Professional Documents

Culture Documents

The Status of Li-Ion Battery Development For LEV Applications

Uploaded by

S.m. FerdousOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Status of Li-Ion Battery Development For LEV Applications

Uploaded by

S.m. FerdousCopyright:

Available Formats

All About E-Bikes

The Status of Li-ion

Battery Development

for LEV Applications

Text: Mo-Hua Yang

Introduction

From the perspective of

market applications and technology advancement, the development of light electric twowheeled vehicles is proceeding

considerably faster than that of

conventional pure-electric vehicles. In 2011, the global light

electric two-wheeled vehicle

market contained more than 3

million vehicles, and the Chinese

market had more than 2.5 million of these. Europe is now the

fastest-growing market for highvalue e-bikes.

The three keys to a successful LEV product are marketing, product design, and technology development. Because LEVs

are highly individualized transportation products, marketing

must reflect the living habits and

state of socioeconomic development in different countries and

areas. The chart shows differences between the Chinese, European, American, and Japanese

markets. In the Chinese market,

e-bikes are a virtual necessity.

In the initial period of economic

reform and market opening, most

72

Bike Market / CBES 2012-2013

people in China relied on ordinary bicycles for transportation.

As economic circumstances gradually improved and incomes rose

in the wake of reforms, obtaining

more convenient means of transportation became an urgent issue.

In addition, the fact that the Chinese government prohibits motorcycles with internal combustion

engines in major cities in order

to reduce air pollution has lent

even greater impetus to demand

for e-bikes and accelerated market growth. As a result, e-bikes

have become the widespread and

convenient means of personal

transportation, and e-bikes are

stimulating economic growth and

www.biketaiwan.com

Mo-Hua Yang

General Manager, TD HiTech Energy Inc.

All About E-Bikes

improving quality of life in China. In contrast, in the European,

American, and Japanese markets,

e-bikes are used as short-distance

personal transportation vehicles,

and most individuals and families

purchasing and using e-bikes also

possess cars. The chief appeals of

e-bikes as means of transportation and a recreational option in

these markets is their environmental-friendliness, energy conservation, carbon reduction, and

exercise and health functions.

The most important technologies used in LEVs constitute

the battery energy storage system

and motor propulsion system.

During the initial stage of LEV

development, many conventional bicycle and motorcycle

manufacturers felt that it was

only necessary to connect the

positive and negative terminals

of the battery to a motor in order to create an electric vehicle.

In reality, however, the safety,

reliability, and efficiency of the

overall LEV system are the keys

to successful product marketing.

As a consequence, the energy

storage system constituting the

battery and battery management

system and the propulsion system

constituting the motor and motor

controller are the key technological items in an LEV. Apart from

transforming energy, these two

important systems are the key to

product reliability and efficiency

because of their role in electromechanical integration and

information communications. In

www.biketaiwan.com

Bike Market / CBES 2012-2013

73

All About E-Bikes

addition, of the two systems, battery energy storage system technology development is the most

important aspect.

The LEV market currently

consists chiefly of e-bikes and

electric motorcycles. Battery

voltage specifications are chiefly

24V, 36V, and 48V, and storage

capacity ranges from 10Ah to

30Ah. The power of LEV motors ranges from 250W to 500W

in the case of e-bikes, and 500W

to 2000W in the case of electric

motorcycles. Apart from power

storage capacity, batteries must

have sufficiently high power

output in order to meet an LEVs

starting, acceleration, and hillclimbing performance needs. The

European market, more than 90%

of LEVs currently employ Li-ion

batteries. These batteries generally have voltages of 24V and

36V, capacity in the range of 250360wh, and the battery module

weighs 3-5kg. Lead-acid batteries still predominate in the Chinese LEV market, and are used

on more than 90% of all LEVs.

In contrast, Li-ion batteries can

be found on only a small number

of high-priced products. Chinese

Li-ion batteries generally have

voltages of 36V and 48V and

capacities ranging from 300wh

to 500wh. Furthermore, Li-ion

batteries in the Chinese market

are mostly inexpensive and have

fairly low safety and reliability;

price is still the decisive factor in

this market.

Most Li-ion batteries currently employed in electric ve74

Bike Market / CBES 2012-2013

hicles are cylindrical, rectangular,

or mounted in a soft pouch. In

the case of type 18650 and 26650

Li-ion batteries, because product

specifications were standardized

at an early date, there is considerable manufacturing technology

and battery safety experience,

and designs are relatively mature.

