Professional Documents

Culture Documents

KFD2 Wac2 1.D

Uploaded by

kfd2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KFD2 Wac2 1.D

Uploaded by

kfd2Copyright:

Available Formats

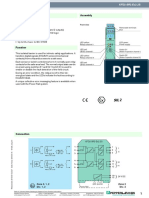

Strain Gauge Converter

KFD2-WAC2-1.D

Assembly

Features

1-channel signal conditioner

24 V DC supply (Power Rail)

Strain gauge input

Output 0 mA ... 20 mA or 0 V ... 10 V

Relay contact output

Programmable high/low alarm

Configurable by PACTwareTM or ke ypad

RS 485 interface

Line fault detection (LFD)

Front view

Removable terminals

green

LED green:

Power supply

LC display

PWR

ERR

1

2

ESC

RS 232

LED yellow:

Output ...

7

13

19

This signal conditioner is used with strain gauges, load cells

and resistance measuring bridges and provides isolation for

non-intrinsically safe applications.

Designed to provide 5 V excitation voltage, this barriers high

quality A/D converter allows it to be used with those devices

requiring 10 V.

OUT

LED red:

Fault signal

Function

KFD2-WAC21.D

OK

8

14

20

9

15

21

10

16

22

11

17

23

Keypad

12

18

24

Removable terminals

green

Programming jack

The unit is easily programmed by the use of a keypad located

on the front of the unit or with the PACTware configuration

software. The actual measurement for tare, zero point, and

final value can be entered in this manner.

A unique collective error messaging feature is available when

used with the Power Rail system.

For additional information, refer to the manual and

www.pepperl-fuchs.com.

Release date 2010-09-08 17:03 Date of issue 2010-09-08 202937_ENG.xml

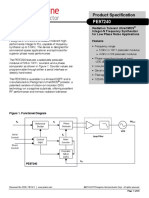

Connection

KFD2-WAC2-1.D

10

11

I

12

16

17

II

18

78+

III

913+

1415+

19+

20 GND RS 485

21-

3+

5+

1+

2-

mA

64-

23+

24-

RS 485

24 V DC

ERR 24 V DC

Power Rail

Subject to reasonable modifications due to technical advances.

Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group Tel.: Germany +49-621-776-0 USA +1-330-4253555 Singapore +65-67-799091 Internet www.pepperl-fuchs.com

Technical data

KFD2-WAC2-1.D

General specifications

Signal type

Analog input

Supply

Connection

Power Rail or terminals 23+, 24-

Rated voltage

20 ... 35 V DC

Ripple

within the supply tolerance

Power consumption

3W

Interface

Connection

Power Rail or terminals 19+, 20 GND, 21-

Type

RS 485

Programming interface

RS 232 programming jack

Field circuit

Connection

terminals 1+, 2-, 3+, 4-, 5+, 6-

Lead resistance

25 per lead

Input I

Connection

Sensor supply

terminals 1+, 21 ... 5 V

Connection

terminals 3+, 4-, 5+, 6-

Short-circuit current

50 mA

Load

116 up to 5V, 85 up to 4V

Input

Connection

Input I: terminals 1+, 2-; Input II: terminals 13+, 14-; Input III: terminals 15+, 14-

Programmable Tare

0 ... 500 % of span

Input I

Signal, analog

Input signal

Input resistance

Input II, III

-100 ... 100 mV

> 1 M for voltage measurement

tare adjustment, calibration and zero

Open circuit voltage/short-circuit

current

18 V / 5 mA

Active/Passive

I > 4 mA/I < 1.5 mA

Output

Connection

Output I: terminals 10, 11, 12; Output II: terminals 16, 17, 18; Output III: terminals 7-, 8+, 9-

Output I, II

Relay output

Contact loading

Mechanical life

Output III

253 V AC/2 A/500 VA/cos min. 0.7; 40 V DC/2 A resistive load

2 x 107 switching cycles

Analog output

Current range

-20 ... 20 mA

Load

550

Analog voltage output

0 ... 10 V; output resistance 500 (bridge between terminal 7 and 9)

