Professional Documents

Culture Documents

S-6011 - DC Asdasd Asda Dad A

Uploaded by

Peja JusohOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S-6011 - DC Asdasd Asda Dad A

Uploaded by

Peja JusohCopyright:

Available Formats

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: DESIGN CALCULATION

DATE: 11.01.2015

DOC. REF. NO.: MSET/M2-251/S-6011/DC

REVISION: 02

SUBJECT: TITLE PAGE

JOB NO: M2-251

SERIAL NO.: M2-251/002

DESIGN CALCULATION

Fuel Gas Filter Coalescer

TAG NO: S-6011

PROJECT NAME:

E6 Development Project

CLIENT NAME:

VME Process

02

01

Rev.

No.

11.01.15

10.12.14

Issued for Approval

Issued for Review

Date

Description of Revision

Mohd Faizal

Muhd Faizal

Prepared

by

Yahasliza

Yahasliza

Reviewed

by

Azahar

Azahar

Approved

by

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: DESIGN CALCULATION

DATE: 11.01.2015

DOC. REF. NO.: MSET/M2-251/S-6011/DC

REVISION: 02

SUBJECT: TITLE PAGE

JOB NO: M2-251

SERIAL NO.: M2-234/002

DESIGN DATA

ITEM NO.

FUEL GAS FILTER COALESCER

ASME SEC.VIII DIV.1, 2013 EDITION +

DEP 31.22. 20.31

DESIGN CODE

DESIGN

OPERATING

TEST PRESSURE

PRESSURE (barg) (Int./Ext.)

18/FV

TEMPERATURE (C) (Max./Min)

50/0

PRESSURE (barg) (In / Out)

7 / 6.8

TEMPERATURE (C) (In / Out)

24.8-38.9 / 24.7-38.8

HYDROTEST (barg)

(1.3xMAPxLSR)(note1) (UG-99c)

24.625 (Horizontal Position)

PNEUMATIC

NO

MAWP (hot & corroded) (barg)

18.347

MAP (new & cold) (barg)

18.998

OUTSIDE DIAMETER / SEAM TO SEAM (mm)

219.1/3120

TYPE OF HEAD

MATERIAL OF CONSTRUCTION (SHELL & HEAD)

HEAT TREATMENT

2:1 ELLIP HEAD/BODY

FLANGE

SA 312 TP 316/316L & SA

403 WP 316/316L

NORMALISED

NO

PWHT

NO

IMPACT TEST

NO

MDMT (C)

RADIOGRAPHY

HEAD: 100%, SHELL: 100%

JOINT EFFICIENCY

HEAD:1.0 , SHELL: 1.0

CORROSION ALLOWANCE (mm)

CONTENTS

HC LIQUID/GAS

ERECTION WEIGHT (kg)

390

CAPACITY (m3)

0.11

PRESSURE VESSEL DESIGN CALCULATION

Note: 1.MAP will be used in lieu of MAWP for determining hydro test pressure

(As per DEP 31.22.20.31-Gen, Jan 09)

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: DESIGN CALCULATION

DATE: 11.01.2015

DOC. REF. NO.: MSET/M2-251/S-6011/DC

REVISION: 02

SUBJECT: TITLE PAGE

JOB NO: M2-251

SERIAL NO.: M2-251/002

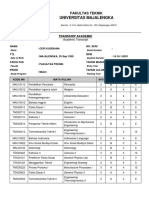

TABLE OF CONTENT

NO

CONTENT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Input Echo

Flg Calc [Int P] : A1 (flange)

Flg Calc [Int P] : A1 (blind)

Internal Pressure Calculations

External Pressure Calculations

Element and Detail Weights

Nozzle Flange MAWP

Wind Load Calculation

Earthquake Load Calculation

Wind / Earthquake Shear, Bending

Wind Deflection

Stress due Combined Loads

Center of Gravity Calculation

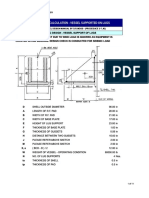

Sup. Lug Calc

Nozzle Calculation

Nozzle Schedule

Nozzle Summary

MDMT Summary

Vessel Design Summary

Attachment 1 : Wind Pressure Calc

Attachment 2 : Transportation Calc

Attachment 3 : Trunnion Calc

PAGE NO.

4

20

25

29

33

37

42

44

45

47

49

55

61

62

78

213

217

220

222

225

227

266

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

PV Elite Vessel Analysis Program: Input Data

Design Internal Pressure (for test)

18.000

Design Internal Temperature

50

Type of Test

bar

C

UG-99(c)

Test Position

Horizontal

Projection of Nozzle from Vessel Top

200.00

mm

Projection of Nozzle from Vessel Bottom

200.00

mm

Minimum Design Metal Temperature

Type of Construction

Welded

Special Service

None

Degree of Radiography

RT 1

Miscellaneous Weight Percent

0.0

Use Higher Longitudinal Stresses (Flag)

Select t for Internal Pressure (Flag)

Select t for External Pressure (Flag)

Select t for Axial Stress (Flag)

Select Location for Stiff. Rings (Flag)

Consider Vortex Shedding

Perform a Corroded Pressure test

Is this a Heat Exchanger

No

User Defined Test Press. (Used if > 0)

0.0000

bar

User defined MAWP

0.0000

bar

User defined MAPnc

0.0000

bar

Load Case 1

NP+EW+WI+FW+BW

Load Case 2

NP+EW+EE+FS+BS

Load Case 3

NP+OW+WI+FW+BW

Load Case 4

NP+OW+EQ+FS+BS

Load Case 5

NP+HW+HI

Load Case 6

NP+HW+HE

4

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Load Case 7

IP+OW+WI+FW+BW

Load Case 8

IP+OW+EQ+FS+BS

Load Case 9

EP+OW+WI+FW+BW

Load Case 10

EP+OW+EQ+FS+BS

Load Case 11

HP+HW+HI

Load Case 12

HP+HW+HE

Load Case 13

IP+WE+EW

Load Case 14

IP+WF+CW

Load Case 15

IP+VO+OW

Load Case 16

IP+VE+EW

Load Case 17

NP+VO+OW

Load Case 18

FS+BS+IP+OW

Load Case 19

FS+BS+EP+OW

Wind Design Code

User Defined

Wind Profile Height mm

Pressure

kPa

10000.0000

0.7500

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

Damping Factor (Beta) for Wind (Ope)

0.0100

Damping Factor (Beta) for Wind (Empty)

0.0000

Damping Factor (Beta) for Wind (Filled)

0.0000

Seismic Design Code

G Loading

Seismic Importance Factor

1.000

G Loading Coefficient Gx

0.500

G Loading Coefficient Gz

0.500

5

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

G Loading Coefficient Gy

-2.000

Percent Seismic for Test

0.000

Design Nozzle for M.A.W.P. (maximum)

Consider MAP New and Cold in Noz. Design

Consider External Loads for Nozzle Des.

