Professional Documents

Culture Documents

Mnemonic S

Uploaded by

Kenneth DayritOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mnemonic S

Uploaded by

Kenneth DayritCopyright:

Available Formats

1

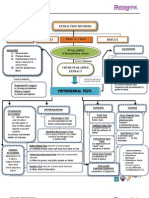

BIOCHEMISTRY

Molecular

Chromatin structure

HeteroChromatin = Highly Condensed

H1 is the linker region between histone octamer balls (beads on

a string) The 1 is like the little piece of string connecting

them

Nucleotides

Purines A, G as in A GangsterTupac taught us how pure

gangsters are; CUT the PY for the PYrimidines

o Pyrimidines only have one ring, as the other was CUT

off

o THYmine has a methyl

o Purine synthesis starts with sugar (Ribose-5P PRPP),

and then this sugar is modified to create the purine;

pyrimidine starts with synthesis of the pyrimidine and then

later a sugar is added;

If you are pure you are as sweet as sugar from the

start

Methionine is encoded by only AUG, unlike the other AAs where

you have redundancy in the code and multiple codons coding for

them Hey (A) you (U), G, I want to buy that meth from you

because it is so special and unique!

Stop the nonsense! Nonsense mutation introduced stop codon

Protein synthesis

Eukaryotes Even 40S + 60S = 80S (all differ by 20)

PrOkaryotes Odd 30S + 50S = 70S (smaller numbers

because are smaller, always smaller by 10, all differ by 20)

Start and stop codons

AUG is mRNA start codon (rarely GUG) AUG

inAUGurates protein synthesis

mRNA stop codons

o UGA U Go Away

o UAA U Are Away

o UAG U Are Gone

1. According to measurability:

a. Variable defect a defect which can be measured directly by

instruments giving dimensions of length, weight, height,

thickness, concentration, volume, viscosity, pH or size

particles.

b. Attribute defect a defect which cannot be measured directly

by instruments.

It shows mainly the conformance or

nonconformance of the material to specifications. This applies

to many things that can be judged only by odor or visual

examination like color, clarity, sheen, cleanliness, smoothness,

taste and presence or absence of a characteristic.

2. According to seriousness or gravity:

a. Critical defect a defect which may endanger life or property

and may render the product non-functional. Absence of

warning in a label for a potent drug or disintegration time of

one hour for an analgesic are considered critical defects.

b. Major defect a defect which may affect the function of the

object and therefore, may render the product useless. The

presence of a crack in a bottle is a major defect.

c. Minor defect a defect which does not endanger life or

property nor will it affect the function but nevertheless remains

a defect since it is outside the prescribed limits. An example of

a minor defect is the slight deviation of the color of the label

from the color standards.

3. According to nature:

Ocular defect a defect that is visible, e.g., foreign particulate

contamination.

Internal defect a defect which is not seen although present, e.g., a

subpotent drug product.

Performance defect a defect in function, e.g., a suppository that does not

melt at body temperature.

Critical Defects in Glass Bottles or Containers

Stuck Plug. A piece of glass, usually very sharp, projecting inwards

just inside the neck bore

Overpress. Is a defect where a small ridge of glass has been formed

on the sealing surface of the finish

Split. An open crack starting at the top of the finish and extending

downward.

Check. A small, shallow surface crack, usually at the bore of the

container

Freaks. Odd shapes and conditions that render the container

completely unusable. Bent or cocked necks are a common defect of

this type.

Poor Distribution. Thin shoulder, slug neck, choke neck, heavy

bottom are terms used to describe the uneven distribution of glass.

Soft Blister. A thin blister, usually found on or near the sealing

surface. It can however show up anywhere on the glass container.

Choked Bore. Here excess of glass has been distributed to the

inside of the finish or opening

Cracks. Partial fractures, usually found in the heel area.

Pinhole. Any opening causing leakage. It occurs most often in

bottles with pointed corners.

Filament. A hair-like string inside the bottle.

Spike. Spikes are glass projections inside the bottle.

Bird Swing. Is a glass thread joining the two walls of the container.

Some Major Defects Commonly Found in Glass Containers

Chipped Finish. Pieces broken out of the top edge in the

manufacturing process.

