Jorge TorresNo ratings yet

- Capability Statement RH - Maritime South East Asia Sep 2012Document62 pagesCapability Statement RH - Maritime South East Asia Sep 2012정진교No ratings yet

- Isolation of Pure CultureDocument7 pagesIsolation of Pure CultureVignesh ReddyNo ratings yet

- Ujjain - Landscape PlanningDocument10 pagesUjjain - Landscape PlanningVidyotma SinghNo ratings yet

- PROBES-75 Guidelines For Developing Greenbelts PDFDocument210 pagesPROBES-75 Guidelines For Developing Greenbelts PDFNur DiansyahNo ratings yet

- Passive Down Draft Evaporative CoolingDocument2 pagesPassive Down Draft Evaporative Coolingأمير معروف75% (4)

- BS en 752-1 - 1996 PDFDocument17 pagesBS en 752-1 - 1996 PDF정진교No ratings yet

- 2.7 Cost Report Verification SheetDocument1 page2.7 Cost Report Verification Sheet정진교No ratings yet

- Bearing ScheduleDocument3 pagesBearing Schedule정진교No ratings yet

- Froude Krylov ForceDocument2 pagesFroude Krylov Force정진교No ratings yet

- Port Experts RHDHV - Extract - Jan 2013Document36 pagesPort Experts RHDHV - Extract - Jan 2013정진교No ratings yet

- CV Sanjay JainDocument37 pagesCV Sanjay JainKumardeep MukhopadhyayNo ratings yet

- 1 28 SafetyDocument28 pages1 28 SafetyLiam WoodredNo ratings yet

- Unit 5Document3 pagesUnit 5Edit KovácsNo ratings yet

- The Earths ClimatesDocument14 pagesThe Earths ClimatesApril Rose AyubanNo ratings yet

- Air Water Chapter EvsDocument10 pagesAir Water Chapter EvsSea HawkNo ratings yet

- Wate Supply 4 EOHSDocument341 pagesWate Supply 4 EOHSYosief DemissieNo ratings yet

- Aeration IEEEDocument7 pagesAeration IEEEdragh meh downNo ratings yet

- Punta Cana.: UnderstandDocument3 pagesPunta Cana.: UnderstandErick Garcia VieyraNo ratings yet

- Dabur ReportDocument32 pagesDabur ReportMudit MisraNo ratings yet

- Jacques Cousteau: Jacques Cousteau, in Full Jacques-Yves Cousteau, (BornDocument4 pagesJacques Cousteau: Jacques Cousteau, in Full Jacques-Yves Cousteau, (BornanguesanNo ratings yet

- Sheringham Geography CourseworkDocument7 pagesSheringham Geography Courseworkf5d7ejd0100% (1)

- Indian Standard - Code of Basic Requirements For Water Supply, Drainage and Sanitation (Fourth Revision)Document19 pagesIndian Standard - Code of Basic Requirements For Water Supply, Drainage and Sanitation (Fourth Revision)Pranshu Devgan100% (1)

- Chapter 2 PracticeDocument9 pagesChapter 2 PracticeDanica TatingNo ratings yet

- Fagor AdvanceDocument99 pagesFagor AdvanceSimeonShoninskiNo ratings yet

- Approval From Colombo Municipal CouncilDocument4 pagesApproval From Colombo Municipal CouncilkamaldeshapriyaNo ratings yet

- Efektivitas Pembubuhan Kaporit Dalam Menurunkan Kadar Zat Besi (Fe) Pada Air Sumur Gali Tahun 2013Document10 pagesEfektivitas Pembubuhan Kaporit Dalam Menurunkan Kadar Zat Besi (Fe) Pada Air Sumur Gali Tahun 2013arifNo ratings yet

- Vitra Faucets and AccessoriesDocument272 pagesVitra Faucets and AccessoriescothacoNo ratings yet

- Oxarol C80 MSDSDocument9 pagesOxarol C80 MSDShiba JamalNo ratings yet

- Msds Ready Mixed Concrete PDFDocument8 pagesMsds Ready Mixed Concrete PDFGangsar Lukmanjaya100% (1)

- Drawing Document List Proyek Pltu Malinau (2 X 3 MW)Document1 pageDrawing Document List Proyek Pltu Malinau (2 X 3 MW)Iwan AbdurahmanNo ratings yet