Professional Documents

Culture Documents

Thick-Walled P.V.

Uploaded by

Erick PalladaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thick-Walled P.V.

Uploaded by

Erick PalladaCopyright:

Available Formats

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

IN

TR O D U C TIO

INTRODUCTIO

N

N

The pressure vessels, according to their dimensions, may be classified as thin shell or

thick shell. When the wall thickness of the shell is greater than 1/10 of the diameter of the

shell, then it is said to be a thick shell. Another criterion to classify the pressure vessels as

thin shell or thick shell is the internal fluid pressure (p) and the allowable stress ( t ). If

the internal fluid pressure is greater than 1/6 of the allowable stress, then it is said to be a

thick shell.

When the wall is thick, the tangential stress at the inside surface is much higher than

that the outside surface. A thickness too small is too dangerous; too large uneconomical

dimensions. A more accurate expression for the tangential stress is obtained by assuming

that the thick shell is composed of series of thin shell is differential thickness for each of

which the stress is uniform, and the plane transverse sections remain plane.

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

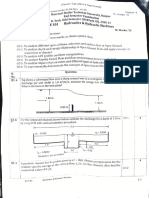

Fig. 4.1 Thick-walled cylinder

Consider a thick walled cylinder with open ends as shown above. It is loaded by

internal pressure Pi and external pressure Po as seen below. It has inner radius r i and

outer radius ro.

Fig. 4.2 Thick-walled cylinder

When a cylindrical shell of a pressure vessel, hydraulic cylinder, gun barrel and a

pipe is subjected to a very high internal fluid pressure, then the walls of the cylinder must

be made extremely heavy or thick. In thin cylindrical shells, we have assumed that the

tensile stresses are uniformly distributed over the section of the walls. But in the case of

thick wall cylinders as shown in Fig. 4.3 (a), the stress over the section of the walls cannot

be assumed to be uniformly distributed. They develop both tangential and radial stresses

with values which are dependent upon the radius of the element under consideration. The

distribution of stress in a thick cylindrical shell is shown in Fig. 4.3 (b) and (c). We see that

the tangential stress is maximum at the inner surface and minimum at the outer surface of

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

the shell. The radial stress is at its maximum at the inner surface and zero at the outer

surface of the shell.

In the design of thick cylindrical shells, the following equations are mostly used:

1. Lames equation;

2. Clavarinos equation;

3. Birnies equation; and

4. Barlows equation. The use of these equations depends upon the type of material

used and the end construction.

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

Fig. 4.3 Stress distribution in thick cylindrical shells subjected to

internal pressure.

DERIVATION OF FORMULAS

Now consider and element at radius r and defined by an angle increment

and a radial increment dr. By circular symmetry, the stresses

and

d

are

functions of r only, not and the shear stress on the element must be zero. For an

element of unit thickness, radial force equilibrium gives:

( r +d r ) ( r + dr ) d= r rd+ ddr

Ignoring second order terms gives:

d r r +

+

=0

dr

r

. (1)

Assuming that there are no body forces.

Now consider strains in the element. By symmetry there is no displacement v.

there is only a radial displacement u given by line aa. Point c is displaced radially

by (u + du) given by line cc. As the original radial length of the element is dr (line

ac), the radial strain is:

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

r =

u+duu du

=

dr

dr

Line ab has length rd and line ab has a length (r + u)d. The tangential strain

is thus:

=

( r +u ) drd u

=

rd

r

As the ends are open,

z= 3=0

and we thus have planes stress conditions.

From Hookes law we get:

r =

du 1

= ( v )

dr E r

u 1

= = ( r )

r E

Solving for the stresses gives:

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

r=

E du

u

+v

2

dr

r

1v

and

Substituting into equation above yields:

2

d u 1 du u

+

2 =0

2

d r r dr r

u=C 1 r+

This has solution:

C2

r

Giving the stresses as:

1+v C2

( 1v

r )

2

C1

E

r=

1v 2

1+v C2

. (2)

1v

r2

( )

C1

E

=

1v 2

. (3)

Chapter 4: Thick-Walled Pressure Vessels

E u

du

+v

2

r

dr

1v

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

The boundary conditions are:

r ( r i) =Pi

and

r ( r o )=Po

This yields the integration constants:

2

2

1v r i Pir o Po

C1 =

E

r o2 r i2

And

2 2

1v r i r o ( PiP o)

C2 =

E

r o2r i2

Giving the stresses as a function of radius:

r

( o 2r i2 )r 2

r(P P )r 2 r 2

( o 2r i2) i o i o

r

2

r i Pir2o2 P2o

(

o

r = 2r i )r

2 2

These are known as Lames

equations.