Use ASME VIII-1 Appendix 1-9

Material Database Year

Current w/Addenda or Code Year

Configuration Directives:

Do not use Nozzle MDMT Interpretation VIII-1 01-37

No

Use Table G instead of exact equation for "A"

Yes

Shell Head Joints are Tapered

Yes

Compute "K" in corroded condition

Yes

Use Code Case 2286

No

Use the MAWP to compute the MDMT

Yes

Using Metric Material Databases, ASME II D

No

Complete Listing of Vessel Elements and Details:

Element From Node

10

Element To Node

20

Element Type

Elliptical

Description

Head

Distance "FROM" to "TO"

55.000

mm

Element Outside Diameter

219.07

mm

Element Thickness

7.1565

mm

Internal Corrosion Allowance

0.0000

mm

Nominal Thickness

8.1788

mm

External Corrosion Allowance

0.0000

mm

Design Internal Pressure

18.000

bar

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Design Temperature Internal Pressure

50

Design External Pressure

1.0342

Design Temperature External Pressure

50

Effective Diameter Multiplier

C

bar

C

1.2

Material Name

SA-403 316L

Allowable Stress, Ambient

115.15

MPa

Allowable Stress, Operating

115.15

MPa

Allowable Stress, Hydrotest

155.14

MPa

Material Density

8027.2

kg/m

P Number Thickness

0.0000

mm

Yield Stress, Operating

165.40

MPa

External Pressure Chart Name

HA-4

UNS Number

Product Form

S31603

Smls. & wld. fittings

Efficiency, Longitudinal Seam

1.0

Efficiency, Circumferential Seam

1.0

Elliptical Head Factor

2.0

Element From Node

10

Detail Type

Nozzle

Detail ID

N3

Dist. from "FROM" Node / Offset dist

0.0000

Nozzle Diameter

2.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

90.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

--------------------------------------------------------------------

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Element From Node

20

Element To Node

30

Element Type

Cylinder

Description

Shell

Distance "FROM" to "TO"

3120.0

mm

Element Outside Diameter

219.07

mm

Element Thickness

7.1565

mm

Internal Corrosion Allowance

0.0000

mm

Nominal Thickness

8.1788

mm

External Corrosion Allowance

0.0000

mm

Design Internal Pressure

18.000

bar

Design Temperature Internal Pressure

50

Design External Pressure

1.0342

Design Temperature External Pressure

50

Effective Diameter Multiplier

C

bar

C

1.2

Material Name

SA-312 TP316L

Allowable Stress, Ambient

115.15

MPa

Allowable Stress, Operating

115.15

MPa

Allowable Stress, Hydrotest

155.14

MPa

Material Density

8027.2

kg/m

P Number Thickness

0.0000

mm

Yield Stress, Operating

165.40

MPa

External Pressure Chart Name

HA-4

UNS Number

Product Form

S31603

Smls. & wld. pipe

Efficiency, Longitudinal Seam

1.0

Efficiency, Circumferential Seam

1.0

Element From Node

20

Detail Type

Liquid

Detail ID

LIQUID (LOWER)

Dist. from "FROM" Node / Offset dist

0.0000

mm

Height/Length of Liquid

650.00

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Liquid Density

803.23

Element From Node

kg/m

20

Detail Type

Nozzle

Detail ID

N1

Dist. from "FROM" Node / Offset dist

1200.0

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

0.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

N2

Dist. from "FROM" Node / Offset dist

2920.0

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

285.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

N4

Dist. from "FROM" Node / Offset dist

1425.0

Nozzle Diameter

2.0

9

mm

in.

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

90.0

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

N5

Dist. from "FROM" Node / Offset dist

3000.0

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

345.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

N6

Dist. from "FROM" Node / Offset dist

200.00

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

90.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

10

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Element From Node

20

Detail Type

Nozzle

Detail ID

K1A

Dist. from "FROM" Node / Offset dist

770.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

20.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K1B

Dist. from "FROM" Node / Offset dist

170.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

20.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K2A

Dist. from "FROM" Node / Offset dist

1010.0

Nozzle Diameter

2.0

Nozzle Schedule

None

11

mm

in.

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Nozzle Class

150

Layout Angle

315.0

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

K2B

Dist. from "FROM" Node / Offset dist

170.00

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

315.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

K3A

Dist. from "FROM" Node / Offset dist

570.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

225.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

12

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Element From Node

20

Detail Type

Nozzle

Detail ID

K3B

Dist. from "FROM" Node / Offset dist

170.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

225.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K4A

Dist. from "FROM" Node / Offset dist

750.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

165.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K4B

Dist. from "FROM" Node / Offset dist

350.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

13

mm

in.

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Layout Angle

165.0

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K6A

Dist. from "FROM" Node / Offset dist

1895.0

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

340.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

K6B

Dist. from "FROM" Node / Offset dist

1445.0

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

340.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

14

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Detail Type

Nozzle

Detail ID

K7A

Dist. from "FROM" Node / Offset dist

1795.0

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

225.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K7B

Dist. from "FROM" Node / Offset dist

1445.0

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

225.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K8A

Dist. from "FROM" Node / Offset dist

1950.0

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

165.0

15

mm

in.

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K8B

Dist. from "FROM" Node / Offset dist

1550.0

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

165.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K5A

Dist. from "FROM" Node / Offset dist

1850.0

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

30.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

16

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Detail ID

K5B

Dist. from "FROM" Node / Offset dist

1500.0

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

30.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

0.0000

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Lug

Detail ID

LUG

Dist. from "FROM" Node / Offset dist

2567.0

Number of Lugs

mm

Dist. from OD to Lug Cntrline(dlug)

600.00

mm

Height of Gusset Plates (hgp)

250.00

mm

Force Bearing Width (wfb)

200.00

mm

Weight of Lug

133.44

Lug Start Angle (degrees)

0.0

Element From Node

20

Detail Type

Weight

Detail ID

FILTER

Dist. from "FROM" Node / Offset dist

1700.0

mm

Miscellaneous Weight

980.60

Offset from Element Centerline

0.0000

mm

Element From Node

20

Detail Type

Weight

Detail ID

LIQUID (UPPER)

Dist. from "FROM" Node / Offset dist

1908.0

17

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Miscellaneous Weight

156.90

Offset from Element Centerline

0.0000

mm

--------------------------------------------------------------------

Element From Node

30

Element To Node

40

Element Type

Flange

Description

Body Flange (DN200)

Distance "FROM" to "TO"

101.60

mm

Flange Inside Diameter (OD for Blinds)

345.00

mm

Element Thickness

28.448

mm

Internal Corrosion Allowance

0.0000

mm

Nominal Thickness

8.1788

mm

External Corrosion Allowance

0.0000

mm

Design Internal Pressure

18.000

bar

Design Temperature Internal Pressure

50

Design External Pressure

1.0342

Design Temperature External Pressure

50

Effective Diameter Multiplier

C

bar

C

1.2

Material Name

SA-182 F316L

Allowable Stress, Ambient

115.15

MPa

Allowable Stress, Operating

115.15

MPa

Allowable Stress, Hydrotest

155.14

MPa

Material Density

8027.2

kg/m

P Number Thickness

0.0000

mm

Yield Stress, Operating

223.30

MPa

External Pressure Chart Name

HA-4

UNS Number

Class / Thickness / Grade

S31603

:: > 5

Product Form

Forgings

Perform Flange Stress Calculation (Y/N)

Weight of ANSI B16.5/B16.47 Flange

0.0000

18

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Input Echo :

Step:

1

1:14p Jan 11,2015

Class of ANSI B16.5/B16.47 Flange

Grade of ANSI B16.5/B16.47 Flange

--------------------------------------------------------------------

Element From Node

40

Element To Node

50

Element Type

Description

Flange

Blind Flange (DN200)

Distance "FROM" to "TO"

28.448

mm

Flange Inside Diameter (OD for Blinds)

345.00

mm

Element Thickness

28.448

mm

Internal Corrosion Allowance

0.0000

mm

Nominal Thickness

0.0000

mm

External Corrosion Allowance

0.0000

mm

Design Internal Pressure

18.000

bar

Design Temperature Internal Pressure

50

Design External Pressure

1.0342

Design Temperature External Pressure

50

Effective Diameter Multiplier

C

bar

C

1.2

Material Name

SA-182 F316L

Perform Flange Stress Calculation (Y/N)

Weight of ANSI B16.5/B16.47 Flange

0.0000

Class of ANSI B16.5/B16.47 Flange

Grade of ANSI B16.5/B16.47 Flange

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

19

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

3

1:14p Jan 11,2015

Flange Input Data Values

Description: A1 (flange) :

Body Flange (DN200)

Description of Flange Geometry (Type)

Design Pressure

Integral Weld Neck

P

18.00

Design Temperature

bar

50

Internal Corrosion Allowance

ci

0.0000

mm

External Corrosion Allowance

ce

0.0000

mm

Use Corrosion Allowance in Thickness Calcs.

