Professional Documents

Culture Documents

RCA26 AK BK EK User Manual PDF

Uploaded by

Marcus DragoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCA26 AK BK EK User Manual PDF

Uploaded by

Marcus DragoCopyright:

Available Formats

KMC PUBLICATION NO.

1403

RCA 26 SERIES

ATTITUDE GYRO

INSTALLATION/OPERATION GUIDE

RCA26 AK/BK

RCA26 EK

KMC

KELLY MANUFACTURING COMPANY

KELLY MANUFACTURING COMPANY

555 SOUTH TOPEKA

WICHITA, KS 67202

(316) 265-6868

FAX (316) 265-6687

KELLYMFG.COM

RCA 26 Series Installation/Operation Guide

KMC

KELLY MANUFACTURING COMPANY

TABLE OF CONTENTS

PAGE

SECTION 1 INSTRUMENT DESCRIPTION

3

1.1 General Description............................................. 3

1.2 Physical Description............................................. 3

1.3 Display Features.................................................. 5

1.4 Options and Configurations................................. 6

SECTION 2

INSTALLATION

6

2.1 General Information............................................. 6

2.2 Handling.............................................................. 6

2.3 Pre-Installation Inspection................................... 6

2.4 Installation........................................................... 7

SECTION 3 OPERATION

7

3.1 Pre-Flight Procedures.......................................... 7

3.2 In-Flight Procedures............................................ 7

3.3 Flight Limitations.................................................. 8

3.4 Emergency Procedures....................................... 8

Frequently Asked Questions............................ 8

LIST OF ILLUSTRATIONS

Figure 1.1, General Dimensions.................................. 4

Figure 1.2, Dial Features............................................. 5

LIST OF TABLES

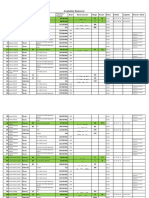

Table 1.1, Leading Particulars...................................... 3

Table 1.2, Options and Configurations......................... 6

REVISION DETAIL

REVISION

DATE

07/03/2008

Page 2 of 8

DETAIL

Initial Release

KMC Publication No.1403

Rev A

RCA 26 Series Installation/Operation Guide

KMC

KELLY MANUFACTURING COMPANY

SECTION 1: INSTRUMENT DESCRIPTION

1.1 GENERAL DESCRIPTION

An attitude indicator, also known as a gyro horizon or artificial horizon, is an instrument used in an aircraft to inform the pilot of the

orientation of the airplane relative to the earth. It indicates pitch (fore and aft tilt) and bank (side to side tilt), and is a primary instrument for flight in instrument meteorological conditions. Attitude indicators also have significant applications under visual flight rules.

The gyroscope actuates a display that has two dimensions of freedom, simultaneously displaying pitch and bank. The display is

colored to indicate the horizon as the division between the two colored segments (typically, blue for sky and brown for ground),

and is intended to be intuitive to use. The actual bank angle is calibrated around the circumference of the instrument dial. The pitch

angle is indicated by a series of calibration lines, each representing 5 or 10 of pitch.

The electrically powered gyroscope rotor not only has the mass to create the gyroscopic effect, it has impeller blades which creates airflow. This airflow from the impeller works with gravity-actuated vanes that direct jets of air to automatically level the gyro.

Attitude indicators can only tolerate a specific range of bank angles. If the aircraft rolls too steeply - while performing aerobatics, for

example - the attitude indicator can tumble and become temporarily unusable. For this reason, the indicator is fitted with a cage

(a device to restore the gyroscope to an level position.) The RCA 26 Series attitude indicators will however, gradually re-erect back

to level after a tumble.

On the attitude indicator you will see two yellow horizontal lines with a dot between them. The horizontal lines represent the wings

and the dot represents the nose of the aircraft. If the symbolic airplane dot is above the horizon line (more blue background) - the

aircraft is nose up. If the symbolic airplane dot is below the horizon line (more brown background) - the aircraft is nose down.

When the dot and wings are on the horizon line, you are in level flight. If the lines representing the wings roll to the left or the right,

the aircraft is probably starting a turn.