Stone. Small inclusion of any non-glass material.

Rocker Bottom. A sunken center portion on in base of the container

Flanged Bottom. A rim of glass around the bottom at the parting

line.

Suncker Shoulder. Not fully blown, or sagged after blowing

Tear. Similar to a check, but opened up. A tear will not break when

tapped, a check will.

Washboard. A wavy condition of horizontal lines in the body of the

bottle.

Hard Blister. A deeply embedded blister that is not easily broken.

Dirty, Scaly, or granular non - glass material.

Heel Tap. A manufacturing defect where excess glass has been

distributed into the heel

Mark. A brush mark is composed of fine vertical laps, e.g. oil

marks from molds.

Wavy bottle. A wavy surface on the inside of the bottle.

Seeds. Small bubbles in the glass.

Neck ring seam. A bulge at the parting line between the neck and

the body.

The physicochemical tests for containers include:

Identification

Infra red properties

Thermal analysis

Extractable substance

Non volatile residue

Water vapor permeation

Moisture

Resistance to water attack

You might also like

- Presentation On Glass PacakgingDocument30 pagesPresentation On Glass PacakgingShailesh JadhavNo ratings yet

- P0004 - Emhart FleXinspect Guide To Container InspectionDocument1 pageP0004 - Emhart FleXinspect Guide To Container Inspectionamyn_s83% (6)

- Emhart Inspection Defect GuideDocument1 pageEmhart Inspection Defect GuideBryan Nadimpally75% (4)

- USP Monographs Sulfamethoxazole and Trimethoprim TabletsDocument2 pagesUSP Monographs Sulfamethoxazole and Trimethoprim TabletshmtlionNo ratings yet

- CapsuleskncopDocument181 pagesCapsuleskncopboozokaranNo ratings yet

- Packaging MaterialsDocument6 pagesPackaging MaterialsSCN StaffNo ratings yet

- Tablet DefectsDocument2 pagesTablet Defectsophelion2112No ratings yet

- Experiment No. 2 Boric AcidDocument4 pagesExperiment No. 2 Boric AcidBlazy InhumangNo ratings yet

- One Point Lesson Item: Bottle Defects Location: Cube Equipment: Bottle BlowerDocument2 pagesOne Point Lesson Item: Bottle Defects Location: Cube Equipment: Bottle BlowerEricsson Botchwey100% (1)

- Pharmaceutical Dosage (Lec) HWDocument3 pagesPharmaceutical Dosage (Lec) HWKimberly Mae MesinaNo ratings yet

- Pharmaceutical Packaging by Metals (RCPSR)Document25 pagesPharmaceutical Packaging by Metals (RCPSR)Shagufta Khan50% (2)

- Phytochemical Tests: Theoretical FrameworkDocument4 pagesPhytochemical Tests: Theoretical Frameworksoubi_yodiNo ratings yet

- Tablets: By: Katryn PunsalangDocument69 pagesTablets: By: Katryn PunsalangKatryn PunsalangNo ratings yet

- Problems and Remedies For Tablet CoatingDocument7 pagesProblems and Remedies For Tablet CoatingAnowar HossainNo ratings yet

- Guide To Container DefectsDocument1 pageGuide To Container Defectsmktg1100% (2)

- Drug StabilityDocument12 pagesDrug StabilityJamilNo ratings yet

- Lecture 2 - Disperse SystemsDocument94 pagesLecture 2 - Disperse Systemsapi-370729792% (12)

- Packaging Products: Baysa - Guerrero - Rebollido - Baltazar - Lura - Lutrania - Morales - Sab-ItDocument37 pagesPackaging Products: Baysa - Guerrero - Rebollido - Baltazar - Lura - Lutrania - Morales - Sab-ItSheena GagarinNo ratings yet

- DdsDocument9 pagesDdsClaudette JunioNo ratings yet

- T.Shivakumar: Kottam Institute of Pharmacy Jntu, A.PDocument45 pagesT.Shivakumar: Kottam Institute of Pharmacy Jntu, A.PFree Escort ServiceNo ratings yet