No

Flange Inside Diameter

202.692

mm

Flange Outside Diameter

345.000

mm

Flange Thickness

28.4480

mm

Thickness of Hub at Small End

go

7.1564

mm

Thickness of Hub at Large End

g1

20.6184

mm

73.1520

mm

Length of Hub

Flange Material

SA-182 F316L

Flange Material UNS number

S31603

Flange Allowable Stress At Temperature

Sfo

115.15

MPa

Flange Allowable Stress At Ambient

Sfa

115.15

MPa

Bolt Material

SA-193 B7

Bolt Allowable Stress At Temperature

Sb

172.38

MPa

Bolt Allowable Stress At Ambient

Sa

172.38

MPa

Diameter of Bolt Circle

298.500

mm

Nominal Bolt Diameter

19.0500

mm

Type of Threads

TEMA Thread Series

Number of Bolts

Flange Face Outside Diameter

Fod

269.748

20

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

3

1:14p Jan 11,2015

Flange Face Inside Diameter

Fid

Flange Facing Sketch

202.692

mm

1, Code Sketch 1a

Gasket Outside Diameter

Go

263.652

mm

Gasket Inside Diameter

Gi

233.426

mm

Gasket Factor

0.0000

Gasket Design Seating Stress

0.00

Column for Gasket Seating

2, Code Column II

Gasket Thickness

tg

3.1750

ANSI Flange Class

150

ANSI Flange Grade

GR 2.2

MPa

mm

ASME Code, Section VIII, Division 1, 2010, 2011a

Hub Small End Required Thickness due to Internal Pressure:

= (P*(D/2+Ca))/(S*E-0.6*P) per UG-27 (c)(1)

= (18.00*(202.6920/2+0.0000))/(115.15*1.00-0.6*18.00)+Ca

= 1.5995 mm

Hub Small End Hub MAWP:

= (S*E*t)/(R+0.6*t) per UG-27 (c)(1)

= (115.15 * 1.00 * 7.1564 )/(101.3460 + 0.6 * 7.1564 )

= 77.993 bar

Corroded Flange ID,

Bcor = B+2*Fcor

202.692

mm

Corroded Large Hub,

g1Cor = g1-ci

20.618

mm

Corroded Small Hub,

g0Cor = go-ci

7.156

mm

Code R Dimension,

R = (C-B)/2 - g1

27.286

mm

Gasket Contact Width,

N = (Go - Gi) / 2

15.113

mm

7.557

mm

Basic Gasket Width,

bo = N / 2

21

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

3

1:14p Jan 11,2015

Effective Gasket Width,

b = Cb sqrt(bo)

Gasket Reaction Diameter,

G = Go (Self-Energizing)

Basic Flange and Bolt Loads:

Hydrostatic End Load due to Pressure [H]:

= 0.785 * G * Peq

= 0.785 * 263.6520 * 18.000

= 98276.719 N

Contact Load on Gasket Surfaces [Hp]:

= 2 * b * Pi * G * m * P

= 2 * 6.9270 * 3.1416 * 263.6520 * 0.0000 * 18.00

= 0.000 N

Hydrostatic End Load at Flange ID [Hd]:

= Pi * Bcor * P

/ 4

= 3.1416 * 202.6920 *18.0000/4

= 58084.695 N

Pressure Force on Flange Face [Ht]:

= H - Hd

= 98276 - 58084

= 40192.023 N

Operating Bolt Load [Wm1]:

= max( H + Hp + H'p, 0 )

= max( 98276 + 0 + 0 , 0 )

= 98276.719 N

Gasket Seating Bolt Load [Wm2]:

= y * b * Pi * G

+ yPart * bPart * lp

= 0.00*6.9270*3.141*263.652+0.00*0.0000*0.00

= 0.000 N

Required Bolt Area [Am]:

= Maximum of Wm1/Sb, Wm2/Sa

= Maximum of 98276/172 , 0/172

= 570.182 mm

22

6.927

mm

263.652

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

3

1:14p Jan 11,2015

ASME Maximum Circumferential Spacing between Bolts per App. 2 eq. (3) [Bsmax]:

= 2a + 6t/(m + 0.5)

= 2 * 19.050 + 6 * 28.448/(0.00 + 0.5)

= 379.476 mm

Actual Circumferential Bolt Spacing [Bs]:

= C * sin( pi / n )

= 298.500 * sin( 3.142/8 )

= 114.231 mm

ASME Moment Multiplier for Bolt Spacing per App. 2 eq. (7) [Bsc]:

= max( sqrt( Bs/( 2a + t )), 1 )

= max( sqrt( 114.231/( 2 * 19.050 + 28.448 )), 1 )

= 1.3102

Bolting Information for TEMA Imperial Thread Series (Non Mandatory):

----------------------------------------------------------------------------Minimum

Actual

Maximum

----------------------------------------------------------------------------Bolt Area, mm

Radial distance bet. hub and bolts

570.182

1558.706

28.575

27.286

Radial distance bet. bolts and the edge

20.637

23.250

Circumferential spacing between bolts

44.450

114.231

379.476

-----------------------------------------------------------------------------

Flange Design Bolt Load, Gasket Seating [W]:

= Sa * ( Am + Ab ) / 2

= 172.38 * ( 570.1817 + 1558.7064 )/2

= 183467.95 N

Gasket Load for the Operating Condition [HG]:

= Wm1 - H

= 98276 - 98276

23

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

3

1:14p Jan 11,2015

= 0.00 N

Moment Arm Calculations:

Distance to Gasket Load Reaction [hg]:

= (C - G ) / 2

= ( 298.5000 - 263.6520 )/2

= 17.4240 mm

Distance to Face Pressure Reaction [ht]:

= ( R + g1 + hg ) / 2

= ( 27.2856 + 20.6184 + 17.4240 )/2

= 32.6640 mm

Distance to End Pressure Reaction [hd]:

= R + ( g1 / 2 )

= 27.2856 + ( 20.6184/2.0 )

= 37.5948 mm

Summary of Moments for Internal Pressure:

Loading

Force

Distance Bolt Corr

Moment

End Pressure,

Md

58085.

37.5948

1.3102

2862. N-m

Face Pressure,

Mt

40192.

32.6640

1.3102

1721. N-m

Gasket Load,

Mg

0.

17.4240

1.3102

0. N-m

183468.

17.4240

1.3102

4190. N-m

Gasket Seating, Matm

Total Moment for Operation,

Mop

4583. N-m

Total Moment for Gasket seating, Matm

4190. N-m

Note: User choose not to perform Stress Calculations on this ANSI Flange.

