Professional Documents

Culture Documents

CIBSE Factor

Uploaded by

ozzy22Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CIBSE Factor

Uploaded by

ozzy22Copyright:

Available Formats

16387: Environmental Engineering Science 2

2 Dynamic Behaviour of Buildings

Handouts: Building for Energy Conservation by Burberry P (section 3.3)

Cibse Guide Section A: Admittance Technique

Steady-State Analysis

This traditional analysis was undertaken for plant sizing assuming typical indoor and

design external conditions. For buildings which have high levels of thermal mass, low

solar gains, and constant internal temperatures (e.g. old hospitals), the steady state

method can give an indication of energy consumption. For this analysis, fabric heat

losses are controlled by conductivity and thickness of the external construction and

surface resistances.

U= 1/Rtot

(W/m2K)

Rtot = Rsi +(t/k) + Rso

(m2K/W)

Dynamic Behaviour

For calculation of dynamic behaviour, it is necessary to take heat storage (thermal

capacity) into account:

specific heat capacity: C

density:

(J/kgK)

(kg/m3)

volumetric heat capacity = C

(J/m3K)

Steady state analysis is often not sufficient because:

Thermal properties of newer buildings tend towards a lightweight constructions

which have lower thermal capacity, faster response to heat inputs and therefore

much greater temperature swings.

Even heavyweight buildings will act as lightweight buildings if the walls are lined

with some insulation.

Improved heating systems have faster response (e.g. gas-fired boilers) and better

controllers, which enable heat to be input when required.

Intermittent occupancy patterns are more common in the domestic sector: this

requires rapid warming up of the building in the morning and again in the evening.

16387: Environmental Engineering Science 2

Table IV in the handout shows the thermal capacity of different materials having the

same U-value. Clearly, surface temperatures of constructions with high thermal mass

would take a long time to increase after a period of no heating (e.g. in an office after a

weekend) and would contribute to poor thermal comfort conditions in a room until the

heating had been on for several hours.

Figures 3.11 to 3.13 in the handout show how different wall constructions react to

intermittent heating. As can be seen, a wall with high thermal mass can have large

differences between internal air temperature and wall surface temperature: this can

lead to condensation problems as well as poor thermal comfort.

Transient Conduction

This is controlled by the Fourier Equation, which for 1 dimensional conduction is:

2

=k 2

t

x

An important property is the ratio of thermal conductivity to volumetric heat capacity,

known as the diffusivity:

= k / C

This has units of m2/s and it indicative of the rate at which a heat pulse will propagate

through a solid.

The time constant (tc) is related to the response of a construction to a step change:

T

0.63

tc

Heavyweight constructions have long time constants, lightweight constructions have

short time constants.

16387: Environmental Engineering Science 2

Response of Heavyweight and Lightweight Buildings

The building response will differ according to whether the building is lightweight or

heavyweight. The following figure illustrates this.

Heating curves for heavyweight and lightweight buildings

Fabric Performance and Fuel Consumption

Figure 3.14 in the handout shows how thermal capacity affects fuel consumption in

lightweight and heavyweight buildings. For intermittent heating, lightweight

buildings offer significant potential fuel savings, unlike heavyweight buildings. For

example, the following table shows the heat required to raise fabric temperature.

Material

Drop in

Heat required to return to

temperature (oC) ambient temperature (kJ/m2)

100mm brick

880

100mm

20

600

fibreboard

Although a fibreboard-lined room will show a greater drop in temperature when

heating is off, less heat is required to get back to temperature. Also less time is

required (see Figure above). During the heating off period, the fibreboard-lined room

would be colder and in practice it may be necessary to have a lower limit, below

which heating is switched on, to prevent condensation risk.

16387: Environmental Engineering Science 2

Figure 3.15 in the handout shows how the use of steady state analysis and design

temperatures instead of more realistic boundary conditions can lead to incorrect

conclusions on potential for fuel saving.