(PiP

2

o )r i r o

( o 2r i )

ro =outer radius of cylinder, in.

ri = inner radius of cylinder, in. r i2 Pir o2 Po

Pi, Po =internal and external pressure,

respectively,

psi

=

t =wall thickness, ro ri

= Poissons ratio

, t , St = tangential stress, psi

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

r , Sr

= radial stress, psi

z , a , S a = axial stress, psi

r

= radial strain

= tangential strain

z , = longitudinal or axial strain

y = yield point stress

u

= ultimate stress

From equation 2 and 3 above we can see that the sum of the radial and

tangential stresses is constant, regardless of radius:

r + =2 E C1 /(1v)

Hence the longitudinal strain is also constant since:

r

+

(

)=

Z =E Z =

Constant. Hence we get

constant = c

v

Z=

E

If the ends of the cylinder and open and free we have FZ = 0, hence

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

r p2

Z .2 rdr=c (r i2)=0

Or c =

ro

Z =0

as we assumed

ri

If the cylinder has closed ends, the axial stress can be found separately using

only force equilibrium considerations as was done for the thin walled cylinder. The

result is then simply superimposed on the above equations.

2

The pressure Pi acts on are given by r i

2

The pressure Po acts on are given by r o

The axial stress

2

2

acts on an are given by ( r o r i )

Force equilibrium then gives:

Z=

Pi r i2Po r o2

r o2r i2

The following is a summary of the equations used to determine the stresses

found in thick walled cylindrical pressure vessels. In the most general case the

vessel is subject to both internal and external pressures. Most vessels also have

closed ends -this results in an axial stress component.

Principal stresses at radius r :

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

1= =K +C /r 2

2= r =K +C /r 2

3 = axial =K

And, if the ends are closed,

Where:

=( Po Pi)

ri ro

r o2r 12

K=

( Po r o2 P i r i2 )

r o2r 12

(a) Internal Pressure only (Po= 0): The most common case dealt with in machine

design is a cylinder subjected to internal pressure only. In this case Po is zero.

r=

z=

Pi r i2

r o2r i2

Pi r i2

r o2r i2

[ ]

1

r o2

r2

[ ]

1+

Pi r i 2

r o2r i2

At inside surface, r = ri:

Chapter 4: Thick-Walled Pressure Vessels

r o2

r2

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

=P i

[ ]

r o2+r i2

r o2r i2

r =Pi

r =0

Pi r i

2

2

r o r i

Z=

Pi r i 2

Z= 2 2

r o r i

At outside surface, r = ro:

2 Pi r i2

r o2r i2

(b) External Pressure only (Pi= 0):

=

Po r o

r o2r i2

[ ]

1+

ri

r2

Po r o

r=

r =0

r o 2r i2

[ ]

1

ri

r2

P o r o2

z= 2 2

r o r i

At inside surface, r = ri:

2 Po r o

r o2r i2

At outside surface, r = ro:

Chapter 4: Thick-Walled Pressure Vessels

P r

Z = 2 o o2

r o r i

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

=Po

[ ]

r o2 +r i2

r o2r i2

r =Po

Chapter 4: Thick-Walled Pressure Vessels

Z=

Po r o

2

2

r o r i

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

Fig. 4.4 Example of cylinder with Pi = 1000 psi, ri= 2 and ro=4

Note that in all cases the greatest magnitude of direct stress is the tangential stress at the

in-side surface. The maximum magnitude of shear stress also occurs at the inside surface.