Pressure rating of the flange will be used to check code compliance.

Estimated Finished Weight of Flange at given Thk.

19.5

kgm

Estimated Unfinished Weight of Forging at given Thk

49.9

kgm

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

24

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Flg Calc [Int P] : A1 (blind)

Flng:

4

1:14p Jan 11,2015

Flange Input Data Values

Description: A1 (blind)

Blind Flange (DN200)

Description of Flange Geometry (Type)

Blind

Design Pressure

18.00

Design Temperature

bar

50

Internal Corrosion Allowance

ci

0.0000

mm

External Corrosion Allowance

ce

0.0000

mm

Use Corrosion Allowance in Thickness Calcs.

Yes

Flange Outside Diameter

345.000

mm

Flange Thickness

28.4480

mm

Flange Material

SA-182 F316L

Flange Material UNS number

S31603

Flange Allowable Stress At Temperature

Sfo

115.15

MPa

Flange Allowable Stress At Ambient

Sfa

115.15

MPa

Bolt Material

SA-193 B7

Bolt Allowable Stress At Temperature

Sb

172.38

MPa

Bolt Allowable Stress At Ambient

Sa

172.38

MPa

Span

0.000

mm

Diameter of the Load Reaction, Short Span

0.000

mm

Perimeter along the Center of the Bolts

937.765

mm

Diameter of Bolt Circle

298.500

mm

Nominal Bolt Diameter

19.0500

mm

Diameter of the Load Reaction, Long

Type of Threads

TEMA Thread Series

Number of Bolts

Flange Face Outside Diameter

Fod

269.748

25

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Flg Calc [Int P] : A1 (blind)

Flng:

4

1:14p Jan 11,2015

Flange Face Inside Diameter

Fid

Flange Facing Sketch

184.150

mm

1, Code Sketch 1a

Gasket Outside Diameter

Go

263.652

mm

Gasket Inside Diameter

Gi

233.426

mm

Gasket Factor

0.0000

Gasket Design Seating Stress

0.00

Column for Gasket Seating

2, Code Column II

Gasket Thickness

tg

3.1750

ANSI Flange Class

150

ANSI Flange Grade

GR 2.2

MPa

mm

ASME Code, Section VIII, Division 1, 2010, 2011a

Gasket Contact Width,

Basic Gasket Width,

N = (Go - Gi) / 2

bo = N / 2

Effective Gasket Width,

b = Cb sqrt(bo)

Gasket Reaction Diameter,

G = Go (Self-Energizing)

Basic Flange and Bolt Loads:

Hydrostatic End Load due to Pressure [H]:

= 0.785 * G * Peq

= 0.785 * 263.6520 * 18.000

= 98276.719 N

Contact Load on Gasket Surfaces [Hp]:

= 2 * b * Pi * G * m * P

= 2 * 6.9270 * 3.1416 * 263.6520 * 0.0000 * 18.00

= 0.000 N

Operating Bolt Load [Wm1]:

26

15.113

mm

7.557

mm

6.927

mm

263.652

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Flg Calc [Int P] : A1 (blind)

Flng:

4

1:14p Jan 11,2015

= max( H + Hp + H'p, 0 )

= max( 98276 + 0 + 0 , 0 )

= 98276.719 N

Gasket Seating Bolt Load [Wm2]:

= y * b * Pi * G

+ yPart * bPart * lp

= 0.00*6.9270*3.141*263.652+0.00*0.0000*0.00

= 0.000 N

Required Bolt Area [Am]:

= Maximum of Wm1/Sb, Wm2/Sa

= Maximum of 98276/172 , 0/172

= 570.182 mm

ASME Maximum Circumferential Spacing between Bolts per App. 2 eq. (3) [Bsmax]:

= 2a + 6t/(m + 0.5)

= 2 * 19.050 + 6 * 28.448/(0.00 + 0.5)

= 379.476 mm

Actual Circumferential Bolt Spacing [Bs]:

= C * sin( pi / n )

= 298.500 * sin( 3.142/8 )

= 114.231 mm

ASME Moment Multiplier for Bolt Spacing per App. 2 eq. (7) [Bsc]:

= max( sqrt( Bs/( 2a + t )), 1 )

= max( sqrt( 114.231/( 2 * 19.050 + 28.448 )), 1 )

= 1.3102

Bolting Information for TEMA Imperial Thread Series (Non Mandatory):

----------------------------------------------------------------------------Minimum

Actual

Maximum

----------------------------------------------------------------------------Bolt Area, mm

Radial distance bet. bolts and the edge

570.182

1558.706

20.637

23.250

27

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Flg Calc [Int P] : A1 (blind)

Flng:

4

1:14p Jan 11,2015

Circumferential spacing between bolts

44.450

114.231

379.476

-----------------------------------------------------------------------------

Flange Design Bolt Load, Gasket Seating [W]:

= Sa * ( Am + Ab ) / 2

= 172.38 * ( 570.1817 + 1558.7064 )/2

= 183467.95 N

Gasket Load for the Operating Condition [HG]:

= Wm1

= 98276.72 N

Moment Arm Calculations:

Distance to Gasket Load Reaction [hg]:

= (C - G ) / 2

= ( 298.5000 - 263.6520 )/2

= 17.4240 mm

Note: User choose not to perform Stress Calculations on this ANSI Flange.

Pressure rating of the flange will be used to check code compliance.

Estimated Finished Weight of Flange at given Thk.

21.3

kgm

Estimated Unfinished Weight of Forging at given Thk

21.3

kgm

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

28

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Internal Pressure Calculations :

Step:

5

1:14p Jan 11,2015

Element Thickness, Pressure, Diameter and Allowable Stress :

| Int. Press |

From| To | + Liq. Hd

|

bar

|

|

Nominal | Total Corr|

Element |

Allowable |

Thickness | Allowance |

Diameter |

Stress(SE)|

mm

mm

mm

MPa

--------------------------------------------------------------------------Head|

18.051 |

8.1788 |

... |

219.07 |

115.15 |

Shell|

18.051 |

8.1788 |

... |

219.07 |

115.15 |

Body Flang|

18.000 |

8.1788 |

... |

345.00 |

115.15 |

Blind Flan|

18.000 |

... |

... |

345.00 |

115.15 |

M.A.P. |

Minimum |

Required |

| New & Cold |

Thickness |

Thickness |

Element Required Thickness and MAWP :

Design |

From| To |

Pressure |

bar

M.A.W.P. |

Corroded

bar

bar

mm

mm

---------------------------------------------------------------------------Head|

18.0000 |

79.8661 |

79.9173 |

7.15645 |

1.69354 |

Shell|

18.0000 |

77.1854 |

77.2366 |

7.15645 |

1.70673 |

Body Flang|

18.0000 |

18.3984 |

18.9983 |

28.4480 |

No Calc |

Blind Flan|

18.0000 |

18.3984 |

18.9983 |

28.4480 |

No Calc |

18.347

18.998

Minimum

Note : The M.A.W.P is Governed by a Standard Flange !