Summer conditions

In hot climates with intermittent active cooling, lightweight buildings offer the same

advantages for heating as discussed above. However, for buildings that are not

actively cooled, heavyweight constructions are best because they reduce peak daily

temperatures. Additional cooling of the thermal mass at night (night purging) can

assist in reducing peak daytime temperatures.

Effect of solar gains on heavyweight and lightweight buildings

Prediction Techniques

16387: Environmental Engineering Science 2

Figure 3.16 shows more realistic variation in internal and external conditions. Three

methods of predicting such dynamic variations in temperature are:

Analogue method: superseded by numerical techniques.

Admittance technique: developed by CIBSE, used in particular for calculating

peak summertime temperatures.

Solution of Fourier Equation: computer programs based on a variety of numerical

methods are used; some examples are covered later in the course.

Analogue Method

There exist a clear analogy between electrical flow and heat flow. Formerly, this

analogy was the basis for constructing electrical analogue devices (sometimes

incorporated in analogue computers) which were used in the study of complex heat

flow phenomena.

Thermal

Electrical

Resistance

Resistance

Capacity

Capacitance

Temperature

Voltage

Heat flow

Current

Thermal/electrical analogy

The following figure shows the electrical network used to generate Figure 3.16 in the

handout.

16387: Environmental Engineering Science 2

Electrical representation of thermal properties

Different heating options and insulation levels can be tested by altering current and

resistance values in the analogue model. Figure 3.19 and Tables VI and VII in the

handout show how energy consumption varies. Such analyses were very time

consuming to set up and only used for research.

Admittance Procedure

This was developed by CIBSE to give a prediction method for dynamic thermal

performance. It takes into account:

both air and radiant temperature for achievement of thermal comfort conditions;

the modifying effect on temperature fluctuations of the materials used for internal

room surfaces;

solar heat gain;

cyclic variations in ventilation, internal gains and external temperature: steady

state and cyclic variations (and any associated time lag) are treated separately and

then combined.

16387: Environmental Engineering Science 2

Temperatures

Inside air temperature (tai):

this is the volume averaged air temperature in the room.

Mean surface temperature (tm):

The mean surface temperature is the area-weighted average temperature of the

internal surfaces of the room.

tm =

( At s )

(A)

Mean radiant temperature (tr)

This is a function of areas, shapes and surface temperatures as viewed from a

specific point in the room; it varies according to view factors between the object

and room surfaces.

It is equal to the mean surface temperature at the centre of a cubical room in which

all surfaces have the same emissivity. It is often used as a good approximation for

other room shapes.

Inside environmental temperature (tei)

This is used to calculate the heat exchange between a surface and an enclosed

space. It is a combination of the mean surface temperature and air temperature.

The combination will depend on the relative magnitudes of the radiant and

convective heat transfer coefficients, but typically the following equation is used:

tei= 1/3 tai + 2/3 tm

Dry resultant temperature (tc)

In cases where air movement is low, the dry resultant temperature is used as an

index of thermal comfort. In such cases:

tc= 1/2 tai + 1/2 tm

where tm is used as an approximation for tr at the centre of the room.

16387: Environmental Engineering Science 2

Outside air temperature (tao)

This is the bulk air temperature of the air surrounding the building

Sol-air temperature (teo) and sol-air excess temperature difference

Sol-air temperature is that temperature which, in the absence of solar radiation,

would give the same rate of heat transfer through the wall or roof as exists with the

actual outdoor air temperature and incident solar radiation. It is effectively the

outside environmental temperature.

It is given by:

teo= tao + Rso ( It + Il )

where It is the total intensity of solar radiation on the outside surface and Il is

the net longwave radiation exchange between a black body at outside air

temperature and the outside environment.

The sol-air temperature is approximately equal to the external air temperature

under overcast conditions.