(c) Press and shrink fits

When a press or shrink fit is used between 2 cylinders of the same material, an

interface pressure pi is developed at the junction of the cylinders. If this pressure is

calculated, the stresses in the cylinders can be found using the above equations. The

pressure is:

c

( 2b )(b2a 2)

2b 2 (c 2a2 )

E

pi =

b

2

Nomenclatures:

E = Youngs Modulus

= radial interference between the two cylinders

a = inner radius of the inner cylinder

b = outer radius of inner cylinder and inner radius of outer cylinder

c = outer radius of outer cylinder

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

It is assumed that is very small compared to the radius b and that there are no

axial stresses. Thus we have = binner bouter. Note that this small difference in the

radii is ignored in the above equation.

Clavarinos Equation

This equation is also based on the maximum-strain theory of failure, but it is

applied to closed-end cylinders (or cylinders fitted with heads) made of ductile

material. According to this equation, the thickness of a cylinder,

t=r i

+ (12 ) p

1

( 1+ ) p

In this case also, the value of

may be taken as 0.8 times the yield point

stress (y).

Birnies Equation

If the cylinder is considered to be open at the end so that no direct axial

stress is possible, an analysis similar to that for Clavarinos equations leads to the

following equations for equivalent stress:

'=( 1 ) a+ ( 1+ )

Chapter 4: Thick-Walled Pressure Vessels

b

r2

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

and

'r =( 1 ) a( 1+ )

b

r2

The equation for the wall thickness is:

t=r i

'+ ( 1 ) p i

1

'( 1+ ) p i

In case of open-end cylinders (such as pump cylinders, rams, gun barrels etc.)

made of ductile material (i.e. low carbon steel, brass, bronze, and aluminum alloys),

the allowable stresses cannot be determined by means of maximum-stress theory of

failure. In such cases, the maximum-strain theory is used.

The value of may be taken as 0.8 times the yield point stress (y).

Barlows Equation

This equation is generally used for high pressure oil and gas pipes. According to

this equation, the thickness of a cylinder,

t=

p ro

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

For ductile materials, = 0.8 y and for brittle materials = 0.125 u, where u

is the ultimate stress.

Sample Problems

1. A HYDRAULIC PRESS HAS A MAXIMUM CAPACITY OF 1000 KN. THE PISTON

DIAMETER IS 250 MM. CALCULATE THE WALL THICKNESS IF THE CYLINDER IS MADE

OF MATERIAL FOR WHICH THE PERMISSIBLE STRENGTH MAY BE TAKEN AS 80 MPA.

THIS MATERIAL MAY BE ASSUMED AS A BRITTLE MATERIAL .

Solution:

Given: W = 1000 kN = 1000 103 N; d = 250 mm; t = 80 MPa = 80 N/mm2

First of all, let us find the pressure inside the cylinder (p). We know that load on the

hydraulic press (W),

3

1000 x 10 =

p=

2

2

3

x d x p= (250) p=49.1 x 10 p

4

4

1000 x 103

=20.37 N /mm2

49.1

Let ri = Inside radius of the cylinder = d / 2 = 125 mm

We know that wall thickness of the cylinder,

t=ri

] [

t+ p

1 =125

t p

80+20.37

1 mm

8+20.37

t=125 ( 1.2971 )=37 mm

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

ANSWER: 37 mm

2. THE

CYLINDER OF A PORTABLE HYDRAULIC RIVETER IS 220 MM IN DIAMETER. THE

PRESSURE OF THE FLUID IS 14 N/MM2 BY GAUGE. DETERMINE SUITABLE THICKNESS

OF THE CYLINDER WALL ASSUMING THAT THE MAXIMUM PERMISSIBLE TENSILE

STRESS IS NOT TO EXCEED 105 MPA.

Solution:

Given : di = 220 mm or ri = 110 mm ; p = 14 N/mm2 ; t = 105 MPa = 105 N/mm2

Since the pressure of the fluid is high, therefore thick cylinder equation is used.

Assuming the material of the cylinder as steel, the thickness of the cylinder wall (t)

may be obtained by using Birnies equation. We know that,

...(Taking Poissons ratio for steel, = 0.3)

t=ri

t=110

t +(1) p

1

t(1+ ) p

]

]

105+(10.3)14

1 =16.5 mm

105(1+ 0.3)14

ANSWER: 16.5 mm

3. THE HYDRAULIC CYLINDER 400 MM BORE OPERATES AT A MAXIMUM PRESSURE OF 5

N/MM2. THE PISTON ROD IS CONNECTED TO THE LOAD AND THE CYLINDER TO THE

FRAME THROUGH HINGED JOINTS.