1.2 PHYSICAL DESCRIPTION

The RCA 26 indicator is a gasket sealed, direct reading instrument which provides a visual display of aircraft pitch and roll in reference to the horizon. Refer to table 1.1 below for leading particulars.

OPERATING VOLTAGE

(RCA26AK Models).......................................................................................... 14VDC

(RCA26BK Models).......................................................................................... 28VDC

(RCA26EK Models)......................................................................... 10VDC to 30VDC

STARTING CURRENT

(RCA26AK Models)............................................................................... 2.4 AMP MAX

(RCA26BK Models)............................................................................... 1.4 AMP MAX

(RCA26EK Models).................................................. 14VDC SYSTEM: 2.4 AMP MAX

................................................................................. 28VDC SYSTEM: 1.4 AMP MAX

RUNNING CURRENT

(RCA26AK Models)............................................................................. 1.21 AMP MAX

(RCA26BK Models)............................................................................. 0.62 AMP MAX

(RCA26EK Models)................................................ 14VDC SYSTEM: 1.21 AMP MAX

............................................................................... 28VDC SYSTEM: 0.62 AMP MAX

ILLUMINATING VOLTAGE

(RCA26AK Models)................................................................................... 0 to 14VDC

(RCA26BK Models)................................................................................... 0 to 28VDC

(RCA26EK Models)................................................................................... 0 to 28VDC

CIRCUIT BREAKER SIZE

(RCA26AK Models)........................................................................................... 3 AMP

(RCA26BK Models)........................................................................................... 2 AMP

(RCA26EK Models)............................................................. 14VDC SYSTEM: 3 AMP

.............................................................................................28VDC SYSTEM: 2 AMP

SETTLING ERROR.............................................................................................................................1 MAXIMUM IN ROLL AND PITCH

OPERATING TEMPERATURE RANGE.............................................................................................................................. -30 TO +50 C

DIMENSIONS......................................................................................................................................................................SEE FIGURE 1

PANEL CUTOUT..................................................................................................................................................................SEE FIGURE 1

FAA SPECIFICATION CONFORMANCE........................................................................................................................................TS0-C4c

TABLE 1.1, LEADING PARTICULARS

Rev A

KMC Publication No.1401

Page 3 of 8

KMC

RCA 26 Series Installation/Operation Guide

0.125

KELLY MANUFACTURING COMPANY

6.35

0.45

3.125

CONNECTOR, MS3112E8-4P

(MATES WITH MS3116E8-4S

OR EQUIVALENT)

1.10

SIDE VIEW

1.19

6-32 UNC-2B THD

(3 PL)

20

3.38

(2 PL)

CONNECTOR PIN DESIGNATION

PIN A

GROUND

PIN B

SPARE

PIN C

+12 - 30 VDC

PIN D

SPARE

CONNECTOR MATES WITH

MS3116E8-4S OR EQUIVALENT

20

10

10

10

10

20

20

0.80

PU L L

TO

CA

GE

0.75

0.50

0.80

REAR VIEW

FRONT VIEW

3.17

.170 THRU

(3 PL)

1.237

(2 PL)

2.474

(2 PL)

NOTE

All measurements in inches.

R .187

PANEL CUTOUT

(REAR MOUNTING)

Figure 1.1, General Dimensions

Page 4 of 8

KMC Publication No.1403

Rev A

RCA 26 Series Installation/Operation Guide

KMC

KELLY MANUFACTURING COMPANY

1.3 DISPLAY FEATURES

See Figure 1.2 below for typical display features. Colors and graphics vary with each model (RCA26 EK-11 shown).

1 ROLL POINTER

2 ROLL DIAL

3 POWER FLAG

8 PITCH DIAL

4 HORIZON LINE

7 SYMBOLIC

AIRPLANE

6 SYMBOLIC

AIRPLANE

ADJUST

5 CAGING KNOB

Figure 1.2, Typical Display Features

1. ROLL POINTER

Whether fixed or rotating (depending on indicator style), the Roll Pointer points to the degree of roll against the Roll Dial.

