Professional Documents

Culture Documents

Directional Control Valves: Log Splitter Control Valve

Uploaded by

invidiuoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Directional Control Valves: Log Splitter Control Valve

Uploaded by

invidiuoCopyright:

Available Formats

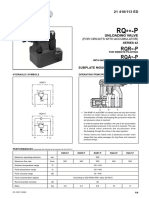

Directional Control Valves

LOg SPLITTER

CONTROL VALVE

VALVES

Model LS3000

SINgLE SPOOL

MONO-BLOCk 20gPM

Model RD2500

V56

PRINCE MANUFACTURING CORPORATION P.O. BOX 7000 NORTH SIOUX CITY, SOUTH DAKOTA 57049-7000

URL: www.princehyd.com E-MAIL: prince@princehyd.com

O.E.M. CUSTOMER SERVICE: (605) 235-1220 FAX (712) 233-2181 DISTRIBUTOR CUSTOMER SERVICE: PHONE (605) 235-1220 FAX (712) 233-2181

CATV 56-07-13-02

MODEL LS3000 DIMENSIONAL DATA

On LS-3000 Models, pressure release detent is in the spool

out position.

On LS-3060 Models, pressure release detent is in the spool

in position.

OUTLET PORT

4.62

2.51

.343 DIA. (3)

SPECIFICATIONS:

1. Max design and test pressure 2750 PSI

2. Max tank port pressure-150 PSI

3. Flow rating-25 GPM max.

4. Relief valve setting-2250 PSI

5. This valve has one position pressure

release detent with spring center to neutral.

6. Weight: 10 lbs.

7. Recommended filtration-ISO 4406 19/17/14

8. Max operation temp-180F

9. In exposed environments do not mount

with spool vertical and handle end down.

OUTLET PORT

A & B WORK PORTS

1.05

.343 DIA. (3)

4.62

2.51

1.25

A & B WORK PORTS

1.05 .44

1.25

OUT

1.42

1.42

8.25

INLET PORT

1.84

5.12

3.25

8.25

INLET PORT

.44

OUT

1.84

5.12

1.13

2.93

IN

IN

2.93

3.25

7.80

4.12

12.31

1.13

9.19

7.80

4.12

12.31

PARTS LIST - LOg SPLITTER VALVES

ITEM PART NUMBER DESCRIPTION

1

2

3

4

5

6

660130001

660125004

660130004

660330003

660330002

660130007

660530001

HANDLE KIT

RELIEF KIT

SPRING CENTER KIT

DETENT SLEEVE & PISON SUB-ASSY

DETENT ADJUSTING CARTRIDGE

COMPLETE PRESSURE RELEASE

DETENT KIT

SEAL KIT (CONTAINS SEALS FOR

SPOOL AND DETENT)

MODEL LSR-3060 RAPID EXTEND LOg SPLITTER VALVE

STANDARD FEATURES

Hydraulically balanced, hard chrome plated spool

Handle can be installed in up or down position

Extend flows of up to 25 GPM with inlet flows of 4 GPM

Relief valve adjustable up to 3500 PSI

Tandem center spool

Manual shift from high speed mode to high force mode

Spring center 4 position spool with soft stop

Pressure release detent on retract

FUNCTION:

The Prince LSR-3060-3 log splitter valve features an extremely fast Rapid Extend high speed mode. The LSR

has been specifically designed to reduce system costs by

allowing a single stage pump to be used in systems currently using two stage (hi-low) pumps. When extra splitting

force is required, the LSR allows the user to manually shift

form high speed mode to high force mode. A soft stop

differentiates between high force and high speed modes.

Laboratory testing has not shown a significant difference

in working cycle times between single stage/rapid extend

systems and two stage systems. (Working cycle is the

average time between extending the cylinder to split the

first log and extending to split the next log after the split

wood has been removed and a new log has been placed

on the log splitter.)

CATV 57-07-13-02

SPECIFICATIONS:

1.

2.

3.

4.

5.