Analog current output

0 ... 20 mA or 4 ... 20 mA; load 0 ... 550 (terminals 7 and 8)

Line fault detection

downscale -21.5 mA (-10.75 V) or 2 mA (1 V), upscale 21.5 mA (10.75 V)

Transfer characteristics

Deviation

Resolution/accuracy

0.05 % incl. non-linearity and hysteresis

Temperature effect

0.01 %/K

Release date 2010-09-08 17:03 Date of issue 2010-09-08 202937_ENG.xml

Reaction time

300 ... 850 ms

Electrical isolation

Input I/other circuits

reinforced insulation according to IEC 61140, rated insulation voltage 300 Veff

Output I, II against eachother

reinforced insulation according to IEC 61140, rated insulation voltage 300 Veff

Output I, II/other circuits

reinforced insulation according to IEC 61140, rated insulation voltage 300 Veff

Output III/Input II, III

not available

Output III/Programming socket

not available

Other circuits from each other

functional insulation, rated insulation voltage 50 Veff

Directive conformity

Electromagnetic compatibility

Directive 2004/108/EC

EN 61326-1:2006

Low voltage

Directive 2006/95/EC

EN 50178:1997

Conformity

Electromagnetic compatibility

NE 21

Protection degree

IEC 60529

Protection against electric shock

IEC 61140

Ambient conditions

Ambient temperature

-20 ... 60 C (-4 ... 140 F)

Mechanical specifications

Subject to reasonable modifications due to technical advances.

Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group Tel.: Germany +49-621-776-0 USA +1-330-4253555 Singapore +65-67-799091 Internet www.pepperl-fuchs.com

Technical data

Protection degree

KFD2-WAC2-1.D

IP20

Mass

approx. 250 g

Dimensions

40 x 119 x 115 mm (1.6 x 4.7 x 4.5 in) , housing type C3

General information

Supplementary information

Statement of Conformity, Declaration of Conformity, Attestation of Conformity and instructions have to be

observed where applicable. For information see www.pepperl-fuchs.com.

Supplementary information

Single or parallel connection of strain gauges with resulting resistance between 116 ... 10 k can be connected and will

provide a 4 mA ... 20 mA output and 2 relay outputs as well as an RS 485 interface in the safe area.

The device supports the transmission of measured values via the RS 485 interface. In this mode of operation, input signal range

may be transmitted with 26 Bit resolution with up to 31 signal converters connected to the Power Rail UPR-05 or via terminals

19, 20 and 21.

RS 485 communication may be done via the Power Rail when using power feed modules with bus access, e. g. KFD2EB2.R4A.B or via the terminals 19, 20 and 21 of one module. The device is addressed via keypad and display or with a PC with

PACTware and adapter K-ADP1.

For additional information, refer to the manual and www.pepperl-fuchs.com.

Accessories

Power feed modules KFD2-EB2...

The power feed module is used to supply the devices with 24 V DC via the Power Rail. The fuse-protected power feed module

can supply up to 100 individual devices depending on the power consumption of the devices. A galvanically isolated mechanical

contact uses the Power Rail to transmit collective error messages.

Power Rail UPR-05

The Power Rail UPR-05 is a complete unit consisting of the electrical inset and an aluminium profile rail 35 mm x 15 mm. To

make electrical contact, the devices are simply engaged.

Release date 2010-09-08 17:03 Date of issue 2010-09-08 202937_ENG.xml

The Power Rail must not be fed via the device terminals of the individual devices!

Subject to reasonable modifications due to technical advances.

Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group Tel.: Germany +49-621-776-0 USA +1-330-4253555 Singapore +65-67-799091 Internet www.pepperl-fuchs.com

You might also like

- Assembly Features: Front ViewDocument4 pagesAssembly Features: Front ViewAkoKhalediNo ratings yet

- KFD2 SR2 Ex2.WDocument4 pagesKFD2 SR2 Ex2.WgoparsucoNo ratings yet

- KFD2-CD-Ex1.32 104204 EngDocument3 pagesKFD2-CD-Ex1.32 104204 EngnileshsbodkeNo ratings yet

- 9RCI20ENDocument4 pages9RCI20ENTejas JasaniNo ratings yet

- Isolated Switch Amplifiers KFD2-SOT-Ex2 Technical DataDocument3 pagesIsolated Switch Amplifiers KFD2-SOT-Ex2 Technical DataSteve Richard Amorim PintoNo ratings yet

- KFD2 CD2 Ex2Document3 pagesKFD2 CD2 Ex2pradeepchennai10_959No ratings yet

- KFD2 CD2 Ex1Document3 pagesKFD2 CD2 Ex1goparsucoNo ratings yet

- Entradas Analogica Kfd2-Stc4-Ex PDFDocument3 pagesEntradas Analogica Kfd2-Stc4-Ex PDFAlfredo Mendez VazquezNo ratings yet

- Assembly Features: Removable Terminals BlueDocument3 pagesAssembly Features: Removable Terminals BlueIsaias Fernandez CalderonNo ratings yet

- DSe IB KFD2-UT2-Ex1 PDFDocument3 pagesDSe IB KFD2-UT2-Ex1 PDFRaj ChavanNo ratings yet

- VP210 En002Document22 pagesVP210 En002Nikhil SinghNo ratings yet

- Duplicator Power Source 102050 - 01 - enDocument11 pagesDuplicator Power Source 102050 - 01 - enCarlos AlbertoNo ratings yet

- Assembly Features: Removable Terminals BlueDocument4 pagesAssembly Features: Removable Terminals Blueandmar2011No ratings yet

- Miniature 5-Digit DC Voltmeter with Flexible OptionsDocument12 pagesMiniature 5-Digit DC Voltmeter with Flexible OptionsbdflorinNo ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- 2nd Review DocumentDocument6 pages2nd Review DocumentBrightworld ProjectsNo ratings yet

- FXP1500 32GDocument16 pagesFXP1500 32GMarcos AnzolaNo ratings yet

- DIN Rail Multimeter: Technical Data Input Influence MagnitudesDocument3 pagesDIN Rail Multimeter: Technical Data Input Influence MagnitudesDiego CordovaNo ratings yet

- Act-Sensor AS-iDocument3 pagesAct-Sensor AS-iEduardo QuispeNo ratings yet

- Assembly Features: Removable Terminal BlueDocument3 pagesAssembly Features: Removable Terminal BlueKoushik DasguptaNo ratings yet

- MAP DE Module (ICP MAP0007)Document3 pagesMAP DE Module (ICP MAP0007)MounirNo ratings yet

- VP210 En002Document22 pagesVP210 En002Praveen KumarNo ratings yet

- Pe 97240 DsDocument21 pagesPe 97240 Dskhanafzaal2576No ratings yet

- Datasheet IBB SystemsDocument4 pagesDatasheet IBB SystemsLaura Daniela GavrilasNo ratings yet

- API DC Input SplittersDocument6 pagesAPI DC Input SplittersAnonymous zdCUbW8HfNo ratings yet

- KFD0 SD2 Ex1Document3 pagesKFD0 SD2 Ex1guardjacoNo ratings yet

- 01.spa CatlogDocument16 pages01.spa CatlogRavinder Gulair100% (1)

- TM221CE24R: Product DatasheetDocument9 pagesTM221CE24R: Product DatasheetNuttakan AsapaviriyaNo ratings yet

- NXP Tja1050Document18 pagesNXP Tja1050Sebastian BryceNo ratings yet

- Siemens Climatix IO ModuleDocument10 pagesSiemens Climatix IO Moduleamitdesai1508No ratings yet

- KFD2 VR4 EX1.26 196355 EngDocument4 pagesKFD2 VR4 EX1.26 196355 EngDurgaram JayavananNo ratings yet