However, heat dissipation and the

series-parallel connections between battery cells make designs

quite bulky. In addition, the storage capacity of individual battery

cells is relatively low. While rectangular batteries have relatively

good heat dissipation characteristics, and their modular design

allows effective use of space,

manufacturing costs are relatively high. And although softpack batteries are light in weight,

have dimensional flexibility, offer

good heat dissipation, and are

relatively easy to mass produce,

their mechanical strength and dimensional stability are doubtful,

and, under high-temperature conditions, the battery seal integrity

www.biketaiwan.com

and gas discharge safety remain

to be improved.

With regard to the development of Li-ion battery cell

specifications, in the case of type

18650 Li-ion batteries, the saturation of the notebook computer

market, and the recent emergence

of tablet PC and ultra-thin notebook markets (type 18650 Liion batteries are not appropriate

for these products), type 18650

battery sales have leveled off or

even fallen. As a result, manufacturers have been searching

for other markets for type 18650

batteries, and LEVs represent

a major new market for these

batteries. Furthermore, because

18650 battery technology and

mass production processes are

highly standardized, these batteries offer large safety, quality, and

price advantages, and they have

gradually become the standard

battery cell specification used in

LEVs. The technology used in

type 18650 Li-ion batteries has

been developed over the course

All About E-Bikes

of more than 20 years. Thanks to

market experience gained over

this period, including several

negative safety and manufacturing experiences encountered by

leading manufacturers, there has

been great progress in the area of

design safety. Type 18650 Li-ion

battery manufacturers involved in

LEV applications include Japans

Sony and Panasonic (Sanyo), and

Koreas Samsung SDI and LG.

In addition, Chinas Lishen and

Bak are actively developing type

18650 Li-ion batteries for LEV

applications.

Li-ion battery modules for

LEVs consist of several tens to

several hundreds of 18650 batteries connected in several parallel

and series circuits. The key to

battery module system technology is to ensure that the performance of Li-ion batteries assembled into a multiple series and

parallel module is consistent with

single-cell performance. The two

chief battery module technologies are module structure design

and battery management system

electronic monitoring technology.

As far as battery module

structure design is concerned,

an appropriate battery cell must

be selected based on the overall

LEV and motor drive system

specifications. The chief factors

considered here are motor voltage, maximum current demand,

maximum instantaneous current

output, and sustained output time.

After selecting the battery cell,

the series-parallel arrangement

of the battery cells is determined

in accordance with the specifications. It is now necessary to consider the optimal series-parallel

arrangement of the battery cells,

as well as the strength of the battery cell mounting supports and

outer shell. The support system

must enable the battery cells to

withstand vibration and loosening, ensuring the mechanical

strength and reliability of the

product. In addition, a modules

structural design must take the

batterys heat dissipation and waterproof seal into consideration.

Wi t h r e g a r d t o b a t t e r y

management system technology,

to maintain battery safety, the

parameters of temperature, current, and voltage must be monitored, and software and firmware

programs employed to perform

protective management of the

battery. The key technological

content of a battery management

system comprises the management systems circuit design

and the design of the protection

panel. Finally, battery module

electromechanical integration

technology includes integration

of mechanisms and electronics, circuit design, connectors

between battery and motor and

battery and charger, and the communications interface.

There are great differences

between battery management

system technologies. Systems

range from simple battery protection circuits to systems with complex functions such as battery

equalization, power output and

battery health monitoring, and

battery and system communication interfaces. All of these can

be termed battery management

systems. While enhancing battery

management system monitoring

functions will increase battery

module cost, it will also dramatically increase the reliability of

the battery module. In the case

of LEV battery modules with

multiple series and parallel connections, the battery management

systems functions will ensure

greater product reliability. Compared with simple cell phone and

notebook battery modules, battery management systems play a

bigger role in the case of LEVs,

and the development of Li-ion

battery module technology is thus

seen as essential to the continued

development of LEVs.

The LEV market, consisting chiefly of e-bikes and electric

motorcycles, has grown steadily

and rapidly in recent years, which

verifies that LEVs are not just a

passing trend. In addition, motivated by the markets growth, an

increasing number of companies

are investing in battery and motor technology development.