Max design and test pressure 3500 PSI

Max tank port pressure -150 PSI

Nominal inlet flow rating 4 gpm

Standard relief valve setting 2250 psi

This valve has a pressure release detent from spool in

w/ spring center to neutral

6. The valve has a 4 position spool with normal extend and

retract positions and a 4th rapid extend position

7. Max operating temperature - 180F.

8. In exposed environments, do not mount with spool in the

vertical position

9. Dimensionally similar to the LS3000 valve

10. In center position, B port connected to tank.

A-Rod end

of Cylinder

B-Base end

of Cylinder

B-Base end

of Cylinder

A-Rod end

of Cylinder

P

P

PRINCE MANUFACTURING CORPORATION P.O. BOX 7000 NORTH SIOUX CITY, SOUTH DAKOTA 57049-7000

URL: www.princehyd.com E-MAIL: prince@princehyd.com

O.E.M. CUSTOMER SERVICE: (605) 235-1220 FAX (712) 233-2181 DISTRIBUTOR CUSTOMER SERVICE: PHONE (605) 235-1220 FAX (712) 233-2181

SEE PAGE 22 OF THE STANDARD PRODUCT PRICE LIST FOR PRICING

V57

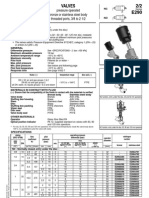

VALVES

STANDARD FEATURES

Hydraulically balanced, hard chrome plated spool

Handle can be installed in up or down position

Detent release pressure adjustable from 1000 to 2000 PSI

For use with system flows up to 25 GPM

Relief valve adjustable up to 2750 PSI

Tandem center spool (in neutral position, both work ports

blocked, pump unloaded to tank)

Ideal for log-splitter applications. Available with 3/4

NPTF work ports for higher flow applications

9.19

MODEL RD2500 DIMENSIONAL DATA

STANDARD FEATURES

Economical monoblock construction of high tensile

strength gray cast iron

Load check

Hard chrome plated spool

4.88

Adjustable

ball spring relief

(1000 PSI to 3000 PSI)

OUTLET PORT

3.75

Open center to closed center

conversion available on

1.18

some models

.90

For use with system flows to

20 GPM

For use with system pressures to 3000.46PSI

OUT

A

4.88

OUTLET PORT

8.25

3.00

2.13

1.50

4.25

3.75

3.00

SPECIFICATIONS:

1. Max design and test pressure 3000 PSI

2. Max tank port pressure-150 PSI

3. Flow rating-20 GPM max.

4. Relief valve setting-1500 PSI

5. Weight: 9.5 Ibs.

6. Recommended filtration-ISO 4406 19/17/14

7. Max operation temp-180F

8. In exposed environments, do not mount

with spool vertical and handle end down.

1.18

3.06

2.13

IN

.90

1.06

.46

3.09

OUT

7.75

12.00

INLET PORT

1.50 .343 DIA. (3)

8.25

3.00

9.06

2.13

A & B WORK PORTS

4.25

3.00

3.06

IN

2.13

1.06

3.09

7.75

12.00

.343 DIA. (3)

9.06

A & B WORK PORTS

INLET PORT

OUTLET PORT

2

3/8 NPTF PIPE PLUG

PART NO. 200018002

OUT

OPEN TO CLOSED CENTER

CONVERSION This feature allows

an otherwise open center valve to be

converted to closed center operation.

As shown, a 3/8 NPTF pipe plug is

installed in the bottom of the outlet port

to block open center passage. A pipe

thread sealant should be used. This

feature is standard on all valves with

3/4 NPTF inlet and outlet ports. The

pipe plug is included with these models.

Discard the pipe plug if the valve is

used on an open center application.

PLEASE NOTE that this closed center

option does not provide for the drain

off of standby spool leakage. This can

allow a very small amount of oil to enter

the work ports when in neutral.

OUTLET PORT

OUT

VALVES

RD-2555-T4-ESA 1 PARTS BREAkDOWN

3

2

NOTE: The Spool is

select fit to the valve

3/8 NPTF PIPE PLUG

body at the factory

PART NO. 200018002

and therefore body

and spool are not

available as repair

parts.