The sol-air excess temperature difference is the quantity that must be added to or

subtracted from the outside air temperature in order to calculate the heat transfer

through opaque external surfaces resulting from the radiation exchange between

those surfaces and the sun and the sky.

teo= Rso ( It + Il )

Non-Steady State Thermal Characteristics

The admittance, decrement factor and surface factor are functions of the thickness,

thermal conductivity, density and specific heat capacity of each of the materials used

within a construction, as well as the relative positions of those materials. Energy

inputs are assumed to be cyclic, usually with a 24 hour period.

Admittance

16387: Environmental Engineering Science 2

The admittance of a construction is the rate of heat flow between its internal

surface and the space temperature, for each degree swing in space temperature

about its mean value. It determines the storage of energy in the room surfaces

following fluctuations in internal temperature. It is related to the diffusivity and

thickness of materials.

It has the same units as U-value (W/m2K) and can be considered as a cyclic Uvalue.

~

~

Q y = (AY) ( t ei t ei )+ = (AY) ( tei )+

where the tilde indicates the cyclic component and the bar indicates the mean

value. Y is the admittance.

For thin constructions, the admittance equals the U-value. Admittance is greater

for higher thermal mass.

Examples are given in Table A3.16 in the handout (from the CIBSE guide).

Decrement Factor

Decrement Factor is the ratio of the rate of heat flow through the structure to the

internal space temperature for each degree of swing in external temperature about

its mean value, to the steady state rate of heat flow or U-value. It is the attenuation

of a wave travelling through an element of the building structure.

For thin structures of low thermal capacity, the decrement factor =1; it decreases

with increasing thickness and capacity.

For fabric transfer due to external fluctuations:

~

~

Qf = (fAU) ( t eo t eo ) = (fAU) ( teo )

where f is the decrement factor and is the time lag.

Surface Factor

Surface Factor is the ratio of the variation of heat flow about its mean value

readmitted to a space from the surface, to the variation of heat flow about its mean

value absorbed in the surface. The surface factor decreases and its time lag

increases with increasing thermal capacity and they are almost constant with

thickness. It is used when allowing for solar radiation and the radiative component

of internal gains on internal surfaces.

16387: Environmental Engineering Science 2

Calculation of Peak Summertime Temperatures

Application of the admittance technique requires the following calculations:

(a) Mean heat gains from all sources.

(b) Mean internal environmental temperature.

(c) Swing (deviation), from mean-to-peak, in heat gains from all sources.

(d) Swing (deviation), from mean-to-peak, in internal environmental temperature.

(e) From (b) and (d), the peak internal environmental temperature.

Intermittent Heating

For intermittent heating, additional plant capacity (above steady state requirements) is

required to bring the building up to temperature after overnight or weekend cooling.

In such cases it is recommended by CIBSE that the total output under boosted

intermittent operating conditions, Qpb, is calculated by

Qpb = F3 Qp

where Qp is the design load for continuous heating and F3 is the plant size ratio (the

factor for intermittent heating). F3 can be calculated from

F3 =

24f r

Hf r + (24 H)

where H is the total hours of heating including pre-heat, and fr is the thermal response

factor (the thermal weight of the building). The thermal response factor is given by

fr =

(AY) + 1 3NV

(AU) + 1 3NV

The thermal response factor is less than 4 for a lightweight (fast-response) building,

and greater than 4 for a heavyweight (slow-response) building. If the calculated value

of F3 is <1.2, a value of 1.2 is taken (to give a safety margin of 20%).

16387: Environmental Engineering Science 2

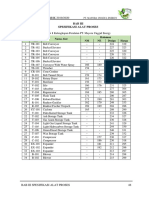

Example:

15m

Surface

Small factory building

Height=5m

12 windows, each 4m2

Doors 6m2

Volume = 562.5m3

Air infiltration = 0.5 ac/h

7.5m

Area

U-value

AxU

Y-value

AxY

(m2)

(W/m2K

(W/K)

(W/m2K

(W/K)

Ext wall

171.0

0.5

85.5

3.5

598.5

Doors

6.0

2.9

17.4

2.9

17.4

Floor

112.5

0.45

50.6

5.2

585.0

Roof

112.5

0.3

33.8

0.7

78.8

Windows

48

3.3

158.4

3.3

158.4

Sum

450

345.7

1438.1

(AU) is calculated over surfaces through which heat flow occurs.

