Professional Documents

Culture Documents

Closed Book Api 572-A (55-65) - 2

Uploaded by

slxantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Closed Book Api 572-A (55-65) - 2

Uploaded by

slxantoCopyright:

Available Formats

Southern Inspection Services

Closed Book API 572

1. What must be considered important in the inspection of a metallic

lining?

a.

b.

c.

d.

That there are no dissimilar welds

That the linings made of pure alloy only

The vent holes exist in all liners.

That there are no holes or cracks present in the lining.

2. Of the following tools which should the inspector have on hand for

vessel inspections?

a.

b.

c.

d.

Pencil and note pad, flash light and scraper

Social security card.

Clean fire retardant clothing

Electrical conductivity testing equipment to test liners.

3. Many of the problems that develop in operating vessels may be traced

to;

a.

b.

c.

d.

Cold winters

On-stream inspections

Electrical shorts

Faulty materials and workmanship

4. The primary cause of deterioration in pressure vessels is;

a.

b.

c.

d.

Corrosion

Operating conditions

Improper installation

Water damage

5. High pressure may develop in a vessel as a result of;

a.

b.

c.

d.

Rapid venting of a vessels pressure source

Lowering heat below normal operating conditions

Thermal contraction of trapped fluids

Blocking off against a pressure source

6. Which of the following techniques is considered the primary means to

determine the minimum thickness of a vessels components?

a.

b.

c.

d.

A boat sample remove from a thin area

Measuring from a corroded area

Any suitable destructive method of examination

Ultrasonic thickness measurements.

API 510 DAY 4

Page 55

Southern Inspection Services

7. before starting the inspection of a pressure vessel, especially one is

severe service the inspector should determine;

a. The pressure and temperature conditions under which the vessel

been operated since the first inspection

b. The pressure and temperature conditions under which the vessel

been operated during the period since the last two inspections.

c. The pressure and temperature conditions under which the vessel

been operated since the current inspection

d. The pressure and temperature conditions under which the vessel

been operated since the last inspection

has

has

has

has

8. The inability to draw the products of fractionation or distillation from

certain trays may

a.

b.

c.

d.

Indicate fouling or loss of tray parts in a process tower

Indicate that instrumentation is giving false readings.

Prove that the piping diameter is too small

Indicate that the trays have lost all bubble caps or tray valves, or

possibly the tray has collapsed

9. Before any repair to a pressure vessel in accordance with its code of

construction, what if any additional requirements for inspection may

need to be considered?

a.

b.

c.

d.

Jurisdictional requirements that might override the API 510 code

Who is doing the repair?

The quality of the repair materials

The need for qualified welding procedures

10. Some jurisdictions require that welded repairs to a pressure vessel be

documented by the completion and filing of;

a.

b.

c.

d.

A detailed report of the location and extent of repairs

A qualifications record of all repair personnel

A permit issued by the jurisdiction

The national Board of Boiler and pressure vessel inspectors form R-1

API 510 DAY 4

Page 56

Southern Inspection Services

11. While inspecting an operating vessel you observe that cracks are

present in the connecting welds for a gauge glass, you also notice

vibrations are occurring in the assembly. Before you recommend

corrective actions you should;

a. Re-evaluate the materials used in the fabrication of the gauge glass

b. Write a report of the location with a recommendation for the type of

repairs needed

c. Research the inspection records for previous failures of this type

d. Check with a pressure vessel engineer to see if the cracks are caused

by fatigue failure

12. The two types of graphitization are

a.

b.

c.

d.

Localized and random graphitization

Ferritic and martensite graphitization

Austenitic and martensitic graphitization

Circular or globular graphitization

13. The main reason(s) for inspecting heat exchanger bundles after removal

and prior to cleaning is/are;

a.

b.

c.

d.

Location of scale on tubes can reveal non-operational problems.

Deposits on the tubes can reveal acid contamination problems

Color of the tube ends can reveal de-zincification

Color of deposits and scale can scale can reveal corrosion problems

14. Hydrogen chloride becomes a problem when,

a. Exposed to air, it will thermally react and result in a fire.

b. Exposed to water, it forms hydrochloric acid.

c. Exposed to water it becomes unstable and can form an explosive

compound

d. Exposed to water and air it produces formic acid

15. Which one of the following types of coating failures may not easily

detected?

a.

b.

c.

d.