Flange MAWP including Static Pressure: 18.347 = 18.398 - 0.051 bar

Internal Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2010, 2011a

Elliptical Head From 10 To 20 SA-403 316L at 50 C

29

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Internal Pressure Calculations :

Step:

5

1:14p Jan 11,2015

Head

Longitudinal

Joint:

Circumferential Joint:

Material UNS Number:

Seamless

Full Radiography per UW-11(a) Type 1

S31603

Required Thickness due to Internal Pressure [tr]:

= (P*Do*Kcor)/(2*S*E+2*P*(Kcor-0.1)) per Appendix 1-4 (c)

= (18.051*219.0750*1.000)/(2*115.15*1.00+2*18.051*(1.000-0.1))

= 1.6935 + 0.0000 = 1.6935 mm

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 0.051 bar

= (2*S*E*t)/(Kcor*Do-2*t*(Kcor-0.1)) per Appendix 1-4 (c)

= (2*115.15*1.00*7.1565)/(1.000*219.0750-2*7.1565*(1.00-0.1))

= 79.917 - 0.051 = 79.866

bar

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (2*S*E*t)/(K*Do-2*t*(K-0.1)) per Appendix 1-4 (c)

= (2*115.15*1.00*7.1565)/(1.000*219.0750-2*7.1565*(1.000-0.1))

= 79.917 bar

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(Kcor*Do-2*t*(Kcor-0.1)))/(2*E*t)

= (18.051*(1.000*219.0750-2*7.1565*(1.000-0.1)))/(2*1.00*7.1565)

= 26.009 MPa

Straight Flange Required Thickness:

= (P*Ro)/(S*E+0.4*P) + ca

per Appendix 1-1 (a)(1)

= (18.051*109.5375)/(115.15*1.00+0.4*18.051)+0.000

= 1.707 mm

30

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Internal Pressure Calculations :

Step:

5

1:14p Jan 11,2015

Straight Flange Maximum Allowable Working Pressure:

Less Operating Hydrostatic Head Pressure of 0.051 bar

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (115.15 * 1.00 * 8.1788 )/(109.5375 - 0.4 * 8.1788 )

= 88.610 - 0.051 = 88.559

bar

SA-403 316L, Min Metal Temp without impact per UHA-51: -196 C

Cylindrical Shell From 20 To 30 SA-312 TP316L at 50 C

Shell

Longitudinal

Joint:

Circumferential Joint:

Material UNS Number:

Seamless

Full Radiography per UW-11(a) Type 1

S31603

Required Thickness due to Internal Pressure [tr]:

= (P*Ro) / (S*E+0.4*P) per Appendix 1-1 (a)(1)

= (18.051*109.5375)/(115.15*1.00+0.4*18.051)

= 1.7067 + 0.0000 = 1.7067 mm

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 0.051 bar

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (115.15*1.00*7.1565)/(109.5375-0.4*7.1565)

= 77.237 - 0.051 = 77.185

bar

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (115.15*1.00*7.1565)/(109.5375-0.4*7.1565)

= 77.237 bar

31

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Internal Pressure Calculations :

Step:

5

1:14p Jan 11,2015

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(Ro-0.4*t))/(E*t)

= (18.051*((109.5375-0.4*7.1565))/(1.00*7.1565)

= 26.911 MPa

SA-312 TP316L, Min Metal Temp without impact per UHA-51: -196 C

Hydrostatic Test Pressure Results:

Pressure per UG99b

= 1.3 * M.A.W.P. * Sa/S

23.851

bar

Pressure per UG99b[34] = 1.3 * Design Pres * Sa/S

23.400

bar

Pressure per UG99c

= 1.3 * M.A.P. - Head(Hyd)

24.625

bar

Pressure per UG100

= 1.1 * M.A.W.P. * Sa/S

20.182

bar

Pressure per PED

= 1.43 * MAWP

26.236

bar

Horizontal Test performed per: UG-99c

Please note that Nozzle, Shell, Head, Flange, etc MAWPs are all considered

when determining the hydrotest pressure for those test types that are based

on the MAWP of the vessel.

Stresses on Elements due to Test Pressure:

From To

Stress

Allowable

Ratio

Pressure

---------------------------------------------------------------------Head

35.5

155.1

0.229

24.65

Shell

36.7

155.1

0.237

24.65

----------------------------------------------------------------------

Elements Suitable for Internal Pressure.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

32

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------External Pressure Calculations :

Step:

6

1:14p Jan 11,2015

External Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2010, 2011a

Elliptical Head From 10 to 20 Ext. Chart: HA-4 at 50 C

Head

Elastic Modulus from Chart: HA-4 at 50 C

: 0.192E+06 MPa

Results for Maximum Allowable External Pressure (MAEP):

Tca

OD

D/t

Factor A

7.156

219.07

30.61

0.0045370

83.75

EMAP = B/(K0*D/t) = 83.7457/(0.9000 *30.6122 ) = 30.3922 bar

Results for Required Thickness (Tca):

Tca

OD

D/t

Factor A

0.579

219.07

378.29

0.0003671

35.22

EMAP = B/(K0*D/t) = 35.2178/(0.9000 *378.2943 ) = 1.0343 bar

Check the requirements of UG-33(a)(1) using P = 1.67 * External Design

pressure for this head.

Material UNS Number:

S31603

Required Thickness due to Internal Pressure [tr]:

= (P*Do*Kcor)/(2*S*E+2*P*(Kcor-0.1)) per Appendix 1-4 (c)

= (1.727*219.0750*1.000)/(2*115.15*1.00+2*1.727*(1.000-0.1))

= 0.1641 + 0.0000 = 0.1641 mm

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

= ((2*S*E*t)/(Kcor*Do-2*t*(Kcor-0.1)))/1.67

per Appendix 1-4 (c)

33

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------External Pressure Calculations :

Step:

6

1:14p Jan 11,2015

= ((2*115.15*1.00*7.1565)/(1.000*219.0750-2*7.1565*(1.00-0.1)))/1.67

= 47.855 bar

Maximum Allowable External Pressure [MAEP]:

= min( MAEP, MAWP )

= min( 30.39 , 47.8547 )

= 30.392 bar

Thickness requirements per UG-33(a)(1) govern the required

thickness of this head.

Cylindrical Shell From 20 to 30 Ext. Chart: HA-4 at 50 C

Shell

Elastic Modulus from Chart: HA-4 at 50 C

: 0.192E+06 MPa

Results for Maximum Allowable External Pressure (MAEP):

Tca

OD

SLEN

D/t

L/D

Factor A

7.156

219.07

3192.06

30.61

14.5706

0.0011983

65.86

EMAP = (4*B)/(3*(D/t)) = (4*65.8589 )/(3*30.6122 ) = 28.6811 bar

Results for Required Thickness (Tca):

Tca

OD

SLEN

D/t

L/D

Factor A

1.939

219.07

3192.06

112.96

14.5706

0.0000914

8.76

EMAP = (4*B)/(3*(D/t)) = (4*8.7631 )/(3*112.9565 ) = 1.0342 bar

Results for Maximum Stiffened Length (Slen):

Tca

OD

SLEN

D/t

L/D

Factor A

7.156

219.07

88373.64

30.61

50.0000

0.0011797

65.64

EMAP = (4*B)/(3*(D/t)) = (4*65.6350 )/(3*30.6122 ) = 28.5836 bar

External Pressure Calculations

34

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------External Pressure Calculations :

Step:

6

1:14p Jan 11,2015

Section |

From| To |

Length |

mm

Outside |

Corroded |

Diameter | Thickness |

mm

mm

Factor

Factor |

MPa

|

|

--------------------------------------------------------------------------10|

20|

No Calc |

219.075 |

7.15645 |

0.0045370 |

83.7457 |

20|

30|

3192.06 |

219.075 |

7.15645 |

0.0011983 |

65.8589 |

30|

40|

No Calc |

... |

28.4480 |

No Calc |

No Calc |

40|

50|

No Calc |

... |

28.4480 |

No Calc |

No Calc |

External Pressure Calculations

From| To |

|

External |

External

Actual T. | Required T.|Des. Press. |

M.A.W.P.