Assume the heating plant operates for 8 hours with a pre-heat time of 3 hours, and

that the total heat loss = 8.72kW for continuous heating (for an internal dry bulb

temperature of 19C and an external design temperature of -1C). Calculate the plant

capacity for intermittent operation.

Ventilation conductance = 1/3 N V = (0.5 x 562.5)/3 = 93.75 W/K.

The thermal response factor fr = (1438.1+93.75) / (345.7+93.75) = 3.49

Therefore the correction factor for intermittent heating

F3 = (24 x 3.49) / ((11 x 3.49) + (24 11)) = 1.63

Therefore the calculated plant capacity for intermittent operation is

Qpb = 8.72 x 1.63 = 14.21 kW

You might also like

- Kubilay2015 PDFDocument18 pagesKubilay2015 PDFBorisBerezovsky100% (1)

- Nuaire Commercial Useful InfoDocument10 pagesNuaire Commercial Useful InfoYaser AkarNo ratings yet

- RTS Example Montreal ASHRAE Chapter 6oct2003Document26 pagesRTS Example Montreal ASHRAE Chapter 6oct2003Sid KherNo ratings yet

- Axial AXBDocument20 pagesAxial AXBhoseyliauNo ratings yet

- U Value CalculationDocument4 pagesU Value CalculationSatish Kumar MauryaNo ratings yet

- Chartered Institution of Building Services Engineers Head Quarters Renewable Energy Integration FeasibilityDocument14 pagesChartered Institution of Building Services Engineers Head Quarters Renewable Energy Integration Feasibilitybombay__badboyNo ratings yet

- Compare ExcelDocument21 pagesCompare ExcelHariharan2994No ratings yet

- Sound Attenuators LeafletDocument7 pagesSound Attenuators LeafletBalanSelvamNo ratings yet

- New Pumping Station at Jabel Haffet Base EPC Contract No:-N-16297Document60 pagesNew Pumping Station at Jabel Haffet Base EPC Contract No:-N-16297unnicyriacNo ratings yet

- ORC Working Fluids Comparison ECOS PresentationDocument16 pagesORC Working Fluids Comparison ECOS Presentationoverlord5555No ratings yet

- Save up to 80% on HVAC Energy Costs with Heat Recovery UnitsDocument35 pagesSave up to 80% on HVAC Energy Costs with Heat Recovery UnitsGabetsos KaraflidisNo ratings yet

- Systems Design ReportDocument24 pagesSystems Design ReportOmaru NimagaNo ratings yet

- Assignment MechanicalDocument5 pagesAssignment MechanicalSoufiane RamdaniNo ratings yet

- ASHRAE climatic design conditions guideDocument2 pagesASHRAE climatic design conditions guideaya maap100% (1)

- Reducing Energy Use in Cold StorageDocument7 pagesReducing Energy Use in Cold StoragePhilip MarphyNo ratings yet

- CIBSE Heat Loss & Heat Gain Calculation MethodsDocument9 pagesCIBSE Heat Loss & Heat Gain Calculation Methodsวรศิษฐ์ อ๋องNo ratings yet

- Installation and Commissioning: GPG347 Good Practice GuideDocument20 pagesInstallation and Commissioning: GPG347 Good Practice GuideДанил ПорохницкийNo ratings yet

- Chapter 7 - Mechanical Ventillation and Smoke Control SystemsDocument23 pagesChapter 7 - Mechanical Ventillation and Smoke Control SystemsBalgo BalgobinNo ratings yet

- Holyoake Engineering DataDocument24 pagesHolyoake Engineering DataSantiago J. ramos jr100% (1)