2. ROLL DIAL

Whether fixed or rotating (depending on indicator style), The Roll Dial shows the degree of roll against the Roll Pointer.

3. POWER FLAG

Indicates when operational power is supplied to the instrument. Flag moves out of view when adequate power is applied to

instrument.

4. HORIZON LINE

Indicates earth horizon relative to aircraft pitch and roll.

5. CAGING KNOB

Re-sets the instrument dial to show as level.

6. SYMBOLIC AIRPLANE ADJUST

Adjusts the Symbolic Airplane to compensate for viewing parallax. Adjust Symbolic Airplane so that it is visually aligned with

the horizon from pilots normal sitting position.

7. SYMBOLIC AIRPLANE

Represents the orientation of the aircrafts wings and nose in relation to the horizon. The dot represents the nose of the aircraft and indicates Pitch. The wings indicate roll.

8. PITCH DIAL

Indicates the Pitch angle as determined by the Symbolic Airplane dot.

Rev A

KMC Publication No.1401

Page 5 of 8

RCA 26 Series Installation/Operation Guide

KMC

KELLY MANUFACTURING COMPANY

1.4 OPTIONS AND CONFIGURATIONS

For available options and configurations, refer to Table 1.2, below.

Panel Tilt Calibration

0 to 18, set to customer requirements

Mating Connector

MS316E8-4S or equivalent

Lighting

Optional (user specified voltage)

Slip Indicator

Optional add-on (order RCA 444-0011-01)

Color Scheme

Available in Various color schemes

Display pointer style

Available as either stationary or rotating

Power Flag

All models

Symbolic Airplane Adjust

All models

Caging knob

All models

Table 1.2, Options and Configurations

SECTION 2, INSTALLATION

2.1 GENERAL INFORMATION

The conditions and tests required for the TSO approval of this article are minimum performance standards. It is the responsibility

of those installing this article either on or within a specific type or class of aircraft to determine that the aircraft installation conditions are within the TSO standards. TSO articles must have a separate approval installation in an aircraft. Installation must only be

performed under 14CFR Part 43 or the applicable airworthiness requirements.

2.2 HANDLING

-CAUTION-

Gyroscopic instruments are easily damaged by improper handling. Please follow all handling precautions to

prevent damage to the gyro.

Gyros are very delicate instruments. Please observe the following precautions while handling.

1. A high gyroscope failure rate can be attributed to poor handling. Do not drop, jar or shake instrument. Store

instrument in shipping container until installation. Avoid placing instrument on hard surfaces. Place on padded

surface only.

2. Gyros should be transported in the original shipping container when moved to and from aircraft. If container is not

available, carefully carry by hand in upright position.

3. Never move the instrument while the gyro is still spinning. Excessive movement while gyro is spinning may damage

gimbal bearings.

4. To prevent further damage, a malfunctioning instrument should be handled as carefully as a new instrument. Most

malfunctioning gyros can be repaired and returned to service. Contact Kelly Manufacturing Co. for repair information.

2.3 PRE-INSTALLATION INSPECTION

1. When instrument is first received, inspect container for any shipping damage.

2. Carefully remove instrument from shipping container and retain container for later storage or shipping.

3. Inspect instrument for any signs of damage. Contact your Shipper to file any claim due to shipping damage.

Page 6 of 8

KMC Publication No.1403

Rev A

RCA 26 Series Installation/Operation Guide

KMC

KELLY MANUFACTURING COMPANY

2.4 INSTALLATION

NOTE

Before installation, check labeling on the instrument to assure that the instrument voltage and panel tilt angle is

correct for your aircraft.

Install the instrument on the aircraft by using the aircraft manufacturers recommendations and by the following steps:

1. The RCA26 Series horizon uses the standard 3 1/8 inch panel cutout. Refer to figure 1.1 General Dimensions for

instrument and cutout dimensions.

2. Refer to label on back of instrument for correct pin designation. See table 1.1 Leading Particulars for additional

electrical information.