bar

mm

External |

mm

External

bar

---------------------------------------------------------------10|

20|

7.15645 |

1.50000 |

1.03420 |

30.3922 |

20|

30|

7.15645 |

1.93946 |

1.03420 |

28.6811 |

30|

40|

28.4480 |

No Calc |

1.03420 |

No Calc |

40|

50|

28.4480 |

No Calc |

1.03420 |

No Calc |

Minimum

28.681

External Pressure Calculations

| Actual Len.| Allow. Len.| Ring Inertia | Ring Inertia |

From| To | Bet. Stiff.| Bet. Stiff.|

|

mm

mm

Required |

mm**4

Available |

mm**4

------------------------------------------------------------------10|

20|

No Calc |

No Calc |

No Calc |

No Calc |

20|

30|

3192.06 |

88373.6 |

No Calc |

No Calc |

30|

40|

No Calc |

No Calc |

No Calc |

No Calc |

40|

50|

No Calc |

No Calc |

No Calc |

No Calc |

35

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------External Pressure Calculations :

Step:

6

1:14p Jan 11,2015

Elements Suitable for External Pressure.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

36

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:14p Jan 11,2015

Element and Detail Weights

Element |

Element |

From| To | Metal Wgt. | ID

|

kgm

Corroded |

Volume |Metal Wgt. |

m

kgm

Corroded | Extra due

ID Volume | Misc %

m

kgm

|

|

|

--------------------------------------------------------------------------10|

20|

5.97865 |

0.0029355 |

5.97865 |

0.0029355 |

0.29893 |

20|

30|

137.032 |

0.10276 |

137.032 |

0.10276 |

6.85162 |

30|

40|

19.5277 |

0.0032789 |

19.5277 |

0.0032789 |

0.97638 |

40|

50|

21.3476 |

... |

21.3476 |

... |

1.06738 |

--------------------------------------------------------------------------Total

183

0.11

183

0.11

Weight of Details

From|Type|

|

Weight of |

X Offset, | Y Offset, |

Detail | Dtl. Cent. |Dtl. Cent. | Description

kgm

mm

mm

------------------------------------------------10|Nozl|

3.82814 |

... |

-51.1905 |

20|Liqd|

17.1931 |

... |

325.000 |

LIQUID (LOWER)

20|Nozl|

7.18497 |

127.781 |

1200.00 |

N1

20|Nozl|

7.18497 |

127.781 |

2920.00 |

N2

20|Nozl|

7.18497 |

127.781 |

1425.00 |

N4

20|Nozl|

7.18497 |

127.781 |

3000.00 |

N5

20|Nozl|

7.18497 |

127.781 |

200.000 |

N6

20|Nozl|

8.15833 |

146.831 |

770.000 |

K1A

20|Nozl|

8.15833 |

146.831 |

170.000 |

K1B

20|Nozl|

7.18496 |

127.781 |

1010.00 |

K2A

20|Nozl|

7.18496 |

127.781 |

170.000 |

K2B

20|Nozl|

8.15833 |

146.831 |

570.000 |

K3A

20|Nozl|

8.15833 |

146.831 |

170.000 |

K3B

37

N3

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:14p Jan 11,2015

20|Nozl|

8.15833 |

146.831 |

750.000 |

K4A

20|Nozl|

8.15833 |

146.831 |

350.000 |

K4B

20|Nozl|

7.18496 |

127.781 |

1895.00 |

K6A

20|Nozl|

7.18496 |

127.781 |

1445.00 |

K6B

20|Nozl|

8.15833 |

146.831 |

1795.00 |

K7A

20|Nozl|

8.15833 |

146.831 |

1445.00 |

K7B

20|Nozl|

8.15833 |

146.831 |

1950.00 |

K8A

20|Nozl|

8.15833 |

146.831 |

1550.00 |

K8B

20|Nozl|

8.15833 |

146.831 |

1850.00 |

K5A

20|Nozl|

8.15833 |

146.831 |

1500.00 |

K5B

20|Lugs|

28.5768 |

... |

2692.00 |

LUG

20|Wght|

100.000 |

... |

1700.00 |

FILTER

20|Wght|

16.0000 |

... |

1908.00 |

LIQUID (UPPER)

Total Weight of Each Detail Type

Total Weight of Liquid

17.2

Total Weight of Nozzles

166.4

Total Weight of Lugs

28.6

Total Weight of Weights

116.0

--------------------------------------------------------------Sum of the Detail Weights

328.2 kgm

Weight Summation

Fabricated

Shop Test

Shipping

Erected

Empty

Operating

-----------------------------------------------------------------------------193.1

388.1

193.1

388.1

193.1

388.1

...

108.9

...

...

...

17.2

166.4

...

166.4

...

...

...

28.6

...

28.6

...

...

...

...

...

...

...

...

116.0

38

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:14p Jan 11,2015

...

...

...

...

...

...

...

...

...

...

166.4

...

...

...

...

...

28.6

...

-----------------------------------------------------------------------------388.1

497.0

388.1

388.1

388.1

521.2 kgm

Miscellaneous Weight Percent: 5.0 %

Note that the above value for the miscellaneous weight percent has

been applied to the shells/heads/flange/tubesheets/tubes etc. in the

weight calculations for metallic components.

Note: The shipping total has been modified because some items have

been specified as being installed in the shop.

Weight Summary

Fabricated Wt.

- Bare Weight W/O Removable Internals

388.1 kgm

Shop Test Wt.

- Fabricated Weight + Water ( Full )

497.0 kgm

Shipping Wt.

- Fab. Wt + Rem. Intls.+ Shipping App.

388.1 kgm

Erected

- Fab. Wt + Rem. Intls.+ Insul. (etc)

388.1 kgm

Ope. Wt. no Liq - Fab. Wt + Intls. + Details + Wghts.

388.1 kgm

Operating Wt.

- Empty Wt + Operating Liq. Uncorroded

521.2 kgm

Field Test Wt.

- Empty Weight + Water (Full)

497.0 kgm

Wt.

Mass of the Upper 1/3 of the Vertical Vessel

102.1 kgm

Outside Surface Areas of Elements

Surface

From| To |

Area

mm

---------------------------39

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:14p Jan 11,2015

10|

20|

91207.0 |

20|

30|

2.167E+06 |

30|

40|

148106. |

40|

50|

124315. |

----------------------------Total

2530993.000 mm

Element and Detail Weights

| To |

From| To |

|

Total Ele.| Total. Ele.|Total. Ele.|

Empty Wgt.|

kgm

Total Dtl.| Oper. Wgt. |

Oper. Wgt.|Hydro. Wgt.| Offset Mom.| No Liquid

kgm

kgm

N-m

kgm

|

|

--------------------------------------------------------------------------10|

20|

10.1057 |

10.1057 |

13.0394 |

... |

10.1057 |

20|Lugs|

252.132 |

361.718 |

336.627 |

182.714 |

347.572 |

Lugs|

30|

54.3161 |

77.9237 |

72.5184 |

39.3614 |

74.8763 |

30|

40|

20.5040 |

20.5040 |

23.7810 |

... |

20.5040 |

40|

50|

22.4150 |

22.4150 |

22.4150 |

... |

22.4150 |

Cumulative Vessel Weight

| Cumulative Ope | Cumulative | Cumulative

From| To | Wgt. No Liquid | Oper. Wgt. | Hydro. Wgt. |

|

kgm

kgm

kgm

------------------------------------------------------10|

20|

... |

... |

... |

20|Lugs|

-10.1057 |

-10.1057 |

-13.0394 |

Lugs|

30|

117.795 |

120.843 |

118.714 |

30|

40|

42.9191 |

42.9191 |

46.1960 |

40|

50|

22.4150 |

22.4150 |

22.4150 |

Note: The cumulative operating weights no liquid in the column above

are the cumulative operating weights minus the operating liquid

40

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:14p Jan 11,2015

weight minus any weights absent in the empty condition.