Film lifting

Rust

Blisters

Film dispersions

API 510 DAY 4

Page 57

Southern Inspection Services

16. A vessel is in a service that subjects it to acidic fluids, what is a major

concern for this type of service?

a.

b.

c.

d.

Graphitic induced corrosion

Caustic blistering

Caustic embrittlement and cracking

Accelerated corrosion, Hydrogen blistering and Hydrogen induced

cracking

17. Ordinarily non-metallic coatings and linings can be most effectively

inspected by what technique?

a.

b.

c.

d.

Law holiday tester

Radiography

Hammer testing

Using a high voltage low current brush type electrode device (spark

Tester)

18. A major concern(s) when inspecting a nozzle flange face is /are;

a.

b.

c.

d.

Brand name of the flange

Brand name of the gaskets used in the flange.

Surface corrosion in the bolt circle.

Distortion of the flange and the condition of the gasket seating

surfaces.

19. If there are leaks in a vessels insulation system or protective coatings,

corrosion can occur. At below what temperature is this corrosion

most likely to be a problem?

a.

b.

c.

d.

250F

212F

350F

275F

20. which of the following is subject to de-alloying when exposed to steam

containing sulfur compounds?

a.

b.

c.

d.

Cuppro brass

Naval brass

Admiralty brass

Monel

API 510 DAY 4

Page 58

Southern Inspection Services

21. Titanium alloys are subject to loss of ductility in certain environments

what is this condition called?

a.

b.

c.

d.

High temperature embrittlement

Low temperature embrittlement

Hi-alloy effect

Hydriding

22. Which of the following describes a crack in metal?

a.

b.

c.

d.

Cracks run parallel to the surface

Cracks run at right angles to the surface

Cracks are usually wide at one end and narrow at the other

Cracks run at obtuse angles to the surface

23. Which of the following describes a lamination in metal plate?

a. Laminations usually represent large cavities

b. Laminations are fish mouth type openings and are only found on the

edges of plate

c. Laminations run at a slant to the plate surface

d. Laminations run at an obtuse angle to the plate surface

24. Above what temperature must hydrogen attack be considered a concern

in an operating carbon steel vessel?

a.

b.

c.

d.

above 650F

below 650F

below 450F

above 450F

25. After removing an exchanger bundle you find a Prussian blue coating

on the tubes, what do you suspect causes this coating?

a.

b.

c.

d.

Amino acid

Cyanide

Ferri-ferrocyanide

Phosphoric acid

26. One major area of concern when inspecting guy wires for a vessel is

crevice corrosion where does this occur?

a.

b.

c.

d.

On the free end of the turn buckle

In the threaded areas

On the guy wires

Where the wires contact the ground

API 510 DAY 4

Page 59

Southern Inspection Services

27. You are inspecting a failure in a vessel wall, what conditions would you

look for if it was believed that the fracture was brittle?

a.

b.

c.

d.

There is almost a no lack of ductility

The fractured surfaces has a smooth surface

The surface of the crack would have jagged edges.

There is an almost complete lack of ductility and the failure site will

have a faceted surface

28. Carbon dioxide considered corrosive when?

a.

b.

c.

d.

When combined with glycol

When combined with water

When combined with ethylene

When combined with water and high temperatures

29. If white salts are found at cracks in a vessel;

a.

b.

c.

d.

It is an indication that the vessel contains an alkaline based chemical

It is an indication that the vessel contains an acidic based chemical

It is an indication that the vessel contains a low pH chemical

It is an indication that the vessel had been operated above normal

temperatures.

30. A poor choice of material for ammonia service would be;

a.

b.

c.

d.

Stainless steels

Copper based alloys

Carbon steels

Carbon Molybdenum steels

31. when manufacturing lubricating oils and aromatics the following

chemical is used.

a.

b.

c.

d.

Phenol

Ammonia

Hydrogen cyanide

glycol

32. Aluminum chloride can affect stainless steel in which of the following

ways?

a.

b.

c.

d.

Severe pitting corrosion only

Intergranular cracking only

Stress corrosion cracking only

Stress corrosion cracking and/or intergranular cracking can occur

API 510 DAY 4

Page 60

Southern Inspection Services

33. The low temperature corrosion of gray cast irons is called;

a.

b.

c.

d.

graphitic corrosion

temper embrittlement

brittle fracture

incipient melting

34. Most active of sulfur compounds found in refinery service is;

a.

b.

c.

d.