Design: cylinder.

The allowable tensile stress for cast steel cylinder and end cover is 80 MPa

Solution:

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

Given : di = 400 mm or ri = 200 mm ; p = 5 N/mm2 ; t = 80 MPa = 80 N/mm2

Design of cylinder

Let do = Outer diameter of the cylinder.

We know that thickness of cylinder,

t=ri

t=200

t+ p

1

t p

]

]

80+5

1 mm

805

t=200 ( 1.061 ) =12mm

ANSWER: 12 mm

Outer diameter of the cylinder,

do = di + 2t = 400 + 2 12 = 424 mm

ANSWER: 424 mm

4. A

CYLINDER HAVING AN INTERNAL DIAMETER OF 20 IN. AND AN EXTERNAL

DIAMETER OF 36 IN. IS SUBJECTED TO AN INTERNAL PRESSURE OF 10000 PSI

AND AN EXTERNAL PRESSURE OF 2000 PSI. DETERMINE THE HOOP STRESS AT

THE INNER AND OUTER SURFACE OF THE CYLINDER.

Solution:

S ti =

Pi ( r o2+ r i2) 2 Po r o2

r o2r i2

Where:

ri = 10

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

Pi = 10000 psi

ro = 18 Po = 2000 psi

S ti =

10000 ( 18 2+102 ) 2(2000)(18)2

=13143 psi

2

2

18 10

ANSWER: Sti = 13143 psi

S=

S=

2 Pi r i2Po ( r o2 +r i2 )

r o2 r i2

2(10000)(10)22000 ( 182 +102 )

=5143 psi

18210 2

ANSWER: S = 5143

5. THE

WORK CYLINDER OF A HYDRAULIC SYSTEM IS ACTED BY A HYDRAULIC

PRESSURE OF 750 PSI WHILE THE MAXIMUM LOAD OF THE PISTON IS 5500 LBS.

IF THE ALLOWABLE TENSILE STRESS IS 2000 PSI, WHAT IS THE REQUIRED WALL

THICKNESS OF THE CYLINDER?

Solution:

Force = Pressure x Area

2

5500 = 370 x ( /4) D

D = 4.35 in

Assume thick-wall cylinder ,

Chapter 4: Thick-Walled Pressure Vessels

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

t=

D

2

t=

4.35

2

S i + Pi

1

Si Pi

2000+350

1 =0.448

2000370

ANSWER: t = 0.448 in

t/D

0.448/4.35

DEFINITION OF TERMS

Angle

back-pressure

valve. An angle backpressure valve is a valve

with its outlet opening

at right angles to its

inlet opening.

Autoclave. A process vessel used

any time a vacuum needs to be

pulled on a product.

Design pressure. The

pressure

used

in

calculating

the

minimum thickness or

design characteristics of a boiler or

pressure vessel.

Design stress. A permissible

maximum stress to which a machine

part or structural member may be

subjected, which is large enough to

Chapter 4: Thick-Walled Pressure Vessels

prevent failure in case the load

exceeds the expected value.

Digester. A pressure vessel that acts

much like a big

stomach to break a

product down.

Heat

Exchanger. A process vessel used

to either add or remove heat from a

product. It works much like the

radiator on a car, trying to remove

heat from the engine.

Hyperbaric chamber. A specially

equipped pressure vessel used in

medicine and physiological research

to administer oxygen at elevated

pressure.

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

Integral-type flange. A flange

which is forge or cast with, or buttwelded to a nozzle neck, pressure

vessel or piping wall.

Ion Exchanger. A process vessel

used in separating a product at the

molecular level, such as ethanol or

bio diesel.

Jacketed. Processed vessel where

material is added to the outside of a

pressure vessel to maintain an

acceptable temperature.

Lined. A process vessel where

material is added to the inside of a

pressure vessel to prevent rust and

erosion or to reduce cost

Normal

operation.

Normal

operation is the operation of boiler

or pressure vessel at or below the

conditions of coincident pressure

and temperature for which the

vessel has been designed.