Looking ahead to the future, as

technology and product quality continue to improve, LEV

safety and reliability will also get

even better, while costs will fall

steadily. These trends will ensure

the sustainable development of

the LEV market.

www.biketaiwan.com

Bike Market / CBES 2012-2013

75

You might also like

- sheet-battery-management-system-pdf-file-dataDocument11 pagessheet-battery-management-system-pdf-file-dataOumaima JORAICHENo ratings yet

- CCC Battery Cost - Element Energy Report - March2012 - Public PDFDocument100 pagesCCC Battery Cost - Element Energy Report - March2012 - Public PDFjuanpazagoNo ratings yet

- State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications Issues and RecommendationsDocument17 pagesState-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications Issues and RecommendationshyvasNo ratings yet

- 2014 Book AutomotiveBatteryTechnology PDFDocument135 pages2014 Book AutomotiveBatteryTechnology PDFFrank AcostaNo ratings yet

- Trends in Electric PropulsionDocument3 pagesTrends in Electric PropulsionggpalomiNo ratings yet

- Automotive Battery TechnologyDocument134 pagesAutomotive Battery Technologyoceanforest100% (4)

- CHAPTER OneDocument3 pagesCHAPTER OneAung MyatNo ratings yet

- Ashutosh PaperDocument9 pagesAshutosh PaperDhananjay KumarNo ratings yet

- Battery Management Systems in Electric and HybridDocument19 pagesBattery Management Systems in Electric and Hybridtou kaiNo ratings yet

- Annual Update On Lithium-Ion Battery Technology White Paper by Inventus PowerDocument11 pagesAnnual Update On Lithium-Ion Battery Technology White Paper by Inventus PowerDanial SadiqNo ratings yet

- BMs Bookchapter1 IGI - AspxDocument36 pagesBMs Bookchapter1 IGI - AspxRaghavendra GopalaNo ratings yet

- Battery Management Systems in Electric and HybridDocument19 pagesBattery Management Systems in Electric and HybridmanalNo ratings yet

- A Review Paper On Challenges and Opportunities in Battery TechnologiesDocument3 pagesA Review Paper On Challenges and Opportunities in Battery TechnologiesVIVA-TECH IJRINo ratings yet

- Role of Power Electronics in Ev DevelopmentDocument14 pagesRole of Power Electronics in Ev DevelopmentVASALA AJAYKUMAR RGUKT BasarNo ratings yet

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Wiring HarnessDocument2 pagesWiring HarnessMuthuKumarNo ratings yet

- Advanced Battery Management System: Pragati Engineering CollegeDocument25 pagesAdvanced Battery Management System: Pragati Engineering CollegeLakshmi TanmaiNo ratings yet

- RBFNN Machine Learning BASED BLDC Motor Driven PV Fed Electric VehicleDocument9 pagesRBFNN Machine Learning BASED BLDC Motor Driven PV Fed Electric VehicleViswanathanBalajiNo ratings yet

- Engineering Philosophy of Electric VehiclesDocument3 pagesEngineering Philosophy of Electric Vehiclesdilan bro SLNo ratings yet

- Mobile Charging Circuit ConceptsDocument25 pagesMobile Charging Circuit ConceptsMustafa Kreet (ICT MAX)No ratings yet

- Renewable and Sustainable Energy Reviews: Ghassan Zubi, Rodolfo Dufo-López, Monica Carvalho, Guzay PasaogluDocument17 pagesRenewable and Sustainable Energy Reviews: Ghassan Zubi, Rodolfo Dufo-López, Monica Carvalho, Guzay PasaogluBattula SuryaNo ratings yet

- Critic ReviewDocument53 pagesCritic ReviewDanson DavidNo ratings yet

- Batteries For Electric CarsDocument18 pagesBatteries For Electric CarsEduardo Jorge pintoNo ratings yet

- EnergiesDocument10 pagesEnergieshajjiNo ratings yet

- Li-ion Battery Management System DesignDocument31 pagesLi-ion Battery Management System DesignAbdullahNo ratings yet

- Energies 12 00446Document35 pagesEnergies 12 00446Vimal SamNo ratings yet

- 3 and 4Document11 pages3 and 4Stephin JanvelNo ratings yet

- Battery Projects, Automobile Batteries-29079Document30 pagesBattery Projects, Automobile Batteries-29079ayaanNo ratings yet

- A Review Paper On Lithium-Ion Battery Pack Design For EVsDocument7 pagesA Review Paper On Lithium-Ion Battery Pack Design For EVsIJRASETPublicationsNo ratings yet