Mercaptans

organic sulfur compounds

hydrogen sulfide

polymorphic sulfides when combined with polymer products.

35. Which of the following is an example of a microstructure change in

metal?

a.

b.

c.

d.

Graphitization

Interstial Corrosion

Dembrittlement

Embossing

36. A common corrosive compound found in crude oil is;

a.

b.

c.

d.

Nitrogen compounds.

Phenolic acid

Napthinic acid.

Carbonic acid

37. Dezincification occurs by attacking metals which contain;

a. Copper Zinc alloys containing less than 95% of copper used in water

service

b. Copper Zinc alloys containing less than 85% of copper used in water

service

c. Copper Zinc alloys containing less than 85% of copper used in

caustic service

d. Copper Zinc alloys containing less than 95% of copper used in acidic

service

38. Which of the following describes a physical change in metal?

a.

b.

c.

d.

Intergranular conosion

Sensitization.

Banite solution.

Amphoric layering.

API 510 DAY 4

Page 61

Southern Inspection Services

39. When looking for surface cracks in a vessel made of ferrous material

which of the following is the most capable of detection?

a.

b.

c.

d.

Fluorescent Penetrant Method.

Radiography

Fluorescent Magnetic Particle Method.

Close visual Inspection with good lighting.

40. The majority of vessel foundations are constructed using;

a.

b.

c.

d.

High grade (load bearing) concrete compounds.

Structural steel fireproofed with concrete.

Concrete reinforced with polymers.

Structural steel overlaid with refractory.

41. Vanadium Oxide corrosion is not known to occur below;

a.

b.

c.

d.

1,050 F

1,100 F

950 F

800 F

42. Which of the following is a major concern when operating vessels that

utilize the fluidized bed principle?

a.

b.

c.

d.

Overheating

Erosion

Corrosion

Cracks

43. The inspection of a vessel to determine if a hydrogen blister is present

is often best performed by;

a.

b.

c.

d.

Researching the inspection records.

Determine the vessels material to see if hydrogen attack is likely.

Shining a flash light parallel to the vessels surface.

Recommending metallurgical tests for blisters in a laboratory.

44. When preparing to inspect a vessel which has had previous inspections

what is the initial step in preparation for the inspection?

a.

b.

c.

d.

Assemble all the required tools to perform the inspection.

Review previous inspection records.

Advice maintenance of any anticipated repairs.

Insure that all non-destructive examinations required have been

scheduled

API 510 DAY 4

Page 62

Southern Inspection Services

45. Which of the following best describes a Corrosion Button as might be

found in a pressure vessel?

a. Buttons made of highly corrosion resistant material from which

corrosion loss can be measured.

b. Buttons which corrode at about the same rate as the vessels material

and are used to estimate the vessels corrosion losses.

c. No such thing exists; there is however a corrosion tab used in vessels.

d. A form of corrosive product produced by certain chemicals in a vessel

when is constructed of high chrome alloy material.

46. Why should weld probe or trepan inspection methods be avoided if at

all possible?

a. The repair concern will normally charge more to repair these

destructive tests sites in the vessel

b. These types of destructive test site (holes) are difficult to repair and the

weld quality of such repairs is likely to be poor.

c. Most jurisdictions prohibit such destructive tests.

d. NDE personnel are ill equipped to test such sites prior to repairs.

47. pitting corrosion is usually found in a vessel by what means?

a. Thickness measurements at all the compass points at one foot

intervals.

b. Scratching with a pointed scraper.

c. Each shell course and head shall be subjected to abrasive blasting.

d. Each shell course and head shall be wire brushed thoroughly.

48. Heavy wall process hydro-carbon reactors operate at high pressures

and have special inspection requirements, chief among these

requirements are inspections for what type of problem?

a.

b.

c.

d.

Laminations of the heavy wall plates used in construction

Crack damage.

Upset trays and down comers.

Severe corrosion in the top head due to corrosive vapors generated in

the process.