Paint Pots. A specialized storage

pressure vessel normally used to

store and transfer paint to a spray

gun. For instance, Thermatech

provides paint pots used in the

transportation industry for striping

roads and highways.

Pressure. Pressure is a type of stress

which is exerted uniformly in all

directions.

Pressure dye test. Leak detection

method in which a pressure vessel is

filled with liquid dye and is

Chapter 4: Thick-Walled Pressure Vessels

pressurized under water to make

possible leakage path visible.

Pressure gage. An instrument used

to measure pressure.

Pressure

Measurement.

Measurement of the internal force

of a process vessel, tank, or piping

caused by pressurized gas or liquid.

Pressure-relief valve.

Pressure relief valve is

a valve which relieves

pressure beyond a

specified limit and recloses upon returning

to normal operating

condition.

Pressure-retaining

member. A part of

pressure-relieving

device loaded by the

restrained pressurized fluid.

Pressure storage. The storage of a

volatile liquid or liquefied gas under

pressure to prevent evaporation.

Pressure vessel. A pressure vessel is

a metal container, generally

cylindrical or spherical in shape

which is capable to withstand

bursting pressure.

Pressurize. To maintain normal

atmospheric pressure in a chamber

subjected to high or low external

pressure.

Radiography (RT). Is used to obtain

an image (on film) of the weld

metal through a seam. A lighted

L

N

REPUBLIC OF THE PHILIPPINES

BATAAN PENINSULA STATE UNIVERSITY

MAIN CAMPUS, PROVINCE OF BATAAN, CITY OF BALANGA C-2100

COLLEGE OF ENGINEERING AND ARCHITECTURE

DEPARTMENT OF MECHANICAL ENGINEEERING

view is required to see the film and

interpret its results. It is used to

detect cracks, slag lines, porosity,

lack of fusion, and suck back,

among other things.

Required thickness. The thickness

calculated by recognized formulas

for boiler or pressure vessel

construction

before

corrosion

allowance is added.

Resealing pressure. The inlet

pressure at which leakage stops

after a pressure relief valve is

closed.

Saturation Diving System. A type

of pressure vessel (PVHO) used for

deep sea dives. A series of living

chambers are fitted together for a

multi-day project. For example,

workers can compress just once on

the way down and once on the way

up for a 30-day deep sea

construction project.

Spring-loaded

regulator.

A

pressure-regulator

valve

for

pressure vessels or flow system.

Stub tube. A short tube welded to a

boiler or pressure vessel to provide

for the attachment of additional

parts.

Super Duplex Stainless Steel. A

specialized material often called an

exotic metal. Super duplex

stainless steel is only manufactured

Chapter 4: Thick-Walled Pressure Vessels

properly in two places in the world.

Thermatech is one of

only a handful of

U.S. manufacturers

with the expertise to

fabricate

pressure

vessels using this unique

material.

Temperature. A property

of an object which determines the

direction of heat flow when the

object is placed in thermal contact

with another object.

Ultrasonic Testing (Angle UT). Is a

process by which ultrasonic waves

are introduced by a transducer into

the weld (typically

from the side of the

weld). A machine will

convert the waves that

bounce back into a visible pattern

that a trained person can use to

detect discontinuities.

Unfired pressure vessel. A pressure

vessel that is not in direct contact

with a heating flame.

Vessel. A container or structural

envelope in which materials are

processed, treated, or stored.

Yield temperature. The temperature

at which a fusible plug device melts

and is dislodge by its holder and

thus relieves pressure in a pressure

vessel.