- Collapsible TubeDocument8 pagesCollapsible TubeNurul NaqibahNo ratings yet

- 634798775670659161Document41 pages634798775670659161Suvin PsNo ratings yet

- Evalutation Parameter of TabletsDocument27 pagesEvalutation Parameter of TabletsAnkush DwivediNo ratings yet

- IpqcDocument37 pagesIpqcAjitha AzhakesanNo ratings yet

- Glass Cleaning With Chromic AcidDocument4 pagesGlass Cleaning With Chromic Acidagarpragya4458No ratings yet

- Pharmaceutical PackagingDocument63 pagesPharmaceutical PackagingMubarakDiedaNo ratings yet

- Tablet Friability PDFDocument18 pagesTablet Friability PDFMuhammad Aleem IjazNo ratings yet

- Packaging Material Drinking WaterDocument9 pagesPackaging Material Drinking WaterAditya GhatgeNo ratings yet

- Liquid OralsDocument55 pagesLiquid OralsShraddha RNo ratings yet

- Unit 10-SuppositoriesDocument42 pagesUnit 10-SuppositoriesKimberly GeorgeNo ratings yet

- Glass ProductionDocument10 pagesGlass ProductionRichelieu M DeleonNo ratings yet

- Glass Production: From Wikipedia, The Free EncyclopediaDocument10 pagesGlass Production: From Wikipedia, The Free EncyclopediaMahfuzur Rahman SiddikyNo ratings yet

- Dosage - Chapter 7Document6 pagesDosage - Chapter 7kaukau4everNo ratings yet

- OmDocument52 pagesOmPratibha AroteNo ratings yet

- APT-Pilot Plant Techniques-Capsules & Liquid OralsDocument32 pagesAPT-Pilot Plant Techniques-Capsules & Liquid Oralssakumar5678No ratings yet

- AssignmentDocument12 pagesAssignmentAbdul Wahid OrakzaiNo ratings yet

- Rheology of SuspensionsDocument16 pagesRheology of SuspensionsManoj Bansal100% (1)

- Submitted To Name Roll: Mohammad Sarowar UddinDocument25 pagesSubmitted To Name Roll: Mohammad Sarowar UddinShahedul IslamNo ratings yet

- Quality Control Tests For Containers, Closures and Secondary Packing MaterialsDocument14 pagesQuality Control Tests For Containers, Closures and Secondary Packing MaterialsFatima Vessalius50% (2)

- CapsulesDocument50 pagesCapsulesneha_dand1591No ratings yet

- Jdidjdgjfghklgjk Polytechnic University of The Philippines: College of Engineering Industrial Engineering DepartmentDocument6 pagesJdidjdgjfghklgjk Polytechnic University of The Philippines: College of Engineering Industrial Engineering DepartmentNorieanne GarciaNo ratings yet

- Drug StabilityDocument14 pagesDrug StabilityBismah SaeedNo ratings yet

- Chapter 27 Suspensions and EmulsionsDocument49 pagesChapter 27 Suspensions and EmulsionsKate Montenegro67% (3)

- Stability in PreformulationDocument48 pagesStability in Preformulationmithaann2353No ratings yet

- Unit 2 CapsuleDocument104 pagesUnit 2 Capsuleabdullah2020No ratings yet

- Ferrous Sulfate (An Official Inorganic Compound) : OccurrenceDocument11 pagesFerrous Sulfate (An Official Inorganic Compound) : Occurrencehumag143No ratings yet

- Aspirin CapsulesDocument2 pagesAspirin CapsulesAbby LumanglasNo ratings yet

- Tablet, Granules, CapsulesDocument49 pagesTablet, Granules, CapsulesRubab Syed100% (1)

- Pharmaceutical Dosage Forms, Drug Delivery Systems and Medical Devices Pharm 201L Name:Tallod, Emerson John L. Group:11 Year/Section:Q2A Final RatingDocument7 pagesPharmaceutical Dosage Forms, Drug Delivery Systems and Medical Devices Pharm 201L Name:Tallod, Emerson John L. Group:11 Year/Section:Q2A Final RatingJames AzurinNo ratings yet

- Tablet Coating With Its DefectsDocument56 pagesTablet Coating With Its Defectsjoshirohan100% (1)

- Opthalmic Preparations Unit III Part-BDocument37 pagesOpthalmic Preparations Unit III Part-BKrishna PrasadNo ratings yet