API 510 DAY 4

Page 63

Southern Inspection Services

Closed Book API 572 ANSWERS

Q.No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

ANSWER

LOCATION OF ANSWER

D

A

D

A

D

D

D

A

A

D

D

A

D

B

A

D

D

D

A

D

D

B

C

D

C

B

D

B

A

B

A

D

A

C

A

A

API 572 10.4.5

API 572 10.2.2

API 572 8.4

API 572 8.2

CHAPTER II 206.021 - .023

API 572 10.5

API 572 10.1

API 572 9.2

API 572 11.0 (see note in text body)

API 572 11.0 (see note in text body)

API 572 10.3.10

CHAPTER 2 204.022

API 572 A.9.1

CHAPTER II 202.022

API 572 10.3.11

CHAPTER II 202.022

API 572 10.4.6

API 572 10.3.8

CHAPTER II 202.042

API 572 8.3.3

API 572 8.3.7

API 572 10.4.4

API 572 10.4.4

CHAPTER II 204.035

API 572 A.9.2

API 572 10.3.7

CHAPTER II 205.01

CHAPTER II 202.024

API 572 10.3.12

CHAPTER II 202.037

CHAPTER II 202.033

CHAPTER II 202.039

CHAPTER II 202.063

CHAPTER II 202.23

API 572 8.3

CHAPTER II 202.021

API 510 DAY 4

Page 64

Southern Inspection Services

37

38

39

40

41

42

43

44

45

46

47

48

B

A

C

B

B

B

C

B

A

B

B

B

API 510 DAY 4

CHAPTER II 202.66

API 572 8.3

API 572 10.4.4

API 572 10.3.3

CHAPTER II 202.054

CHAPTER II 202.32

API 572 10.3.13

API 572 10.4.3

API 572 10.5

API 572 11.0

API 572 10.4.4

API 572 10.4.4

Page 65

You might also like

- API 510 Exam Study GuideDocument6 pagesAPI 510 Exam Study GuidetayyabNo ratings yet

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- Examination Question 510Document12 pagesExamination Question 510ohengjkt100% (1)

- Casti CourseDocument43 pagesCasti CoursekazumiyutoriNo ratings yet

- 3.4 Arc Length: The Distance From The Tip of The WeldingDocument7 pages3.4 Arc Length: The Distance From The Tip of The WeldingMohammed IlliasuddinNo ratings yet

- API 577 Questions Scope and DefinitionsDocument10 pagesAPI 577 Questions Scope and DefinitionsmaorealesNo ratings yet

- Api 578-Mock 1 - KeyDocument28 pagesApi 578-Mock 1 - KeysheikmoinNo ratings yet

- Open Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedDocument16 pagesOpen Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedBeantickNo ratings yet

- 1 API 653 Memories March 2014 ExamDocument16 pages1 API 653 Memories March 2014 ExammajidNo ratings yet

- Undercut (Per API 577, Table 6) Can Be Corrected by (Practical Solution Column)Document2 pagesUndercut (Per API 577, Table 6) Can Be Corrected by (Practical Solution Column)korichiNo ratings yet

- API 510 Closed Questions GuideDocument5 pagesAPI 510 Closed Questions GuideEinsteinw2No ratings yet

- 63 Multiple Choice Questions: No Answer GivenDocument16 pages63 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvR100% (1)

- API 510 Certification Prep: 60-hr Pressure Vessel Inspector CourseDocument1 pageAPI 510 Certification Prep: 60-hr Pressure Vessel Inspector CourseAbu Huraira0% (1)

- API-570 SAMPLE Closed Book ExamDocument12 pagesAPI-570 SAMPLE Closed Book ExamuttamNo ratings yet

- (PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduDocument4 pages(PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduKumar R100% (1)

- API 570 Libro Abierto GeneralDocument26 pagesAPI 570 Libro Abierto GeneralWveimar BriceñoNo ratings yet

- 17 Multiple Choice Questions: No Answer GivenDocument5 pages17 Multiple Choice Questions: No Answer GivenAkram AlhaddadNo ratings yet

- API 510 Prep Course QuestionsDocument30 pagesAPI 510 Prep Course QuestionsRanaweera AriyamanjulaNo ratings yet

- 17 Multiple Choice QuestionsDocument3 pages17 Multiple Choice QuestionsAnonymous Q4YUvR100% (1)

- 2-Questions API 650 Question N°02 2022Document3 pages2-Questions API 650 Question N°02 2022korichiNo ratings yet