3 POSITION DETENT

NON-STANDARD RELIEF SETTINGS

RD2575-T4-ESA1-25

THE LAST TWO DIGITS ARE THE RELIEF SETTING

IN HUNDREDS. Ex: 25=2500 PSI @ 12 GPM. ALL

RELIEFS ARE SET AT 12 GPM.

V58

ITEM

PART NUMBER

1

2

3

4

5

6

660130001

660125004

660525001

660125002

660150015

660125001

DESCRIPTION

6

HANDLE KIT

RELIEF KIT

SEAL KIT

SPRING CENTER KIT

3 LOAD

POSITION

DETENT KIT

CHECK

3 POSITION DETENT KIT

PRINCE MANUFACTURING CORPORATION P.O. BOX 7000 NORTH SIOUX CITY, SOUTH DAKOTA 57049-7000

URL: www.princehyd.com E-MAIL: prince@princehyd.com

O.E.M. CUSTOMER SERVICE: (605) 235-1220 FAX (712) 233-2181 DISTRIBUTOR CUSTOMER SERVICE: PHONE (605) 235-1220 FAX (712) 233-2181

SEE PAGE 22 OF THE STANDARD PRODUCT PRICE LIST FOR PRICING

CATV 58-07-13-02

LS-3000, RD-2500 PRESSURE DROP, RELIEF CURVE AND STANDARD MODELS

PRESSURE DROP

110 SUS OIL AT 115

LS-3000/RD-2500 RELIEF VALVE

CURVES AT VARIOUS SET POINTS

110 SUS OIL AT 115F

P-PSI

FLOW

(gPM)

INLET TO

OUTLET

LS-3000

INLET TO

A OR B

INLET TO

A OR B TO OUTLET OUTLET

3000

INLET TO

A OR B

A OR B

TO OUTLET

20

10

39

15

11

13

15

19

60

32

23

24

20

31

90

54

11

40

42

PRESSURE (PSI)

RD-2500

2500

2000

LS-3000/RD-2500

LS-3000/RD-2500

LS-3000/RD-2500

RELIEF

RELIEF

VALVE

RELIEF

VALVE VALVE

CURVES

CURVES

AT CURVES

VARIOUS

AT

VARIOUS

AT

SET

VARIOUS

SET

POINTS

POINTS

SET POINTS

1500

110 SUS

110 SUS

OIL110

AT

OIL115F

SUS

AT 115F

OIL AT 115F

30003000

3000

25002500

2500

1000

500

PRESSURE (PSI)

PRESSURE (PSI)

PRESSURE (PSI)

8

12

16

20

FLOW (GPM)

2000 2000

All standard valves have a load check (except LS3000 models), a complete lever handle 2000

assembly,

and an adjustable ball-spring relief, see below

for settings. For other relief settings, please specify.

15001500 1500

SPOOL TYPE

SPOOL ACTION

STANDARD VALVES AVAILABLE

VALVE PART

NUMBER

RD-2555-T4-ESA1

1/2 NPTF 1/2 NPTF 1500 PSI @

12 GPM

NO

RD-2575-T4-ESA1

3/4 NPTF 1/2 NPTF 1500 PSI @

12 GPM

YES

RD-2575-T4-EDA1

3/4 NPTF 1/2 NPTF 1500 PSI @

12 GPM

YES

RD-2575-T3-ESA1

X

X

RD-2575-M4-ESA1

RD-2508-T4-ESA1

3/4 NPTF 1/2 NPTF

1500 PSI @

12 GPM

YES

3/4 NPTF 1/2 NPTF

1500 PSI @

12 GPM

YES

#10 SAE

1500 PSI @

12 GPM

YES

3/4 NPTF 1/2 NPTF 1500 PSI @

12 GPM

YES

RD-2575-M4-EDA1

#8 SAE

LS-3000-1

(detent spool out)

3/4 NPTF 1/2 NPTF 2250 PSI @

3 GPM

NO

LS-3000-2

(detent spool out)

3/4 NPTF 3/4 NPTF

2250 PSI @

3 GPM

NO

LS-3060-1

(detent spool in)

3/4 NPTF 1/2 NPTF 2250 PSI @

3 GPM

NO

LS-3040-1

3/4 NPTF 1/2 NPTF

2250 PSI @

12 GPM

NO

1/2 NPTF 3/4 NPTF

2250 PSI @

3 GPM

NO

LSR-3060-3

(detent spool in)

X

X

4 WAY 4 POSITION W/

MANUAL RAPID EXTEND

B A

4 WAY SPOOL

3 WAY SPOOL

This spool option is used to control

a double acting cylinder. In neutral

both of the work ports are blocked

and oil goes through

P-T the open

center passage to the outlet. This is

the most popular spool option.