- Innovation and DevelopmentDocument10 pagesInnovation and DevelopmentISAI dali Perez navaNo ratings yet

- Electric Vehicles in India and Its Impact On GridDocument9 pagesElectric Vehicles in India and Its Impact On GridSureshNo ratings yet

- Charging and Discharging Control of Li Ion Battery For Electric Vehicle ApplicationsDocument7 pagesCharging and Discharging Control of Li Ion Battery For Electric Vehicle ApplicationsEditor IJTSRDNo ratings yet

- BMS in EVsDocument6 pagesBMS in EVsVIVEK UPADHYAY100% (1)

- Battery Management System An Overview of Its Application in The Smart Grid and Electric VehiclesDocument13 pagesBattery Management System An Overview of Its Application in The Smart Grid and Electric Vehiclesadityasinghal08No ratings yet

- Digital Twin Based Battery Management System - A ReviewDocument5 pagesDigital Twin Based Battery Management System - A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Bms ProposalDocument5 pagesBms ProposalAvwerosuo Hope OyawiriNo ratings yet

- BMS Electric Vehicles Monitors Controls ChargingDocument5 pagesBMS Electric Vehicles Monitors Controls ChargingJagdish ThakurNo ratings yet

- Literature SurveyDocument9 pagesLiterature SurveyifyNo ratings yet

- Lithium Ion Battery Research Paper PDFDocument6 pagesLithium Ion Battery Research Paper PDFafmczrsey100% (1)

- Day 1 EV Battery Management - Module 1Document43 pagesDay 1 EV Battery Management - Module 1Para CommandoNo ratings yet

- Cleantechnol 04 00056 v4Document23 pagesCleantechnol 04 00056 v4frank thompsonNo ratings yet

- Batteries For Electric Cars FocusDocument18 pagesBatteries For Electric Cars Focusjose carlos braguinhaNo ratings yet

- Tech RepDocument31 pagesTech RepNaveen BosNo ratings yet

- Ev Lit Rev FinalDocument17 pagesEv Lit Rev Finalkapilsharma10No ratings yet

- City Research Online: City, University of London Institutional RepositoryDocument20 pagesCity Research Online: City, University of London Institutional RepositoryGautham NNo ratings yet

- MarketResearch, 4PsDocument15 pagesMarketResearch, 4PsAmansapraSapraNo ratings yet

- Chapter 1Document10 pagesChapter 1BHAVANA B KNo ratings yet

- A Ug Bt0001e01Document52 pagesA Ug Bt0001e01Andre TeixeiraNo ratings yet

- A Ug Bt0001e01Document52 pagesA Ug Bt0001e01tripathi prashantNo ratings yet

- Ev Battery Optimization .DocxDocument8 pagesEv Battery Optimization .DocxVigneshNo ratings yet

- Ev Battery Optimization .Docx (1)Document8 pagesEv Battery Optimization .Docx (1)VigneshNo ratings yet

- Battery Powered: The Social, Economical, and Environmental Impacts of the Lithium Ion BatteryFrom EverandBattery Powered: The Social, Economical, and Environmental Impacts of the Lithium Ion BatteryNo ratings yet

- KE 26803 ELECTROMAGNETICS (2014/15) : Assignment 1Document6 pagesKE 26803 ELECTROMAGNETICS (2014/15) : Assignment 1ram010No ratings yet

- Li-Ion Batteries Basics, Progress, and ChallengesDocument34 pagesLi-Ion Batteries Basics, Progress, and ChallengesMDRNo ratings yet

- Lithium-Ion Battery Thermal Management System Using Thermoelectric Module and Microcontroller.Document13 pagesLithium-Ion Battery Thermal Management System Using Thermoelectric Module and Microcontroller.Aniket DusaneNo ratings yet

- PDFDocument6 pagesPDFAbderrezak BadjiNo ratings yet

- Mech Mod 3Document22 pagesMech Mod 3brave playerNo ratings yet

- Module3 - Electric VehiclesDocument16 pagesModule3 - Electric VehiclesRanjith KNo ratings yet

- Lean Startup Management Lean Startup Management Lean Startup ManagementDocument8 pagesLean Startup Management Lean Startup Management Lean Startup ManagementsunnyNo ratings yet

- Lesson 5 - Transistor Behaviour and ModelsDocument40 pagesLesson 5 - Transistor Behaviour and ModelsS.m. FerdousNo ratings yet