- Api 577 Reponse01Document3 pagesApi 577 Reponse01korichiNo ratings yet

- API-510 Exam Prep Course Practice Exam #3 SolutionsDocument14 pagesAPI-510 Exam Prep Course Practice Exam #3 SolutionsKarim MamdouhNo ratings yet

- Boost Your API-570 Piping Inspectors Exam ScoreDocument6 pagesBoost Your API-570 Piping Inspectors Exam Scorejaire esparzaNo ratings yet

- Additional API 571 Practice Questions flashcardsDocument4 pagesAdditional API 571 Practice Questions flashcardsMohammad Aamir Perwaiz100% (1)

- API 510 Preparatory Course GuideDocument7 pagesAPI 510 Preparatory Course GuideRanaweera AriyamanjulaNo ratings yet

- Sis Book1Document99 pagesSis Book1Hamza AlamNo ratings yet

- API.570. Closed Book 3Document31 pagesAPI.570. Closed Book 3Siva KumarNo ratings yet

- API RP 571 corrosion questionsDocument5 pagesAPI RP 571 corrosion questionsأحمد صبحى100% (1)

- API 510 QUIZ No.4Document5 pagesAPI 510 QUIZ No.4Hatem RagabNo ratings yet

- API 510 Data Sheets - QuizletDocument1 pageAPI 510 Data Sheets - Quizletads_1203No ratings yet

- API 510.jan 2022 (Open & Closed)Document79 pagesAPI 510.jan 2022 (Open & Closed)Ali BEN YESAADNo ratings yet

- API 510 TestDocument3 pagesAPI 510 Testshabbir626No ratings yet

- Test - API 577 - Quizlet 145qDocument38 pagesTest - API 577 - Quizlet 145qAnonymous Q4YUvRNo ratings yet

- API 510 PC 20 31 Aug05 Bench MarkDocument4 pagesAPI 510 PC 20 31 Aug05 Bench MarknikafiqNo ratings yet

- API 570 - Mockup CB - Paper 2Document16 pagesAPI 570 - Mockup CB - Paper 2Shanawas Abdul Razak100% (1)

- API 570 - CL Book 111122112010 R0... Mockup 3Document18 pagesAPI 570 - CL Book 111122112010 R0... Mockup 3patvinderNo ratings yet

- Api 510 Q&a-2Document32 pagesApi 510 Q&a-2Mohammed ShakilNo ratings yet

- C Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsDocument10 pagesC Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsElankumaran Periakaruppan100% (1)

- API 510 Mid Session Closed0Document10 pagesAPI 510 Mid Session Closed0مبشر أحمد100% (2)

- 10 MCQS API 510 Anees Ul HasnainDocument126 pages10 MCQS API 510 Anees Ul HasnaintayyabNo ratings yet

- Test - API 577 - Quizlet 72qDocument23 pagesTest - API 577 - Quizlet 72qAnonymous Q4YUvRNo ratings yet

- MSTS Mark's API 510 STUDY GUIDE.Document30 pagesMSTS Mark's API 510 STUDY GUIDE.Hares SlalNo ratings yet

- Open Book For API 653Document10 pagesOpen Book For API 653gopiNo ratings yet

- Closed Book API RP 578 Practice QuestionsDocument5 pagesClosed Book API RP 578 Practice QuestionsIsmail Jamaluddin100% (1)

- API 510 Case Study - 7Document2 pagesAPI 510 Case Study - 7Khaled FatnassiNo ratings yet

- Daily Points To Recall (Day 8) : Page 1 of 3Document3 pagesDaily Points To Recall (Day 8) : Page 1 of 3chowhkNo ratings yet

- API 576 Pressure Relief Device QuestionsDocument1 pageAPI 576 Pressure Relief Device QuestionsGanesh PatilNo ratings yet

- API 570 Questions 06Document22 pagesAPI 570 Questions 06Ravindra S. Jivani75% (4)

- API 570 Exam Prep TrainingDocument3 pagesAPI 570 Exam Prep Trainingalouis100% (1)

- API 570 Exam 574 QuizDocument3 pagesAPI 570 Exam 574 Quizessnelson100% (2)

- API 570 Bench Mark Quiz (1-55)Document56 pagesAPI 570 Bench Mark Quiz (1-55)Christopher Randolph100% (5)