B AB A

B A

P-T P-T

P-T

CATV 59-07-13-02

This spool option is used to

control a single acting cylinder

or a uni-directional motor. In

neutral the work port is blocked

P-T

and oil goes through the open

center passage to the outlet.

The B work port is plugged for

this option.

A A

A

P-T P-T

P-T

B A

4 WAY MOTOR SPOOL

This spool option is used to control

a reversing motor or a double acting

cylinder. In neutral the work ports are

connected to tank and oil goes through

P-T

the open center passage to the outlet.

This allows a motor to free-wheel or a

cylinder to float in the neutral position.

B AB A

B A

P-T P-T

P-T

VALVES

RELIEF

CONVERTIBLE

PRESSURE

SETTINg

FROM OPEN

1000

1000

1000

RELEASE

SPRINg

To Specify

WORk

4 WAY

CENTER

IN/OUT

3 WAY

4 WAY

DETENT

CENTER 3 POSITION

Other Settings

PORT

3 POSITION

PORT SIZE

DETENT

3 POSITION

3 POSITION

SPRINg

TO

See Previous TO CLOSED

SIZE

MOTOR

500 500

500

CENTER

CENTER TO

NEUTRAL

0 0 4 408 8412 12816 161220Page

2016

20

NEUTRAL

FLOW

FLOW

(GPM)

(GPM)

FLOW (GPM)

LOAD CHECk

The load check feature is standard

on all RD-2500 valve models.

The load check will prevent the

fall of a cylinder as the spool is

shifted. It does this by preventing

the back-flow of oil from work port

to inlet. The pump must build up

enough pressure to overcome

the pressure on the work port and

lift the load check poppet. The

load check has nothing to do with

holding a cylinder when the spool

is in neutral.

PRINCE MANUFACTURING CORPORATION P.O. BOX 7000 NORTH SIOUX CITY, SOUTH DAKOTA 57049-7000

URL: www.princehyd.com E-MAIL: prince@princehyd.com

O.E.M. CUSTOMER SERVICE: (605) 235-1220 FAX (712) 233-2181 DISTRIBUTOR CUSTOMER SERVICE: PHONE (605) 235-1220 FAX (712) 233-2181

SEE PAGE 22 OF THE STANDARD PRODUCT PRICE LIST FOR PRICING

V59

You might also like

- Black & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFDocument349 pagesBlack & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFHector100% (1)

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Valves Grese NDocument92 pagesValves Grese NYair Alexis Muñoz Rojas100% (1)

- PULLMASTER Model Hl25 Service ManualDocument44 pagesPULLMASTER Model Hl25 Service ManualinvidiuoNo ratings yet

- Buttress DamDocument65 pagesButtress DamAF.RISHARD FAIS77% (13)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Inergen SpecDocument19 pagesInergen SpecMargaret DaughertyNo ratings yet

- TSPL-1905 Technical Offer Dt.16.04.2022Document4 pagesTSPL-1905 Technical Offer Dt.16.04.2022SECI 2020No ratings yet

- b3311 722-2Document7 pagesb3311 722-2Arnaldo BenitezNo ratings yet

- PLL 2144Document80 pagesPLL 2144Amit TandelNo ratings yet

- Product Range Overview RexrothDocument21 pagesProduct Range Overview RexrothEustahije BrzicNo ratings yet

- PCS-Ferguson-Plunger-Lift-Catalog Plunger Lift Embolo Viajero Apergy PDFDocument48 pagesPCS-Ferguson-Plunger-Lift-Catalog Plunger Lift Embolo Viajero Apergy PDFinvidiuoNo ratings yet

