Professional Documents

Culture Documents

Apcd 45

Uploaded by

Teguh SetionoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apcd 45

Uploaded by

Teguh SetionoCopyright:

Available Formats

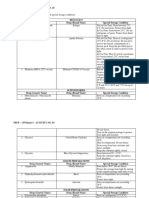

ODORANT & METERING STATION SUMMARY

FACILITY NAME: ____________________________________________________________________

ADDRESS: __________________________________________________________________________

____________________________________________________________________________________

1.

Pressure Controller(s):

Mfgr:_________________________________

Model #:____________________

ID #:_________________________________

Gas [ ] or

Bleed Gas rate: ________________________

Air [ ]

(scf / hr)

Pressure Set Points: _____________________________________________________

Mfgr:_________________________________

Model #:____________________

ID #: _________________________________

Gas [ ] or

Bleed Gas rate: ________________________

Air [ ]

(scf / hr)

Pressure Set Points: _____________________________________________________

Describe the function of each controller: ______________________________________

______________________________________________________________________

______________________________________________________________________

Not applicable pressure switches are installed.

2.

Liquid / Gas Separator:

Vessel Capacity: _________________ (ft3)

ID #:______________________

Operating Pressure: ______________ Relief Valve Setting: ________________

APCD 45 (01/2002)

Page 1 of 4

3.

Gravitometer:

Mfgr: __________________________ Model #: ________________________

ID #:___________________ Bleed Gas Rate: ____________________ (scf/hr)

4.

H2S Analyzer:

Mfgr: ___________________________ Model #:________________________

ID #: _____________________ Bleed Gas Rate: ___________________(scf/hr)

Analyzer Set Point: ____________ PPM Alarm _____________ PPM Shutdown

5.

Gas Sampler:

Mfgr:__________________________ Model #:_________________________

ID #: _____________________Bleed Gas Rate:____________________(scf/hr)

6.

Odorant Storage Tank:

Vessel Dimensions: _________________ Vessel Capacity: ________________

Tank ID #: ________________________ Relief Valve Setting: _____________

Describe the procedures used to fill the vessel:___________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

7.

Odorant Run Tank:

Vessel Dimensions: _________________ Vessel Capacity: ________________

Tank ID #: ________________________ Relief Valve Setting: _____________

Describe the procedures used to fill the vessel: __________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

APCD 45 (01/2002)

Page 2 of 4

8.

Metering Pump:

Mfgr: ______________________________

ID #: _________________________

Model #:___________________

Gas [ ] or Air [ ] operated

Bleed Gas Rate: _____________________________ (scf/hr) {at max rating}

9.

Charcoal Filter:

Mfg: _______________________________ Model #:___________________

ID #: __________________________ Vessel Dimensions: _______________

Weight of Charcoal: ______________ Type of Charcoal: _________________

Frequency of Bed Replacement: _____________________________________

10.

As an attachment, list all other potential sources of hydrocarbon emissions from the

facility. Provide the appropriate equipment descriptions and the rate of emissions

in scf / hr.

11.

Odorant:

Type: _____________________ Concentration: _______________________

Vapor Pressure at 70F and 1 atm: ______________________________psia

If dilute, what solvent is used?: _____________________________________

Yearly usage: _____________________________________________Gallons

Density (lb / gal): ________________ Molecular Weight: ________________

12.

Fugitive Emission Source:

On an Attachment list the fugitive emission sources, the quantity of each

source, the number of components per source, the total components, and the

emissions in lb / hr ROC. Fugitive emissions are calculated using emission

factors from Table 2.8 of the Tecolote Report (Modeling of Fugitive Emissions,

January 1986).

13.

Average Gas Analysis:

Non-methane HC weight %:___________ % HC Mol Wt Avg:____________

Provide as an Attachment a Certificate of Analysis, showing: identification

parameters; sample date; analysis date; components listed by mol%;

corrected Btu (dry); and corrected specific gravity.

APCD 45 (01/2002)

Page 3 of 4

14.

Operating Parameters:

Source of the Natural Gas: _______________________________________

Highest monthly gas throughput in the past three (3) years: _____________

Average monthly gas throughput: _________________________________

So Cal Gas Distribution line #:

_________________________________

15.

As an Attachment provide 1) a process flow diagram, which shows all the above listed

equipment, and 2) a general site plan, which identifies the location of: all roads, property

lines, and adjacent property owners.