- Api 510 QDocument25 pagesApi 510 QShyam Singh100% (1)

- 510 Closed Exam B, Rev8Document20 pages510 Closed Exam B, Rev8yrdna nawaiteosNo ratings yet

- ASME B16.5 practice questions and answersDocument66 pagesASME B16.5 practice questions and answersAbdul Qhadeer AnsariNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- API 510 PC 4sept04 Daily Exam 5 Closed PSJDocument12 pagesAPI 510 PC 4sept04 Daily Exam 5 Closed PSJMohammed Shakil100% (1)

- API 510 Exam 9 ReviewDocument6 pagesAPI 510 Exam 9 ReviewCss SfaxienNo ratings yet

- API 571 Exam Questions 2014Document8 pagesAPI 571 Exam Questions 2014Mansoor Ali100% (1)

- Api 510 Preparatory Final Exam (Closed Book) : Answers in A Separate Answer SheetDocument14 pagesApi 510 Preparatory Final Exam (Closed Book) : Answers in A Separate Answer SheetCss Sfaxien100% (1)

- Bgas Paint Faults, BittinessDocument49 pagesBgas Paint Faults, BittinessslxantoNo ratings yet

- ASME VIII CalculationDocument15 pagesASME VIII CalculationJoao Osmar Correa100% (1)

- Hydro Vs PneumaticDocument4 pagesHydro Vs PneumaticAnonymous rYZyQQot55No ratings yet

- Pid37451 PMAADocument6 pagesPid37451 PMAAslxantoNo ratings yet

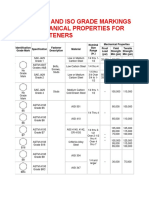

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersCarlos Nina OchoaNo ratings yet

- API 510 Examination Sample ItemsDocument3 pagesAPI 510 Examination Sample ItemsMagira PasaribuNo ratings yet

- Overseas Jobs Times MumbaiDocument3 pagesOverseas Jobs Times MumbaislxantoNo ratings yet

- Abrasive Sand-Blasting Procedure PDFDocument5 pagesAbrasive Sand-Blasting Procedure PDFEko Kurniawan100% (5)

- H2S Safety CourseDocument98 pagesH2S Safety CourseWalter RuedaNo ratings yet

- ASTM and Grain Size MeasurementsDocument6 pagesASTM and Grain Size MeasurementsTomy George100% (1)

- BGas MaterialDocument65 pagesBGas Materialslxanto100% (4)

- Southern Inspection Services ASME SEC VIII QB and API 510 Exam QuestionsDocument15 pagesSouthern Inspection Services ASME SEC VIII QB and API 510 Exam Questionsslxanto100% (1)

- API Certification Exam Dates & Deadlines 2015Document2 pagesAPI Certification Exam Dates & Deadlines 2015slxantoNo ratings yet

- API Certification Exam Dates & Deadlines 2015Document2 pagesAPI Certification Exam Dates & Deadlines 2015slxantoNo ratings yet

- API Inspector Training CoursesDocument10 pagesAPI Inspector Training CoursesslxantoNo ratings yet

- API 2014 Exam ScheduleDocument1 pageAPI 2014 Exam ScheduleslxantoNo ratings yet

- Api510practiceexams 130208053530 Phpapp02Document138 pagesApi510practiceexams 130208053530 Phpapp02slxantoNo ratings yet

- Mos GRPDocument53 pagesMos GRPslxanto100% (3)

- API Inspector Training CoursesDocument10 pagesAPI Inspector Training CoursesslxantoNo ratings yet

- Radiation Hazards From Cell Phones and Cell Towers - Presentation at KEM HospitalDocument61 pagesRadiation Hazards From Cell Phones and Cell Towers - Presentation at KEM HospitalNeha KumarNo ratings yet

- Course BrochureDocument25 pagesCourse BrochureslxantoNo ratings yet

- Er.Sulthan's Ayurvedic Home RemediesDocument321 pagesEr.Sulthan's Ayurvedic Home Remediesarunram86100% (2)

- ASME B31.1 Power PipingDocument1 pageASME B31.1 Power Pipingslxanto25% (4)

- Evolution of Oilfield BatteriesDocument16 pagesEvolution of Oilfield BatteriesPasquale CutriNo ratings yet