- Powders and GranulesDocument18 pagesPowders and GranulesAlaa Salymeh100% (1)

- C 14 SuspensionDocument119 pagesC 14 SuspensionVinod ChoudharyNo ratings yet

- Dosage Chapter 15Document66 pagesDosage Chapter 15formalreport1996No ratings yet

- Bottle DefectsDocument4 pagesBottle DefectsJasmine DewieNo ratings yet

- Manufacturing Pharmacy LECTURE AutosavedDocument110 pagesManufacturing Pharmacy LECTURE AutosavedBirmej NatapgasNo ratings yet

- Analysis of Canned FoodsDocument16 pagesAnalysis of Canned FoodsExtinctspecieNo ratings yet

- Module 2 - Glass Design and TestingDocument38 pagesModule 2 - Glass Design and TestingSagar WaghmareNo ratings yet

- Injection-Molding-Flaws-and-Defects LopottDocument28 pagesInjection-Molding-Flaws-and-Defects Lopotttalán gybrNo ratings yet

- Spoilage On Canned Foods BAMDocument28 pagesSpoilage On Canned Foods BAMGuillermo BarriosNo ratings yet

- Pharmacy: Cephalosporins: A Focus On Side Chains and - Lactam Cross-ReactivityDocument16 pagesPharmacy: Cephalosporins: A Focus On Side Chains and - Lactam Cross-ReactivityKenneth DayritNo ratings yet

- ThesisDocument1 pageThesisKenneth DayritNo ratings yet

- HOSPI Qs CLINICAL PHARMACYDocument9 pagesHOSPI Qs CLINICAL PHARMACYKenneth DayritNo ratings yet

- BREX Pharmacy Review Module 1Document9 pagesBREX Pharmacy Review Module 1Kenneth DayritNo ratings yet

- The 5 ADocument11 pagesThe 5 AKenneth DayritNo ratings yet

- Lange 10Document1 pageLange 10Kenneth DayritNo ratings yet

- Pharmacology BookDocument332 pagesPharmacology BookKenneth DayritNo ratings yet

- ThesisDocument92 pagesThesisKenneth Dayrit50% (4)

- SMRDocument1 pageSMRKenneth DayritNo ratings yet

- Product FormulationDocument1 pageProduct FormulationKenneth DayritNo ratings yet

- Consent FormDocument5 pagesConsent FormKenneth Dayrit100% (1)

- LevothyroxineDocument21 pagesLevothyroxineKenneth DayritNo ratings yet

- GamesDocument2 pagesGamesKenneth DayritNo ratings yet

- Physical StandardsDocument1 pagePhysical StandardsKenneth DayritNo ratings yet

- Dayrit, Kenneth G. Angeles Medical Center Rizal ST., Angeles City. APRIL 2013 160/200 HrsDocument2 pagesDayrit, Kenneth G. Angeles Medical Center Rizal ST., Angeles City. APRIL 2013 160/200 HrsKenneth DayritNo ratings yet

- Calculations Review For Evaluation Exam of PharmacistDocument56 pagesCalculations Review For Evaluation Exam of Pharmacistqiyu100% (15)

- Core ValuesDocument1 pageCore ValuesKenneth DayritNo ratings yet

- CheckDocument1 pageCheckKenneth DayritNo ratings yet

- DailDocument1 pageDailKenneth DayritNo ratings yet

- Tips 11-20Document43 pagesTips 11-20Kenneth DayritNo ratings yet

- Cardiology IDocument11 pagesCardiology IKenneth DayritNo ratings yet

- TV SerDocument1 pageTV SerKenneth DayritNo ratings yet

- Diskless Solution ProjectDocument5 pagesDiskless Solution ProjectJonathan CastañedaNo ratings yet

- CH 1Document15 pagesCH 1Kenneth DayritNo ratings yet

- UboDocument1 pageUboKenneth DayritNo ratings yet

- CurriculumDocument3 pagesCurriculumKenneth DayritNo ratings yet

- Boy Scouts Notes: Flag Code 101Document5 pagesBoy Scouts Notes: Flag Code 101scoutingresources100% (3)