- PCS-Ferguson-Plunger-Lift-Catalog Plunger Lift Embolo Viajero Apergy PDFDocument48 pagesPCS-Ferguson-Plunger-Lift-Catalog Plunger Lift Embolo Viajero Apergy PDFinvidiuoNo ratings yet

- Select the Right Pressure Reducing Valve for Steam ApplicationsDocument82 pagesSelect the Right Pressure Reducing Valve for Steam Applicationstungbk9No ratings yet

- PSI PumpsDocument12 pagesPSI PumpsagiacomuzoNo ratings yet

- Proposed EquipmentDocument8 pagesProposed EquipmentImani ZoufikarNo ratings yet

- Vanzetti Cryogenic Pumps & Technology GuideDocument0 pagesVanzetti Cryogenic Pumps & Technology GuidekanchanabalajiNo ratings yet

- Hyd Inc SwivelsDocument140 pagesHyd Inc SwivelsCentral HydraulicsNo ratings yet

- Vickers DG4V-3 DG4V-3S 6xDocument32 pagesVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroNo ratings yet

- Dishwasher Explanation TextDocument3 pagesDishwasher Explanation TextMai - Patcharee RushNo ratings yet

- HPG Range: Direct High-Pressure Gas ActuatorsDocument8 pagesHPG Range: Direct High-Pressure Gas ActuatorsLuan HuynhNo ratings yet

- Pumps+Valves4 MudGateValves 081129Document6 pagesPumps+Valves4 MudGateValves 081129isamelgqNo ratings yet

- Dokumen - Tips Operating and Maintenance Instructions Operating and Maintenance InstructionsDocument61 pagesDokumen - Tips Operating and Maintenance Instructions Operating and Maintenance InstructionsAri sofyan100% (1)

- 50PVB ProductDocument29 pages50PVB Producthakimmunas100% (1)

- KDW 2204 - 7396335 Vista Explodida - CompressedDocument50 pagesKDW 2204 - 7396335 Vista Explodida - Compressedjoildo juniorNo ratings yet

- Reg RedQ Specialy Regulators PDFDocument20 pagesReg RedQ Specialy Regulators PDFDavid SaldarriagaNo ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- 6300 CatalogDocument15 pages6300 CatalogMarco MinariniNo ratings yet

- Catalogos BombasDocument12 pagesCatalogos BombasJose NavarreteNo ratings yet

- Dynex PF 500 SpecsDocument7 pagesDynex PF 500 SpecsWaseem WaqarNo ratings yet

- Schmidt Armaturen FlowPak Class 150, 1/2” - 4” Technical DocumentDocument12 pagesSchmidt Armaturen FlowPak Class 150, 1/2” - 4” Technical DocumentMisael Castillo CamachoNo ratings yet

- Hawe Rapid RangeDocument16 pagesHawe Rapid RangecinbrekNo ratings yet

- Directional Control Valve GuideDocument11 pagesDirectional Control Valve GuideDaniel VillarroelNo ratings yet

- Valves Grese NDocument92 pagesValves Grese NRandall KirchbergNo ratings yet

- Air Preparation ProductsDocument6 pagesAir Preparation ProductssenamotoNo ratings yet

- Dynex PF 1300 SpecsDocument7 pagesDynex PF 1300 SpecsAdeel HassanNo ratings yet

- Manostat CatalogDocument8 pagesManostat CatalogadamdwaldropNo ratings yet

- Solenoid Controlled Pilot Operated Directional Valves Specifications and RatingsDocument50 pagesSolenoid Controlled Pilot Operated Directional Valves Specifications and RatingsphaindikaNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Solenoide Mac 400barDocument30 pagesSolenoide Mac 400barDiego IvanNo ratings yet

- Vad 213Document11 pagesVad 213Sen Van0% (1)

- R10/R11 General Purpose RegulatorsDocument1 pageR10/R11 General Purpose RegulatorsDemnyer Asid RaultNo ratings yet

- Solinoid Popet ValveDocument3 pagesSolinoid Popet ValvesaqureshNo ratings yet

- SD 6 eDocument16 pagesSD 6 eseaqu3stNo ratings yet

- 2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StyleDocument2 pages2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StylemaarwaanNo ratings yet