- Signal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsDocument11 pagesSignal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsFeela NazNo ratings yet

- PKK 3 S 03 A 0601 ADocument2 pagesPKK 3 S 03 A 0601 AdfsklnsdfklnsdfNo ratings yet

- Kfd2 Scd2 2.LkDocument3 pagesKfd2 Scd2 2.Lkpradeepchennai10_9590% (1)

- IEC-Compliant Electricity Meter Technical SpecsDocument6 pagesIEC-Compliant Electricity Meter Technical Specsroadkill7No ratings yet

- User Manual Sepam 20-1Document78 pagesUser Manual Sepam 20-1Ursula JohnsonNo ratings yet

- TDA8925Document23 pagesTDA8925Mahmoued YasinNo ratings yet

- E560 23WT23 DSDocument4 pagesE560 23WT23 DSSalvador FayssalNo ratings yet

- I Sol TesterDocument29 pagesI Sol TesterDrayton Mizael de SouzaNo ratings yet

- Scanner: Monitor. Protect. Control. Visualize. CommunicateDocument2 pagesScanner: Monitor. Protect. Control. Visualize. CommunicateThanhha NguyenNo ratings yet

- User Manual ISOLTESTER-DIGDocument23 pagesUser Manual ISOLTESTER-DIGJuan Alberto Cayetano GomezNo ratings yet

- D1064 Ism0088 enDocument11 pagesD1064 Ism0088 enAmer CajdricNo ratings yet

- Datasheet ATV61EXS5C63N4Document8 pagesDatasheet ATV61EXS5C63N4flake03No ratings yet

- Phoenix - MCR - CLP - I - I - 00 - 5105625Document6 pagesPhoenix - MCR - CLP - I - I - 00 - 5105625Alejandro Cortes BoladosNo ratings yet

- Benning Products BrochureDocument14 pagesBenning Products BrochureGlen FordNo ratings yet

- Data Sheet Inverter INV222 48VDCDocument2 pagesData Sheet Inverter INV222 48VDCSharmin SultanaNo ratings yet

- MC 34825Document39 pagesMC 34825chshfeng100% (1)

- Advanced Motion Controls Dq111se25a20nacDocument7 pagesAdvanced Motion Controls Dq111se25a20nacElectromateNo ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Conversion of 60870 To IEC61850 Using Toshiba RelayDocument9 pagesConversion of 60870 To IEC61850 Using Toshiba RelayEshwar MadiwalNo ratings yet

- Pepperl Fuchs KFU8 USC 1DDocument2 pagesPepperl Fuchs KFU8 USC 1DAlejandro AlegriaNo ratings yet

- DK PC3000 ModulesDocument11 pagesDK PC3000 ModulessickosatNo ratings yet

- RF2125 High Power Linear Amplifier IC DatasheetDocument6 pagesRF2125 High Power Linear Amplifier IC Datasheetmichaelliu123456No ratings yet

- 10gigabit XFP Optical ReceiverDocument6 pages10gigabit XFP Optical ReceivermichelNo ratings yet

- UP220-AE-A Power SupplyDocument8 pagesUP220-AE-A Power SupplyAndy WilsonNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- MMQCDocument4 pagesMMQCkfd2No ratings yet

- Modicon Quantum Automation Platform 600558000Document1 pageModicon Quantum Automation Platform 600558000kfd2No ratings yet

- Magelis XBTR XBTR411Document4 pagesMagelis XBTR XBTR411kfd2No ratings yet

- Overview of The Steelmaking Process PDFDocument2 pagesOverview of The Steelmaking Process PDFŞükrü_talaş100% (2)

- DatashKFD2eet 1Document3 pagesDatashKFD2eet 1kfd2No ratings yet

- Altivar 71 Plus Atv71exa5c80yDocument7 pagesAltivar 71 Plus Atv71exa5c80ykfd2No ratings yet