Cumulative Vessel Moment

| Cumulative | Cumulative |Cumulative |

From| To | Empty Mom. | Oper. Mom. |Hydro. Mom.|

|

N-m

N-m

N-m

------------------------------------------------10|

20|

... |

... |

... |

20|Lugs|

182.714 |

182.714 |

182.714 |

Lugs|

30|

39.3614 |

39.3614 |

39.3614 |

30|

40|

... |

... |

... |

40|

50|

... |

... |

... |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

41

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Nozzle Flange MAWP :

Step:

8

1:14p Jan 11,2015

Nozzle Flange MAWP Results :

Nozzle

----- Flange Rating

Description

Operating

bar

Ambient

Temperature

bar

Class

Grade|Group

---------------------------------------------------------------------------N3

18.4

19.0

50

150

GR 2.2

N1

18.4

19.0

50

150

GR 2.2

N2

18.4

19.0

50

150

GR 2.2

N4

18.4

19.0

50

150

GR 2.2

N5

18.4

19.0

50

150

GR 2.2

N6

18.4

19.0

50

150

GR 2.2

K1A

18.4

19.0

50

150

GR 2.2

K1B

18.4

19.0

50

150

GR 2.2

K2A

18.4

19.0

50

150

GR 2.2

K2B

18.4

19.0

50

150

GR 2.2

K3A

18.4

19.0

50

150

GR 2.2

K3B

18.4

19.0

50

150

GR 2.2

K4A

18.4

19.0

50

150

GR 2.2

K4B

18.4

19.0

50

150

GR 2.2

K6A

18.4

19.0

50

150

GR 2.2

K6B

18.4

19.0

50

150

GR 2.2

K7A

18.4

19.0

50

150

GR 2.2

K7B

18.4

19.0

50

150

GR 2.2

K8A

18.4

19.0

50

150

GR 2.2

K8B

18.4

19.0

50

150

GR 2.2

K5A

18.4

19.0

50

150

GR 2.2

K5B

18.4

19.0

50

150

GR 2.2

---------------------------------------------------------------------------Minimum Rating

18.4

19.0

bar

42

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Nozzle Flange MAWP :

Step:

8

1:14p Jan 11,2015

Note: ANSI Ratings are per ANSI/ASME B16.5 2009 Metric Edition

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

43

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Natural Frequency Calculation :

Step:

9

1:14p Jan 11,2015

The Natural Frequencies for the vessel have been computed iteratively

by solving a system of matrices. These matrices describe the mass

and the stiffness of the vessel. This is the generalized eigenvalue/

eigenvector problem and is referenced in some mathematical texts.

The Natural Frequency for the Vessel (Empty.) is 11.6100 Hz.

The Natural Frequency for the Vessel (Ope...) is 11.3756 Hz.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

44

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Wind Load Calculation :

Step:

10

1:14p Jan 11,2015

Note: Using the User Defined Wind Profile ...

Wind Vibration Calculations

This evaluation is based on work by Kanti Mahajan and Ed Zorilla

Nomenclature

Cf

- Correction factor for natural frequency

- Average internal diameter of vessel mm

Df

- Damping Factor < 0.75 Unstable,

Dr

- Average internal diameter of top half of vessel mm

f

f1

L

> 0.95 Stable

- Natural frequency of vibration (Hertz)

- Natural frequency of bare vessel based on a unit value of (D/L)(104)

- Total height of structure mm

Lc

- Total length of conical section(s) of vessel mm

tb

- Uncorroded plate thickness at bottom of vessel mm

V30 - Design Wind Speed provided by user km/hr

Vc

- Critical wind velocity km/hr

Vw

- Maximum wind speed at top of structure km/hr

- Total corroded weight of structure N

Ws

- Cor. vessel weight excl. weight of parts which do not effect stiff. N

- Maximum amplitude of vibration at top of vessel mm

Dl

- Logarithmic decrement ( taken as 0.03 for Welded Structures )

Vp

- Vib. Chance, <= 0.314E-05 (High); 0.314E-05 < 0.393E-05 (Probable)

P30 - wind pressure 30 feet above the base

Check other Conditions and Basic Assumptions:

#1 - Total Cone Length / Total Length < 0.5

0.000/3305.048 = 0.000

45

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Wind Load Calculation :

Step:

10

1:14p Jan 11,2015

#2 - ( D / L ) * 104 < 8.0 (English Units)

- ( 0.72/10.84 ) * 104 = 60.973 [Geometry Violation]

Compute the vibration possibility. If Vp > 0.393E-05 no chance. [Vp]:

= W / ( L * Dr)

= 5111/( 3305.05 * 204.762 )

= 0.36885E-04

Since Vp is > 0.393E-05 no further vibration analysis is required !

Wind Loads on Masses/Equipment/Piping

ID

Wind Area

mm

Elevation

mm

Pressure

Force

kPa

------------------------------------------------------------------------FILTER

0.00

1755.00

0.75

0.00

LIQUID (UPPER

0.00

1963.00

0.75

0.00

The Natural Frequency for the Vessel (Ope...) is 11.3756 Hz.

Wind Load Calculation

Wind

Wind |

Wind |

Wind

Element |

From| To |

Height

Diameter |

Area |

Pressure

Wind Load |

kPa

mm

mm

mm

--------------------------------------------------------------------------10|

20|

62.0931 |

262.890 |

26506.0 |

0.75000 |

19.8791 |

20|

30|

1666.19 |

262.890 |

820217. |

0.75000 |

615.148 |

30|

40|

3276.99 |

245.715 |

24964.6 |

0.75000 |

18.7230 |

40|

50|

3342.01 |

245.715 |

6990.09 |

0.75000 |

5.24244 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

46

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Earthquake Load Calculation :

Step:

11

1:14p Jan 11,2015

Earthquake Loading Specified in G's

Horizontal Acceleration factor

(GX)

0.500

Horizontal Acceleration factor

(GZ)

0.500

Vertical

(GY)

-2.000

Acceleration factor

The Natural Frequency for the Vessel (Ope...) is 11.3756 Hz.

Earthquake Load Calculation

| Earthquake | Earthquake |

From| To |

|

Element |

Height |

Weight | Ope

mm

Load |

N

Element |

Emp Load |

N

-------------------------------------------------------------10|

20|

27.5000 |

99.0967 |

70.0719 |

70.0719 |

20|Lugs|

2622.00 |

3547.01 |

2508.11 |

1748.26 |

Lugs|

30|

2898.50 |

764.119 |

540.314 |

376.621 |

30|

40|

3225.80 |

201.063 |

142.173 |

142.173 |

40|

50|

3290.82 |

219.802 |

155.423 |

155.423 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

47

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Wind/Earthquake Shear, Bending :

Step:

12

1:14p Jan 11,2015

The following table is for the Operating Case.