COMPLETED BY:___________________________________ TITLE:____________________

DATE: ____________________________________________ PHONE: __________________

APCD 45 (01/2002)

Page 4 of 4

You might also like

- Form Blank Kelengkapan Data SampleDocument1 pageForm Blank Kelengkapan Data SampleVin DieselNo ratings yet

- Ops Plan TempDocument21 pagesOps Plan TempTiago HenriquesNo ratings yet

- Ops Plan TempDocument24 pagesOps Plan TempR ShindeNo ratings yet

- Installation Oxygen ConcentratorDocument1 pageInstallation Oxygen Concentratordean HaroldNo ratings yet

- Heatpump ApplicationDocument1 pageHeatpump ApplicationsandyolkowskiNo ratings yet

- Application STEAM GAS HYDRO TURBINE InstallationDocument2 pagesApplication STEAM GAS HYDRO TURBINE InstallationEfren Jr. FloresNo ratings yet

- Fire Alarm System Inspection and Testing FormDocument4 pagesFire Alarm System Inspection and Testing FormBrahim SemariNo ratings yet

- GRN 6 Residential O and M Manual 01.01.23Document4 pagesGRN 6 Residential O and M Manual 01.01.23kamatsho153No ratings yet

- ER-10-4-01 EN Installation List Data and Start Up ChecksDocument9 pagesER-10-4-01 EN Installation List Data and Start Up ChecksCamilo Andres Cardozo FajardoNo ratings yet

- PG 5 - Your Pools Personalized Info & Equip. ListDocument1 pagePG 5 - Your Pools Personalized Info & Equip. ListPrestonNo ratings yet

- Tax Declaration RPT PDFDocument1 pageTax Declaration RPT PDFEder Epi100% (1)

- Dimensioning Sheet Oxistop Oxs Unit: ProjectDocument1 pageDimensioning Sheet Oxistop Oxs Unit: Projectjean bouNo ratings yet

- Shimadzu PdaDocument11 pagesShimadzu PdaARAS InstrumentNo ratings yet

- Risk Mgt. Survey Questionnaire 2023Document3 pagesRisk Mgt. Survey Questionnaire 2023jamaica tarayaoNo ratings yet

- UTR FormDocument1 pageUTR FormLeorenz Marc EstaNo ratings yet

- Questionaire 1 Mechanical PretreatmentDocument2 pagesQuestionaire 1 Mechanical PretreatmentLuis Ernesto Rodríguez RodríguezNo ratings yet

- Er 10 4 01Document8 pagesEr 10 4 01Mohammad Shafaet JamilNo ratings yet

- 12 Bolt: Signature: - SignatureDocument1 page12 Bolt: Signature: - SignatureAkaalj InspeccionNo ratings yet

- Vertical Screw Data SheetDocument3 pagesVertical Screw Data SheetMIGUELNo ratings yet

- 04B ExemptionDocument3 pages04B ExemptionbuenaNo ratings yet

- Questionnaire SDDocument3 pagesQuestionnaire SDrajNo ratings yet

- Pressure Switch Calibration FormDocument1 pagePressure Switch Calibration FormAli AkbarNo ratings yet

- Bha Dust Collection Application InformationDocument1 pageBha Dust Collection Application Informationmazouz.lmfNo ratings yet

- Fire Freeze Ras Al Khair Power Plant, Phase-1: Vehicle/Equipment Check ListDocument1 pageFire Freeze Ras Al Khair Power Plant, Phase-1: Vehicle/Equipment Check ListFarooq MohammadNo ratings yet

- General Plant Description: Form No. 7Document4 pagesGeneral Plant Description: Form No. 7Ranndolf JavierNo ratings yet

- Vuee Tuee Verbal OrdersDocument5 pagesVuee Tuee Verbal Ordersthaliasingh28No ratings yet

- Lapu-Lapu City-Plumbing WorksheetDocument1 pageLapu-Lapu City-Plumbing Worksheetmalahay.shananemarieNo ratings yet

- WORK ORDER Format 21Document2 pagesWORK ORDER Format 21Anonymous 9WvrDsFN6No ratings yet

- Aviation Insurance Proposal FormDocument4 pagesAviation Insurance Proposal FormbestonthekaNo ratings yet

- General Inspection FormDocument1 pageGeneral Inspection FormBernadette Lou LasinNo ratings yet