- Acoustic Ventilation BrochureDocument10 pagesAcoustic Ventilation BrochureraghuragooNo ratings yet

- Spitler McQuiston Lindsey 93 2Document11 pagesSpitler McQuiston Lindsey 93 2Shafawati ShahneelNo ratings yet

- Borella Housing Project Lps ReportDocument10 pagesBorella Housing Project Lps Reportbdaminda6701No ratings yet

- TD 6 - Design CalculationsDocument25 pagesTD 6 - Design CalculationsKim Angelique PerialdeNo ratings yet

- 02 - IEM EC - Electrical Safety SeminarDocument91 pages02 - IEM EC - Electrical Safety SeminarZaid ChelseaNo ratings yet

- Application of Hydronic Radiant and Beam SystemsDocument86 pagesApplication of Hydronic Radiant and Beam SystemsDhirendra Singh RathoreNo ratings yet

- AHRI 880 Performance Rating of Air TerminalsDocument16 pagesAHRI 880 Performance Rating of Air TerminalsDumitru Cristina100% (1)

- AHU Heat Gain Due To Supply Fan Motor - HVAC - R Engineering - Eng-TipsDocument8 pagesAHU Heat Gain Due To Supply Fan Motor - HVAC - R Engineering - Eng-TipsNatarajNo ratings yet

- Air-Conditioning Load EstimationDocument23 pagesAir-Conditioning Load Estimationtkm2004No ratings yet

- Natural Ventilation - Whole Building Design GuideDocument8 pagesNatural Ventilation - Whole Building Design Guidedhwani.talati5920No ratings yet

- HVAC - Overview of Space Heating Systems PDFDocument68 pagesHVAC - Overview of Space Heating Systems PDFFredie UnabiaNo ratings yet

- F ChartDocument7 pagesF Charthemal4379No ratings yet

- Cooling and dehumidifying heat load estimateDocument149 pagesCooling and dehumidifying heat load estimateHenry San PedroNo ratings yet

- Apachesim Ve 2014 Session B Training Notes PDFDocument30 pagesApachesim Ve 2014 Session B Training Notes PDFKa Hung LeungNo ratings yet

- Why Enthalpy Economizers Don't WorkDocument11 pagesWhy Enthalpy Economizers Don't WorkDGGNo ratings yet

- Example Kitchen Ventilation CalculationDocument4 pagesExample Kitchen Ventilation Calculationwillis0000No ratings yet

- 2015 Clean-Air enDocument19 pages2015 Clean-Air enjonh66-1No ratings yet

- So-Pro: Solar Process HeatDocument28 pagesSo-Pro: Solar Process Heat-roseira-No ratings yet

- Heating Load Calculation ExampleDocument1 pageHeating Load Calculation Examplemuhd.qasimNo ratings yet

- HVAC Control in The New MillenniumDocument389 pagesHVAC Control in The New Millenniumnicky1213aNo ratings yet

- Engineeringreference Energy PlusDocument1,375 pagesEngineeringreference Energy PlusrlicinioNo ratings yet

- Research Paper Final v1 0Document9 pagesResearch Paper Final v1 0ums6120No ratings yet

- Establishing Thermal ComfortDocument12 pagesEstablishing Thermal ComfortShahruzi MahadzirNo ratings yet

- 2019 ASHRAE Handbook HVAC Applications SI-Chapter 6-Ahu PDFDocument15 pages2019 ASHRAE Handbook HVAC Applications SI-Chapter 6-Ahu PDFLệ HoaNo ratings yet

- Marlow Termoelectric Design GuideDocument23 pagesMarlow Termoelectric Design GuideLutionnnNo ratings yet

- Noise Measurement Analysis and Sound Propagation FundamentalsDocument2 pagesNoise Measurement Analysis and Sound Propagation FundamentalsSohJiaJieNo ratings yet