- SAPCDocument2 pagesSAPCShanArisNo ratings yet

- Regulador 1253 B - American M.Document8 pagesRegulador 1253 B - American M.Jheysson FloresNo ratings yet

- Unloading Valve for Circuits with AccumulatorDocument4 pagesUnloading Valve for Circuits with AccumulatorLibinNo ratings yet

- Prince Hydraulics Sectional Body Model SV Offered by PRC Industrial SupplyDocument18 pagesPrince Hydraulics Sectional Body Model SV Offered by PRC Industrial SupplyPRC Industrial SupplyNo ratings yet

- Reliable Interface Valve for Up to 690 bar ApplicationsDocument10 pagesReliable Interface Valve for Up to 690 bar ApplicationsMargaret Daugherty0% (1)

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNo ratings yet

- E4Document14 pagesE4juanca_eduNo ratings yet

- Wellmark Section-5.1-W7702 (1) BPRDocument2 pagesWellmark Section-5.1-W7702 (1) BPRJoeset Wu100% (1)

- FEPA Gas-over-oil ActuatorsDocument4 pagesFEPA Gas-over-oil Actuatorstoader56No ratings yet

- BusDocument34 pagesBusernesto hidalgoNo ratings yet

- Norgren PressureRegulatorDocument3 pagesNorgren PressureRegulatormreichenNo ratings yet

- Dtda Valvula SeguridadDocument4 pagesDtda Valvula SeguridadJean CcNo ratings yet

- Belimo valves and actuators guide for shut-off and butterfly valvesDocument12 pagesBelimo valves and actuators guide for shut-off and butterfly valves윤병택No ratings yet

- FOXPAK Control Valve System SpecificationsDocument0 pagesFOXPAK Control Valve System Specificationscico_ctNo ratings yet

- Valvula de Alivio de PresionDocument4 pagesValvula de Alivio de PresioneselcosacNo ratings yet

- pt3 4diaphragm DrumPumpsDocument29 pagespt3 4diaphragm DrumPumpsMatthew NievesNo ratings yet

- Elec Grs Pumps 203seriesDocument5 pagesElec Grs Pumps 203serieschand_yelNo ratings yet

- Allenair Catalog 4 Way ValvesDocument5 pagesAllenair Catalog 4 Way ValvesEddie WallsNo ratings yet

- Bomba Pistao Dynex MorlinaDocument6 pagesBomba Pistao Dynex MorlinaoperariopantaleaoNo ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- WW iCUE H100i H115i H150i ELITE SERIES QSG AADocument134 pagesWW iCUE H100i H115i H150i ELITE SERIES QSG AAinvidiuoNo ratings yet

- Includes Applications: Truck Mounted X-CELERATORDocument2 pagesIncludes Applications: Truck Mounted X-CELERATORinvidiuo0% (1)

- Acl 4000 - Manual Flare StackDocument8 pagesAcl 4000 - Manual Flare StackinvidiuoNo ratings yet

- Bulletin 71.1:1301: Types 1301F and 1301G High-Pressure RegulatorsDocument8 pagesBulletin 71.1:1301: Types 1301F and 1301G High-Pressure RegulatorsinvidiuoNo ratings yet

- Roscas NPT NPTF RCDocument1 pageRoscas NPT NPTF RCorlandresNo ratings yet

- How To Determine What Sae Housing You HaveDocument1 pageHow To Determine What Sae Housing You HaveinvidiuoNo ratings yet

- PCP Catalog - NovaPDocument12 pagesPCP Catalog - NovaPThinh OnNo ratings yet

- Lone Star Install Manual W Cover - EnglishDocument30 pagesLone Star Install Manual W Cover - EnglishinvidiuoNo ratings yet

- Colfax MR Series CompresorDocument2 pagesColfax MR Series CompresorinvidiuoNo ratings yet

- FSI Manual and Install Guide 0.1 PrintDocument12 pagesFSI Manual and Install Guide 0.1 PrintinvidiuoNo ratings yet