R

T

V

Y

You might also like

- ME 354 Tutorial, Week#9 Brayton Cycle With Intercooling, Reheat & RegenerationDocument7 pagesME 354 Tutorial, Week#9 Brayton Cycle With Intercooling, Reheat & RegenerationJesus Daniel QuispeNo ratings yet

- Electrical Machines EE 250 Laboratory Manual - Hajvery University Lahore PakistanDocument36 pagesElectrical Machines EE 250 Laboratory Manual - Hajvery University Lahore Pakistanadnan_ashraf2No ratings yet

- Work and Heat in ThermodynamicsDocument129 pagesWork and Heat in Thermodynamicssohan2902No ratings yet

- Chapter 1Document15 pagesChapter 1سعيد بن إدريس100% (1)

- Exercises Problem On Spur Gear Force Analysis: Module 2: Activity No. 5Document1 pageExercises Problem On Spur Gear Force Analysis: Module 2: Activity No. 5Ariel GamboaNo ratings yet

- Merged Refresher MESL Questions OCRDocument22 pagesMerged Refresher MESL Questions OCRBernalynMalinaoNo ratings yet

- Aim: Capacitive RectificationDocument9 pagesAim: Capacitive RectificationPriNo ratings yet

- Integration Course 2 Solutions and AnswersDocument38 pagesIntegration Course 2 Solutions and Answersanya ForgerNo ratings yet

- Ee 4101Document183 pagesEe 4101Franz TabioloNo ratings yet

- HW 1Document5 pagesHW 1Yohan ManaligodNo ratings yet

- 311 ThermoDynamics ThermoDynamicsDocument5 pages311 ThermoDynamics ThermoDynamicsmozam haqNo ratings yet

- BorinagaaaaDocument7 pagesBorinagaaaaNaitsirhc AganirobNo ratings yet

- Ideal Gas Law Simulation: PV NRTDocument3 pagesIdeal Gas Law Simulation: PV NRTElla GreenNo ratings yet

- CO Assign#2 BSEE-2ADocument3 pagesCO Assign#2 BSEE-2AEisen JaylordNo ratings yet

- Chapter 1 Thermodynamics 2Document2 pagesChapter 1 Thermodynamics 2afiqzeroNo ratings yet

- Welding Design ProblemsDocument41 pagesWelding Design ProblemsMark EstepaNo ratings yet

- Ref MathDocument7 pagesRef MathMd.Tanvir RahmanNo ratings yet

- SOLUTIONDocument11 pagesSOLUTIONKim Howard CastilloNo ratings yet

- ME3122E - Tutorial Solution 5Document21 pagesME3122E - Tutorial Solution 5LinShaodun64% (11)

- Brayton CycleDocument5 pagesBrayton CycleDanang Wahdiat Aulia IshaqNo ratings yet

- Gmas Plane and Solid GeometryDocument11 pagesGmas Plane and Solid Geometryjonnel batuigasNo ratings yet

- 3rd CheckingDocument21 pages3rd CheckingKing Cyruz PabloNo ratings yet

- Refrigerants - Physical PropertiesDocument3 pagesRefrigerants - Physical PropertiesEder PereiraNo ratings yet

- Newton's Law of Cooling: DE 730 MWDocument2 pagesNewton's Law of Cooling: DE 730 MWKim ChuaNo ratings yet

- ME 230 Kinematics and Dynamics Equations of MotionDocument93 pagesME 230 Kinematics and Dynamics Equations of MotiongNo ratings yet

- Experiment 2Document9 pagesExperiment 2Narry StrummerNo ratings yet

- F =σA F =3.5 (π (430) ) F =508270.42N: Problem 142Document2 pagesF =σA F =3.5 (π (430) ) F =508270.42N: Problem 142Kers CelestialNo ratings yet

- Physics Problems on Mechanics and DynamicsDocument34 pagesPhysics Problems on Mechanics and DynamicsHatsady ThonginNo ratings yet

- Laboratory Activity 7 - Acceleration AnalysisDocument2 pagesLaboratory Activity 7 - Acceleration AnalysisDavid SaldivarNo ratings yet

- Thermodynamics 2 Review Problem No 7 SOLUTIONDocument3 pagesThermodynamics 2 Review Problem No 7 SOLUTIONangie 2498100% (1)

- ME-411 Fluid Machinery Quiz Problems on Hydroelectric Power Plant Estimations and CalculationsDocument1 pageME-411 Fluid Machinery Quiz Problems on Hydroelectric Power Plant Estimations and CalculationsJohn MameNo ratings yet

- Circuits1 1 Laboratory Meters and Power SupplyDocument2 pagesCircuits1 1 Laboratory Meters and Power SupplyJad DimabuyuNo ratings yet