- Lesson 4 - LEDs and PhotodiodesDocument17 pagesLesson 4 - LEDs and PhotodiodesS.m. FerdousNo ratings yet

- Zener Diode Voltage Regulator Circuit DesignDocument32 pagesZener Diode Voltage Regulator Circuit DesignS.m. FerdousNo ratings yet

- AIPDocument19 pagesAIPS.m. FerdousNo ratings yet

- Accion Control y Aplicacion de Motores ElectricosDocument358 pagesAccion Control y Aplicacion de Motores Electricosnikoll1953No ratings yet

- Lesson 2 - Simple Diode Models and Circuits - (Presentation - Slides)Document29 pagesLesson 2 - Simple Diode Models and Circuits - (Presentation - Slides)S.m. FerdousNo ratings yet

- Lesson 1 - Introduction and Diode ModelsDocument45 pagesLesson 1 - Introduction and Diode ModelsS.m. FerdousNo ratings yet

- EmbeddedLab v1.60 RemoteDocsDocument197 pagesEmbeddedLab v1.60 RemoteDocsAshok ObuliNo ratings yet

- ENG207 Operational Amplifiers Principles of Electronic InstrumentationDocument38 pagesENG207 Operational Amplifiers Principles of Electronic InstrumentationS.m. FerdousNo ratings yet

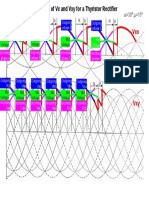

- Thyristor Commutation Animation VxVxyDocument1 pageThyristor Commutation Animation VxVxyS.m. FerdousNo ratings yet

- Recent Dev in Power Electronic - FinalDocument51 pagesRecent Dev in Power Electronic - FinalS.m. FerdousNo ratings yet

- Recent Development in Power Electronic - ContentDocument2 pagesRecent Development in Power Electronic - ContentS.m. FerdousNo ratings yet

- Normallised Parameters: The Parallel Resonant Converter: AnalysisDocument12 pagesNormallised Parameters: The Parallel Resonant Converter: AnalysisS.m. FerdousNo ratings yet

- Comparative Study Between Series Resonant Converter and Parallel Resonant ConverterDocument23 pagesComparative Study Between Series Resonant Converter and Parallel Resonant ConverterS.m. FerdousNo ratings yet

- Technical Implications of Electric Vehicle (EV) Integration For The Grid, Bulk and Local DistributionDocument16 pagesTechnical Implications of Electric Vehicle (EV) Integration For The Grid, Bulk and Local DistributionS.m. FerdousNo ratings yet

- Quote For MR - Shuvo, American International University BangladeshDocument3 pagesQuote For MR - Shuvo, American International University BangladeshS.m. FerdousNo ratings yet

- Busbar: Energy Storing and Recovering in Power Systems and Hev and EvDocument12 pagesBusbar: Energy Storing and Recovering in Power Systems and Hev and EvS.m. FerdousNo ratings yet

- FlywheelDocument8 pagesFlywheelS.m. FerdousNo ratings yet

- Checklist For Chapter 1: Introduction To Machinery PrinciplesDocument1 pageChecklist For Chapter 1: Introduction To Machinery PrinciplesS.m. FerdousNo ratings yet

- 3.2.3 Flux-Weakening Control Design and Analysis: Semiaxis Because of IDocument13 pages3.2.3 Flux-Weakening Control Design and Analysis: Semiaxis Because of IPierumberto PampaninNo ratings yet

- Analog MultipliersDocument5 pagesAnalog MultipliersS.m. FerdousNo ratings yet

- BatteryDocument9 pagesBatteryS.m. FerdousNo ratings yet

- Current Sources BJTDocument15 pagesCurrent Sources BJTS.m. FerdousNo ratings yet

- Chap 1Document21 pagesChap 1S.m. FerdousNo ratings yet

- Chapter 7 ChecklistDocument2 pagesChapter 7 ChecklistS.m. FerdousNo ratings yet

- Cover PagesDocument12 pagesCover PagesS.m. FerdousNo ratings yet

- Checklist For Chapter 6: Synchronous MotorsDocument2 pagesChecklist For Chapter 6: Synchronous MotorsS.m. FerdousNo ratings yet

- Chap 3Document42 pagesChap 3S.m. FerdousNo ratings yet

- Chap 2Document11 pagesChap 2S.m. FerdousNo ratings yet

- Harsh Sharma ResumeDocument2 pagesHarsh Sharma ResumeHarsh sharmaNo ratings yet