- 120mm Red 24V Rotating Beacon Data SheetDocument3 pages120mm Red 24V Rotating Beacon Data Sheetkfd2No ratings yet

- VFD BasicsDocument7 pagesVFD Basicskfd2No ratings yet

- ATV312HU75N4: Product Data SheetDocument3 pagesATV312HU75N4: Product Data Sheetkfd2No ratings yet

- Des Ti Lin at IonDocument7 pagesDes Ti Lin at Ionapi-3703633No ratings yet

- Kfa6 Er 1.6Document2 pagesKfa6 Er 1.6kfd2No ratings yet

- Food and Beverage Processing Soft DrinkDocument9 pagesFood and Beverage Processing Soft Drinkkfd2No ratings yet

- Cement Directory SampleDocument19 pagesCement Directory SampleJigish MistryNo ratings yet

- Offshore Oil and ProdDocument101 pagesOffshore Oil and ProdSuresh Erath100% (5)

- Hid2101/Dc: 1 Position Termination Board For Din Rail MountingDocument2 pagesHid2101/Dc: 1 Position Termination Board For Din Rail Mountingkfd2No ratings yet

- Computer-Basics - Computer Basics2Document43 pagesComputer-Basics - Computer Basics2api-216226726No ratings yet

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=resorts_hotels_Chickmagalur%5B1%5D.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: e60a116c930022fe4d61f2afa60598ebeebb9f8f User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/27.0.1453.110 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=11225Document6 pages<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=resorts_hotels_Chickmagalur%5B1%5D.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: e60a116c930022fe4d61f2afa60598ebeebb9f8f User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/27.0.1453.110 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=11225kfd2No ratings yet

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Problem+solvers+in+signal+conditioning+_+ISA.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: e60a116c930022fe4d61f2afa60598ebeebb9f8f User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/27.0.1453.110 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archiveDocument4 pages<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Problem+solvers+in+signal+conditioning+_+ISA.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: e60a116c930022fe4d61f2afa60598ebeebb9f8f User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/27.0.1453.110 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archivekfd2No ratings yet

- A Young Persons Guide To Success in Life - Swami SivanandaDocument32 pagesA Young Persons Guide To Success in Life - Swami SivanandaAnonymous DLEF3GvNo ratings yet

- Art of Intrinsically SafeDocument29 pagesArt of Intrinsically Safearomero888No ratings yet

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Rockwell+Automation+Plant+PAx+System.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: e60a116c930022fe4d61f2afa60598ebeebb9f8f User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/27.0.1453.110 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=104Document44 pages<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Rockwell+Automation+Plant+PAx+System.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: e60a116c930022fe4d61f2afa60598ebeebb9f8f User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/27.0.1453.110 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=104kfd2No ratings yet

- Choosing A Method of Explosion Protection: Serious About SafetyDocument2 pagesChoosing A Method of Explosion Protection: Serious About Safetykfd2No ratings yet

- Transend Music Player ManualDocument76 pagesTransend Music Player Manualkfd2No ratings yet

- Technical - GLD - INDUCTION FURNACEDocument2 pagesTechnical - GLD - INDUCTION FURNACEAkash Sharma100% (3)

- Plastic Analysis AssignmentDocument6 pagesPlastic Analysis AssignmentLeo DoeNo ratings yet

- Three-Phase Rectifier Using A Sepic DC-DC Converter in Continuous Conduction Mode For Power Factor CorrectionDocument7 pagesThree-Phase Rectifier Using A Sepic DC-DC Converter in Continuous Conduction Mode For Power Factor CorrectionuakragunathanNo ratings yet

- 3adw000078r0301 Dcs5 Software Descr e CDocument228 pages3adw000078r0301 Dcs5 Software Descr e Caninda_dNo ratings yet

- Optimal Design of Cooling Water Systems: August 2011Document23 pagesOptimal Design of Cooling Water Systems: August 2011Hansraj RahulNo ratings yet