- Multidimentional Observation and Score Worksheet: Sample Dosage (MG)Document1 pageMultidimentional Observation and Score Worksheet: Sample Dosage (MG)Hiro TakanoriNo ratings yet

- Service ReportDocument1 pageService ReportMohammed R. Al Khaz'alyNo ratings yet

- Blank Condition ReportDocument2 pagesBlank Condition ReportJoe HernandezNo ratings yet

- Application For Crane and Hoist Installation: Department of Labor and EmploymentDocument1 pageApplication For Crane and Hoist Installation: Department of Labor and EmploymentCharlie MendozaNo ratings yet

- Tissues VerificationDocument1 pageTissues VerificationratlhogoandriesNo ratings yet

- ESI Oil Sampling SheetDocument1 pageESI Oil Sampling SheetGM PNo ratings yet

- Sample Report of Magnetic-Particle Examination of WeldsDocument1 pageSample Report of Magnetic-Particle Examination of WeldsNavanitheeshwaran SivasubramaniyamNo ratings yet

- Sachibondu Request Form & Budget-1Document2 pagesSachibondu Request Form & Budget-1bruce mulengaNo ratings yet

- SECTION 04 After Sales Service PolicyDocument14 pagesSECTION 04 After Sales Service PolicyRFamDamilyNo ratings yet

- Annex 1 Application Form CHRDR-WaterDocument1 pageAnnex 1 Application Form CHRDR-WaterAnonymous ku7POqvKNo ratings yet

- Y. Evaporator TC 15000 PDFDocument187 pagesY. Evaporator TC 15000 PDFGloria Del Carmen MuñozNo ratings yet

- Annual Test & Maintenance Report For Backflow Prevention DevicesDocument1 pageAnnual Test & Maintenance Report For Backflow Prevention DevicesBlazo MedenicaNo ratings yet

- Testing Commisioning Report Ac Split: ProjectDocument2 pagesTesting Commisioning Report Ac Split: Projectagun gunawanNo ratings yet

- Attachment D (SAEP 316)Document1 pageAttachment D (SAEP 316)imtiazNo ratings yet

- Commercial Customer Load RequirementsDocument1 pageCommercial Customer Load Requirementsscsam05No ratings yet

- Triage Assessment SlipDocument1 pageTriage Assessment SlipJm unite100% (1)

- Preventive Maintenance Checklist: Biomedical. EngDocument150 pagesPreventive Maintenance Checklist: Biomedical. EngJuli AgustonoNo ratings yet

- Noel Brians Motor Works: Brgy. Camambugan, Daet, Camarines Norte 09982782998Document1 pageNoel Brians Motor Works: Brgy. Camambugan, Daet, Camarines Norte 09982782998RonaldNo ratings yet

- Plumbing Report TempelateDocument4 pagesPlumbing Report TempelateWjz WjzNo ratings yet

- Target Cleanliness WorksheetDocument6 pagesTarget Cleanliness WorksheetMauricio Marin PinedaNo ratings yet

- 416 Theatre Practice PolicyDocument131 pages416 Theatre Practice Policybalab2311No ratings yet

- Chemical Approval Form - Polintek Stop LeakDocument2 pagesChemical Approval Form - Polintek Stop LeakYosep SasadaNo ratings yet

- Quality Accreditation Checklist Form 4Document1 pageQuality Accreditation Checklist Form 4Joy Dimaano0% (1)

- Offer To Sell: Date Buyer Address TelephoneDocument2 pagesOffer To Sell: Date Buyer Address Telephonemarc gonzalesNo ratings yet

- Chemical Approval Form - Polintek Lining & Protection Plus For MetalDocument2 pagesChemical Approval Form - Polintek Lining & Protection Plus For MetalYosep SasadaNo ratings yet

- Pressure Vessel FabricationDocument1 pagePressure Vessel FabricationRaul Dela Cerna VentenillaNo ratings yet

- Report of Magnetic-Particle Examination of WeldsDocument1 pageReport of Magnetic-Particle Examination of WeldsSathish KumarNo ratings yet

- Hacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)From EverandHacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)No ratings yet

- The Stress-Free Guide to Parenting a Child With ADHD: Effective and Proven Strategies for Alleviating Anxiety and Forming Strong Bonds Without the HassleFrom EverandThe Stress-Free Guide to Parenting a Child With ADHD: Effective and Proven Strategies for Alleviating Anxiety and Forming Strong Bonds Without the HassleNo ratings yet