- It DBMS RecDocument77 pagesIt DBMS RecLokeshkumar Ramasamy100% (1)

- Cisco Firepower NGIPS Deployment GuideDocument21 pagesCisco Firepower NGIPS Deployment GuideMohcine OubadiNo ratings yet

- Photoshop green screen background removalDocument2 pagesPhotoshop green screen background removalJatiNo ratings yet

- Number Theory PresentstionDocument40 pagesNumber Theory PresentstionLovejoy0% (1)

- Dev2000 Build Reports Student Guide Vol01Document332 pagesDev2000 Build Reports Student Guide Vol01i4wchsu1222No ratings yet

- IBM Websphere Application Server Types of ProfilesDocument15 pagesIBM Websphere Application Server Types of ProfilessrisylamNo ratings yet

- Basics of Reversible Logic GatesDocument22 pagesBasics of Reversible Logic GatesRashika AggarwalNo ratings yet

- TG 9780199400591 PDFDocument100 pagesTG 9780199400591 PDFkhurram ShehzadNo ratings yet

- Panasonic KX td1232 - CompressDocument6 pagesPanasonic KX td1232 - CompressasfdsadfNo ratings yet

- Notes On Jensen's InequalityDocument7 pagesNotes On Jensen's InequalityJun WangNo ratings yet

- Easy Neural Networks With FANNDocument6 pagesEasy Neural Networks With FANNRoberto SolanoNo ratings yet

- Selecting The Best Delay Analysis TechniqueDocument4 pagesSelecting The Best Delay Analysis TechniquesmshaidrNo ratings yet

- CCIE EI v1.1 Blue PrintDocument7 pagesCCIE EI v1.1 Blue PrintZeinNo ratings yet

- RetextDocument86 pagesRetextAndrei Cosmin TrîncăNo ratings yet

- Network Analysis Mesh & Supermesh Analysis TheoryDocument5 pagesNetwork Analysis Mesh & Supermesh Analysis TheoryPrashant SharmaNo ratings yet

- Qoutation of Vehicle Tracking (GPS)Document4 pagesQoutation of Vehicle Tracking (GPS)Tabrez ahmed100% (1)

- PVTsim Hands-On Webinar Handout - Introduction To EoS ModelingDocument22 pagesPVTsim Hands-On Webinar Handout - Introduction To EoS ModelingsabrineNo ratings yet

- Quest HW1 SolutionsDocument6 pagesQuest HW1 Solutionsellie<3No ratings yet

- Asr 1005 Aps 900 Ima 08Document21 pagesAsr 1005 Aps 900 Ima 08Anonymous vguPVDzZ7TNo ratings yet

- APlus Catalog - AC6530MUDocument1 pageAPlus Catalog - AC6530MUNgọc TrầnNo ratings yet

- CMT2220LS Datasheet-EN-V1.0-20210917Document15 pagesCMT2220LS Datasheet-EN-V1.0-20210917Humberto Souza ArrudaNo ratings yet

- Orphan Process: Write A Program To Create A Thread To Find The Factorial of A Natural Number N'Document40 pagesOrphan Process: Write A Program To Create A Thread To Find The Factorial of A Natural Number N'srinivasa reddyNo ratings yet

- Nikon D5500 Brochure PDFDocument9 pagesNikon D5500 Brochure PDFJeremy LermanNo ratings yet

- CALCULUS 2 FUNCTION and LIMIT PDFDocument74 pagesCALCULUS 2 FUNCTION and LIMIT PDFZikraWahyudiNazirNo ratings yet

- EventlogDocument16 pagesEventlogDaniel QuirogaNo ratings yet

- Installation and Commissioning Manual for UNIDRIVE SP Universal Speed DriveDocument244 pagesInstallation and Commissioning Manual for UNIDRIVE SP Universal Speed DrivemssNo ratings yet

- CNF CVDocument4 pagesCNF CVJnz OlanNo ratings yet

- Module 1 Ethernet and VLAN: Lab 1-1 Ethernet Interface and Link Configuration Learning ObjectivesDocument15 pagesModule 1 Ethernet and VLAN: Lab 1-1 Ethernet Interface and Link Configuration Learning ObjectivesChaima BelhediNo ratings yet

- Winccflex2008sp3 PDFDocument78 pagesWinccflex2008sp3 PDFopenid_6qpqEYklNo ratings yet