- Documentation For: Bank - MasterDocument6 pagesDocumentation For: Bank - MastervijucoolNo ratings yet

- Vapor Pressure Experiment Data AnalysisDocument3 pagesVapor Pressure Experiment Data AnalysisRanaNo ratings yet

- Life 365 V 2 Users ManualDocument67 pagesLife 365 V 2 Users ManualAmanda VegaNo ratings yet

- R07-HC3C20-AAP-MTS-CI-0005 (02) Method Statement of Site Mobilization at Island (Revised)Document32 pagesR07-HC3C20-AAP-MTS-CI-0005 (02) Method Statement of Site Mobilization at Island (Revised)like saddamNo ratings yet

- Mousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeDocument1 pageMousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeMorteza AtaeiNo ratings yet

- Wae 22462 AuDocument8 pagesWae 22462 AuDaniel ManoleNo ratings yet

- Improved M16A2 - A3 - A4 Zero TargetDocument6 pagesImproved M16A2 - A3 - A4 Zero Targetbeetho1990No ratings yet

- Xlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundDocument3 pagesXlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundLe MinhNo ratings yet

- Applications: H D P TDocument2 pagesApplications: H D P TEnrique MurgiaNo ratings yet

- Queen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Document4 pagesQueen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Salustino AbreuNo ratings yet

- Performance Fluids Oh32 Oh150 Hydraulic OilDocument3 pagesPerformance Fluids Oh32 Oh150 Hydraulic Oilpancho7rNo ratings yet

- Column and Wall Load Take Down Spreadsheet v1.0 - CLDocument28 pagesColumn and Wall Load Take Down Spreadsheet v1.0 - CLBilal KhattabNo ratings yet

- PE Electromagnetic Pump Unit PE GB T1101 01-02-182Document4 pagesPE Electromagnetic Pump Unit PE GB T1101 01-02-182li geneNo ratings yet

- Furuno GMDSS Installation Manual PDFDocument64 pagesFuruno GMDSS Installation Manual PDFEric PskdNo ratings yet

- User Interface DesignDocument6 pagesUser Interface DesignpoojaqNo ratings yet

- Sintesis Biodiesel Melalui Transesterifikasi Minyak Goreng Bekas Berbasis Katalis Heterogen Cao Dari Limbah Cangkang Telur AyamDocument6 pagesSintesis Biodiesel Melalui Transesterifikasi Minyak Goreng Bekas Berbasis Katalis Heterogen Cao Dari Limbah Cangkang Telur Ayamkarim kasmudinNo ratings yet

- SUN 72M Mono Crystalline Module PerformanceDocument2 pagesSUN 72M Mono Crystalline Module PerformanceFernando VieiraNo ratings yet

- Demo-C Tfin52 67Document5 pagesDemo-C Tfin52 67namank005No ratings yet

- DDNS Management System User's Manual V1.0 - 20120301Document7 pagesDDNS Management System User's Manual V1.0 - 20120301judapiesNo ratings yet

- Pfaff 360 Sewing Machine Instruction ManualDocument55 pagesPfaff 360 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Sika PDS E SikaRep SDocument3 pagesSika PDS E SikaRep Slwin_oo2435No ratings yet

- Adf Interview Questions and AnsewrsDocument85 pagesAdf Interview Questions and Ansewrsleninbabus100% (2)

- Control your ship with Kobelt electronic controlsDocument36 pagesControl your ship with Kobelt electronic controlsBERANGER DAVESNE DJOMALIA SIEWENo ratings yet

- Davao October 2014 Criminologist Board Exam Room AssignmentsDocument113 pagesDavao October 2014 Criminologist Board Exam Room AssignmentsPRC Board0% (1)

- Cisco Expressway IP Port Usage For Firewall Traversal Deployment Guide X12 5Document60 pagesCisco Expressway IP Port Usage For Firewall Traversal Deployment Guide X12 5JodieNo ratings yet

- Diesel Engine: Service Parts List ForDocument49 pagesDiesel Engine: Service Parts List ForIgnacio OsorioNo ratings yet

- Coiled Tubing For Downhole ProcessDocument10 pagesCoiled Tubing For Downhole ProcessCristian BarbuceanuNo ratings yet

- SHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsDocument8 pagesSHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsMahmoud ElsherifNo ratings yet

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesDocument7 pagesMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94No ratings yet