- 476 Data SheetDocument1 page476 Data SheetinvidiuoNo ratings yet

- Westport 3.8l Industrial EngineDocument2 pagesWestport 3.8l Industrial EngineinvidiuoNo ratings yet

- Zero-Max - Schmidt-Mgz Cople Acoplamiento PDFDocument12 pagesZero-Max - Schmidt-Mgz Cople Acoplamiento PDFinvidiuoNo ratings yet

- Thread Callout in SolidworksDocument11 pagesThread Callout in SolidworksmanozkriNo ratings yet

- Sauer Danfoss Bomba Caudal VariableDocument140 pagesSauer Danfoss Bomba Caudal Variableinvidiuo100% (1)

- High-Strength Epoxy Grout Data SheetDocument2 pagesHigh-Strength Epoxy Grout Data SheetAtulNo ratings yet

- 3M One Pass Fiber PathwayDocument5 pages3M One Pass Fiber PathwayAhmad Hazmin HalimNo ratings yet

- The Branch Supply Duct As Far As Practical From The OutletDocument11 pagesThe Branch Supply Duct As Far As Practical From The OutletKevinNavidadNo ratings yet

- 2019-05-28 - DA - RSLF Artillery Brigade - Volume 2 PDFDocument490 pages2019-05-28 - DA - RSLF Artillery Brigade - Volume 2 PDFDusngi MoNo ratings yet

- D7032 1213477 1 PDFDocument11 pagesD7032 1213477 1 PDFBodhi RudraNo ratings yet

- Iapmo Ues Er712Document10 pagesIapmo Ues Er712Ngân NguyễnNo ratings yet

- 2-Stage D - Part 2 - Structural Design Report - FX Rev1Document168 pages2-Stage D - Part 2 - Structural Design Report - FX Rev1Prima AdhiyasaNo ratings yet

- Nagara Style at KhajurahoDocument25 pagesNagara Style at KhajurahosalmanNo ratings yet

- NTRBTDocument12 pagesNTRBTRanjanDsNo ratings yet

- Geosynthetics ApplicationsDocument51 pagesGeosynthetics ApplicationsCharlotte TilburyNo ratings yet

- Behaviour of Masonry StructuresDocument27 pagesBehaviour of Masonry StructuresvarshaNo ratings yet

- Quick Change Connectors: JK 201 Nipples (Special Mold Plug)Document2 pagesQuick Change Connectors: JK 201 Nipples (Special Mold Plug)Anilabc VermaxyzNo ratings yet

- Rehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadDocument2 pagesRehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadAljie CañeteNo ratings yet

- Loxeal InfotechDocument16 pagesLoxeal InfotechAlexNo ratings yet

- Katmon Tree - : Trees For Noise CancellingDocument7 pagesKatmon Tree - : Trees For Noise CancellingJashley RoviraNo ratings yet

- (AHU) Clivet AHU and Modular Air Handling UnitDocument27 pages(AHU) Clivet AHU and Modular Air Handling UnitDoniNo ratings yet

- Alma Phase 2 Community Facilities: 16-084 FFE SpecificationDocument21 pagesAlma Phase 2 Community Facilities: 16-084 FFE Specificationjoe whiteNo ratings yet

- Repair Concrete StructuresDocument3 pagesRepair Concrete StructuresSindhe SwethaNo ratings yet

- Module 1 - National Building Code of The Philippines - Part 1Document37 pagesModule 1 - National Building Code of The Philippines - Part 1Rovic VincentNo ratings yet

- Introduction To Prestressing CE 572: Purdue University School of Civil EngineeringDocument21 pagesIntroduction To Prestressing CE 572: Purdue University School of Civil EngineeringNatarajan SaravananNo ratings yet

- CVE 2113 Quantity Surveying and Estimating - Lecture #13Document3 pagesCVE 2113 Quantity Surveying and Estimating - Lecture #13sikandar abbasNo ratings yet

- Mod 1Document18 pagesMod 1Zac IriberriNo ratings yet

- Steemaster 1200 CF5276 Jotun - 413464Document50 pagesSteemaster 1200 CF5276 Jotun - 413464Tanmay GorNo ratings yet

- Fly OverDocument29 pagesFly OverUrvisha Butani100% (1)