- Ashrae - 2009 I-P - F09 - AddDocument2 pagesAshrae - 2009 I-P - F09 - AddSergio SemmNo ratings yet

- Fire Size Calculation for Smoke Spill SystemsDocument1 pageFire Size Calculation for Smoke Spill SystemsLee SienNo ratings yet

- 02 Cooling Load Calculation - HAPDocument2 pages02 Cooling Load Calculation - HAPU DEEPAKNo ratings yet

- Res Load 11Document18 pagesRes Load 11nguyentienphatNo ratings yet

- ASHRAE SWFL Chapter - Library Archive: HistoryDocument1 pageASHRAE SWFL Chapter - Library Archive: HistoryHarendra kumarNo ratings yet

- Materaial For Question 3. - Cooling Load CLTD Example Ashrae PDFDocument5 pagesMateraial For Question 3. - Cooling Load CLTD Example Ashrae PDFkumarNo ratings yet

- Innovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987From EverandInnovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987D A ReayNo ratings yet

- CTV003Document20 pagesCTV003Sujani MaarasingheNo ratings yet

- HVAC and Psychrometric Charts SI TranscriptDocument15 pagesHVAC and Psychrometric Charts SI TranscriptLaptuca GabrielNo ratings yet

- Living Room Heat Loss Calculation in BudapestDocument5 pagesLiving Room Heat Loss Calculation in BudapestJoshua RanjithNo ratings yet

- NZICC Fire Engineering Peer ReviewDocument11 pagesNZICC Fire Engineering Peer ReviewStuff NewsroomNo ratings yet

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86No ratings yet

- Analysis and Design of Cooling Load With and Without Installation of Insulating MaterialDocument15 pagesAnalysis and Design of Cooling Load With and Without Installation of Insulating MaterialFaizan NazeerNo ratings yet

- AnalysisDocument1 pageAnalysisozzy22No ratings yet

- UIUC CEE Structures QE Topics List - (FINAL - ) - Structural MechanicsDocument1 pageUIUC CEE Structures QE Topics List - (FINAL - ) - Structural MechanicsSayna KellenyNo ratings yet

- Material Properties enDocument7 pagesMaterial Properties enogabsonNo ratings yet

- 2.01. VE7 - 3 Board Notes Simona SocrateDocument4 pages2.01. VE7 - 3 Board Notes Simona Socrateozzy22No ratings yet

- UIUC CEE Structures QE Topics List - (FINAL - ) AÇO Structural MechanicsDocument1 pageUIUC CEE Structures QE Topics List - (FINAL - ) AÇO Structural MechanicsSayna KellenyNo ratings yet

- 2.01. V7 - 4 Board Notes Simona SocrateDocument1 page2.01. V7 - 4 Board Notes Simona Socrateozzy22No ratings yet

- Geot55 699Document5 pagesGeot55 699ozzy22No ratings yet

- UIUC CEE Structures QE Topics Lis) - Structural MechanicsDocument1 pageUIUC CEE Structures QE Topics Lis) - Structural MechanicsSayna KellenyNo ratings yet

- UIUC CEE Structures QE Topics Structural MechanicsDocument1 pageUIUC CEE Structures QE Topics Structural MechanicsSayna KellenyNo ratings yet

- Rev 25 Dura BestDocument19 pagesRev 25 Dura Bestozzy22No ratings yet

- Modeling Sediment Erosion and Deposition With The FLOW-3D Sedimentation & Scour ModelDocument22 pagesModeling Sediment Erosion and Deposition With The FLOW-3D Sedimentation & Scour Modelozzy22No ratings yet

- De-Mystifying AutoCAD Plant 3D Isometrics Configuration ReferenceDocument69 pagesDe-Mystifying AutoCAD Plant 3D Isometrics Configuration Referenceozzy22No ratings yet

- V7_3 Board Meeting NotesDocument1 pageV7_3 Board Meeting Notesozzy22No ratings yet