- Cuares Davied Joshua 3B - Diesel SolutionDocument5 pagesCuares Davied Joshua 3B - Diesel Solutionjethro ganeloNo ratings yet

- Nidec Philippines Corporation Company ProfileDocument35 pagesNidec Philippines Corporation Company ProfileVergel MartinezNo ratings yet

- PUMPS Part 2Document11 pagesPUMPS Part 2Kaiser CarloNo ratings yet

- DC Machine 2Document20 pagesDC Machine 2Fadhil A. HasanNo ratings yet

- Chapter 3Document8 pagesChapter 3Jerome CansadoNo ratings yet

- Melab1 Exp3Document11 pagesMelab1 Exp3privateziel100% (1)

- Question BAB 5Document3 pagesQuestion BAB 5Justin GriffithNo ratings yet

- Ideal Gas Refrigeration Cycle & R-134a Vapor Compression Refrigerator PerformanceDocument3 pagesIdeal Gas Refrigeration Cycle & R-134a Vapor Compression Refrigerator Performanceanask15No ratings yet

- Anto ME463 Plate No. 3Document18 pagesAnto ME463 Plate No. 3Eman Lampago AntoNo ratings yet

- Neil Chester C. HernaezDocument5 pagesNeil Chester C. HernaezSka dooshNo ratings yet

- Subject: Electrical Machines Conventional Practice QuestionsDocument9 pagesSubject: Electrical Machines Conventional Practice QuestionsPriya SharmaNo ratings yet

- Chap 08 Soln PDFDocument26 pagesChap 08 Soln PDFsoma sundaramNo ratings yet

- TIP MANILA STUDENT ASSIGNMENT SOLUTIONSDocument14 pagesTIP MANILA STUDENT ASSIGNMENT SOLUTIONSTyrone PaulinoNo ratings yet

- PPE Problem Set on Thermodynamics, Rankine Cycle, Diesel EnginesDocument3 pagesPPE Problem Set on Thermodynamics, Rankine Cycle, Diesel EnginesElisif DeFairNo ratings yet

- Solution Machine DesignDocument9 pagesSolution Machine DesignRheymar MercadoNo ratings yet

- Machine Desing 1 Exam #2 Problem Solving InstructionsDocument2 pagesMachine Desing 1 Exam #2 Problem Solving InstructionsMarc JabarNo ratings yet

- Physics II Problems PDFDocument1 pagePhysics II Problems PDFBOSS BOSSNo ratings yet

- ME463 - Lab Exercise 1: Design of Flat BeltDocument4 pagesME463 - Lab Exercise 1: Design of Flat BeltJoshua OliverNo ratings yet

- Chapter 4 (1) & (2) Homework SolutionDocument18 pagesChapter 4 (1) & (2) Homework SolutionAnderson Niño Velasco0% (1)

- STB35103 Control System Theory Tutorial 1 QuestionsDocument7 pagesSTB35103 Control System Theory Tutorial 1 QuestionsahmadkamalNo ratings yet

- Research1 5Document44 pagesResearch1 5izzeah ramodNo ratings yet

- Thermodynamics Lab: Experiment No. 1: Calibration of Bourdon Pressure Gage Apparatus: Theory: CalibrationDocument4 pagesThermodynamics Lab: Experiment No. 1: Calibration of Bourdon Pressure Gage Apparatus: Theory: CalibrationAli JawadNo ratings yet

- Thick Walled Cylinders (Corrected)Document17 pagesThick Walled Cylinders (Corrected)John Larry CorpuzNo ratings yet

- A Comparative Study On Failure Pressure Estimations of Unflawed Cylindrical VesselsDocument14 pagesA Comparative Study On Failure Pressure Estimations of Unflawed Cylindrical VesselsBrighton JohnNo ratings yet

- Pressure VesselDocument32 pagesPressure VesselYonjon SubhaNo ratings yet

- Stresses in Thin, Thick, Spherical PVsDocument22 pagesStresses in Thin, Thick, Spherical PVsSuresh SjNo ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- 5th Semester ESE Paper... (CE)Document16 pages5th Semester ESE Paper... (CE)MOHD NAZIM - 33 HBTUNo ratings yet