- Trivia QuizDocument4 pagesTrivia QuizKenneth DayritNo ratings yet

- Chem Assign.Document2 pagesChem Assign.Kenneth DayritNo ratings yet

- Brook Health Care Center Inc Has Three Clinics Servicing TheDocument1 pageBrook Health Care Center Inc Has Three Clinics Servicing Thetrilocksp SinghNo ratings yet

- Design of Marina Structures and FacilitiesDocument23 pagesDesign of Marina Structures and FacilitiesAhmed Balah0% (1)

- DT-M Datasheet Vertex Ne19r en 2022 Pa1 Web Ne19r 2022pa1 en 20220916Document2 pagesDT-M Datasheet Vertex Ne19r en 2022 Pa1 Web Ne19r 2022pa1 en 20220916Producto ITICCOLNo ratings yet

- Ielts ReadingDocument7 pagesIelts ReadingTrọng Nguyễn DuyNo ratings yet

- WhatsApp Chat With Chinnu HeartDocument30 pagesWhatsApp Chat With Chinnu HeartSäi DäťťaNo ratings yet

- O&M Manual For Vms PumpDocument11 pagesO&M Manual For Vms PumpKaushik ChakrabortyNo ratings yet

- Aqa Chm6w W QP Jun02Document18 pagesAqa Chm6w W QP Jun02Diksha KoossoolNo ratings yet

- DMD 2018 Stem and Non Stem Checklist Effective 2020-2021Document8 pagesDMD 2018 Stem and Non Stem Checklist Effective 2020-2021Elle DyNo ratings yet

- Football Speed TrainingDocument6 pagesFootball Speed TrainingTBM607No ratings yet

- Cardiovascular SystemDocument100 pagesCardiovascular SystemTerence ValdehuezaNo ratings yet

- Mitra SejatiDocument2 pagesMitra Sejatiestu kurniaNo ratings yet

- Issues Pertaining To Maintenance of WifeDocument2 pagesIssues Pertaining To Maintenance of WifeVaishnavi YadavNo ratings yet

- Parreira CVDocument8 pagesParreira CVapi-595476865No ratings yet

- Gazettes 1686290048232Document2 pagesGazettes 1686290048232allumuraliNo ratings yet

- 1-1FlowCharts For HaccpDocument3 pages1-1FlowCharts For HaccpPeter George0% (1)

- 1198-Article Text-5716-1-10-20221219Document9 pages1198-Article Text-5716-1-10-20221219Hendarko AriNo ratings yet

- 004 Torillo v. LeogardoDocument2 pages004 Torillo v. LeogardoylessinNo ratings yet

- AASHTO Digital Publications: Instructions Located HereDocument2 pagesAASHTO Digital Publications: Instructions Located HereMinn LwinNo ratings yet

- PM PillarDocument56 pagesPM PillarNavneet Sharma75% (4)

- CFM56 3Document148 pagesCFM56 3manmohan100% (1)

- Fdocuments - in From The Margins To The Mainstream Disaster Research at The CrossroadsDocument26 pagesFdocuments - in From The Margins To The Mainstream Disaster Research at The CrossroadsHanan M. HadidiNo ratings yet

- Passive In-Line Chlorination For Drinking Water DiDocument18 pagesPassive In-Line Chlorination For Drinking Water DitefovNo ratings yet

- A Guide To Patient Medication Review: September 2003Document33 pagesA Guide To Patient Medication Review: September 2003Muhamad GunturNo ratings yet

- College RecipesDocument29 pagesCollege RecipeskrunziNo ratings yet

- 250 Watt Solar Panel SpecificationsDocument2 pages250 Watt Solar Panel Specificationsfopoku2k20% (1)

- Kevin Coleman's Sentencing MemoDocument26 pagesKevin Coleman's Sentencing MemoThe Valley IndyNo ratings yet

- CoasteeringDocument1 pageCoasteeringIrishwavesNo ratings yet

- Conditional Type 0Document16 pagesConditional Type 0marore100% (1)

- EO MNC 10 June 2022Document4 pagesEO MNC 10 June 2022LeulaDianneCantosNo ratings yet

- Cocoa Nursery Manual Feb 2013Document51 pagesCocoa Nursery Manual Feb 2013jeffreyNo ratings yet