- 2.01. V5 - 1 Board Notes Simona SocrateDocument1 page2.01. V5 - 1 Board Notes Simona Socrateozzy22No ratings yet

- V8_1 Board Meeting NotesDocument1 pageV8_1 Board Meeting Notesozzy22No ratings yet

- 2.01. V7 - 2 Board Notes Simona SocrateDocument1 page2.01. V7 - 2 Board Notes Simona Socrateozzy22No ratings yet

- Handouts D8 1Document8 pagesHandouts D8 1ozzy22No ratings yet

- 2.01. V7 - 2 Board Notes Simona SocrateDocument1 page2.01. V7 - 2 Board Notes Simona Socrateozzy22No ratings yet

- 2.01. V6 - 2 Board Notes Simona SocrateDocument1 page2.01. V6 - 2 Board Notes Simona Socrateozzy22No ratings yet

- 2.01. V6 - 1 Board Notes Simona SocrateDocument1 page2.01. V6 - 1 Board Notes Simona Socrateozzy22No ratings yet

- 2.01. V3 - 5 Board Notes Simona SocrateDocument1 page2.01. V3 - 5 Board Notes Simona Socrateozzy22No ratings yet

- 2.01. V5 - 1 Board Notes Simona SocrateDocument1 page2.01. V5 - 1 Board Notes Simona Socrateozzy22No ratings yet

- 2.01. V3 - 4 Board Notes Simona SocrateDocument2 pages2.01. V3 - 4 Board Notes Simona Socrateozzy22No ratings yet

- 2.01. V4 - 5 Board Notes Simona SocrateDocument1 page2.01. V4 - 5 Board Notes Simona Socrateozzy22No ratings yet

- 2.01. V3 - 4 Board Notes Simona SocrateDocument2 pages2.01. V3 - 4 Board Notes Simona Socrateozzy22No ratings yet

- Boardnotes VR2 3B BNDocument1 pageBoardnotes VR2 3B BNozzy22No ratings yet

- Suportes e Reações em EstruturasDocument1 pageSuportes e Reações em EstruturasGetulio GutembergNo ratings yet

- 2.01. V3 - 1 Board Notes Simona SocrateDocument1 page2.01. V3 - 1 Board Notes Simona Socrateozzy22No ratings yet

- 2.01. V3 - 3 Board Notes Simona SocrateDocument2 pages2.01. V3 - 3 Board Notes Simona Socrateozzy22No ratings yet

- Boardnotes VR2 3B BNDocument1 pageBoardnotes VR2 3B BNozzy22No ratings yet

- Performance-Based Seismic Design of Reinforced Concrete Frame Buildings: A Direct Displacement-Based ApproachDocument12 pagesPerformance-Based Seismic Design of Reinforced Concrete Frame Buildings: A Direct Displacement-Based ApproachSanjeev SahNo ratings yet

- Critical Condition for Flow Transition in a Full-Developed Annulus FlowDocument6 pagesCritical Condition for Flow Transition in a Full-Developed Annulus FlowphrqdurhNo ratings yet

- Thermal Analysis of Continuous Casting Process (Maryeling)Document10 pagesThermal Analysis of Continuous Casting Process (Maryeling)Marko's Brazon'No ratings yet

- Design of Packed ColumnDocument4 pagesDesign of Packed Columnمنى عبد المنعم صالح رداد منى عبد المنعم صالح ردادNo ratings yet

- RPP 04 BFC 34402 Sem II 1415Document7 pagesRPP 04 BFC 34402 Sem II 1415Tikar MengkuangNo ratings yet

- The Predictive Capability of Failure Mode Concept-Based Strength Criteria For Multi-Directional Laminates-Part BDocument30 pagesThe Predictive Capability of Failure Mode Concept-Based Strength Criteria For Multi-Directional Laminates-Part BChris KořánNo ratings yet