- X-Ray Filtration and Beam QualityDocument10 pagesX-Ray Filtration and Beam Qualitywajira sanjaya pereraNo ratings yet

- Electrochemistry 494 PDFDocument55 pagesElectrochemistry 494 PDFHarsh SaxenaNo ratings yet

- DNV SOFTWARE PIPELINE TOOLDocument2 pagesDNV SOFTWARE PIPELINE TOOLandrey25No ratings yet

- Light Microscope: E.G. During DissectionDocument2 pagesLight Microscope: E.G. During DissectionDr.CharinNo ratings yet

- 27.viscoelastic Responses of Polyhedral Oli PDFDocument5 pages27.viscoelastic Responses of Polyhedral Oli PDFVansala GanesanNo ratings yet

- WPS & PQR - 2021Document82 pagesWPS & PQR - 2021Subramanian RNo ratings yet

- NMJT 2 LatestDocument19 pagesNMJT 2 LatestAnonymous pSozzNFcNo ratings yet

- Motor Size SelectionDocument4 pagesMotor Size SelectionArnoah RamirezNo ratings yet

- Icephobic Strategies and Materials With Superwettability: Design Principles and MechanismDocument61 pagesIcephobic Strategies and Materials With Superwettability: Design Principles and MechanismAnonymous ahNUZsrQpSNo ratings yet

- HT Tutorial 1 QuestionsDocument7 pagesHT Tutorial 1 QuestionssairamNo ratings yet

- Mn-Cu Alloying Improves Mechanical Properties of Ductile IronDocument7 pagesMn-Cu Alloying Improves Mechanical Properties of Ductile IronabhiNo ratings yet

- Nagendra G M: Teaching ExperienceDocument3 pagesNagendra G M: Teaching Experiencenagendra_gmNo ratings yet

- Stabilizing Slider-Crank Mechanism With Clearance JointsDocument13 pagesStabilizing Slider-Crank Mechanism With Clearance JointsTomé GuenkaNo ratings yet

- Ce2202 - Mechanics of FluidsDocument3 pagesCe2202 - Mechanics of FluidsPrashant GaradNo ratings yet

- Study of A Single Pass Shell and Tube Heat ExchangerDocument21 pagesStudy of A Single Pass Shell and Tube Heat Exchangermahbub1332No ratings yet

- Tablet Disintegration Test and Basket Rack AssemblyDocument2 pagesTablet Disintegration Test and Basket Rack AssemblyPhoenix100% (1)

- Technical Specification For Vacuum SystemsDocument284 pagesTechnical Specification For Vacuum SystemsUday SuleNo ratings yet

- Fundamentals of Welding - Chapter 30Document50 pagesFundamentals of Welding - Chapter 30xharpreetxNo ratings yet

- Laboratory Exercise 3: Atterberg Limits Test: ReferencesDocument10 pagesLaboratory Exercise 3: Atterberg Limits Test: ReferencesmoNo ratings yet

- TACO PVC Sheet E-CatalogueDocument9 pagesTACO PVC Sheet E-CataloguedickiNo ratings yet

- 4 Tension MemberDocument15 pages4 Tension Memberhari1008108No ratings yet

- Hydraulic Calculation Report - PSDocument289 pagesHydraulic Calculation Report - PSAob AprilNo ratings yet

- Beam Design (SSB)Document7 pagesBeam Design (SSB)SaiSowmithGoudNaramalaNo ratings yet

- Preparation of Chemical Manganese Dioxide From Manganese SulfateDocument5 pagesPreparation of Chemical Manganese Dioxide From Manganese Sulfate郭超No ratings yet

- Wet CompressionDocument6 pagesWet CompressionjdelosriosNo ratings yet

- Process of Formation of All MineralsDocument1 pageProcess of Formation of All MineralsStephanie CorpuzNo ratings yet

- Design of Purlins and Sag RodDocument2 pagesDesign of Purlins and Sag Rodliezel100% (1)

- Forms of Corrosion: CHE-545-172 DR Ime B.ObotDocument17 pagesForms of Corrosion: CHE-545-172 DR Ime B.ObotAnonymous NxpnI6jCNo ratings yet

- TitraDocument8 pagesTitraAbdoul RahimNo ratings yet