Wind/Earthquake Shear, Bending

| Distance to| Cumulative |Earthquake |

From| To |

|

Wind | Earthquake |

Support| Wind Shear |

Shear |

Bending |

Bending |

mm

N-m

N-m

--------------------------------------------------------------------------10|

20|

2618.25 |

... |

... |

... |

... |

20|Lugs|

1283.50 |

19.8791 |

70.0719 |

0.074501 |

0.26261 |

Lugs|

30|

276.500 |

152.876 |

907.982 |

655.864 |

3060.82 |

30|

40|

603.800 |

23.9655 |

297.596 |

1.55896 |

25.2343 |

40|

50|

668.824 |

5.24244 |

155.423 |

0.074598 |

2.21161 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

48

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Wind Deflection :

Step:

13

1:14p Jan 11,2015

Wind Deflection Calculations:

The following table is for the Operating Case.

Wind Deflection

| Cumulative |

Centroid | Elem. End | Elem. Ang. |

From| To | Wind Shear | Deflection |Deflection |

|

mm

mm

Rotation

|

|

-------------------------------------------------------------10|

20|

... |

0.010864 |

0.021727 |

... |

20|Lugs|

19.8791 |

-0.39317 |

... |

... |

Lugs|

30|

152.876 |

-0.42107 |

-0.31128 |-0.00039289 |

30|

40|

23.9655 |

-0.29111 |

-0.27093 |-0.00039289 |

40|

50|

5.24244 |

-0.26528 |

-0.25963 |-0.00039289 |

Critical Wind Velocity for Tower Vibration

1st Crit. |

2nd Crit. |

From| To | Wind Speed | Wind Speed |

|

km/hr

km/hr

------------------------------------10|

20|

53.6847 |

335.529 |

20|

30|

53.6847 |

335.529 |

30|

40|

50.1773 |

313.608 |

40|

50|

50.1773 |

313.608 |

Allowable deflection at the Tower Top (Ope)(

Allowable deflection : 16.525

6.000"/100ft. Criteria)

Actual Deflection : 0.022 mm

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

49

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Longitudinal Stress Constants :

Step:

14

1:14p Jan 11,2015

Longitudinal Stress Constants

| Metal Area | Metal Area |New & Cold |

From| To | New & Cold |

|

mm

Corroded

Corroded |Sect. Mod. | Sect. Mod. |

mm

mm

mm

-------------------------------------------------------------10|

20|

4764.49 |

4764.49 |

244454. |

244454. |

20|

30|

4764.49 |

4764.49 |

244454. |

244454. |

30|

40|

4764.49 |

4764.49 |

244454. |

244454. |

40|

50|

4764.49 |

4764.49 |

244454. |

244454. |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

50

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Longitudinal Allowable Stresses :

Step:

15

1:14p Jan 11,2015

Longitudinal Allowable Stresses

| Hydrotest

| Compressive | Compressive |

From| To |

Tensile

MPa

Tensile

MPa

| Hydrotest

MPa

MPa

------------------------------------------------------------------10|

20|

138.176 |

186.165 |

-109.117 |

-111.814 |

20|Lugs|

138.176 |

186.165 |

-109.117 |

-111.814 |

Lugs|

30|

138.176 |

186.165 |

-109.117 |

-111.814 |

30|

40|

138.176 |

186.165 |

-109.117 |

-111.814 |

40|

50|

138.176 |

186.165 |

-109.117 |

-111.814 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

51

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Longitudinal Stresses Due to . . .

Step:

16

1:14p Jan 11,2015

Longitudinal Stress Report

Note: Longitudinal Operating and Empty Stresses are computed in the

corroded condition. Stresses due to loads in the hydrostatic test

cases have been computed in the new and cold condition.

Longitudinal Stresses Due to . . .

| Long. Str. | Long. Str. |Long. Str. |

From| To | Int. Pres. | Ext. Pres. |Hyd. Pres. |

|

MPa

MPa

MPa

------------------------------------------------10|

20|

12.5173 |

-0.81833 |

17.1242 |

20|

30|

12.5173 |

-0.81833 |

17.1242 |

30|

40|

... |

... |

... |

40|

50|

... |

... |

... |

Longitudinal Stresses Due to . . .

| Wght. Str. | Wght. Str. |Wght. Str. | Wght. Str. | Wght. Str. |

From| To |

|

Empty

MPa

| Operating

|Hydrotest

MPa

MPa

Emp. Mom. |

MPa

Opr. Mom. |

MPa

--------------------------------------------------------------------------10|

20|

... |

... |

... |

... |

... |

20|Lugs|

0.020801 |

0.020801 |

... |

0.74720 |

0.74720 |

Lugs|

30|

-0.24246 |

-0.21334 |

... |

0.16097 |

0.16097 |

30|

40|

-0.088341 |

-0.088341 |

... |

... |

... |

40|

50|

-0.046137 |

-0.046137 |

... |

... |

... |

Longitudinal Stresses Due to . . .

| Wght. Str. | Bend. Str. |Bend. Str. | Bend. Str. | Bend. Str. |

52

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Longitudinal Stresses Due to . . .

Step:

16

1:14p Jan 11,2015

From| To |

|

Hyd. Mom. | Oper. Wind |Oper. Equ. | Hyd. Wind

MPa

MPa

MPa

MPa

|

|

Hyd. Equ. |

MPa

--------------------------------------------------------------------------10|

20|

... |

20|Lugs|

... |

... |

... |

... |

... | 0.00030467 | 0.0010739 |

... |

... |

Lugs|

30|

... |

2.68212 |

12.5171 |

... |

... |

30|

40|

... |

0.0063753 |

0.10319 |

... |

... |

40|

50|

... | 0.00030506 | 0.0090443 |

... |

... |

Longitudinal Stresses Due to . . .

| Long. Str. | Long. Str. |Long. Str. | EarthQuake |

From| To | Vortex Ope.| Vortex Emp.|Vortex Tst.|

|

MPa

MPa

MPa

Empty |

MPa

-------------------------------------------------------------10|

20|

... |

... |

... |

... |

20|Lugs|

... |

... |

... |

0.0010739 |

Lugs|

30|

... |

... |

... |

8.71229 |

30|

40|

... |

... |

... |

0.10319 |

40|

50|

... |

... |

... |

0.0090443 |

Longitudinal Stresses Due to . . .

| Long. Str. | Long. Str. |

From| To | Y Forces W | Y ForceS S |

|

MPa

MPa

------------------------------------10|

20|

... |

0.041602 |

20|Lugs|

... |

1.53066 |

Lugs|

30|

... |

-0.49746 |

30|

40|

... |

-0.17668 |

40|

50|

... |

-0.092274 |

53

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : S-6011

---------------------------------------Longitudinal Stresses Due to . . .

Step:

16

1:14p Jan 11,2015

Long. Stresses due to User Forces and Moments

|Wind For/Mom| Eqk For/Mom|Wnd For/Mom| Eqk For/Mom|

From| To | Corroded

|

MPa

| Corroded

MPa

No Corr. |

MPa

No Corr. |

MPa

-------------------------------------------------------------10|

20|

... |

... |

... |

... |

20|Lugs|

... |

... |

... |

... |

Lugs|

30|

... |

... |

... |

... |

30|

40|

... |

... |

... |

... |

40|