- Tutorial Flow Measurement (GROUP D)Document8 pagesTutorial Flow Measurement (GROUP D)Nur Fatiha Aziera Ain Binti Mohd KhimeNo ratings yet

- ECSS E HB 32 20 - Part2A PDFDocument434 pagesECSS E HB 32 20 - Part2A PDFVesa RäisänenNo ratings yet

- THD3602 Major Test 1 2023Document3 pagesTHD3602 Major Test 1 2023LeighNo ratings yet

- Jet Pumping Oil Wells, Guiberson, WO, 1983 & 1984, 18 PgsDocument18 pagesJet Pumping Oil Wells, Guiberson, WO, 1983 & 1984, 18 PgsAnonymous Xy309m9Sm9100% (2)

- Specific and Latent Heat: MarkschemeDocument6 pagesSpecific and Latent Heat: MarkschememNo ratings yet

- Rectangular Concrete Beam, Column Analysis and DesignDocument17 pagesRectangular Concrete Beam, Column Analysis and DesignRohit Khandelwal100% (3)

- Ahu DehumidifierDocument5 pagesAhu DehumidifierMichael Mangada100% (1)

- Group5 - Hexamine - Special Topic - Piping Slugging and Piping PiggingDocument10 pagesGroup5 - Hexamine - Special Topic - Piping Slugging and Piping PiggingPapol PimsriNo ratings yet

- Mechanical Properties of Mild Steel, Copper and Aluminum under Tensile TestingDocument9 pagesMechanical Properties of Mild Steel, Copper and Aluminum under Tensile TestingAdarsh BujadeNo ratings yet

- Fluid Properties and Kinematics GuideDocument1 pageFluid Properties and Kinematics Guideshalom_pkl100% (1)

- Secant ModulusDocument1 pageSecant ModulushudpalNo ratings yet

- Chbe 6300 Graduate Kinetics and Reactor Design: Carsten Sievers 8/20/2020Document27 pagesChbe 6300 Graduate Kinetics and Reactor Design: Carsten Sievers 8/20/2020AnnNo ratings yet

- KMO CHEM DRAW Guide Membuat Struktur Kimia Senyawa ObatDocument28 pagesKMO CHEM DRAW Guide Membuat Struktur Kimia Senyawa ObatDefitriTrimardaniNo ratings yet

- Lab 7Document23 pagesLab 7Zorin RealceNo ratings yet

- Analysis Methods For Leakage Rates in Pressurized ComponentsDocument20 pagesAnalysis Methods For Leakage Rates in Pressurized ComponentsGeorgiosLupusMogueidaNo ratings yet

- Barc InterviewDocument4 pagesBarc InterviewjishnuNo ratings yet

- (PPT) Fire Resistance Assessment of Concrete StructuresDocument81 pages(PPT) Fire Resistance Assessment of Concrete StructuresGregory Simmon100% (2)

- This Study Resource Was: Problem #1 A Sharp-Edge Orifice, 50 MMDocument6 pagesThis Study Resource Was: Problem #1 A Sharp-Edge Orifice, 50 MMJemuel FloresNo ratings yet

- Gen Chem 2 Quiz 8 13 and Long Quiz 2Document46 pagesGen Chem 2 Quiz 8 13 and Long Quiz 2Kristine Joy Catedrilla100% (4)

- SQ RC Driven Pile Capacity CalculationDocument251 pagesSQ RC Driven Pile Capacity Calculationsaravanan100% (1)

- Cementing (Sharing Knowledge)Document15 pagesCementing (Sharing Knowledge)Moh Syamsul BahriNo ratings yet

- Teh 908a PDFDocument30 pagesTeh 908a PDFAnonymous 73gEYyEtLNo ratings yet

- Perpab6-Spesifikasi AlatDocument38 pagesPerpab6-Spesifikasi AlatardiNo ratings yet

- Rock Engineering & Ground Control M205Document4 pagesRock Engineering & Ground Control M205Pawan SahuNo ratings yet