- Behaviour of Continuous Pipeline Subject To Transverse PGD: Xuejie Liu S and Michael J. O'RourketDocument15 pagesBehaviour of Continuous Pipeline Subject To Transverse PGD: Xuejie Liu S and Michael J. O'RourketMarcelo Andrés Rojas GonzálezNo ratings yet

- Horn SystemDocument9 pagesHorn SystemMirceaNo ratings yet

- Astor: Test TransformerDocument1 pageAstor: Test TransformermominzadahNo ratings yet

- Manual - IR Nirvana Troubleshooting GuideDocument63 pagesManual - IR Nirvana Troubleshooting GuideKurserg92% (51)

- Garnituri DIN 2697Document12 pagesGarnituri DIN 2697Dumitru SorinaNo ratings yet

- Foton Operation and Miantenance Manuai For View Series Light BusDocument279 pagesFoton Operation and Miantenance Manuai For View Series Light BusHarlinton descalzi82% (17)

- Application HydrostaticsDocument23 pagesApplication HydrostaticsHASSAN ARSHADNo ratings yet

- Alan Electronics' Story of Quality, Consistency and ReliabilityDocument6 pagesAlan Electronics' Story of Quality, Consistency and Reliabilitysathishsutharsan87No ratings yet

- The Digital Mine - 2022Document66 pagesThe Digital Mine - 2022majidNo ratings yet

- Hänchen Range From The Cylinder To The Complete Drive SystemDocument21 pagesHänchen Range From The Cylinder To The Complete Drive SystemSympatyagaNo ratings yet

- Jean Dubuis - Initiatory Alchemical TreatiseDocument7 pagesJean Dubuis - Initiatory Alchemical Treatiseeljedioscuro100% (1)

- PTK MateriDocument101 pagesPTK MateriAnnisah MardiyyahNo ratings yet

- Series 150 Overshot Make Up Torques PDFDocument8 pagesSeries 150 Overshot Make Up Torques PDFRazvan RaduNo ratings yet

- Description Features: Ait Semiconductor IncDocument10 pagesDescription Features: Ait Semiconductor IncMaktum KamatNo ratings yet

- Implementation of The Behavior of A Particle in A Double-Well Potential Using The Fourth-Order Runge-Kutta MethodDocument3 pagesImplementation of The Behavior of A Particle in A Double-Well Potential Using The Fourth-Order Runge-Kutta MethodCindy Liza EsporlasNo ratings yet

- Efficient Artificial Lighting Systems For Apparel Stores: Sailee RaisoniDocument3 pagesEfficient Artificial Lighting Systems For Apparel Stores: Sailee RaisoniSailee Raisoni BafnaNo ratings yet

- Mehdi Rahmani Andebili Differential Equations Practice ProblemsDocument109 pagesMehdi Rahmani Andebili Differential Equations Practice ProblemsvdeodaatoNo ratings yet

- Beam Powered PropulsionDocument19 pagesBeam Powered PropulsionSai Sushma100% (1)

- Wet Granulation End-Point DeterminationDocument18 pagesWet Granulation End-Point DeterminationPreeti Wavikar-PanhaleNo ratings yet

- Field Bus CommunicationDocument30 pagesField Bus CommunicationArun KumarNo ratings yet

- Request For Information: 8 June 2020Document11 pagesRequest For Information: 8 June 2020Mhae PotNo ratings yet

- Toyota YarisDocument5 pagesToyota YarisMohammed Yusuf100% (1)

- Installation Instructions For The TBLZ-1-27-a, Set of Electrical Connections For Air Heater/air Cooler, Water GOLD, Version E/FDocument2 pagesInstallation Instructions For The TBLZ-1-27-a, Set of Electrical Connections For Air Heater/air Cooler, Water GOLD, Version E/FKaptinNo ratings yet

- Smart Grid in IndiaDocument17 pagesSmart Grid in Indiatejomayi100% (1)

- Mas and e PDFDocument5 pagesMas and e PDFtulasi saladiNo ratings yet