- Cloth Inserted Neo RubberDocument2 pagesCloth Inserted Neo RubberTeguh SetionoNo ratings yet

- Tank Specs - 5 - 3Document1 pageTank Specs - 5 - 3Teguh SetionoNo ratings yet

- Tank Talk 28Document4 pagesTank Talk 28TecsloNo ratings yet

- 187 DMR BearingIsolators 01Document7 pages187 DMR BearingIsolators 01Teguh SetionoNo ratings yet

- FAT PanelDocument6 pagesFAT PanelTeguh SetionoNo ratings yet

- Section 1 - Material Identification and Use: Material Safety Data Sheet (Canada) Condensate (Sweet 1% Benzene)Document2 pagesSection 1 - Material Identification and Use: Material Safety Data Sheet (Canada) Condensate (Sweet 1% Benzene)Teguh SetionoNo ratings yet

- Viscosity and Density (Metric SI Units)Document3 pagesViscosity and Density (Metric SI Units)malith kmlNo ratings yet

- Performance Curve BS2640.180 MTDocument1 pagePerformance Curve BS2640.180 MTTeguh SetionoNo ratings yet

- pd05011015f 16 PDFDocument12 pagespd05011015f 16 PDFTeguh SetionoNo ratings yet

- 15510-2015 BPVDocument4 pages15510-2015 BPVTeguh SetionoNo ratings yet

- AMERICAN Ductile Iron Flanged FittingsDocument7 pagesAMERICAN Ductile Iron Flanged FittingsDavid BerríoNo ratings yet

- Westfield Standard - 10/06 02310Document5 pagesWestfield Standard - 10/06 02310Teguh SetionoNo ratings yet

- No 05Document2 pagesNo 05jkhgvdj mnhsnjkhgNo ratings yet

- Steel Interchange: Design of Lifting LugsDocument2 pagesSteel Interchange: Design of Lifting LugsTeguh SetionoNo ratings yet

- JP One Pipeline A Unique Pipeline Project - 33km X 14"Document3 pagesJP One Pipeline A Unique Pipeline Project - 33km X 14"Teguh SetionoNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- For Comments Only Draft Indian Standard: Reciprocating Internal Combustion Engine - Fire ProtectionDocument1 pageFor Comments Only Draft Indian Standard: Reciprocating Internal Combustion Engine - Fire ProtectionTeguh SetionoNo ratings yet

- MarlinspikeDocument6 pagesMarlinspikeTeguh SetionoNo ratings yet

- المسافات بين الانابيبDocument6 pagesالمسافات بين الانابيبalaa4altaieNo ratings yet

- Fire Hydrant (Private) Testing Procedure: 1.0 Aim of TaskDocument3 pagesFire Hydrant (Private) Testing Procedure: 1.0 Aim of TaskTeguh SetionoNo ratings yet

- T" 0.047" Gone in Miling Process: LP LP LDocument1 pageT" 0.047" Gone in Miling Process: LP LP LTeguh SetionoNo ratings yet

- NPSH SimplifiedDocument4 pagesNPSH Simplifiedtexwan_No ratings yet

- H Beams in Accordance With JISDocument3 pagesH Beams in Accordance With JISTeguh SetionoNo ratings yet

- STS PRT 6 - Valve and Fire Hydrant InstallationDocument3 pagesSTS PRT 6 - Valve and Fire Hydrant InstallationTeguh SetionoNo ratings yet

- Pump Test Data Sheet: Drawdown Data Recovery DataDocument1 pagePump Test Data Sheet: Drawdown Data Recovery Dataisaac2408100% (1)

- Seh 37Document1 pageSeh 37Teguh SetionoNo ratings yet

- 22 11 17 - Gas Pipe and AppurtenancesDocument7 pages22 11 17 - Gas Pipe and AppurtenancesTeguh SetionoNo ratings yet

- DE27Document4 pagesDE27Teguh SetionoNo ratings yet

- MLT IMLT Content Guideline 6-14Document4 pagesMLT IMLT Content Guideline 6-14Arif ShaikhNo ratings yet

- Case Study of Flixborough UK DisasterDocument52 pagesCase Study of Flixborough UK Disasteraman shaikhNo ratings yet

- Digital Habits Across Generations: Before ReadingDocument3 pagesDigital Habits Across Generations: Before ReadingSharina RamallahNo ratings yet

- Untitled Form - Google Forms00Document3 pagesUntitled Form - Google Forms00Ericka Rivera SantosNo ratings yet

- Deductions From Gross IncomeDocument2 pagesDeductions From Gross Incomericamae saladagaNo ratings yet

- Government of Tamilnadu Directorate of Legal Studies: Inter-Collegeiate State Level Moot Court Competition-2022Document30 pagesGovernment of Tamilnadu Directorate of Legal Studies: Inter-Collegeiate State Level Moot Court Competition-2022Divya SrinimmiNo ratings yet

- Group Interative Art TherapyDocument225 pagesGroup Interative Art TherapyRibeiro CatarinaNo ratings yet

- Amino AcidsDocument17 pagesAmino AcidsSiddharth Rohilla100% (2)

- Contoh Reflection PaperDocument2 pagesContoh Reflection PaperClaudia KandowangkoNo ratings yet

- D2C - Extensive ReportDocument54 pagesD2C - Extensive ReportVenketesh100% (1)

- Giardiasis PDFDocument14 pagesGiardiasis PDFSaad Motawéa0% (1)

- Park Agreement LetterDocument2 pagesPark Agreement LetterKrishna LalNo ratings yet

- Project Report On MKT Segmentation of Lux SoapDocument25 pagesProject Report On MKT Segmentation of Lux Soapsonu sahNo ratings yet

- Information HumaLyzer Primus Setting Update and Extension enDocument3 pagesInformation HumaLyzer Primus Setting Update and Extension enluisoft88No ratings yet

- Tarot Cards: Cheat SheetDocument1 pageTarot Cards: Cheat SheetDipti100% (7)

- MPSI OverviewDocument15 pagesMPSI OverviewZaqee AlvaNo ratings yet

- JOHARI Window WorksheetDocument2 pagesJOHARI Window WorksheetAnonymous j9lsM2RBaINo ratings yet

- Helicopter Logging Operations - ThesisDocument7 pagesHelicopter Logging Operations - ThesisAleš ŠtimecNo ratings yet

- Protein Metabolism and Urea Recycling in Rodent HibernatorsDocument5 pagesProtein Metabolism and Urea Recycling in Rodent HibernatorsBud Marvin LeRoy RiedeselNo ratings yet

- Senior Cohousing - Sherry Cummings, Nancy P. KropfDocument86 pagesSenior Cohousing - Sherry Cummings, Nancy P. KropfAnastasia JoannaNo ratings yet

- FS011 Audit Plan Stage 2Document2 pagesFS011 Audit Plan Stage 2Ledo Houssien0% (1)

- MediclaimDocument3 pagesMediclaimPrajwal ShettyNo ratings yet

- Edunsol@gmail - Com, 09996522162, Career Counseling, Direct Admissions, MBBS, BDS, BTECH, MBA, Pharmacy, New Delhi, Mumbai, Pune, Bangalore....Document377 pagesEdunsol@gmail - Com, 09996522162, Career Counseling, Direct Admissions, MBBS, BDS, BTECH, MBA, Pharmacy, New Delhi, Mumbai, Pune, Bangalore....Education SolutionsNo ratings yet

- LapasiDocument3 pagesLapasiWenny MellanoNo ratings yet

- Unit 5.4 - Incapacity As A Ground For DismissalDocument15 pagesUnit 5.4 - Incapacity As A Ground For DismissalDylan BanksNo ratings yet

- VedasUktimAlA Sanskrit Hindi EnglishDocument47 pagesVedasUktimAlA Sanskrit Hindi EnglishAnantha Krishna K SNo ratings yet

- Positioning Strategy - Mineral WaterDocument2 pagesPositioning Strategy - Mineral WaterRakesh SelvamNo ratings yet

- Uric Acid Mono SL: Clinical SignificanceDocument2 pagesUric Acid Mono SL: Clinical SignificancexlkoNo ratings yet

- 33 KV Transmission Line Design DrawingsDocument265 pages33 KV Transmission Line Design DrawingsJuben Bhaukajee89% (9)

- Damasco - Cpi - Activity No. 10Document18 pagesDamasco - Cpi - Activity No. 10LDCU - Damasco, Erge Iris M.No ratings yet