3. Attach aircraft electrical connector to instrument and insert the instrument into the instrument panel cutout.

4. With the aircraft on level surface, level the instrument using an L bubble level on the lip of the bezel at the bottom

of the glass and adjust the instrument until the bubble is centered.

5. Secure instrument with user supplied screws. Use 6-32 UNC-2b screws or equivalent. Screw length should not

exceed .38 inches plus bezel and panel thickness.

6. Apply power to instrument. Observe that the Power Flag moves out of view and lighting (if installed) is working

properly.

SECTION 3, OPERATION GUIDE

3.1 PRE-FLIGHT PROCEDURES

During pre-flight procedures, the attitude gyro must be provided with adequate electrical power under normal vibration conditions

(engine running). Allow a minimum of three minutes for the gyro to settle to true level.

The gyro will normally settle to true level on its own but you may level the gyro presentation if desired by pulling the PULL TO

CAGE knob. The caging knob is spring-loaded to return the caging mechanism to return to normal position.

-CAUTION-

Do not allow the caging knob to snap back to the normal position by prematurely releasing the knob from the

pulled position. Use a steady pull until the gyro presentation has stopped moving and indicates level in both

pitch and roll. Gently release the knob to return it to the spring-loaded position.

NOTE

On tail-dragger aircraft, caging should be done after take-off and after achieving level flight.

Adjust the Symbolic Airplane to visually align the wings with the horizon line. This adjustment compensates for viewing parallax

error (pilots viewing angle).

3.2 IN-FLIGHT PROCEDURES

In flight, you may cage the unit at any time as needed. You may also adjust the Symbolic Airplane indicator at any time.

WARNING

Caging the gyro while in flight when the aircraft is not level will cause the level indication to be incorrect. The

gyro must be allowed a few minutes to settle to True Level before it can be safely relied upon. The gyro is settled

when both pitch and roll indications remain constant.

If you must cage the gyro while in flight, it is best to have your aircraft as close to level flight as possible. The closer to level the

aircraft, the quicker the gyro will settle to True Level.

Rev A

KMC Publication No.1401

Page 7 of 8

RCA 26 Series Installation/Operation Guide

KMC

KELLY MANUFACTURING COMPANY

3.3 FLIGHT LIMITATIONS

It is not recommended to perform aerobatic maneuvers while using the RCA26 Series Attitude Indicator. Extreme maneuvers will

cause the instrument to show an error and will become unreliable as a reference to the horizon. Damage to the instrument may

also occur under these conditions. Turn the unit off at least 5 minutes before performing any extreme maneuvers to allow the gyro

to spin down.

3.4 EMERGENCY PROCEDURES

In the event that the Power Flag comes into view, the accuracy of the instrument becomes unreliable until the flag moves back out

of view. The Power Flag is actuated by the amount of voltage to the instrument and will display in the off position when less than

minimum voltage is available to the instrument. A thorough check of the instrument power source is recommended if this situation

should occur.

Frequently Asked Questions

How long should my gyro last?

There are many factors that determine the life of a gyro. We have seen gyros with everything from corrosion from sea air to

excessive bearing wear from rough landings. Ideally you should receive hundreds of hours of use, but it is completely dependent

on how the unit is treated and the environment in which it is used. If a gyro sits stationary for a long period of time, the bearings

become unusable. The gyro should be run at least once a month to keep the bearings lubricated.

At what voltage level will my gyro become unreliable?

For the RCA26 AK (14VDC system), a minimum of 12VDC is required for the unit to operate accurately.

For the RCA26 BK (28VDC system), a minimum of 26.5VDC is required for the unit to operate accurately.

For the RCA26EK a minimum of 10VDC is required for the unit to operate accurately.

What is the recommended circuit breaker for my gyro?

Starting current for a 14VDC system is 2.4A max. with a recommended circuit breaker of 3A.

Starting current for a 28VDC system is .6A max. with a recommended circuit breaker of 2A.

Starting currents and circuit breakers for the RCA26 EK series are the same as above depending on the voltage system of the

aircraft.

My instrument is showing a climb/dive, what can I do?

You can check your aircraft owners manual or contact the aircraft manufacturer to determine if your aircrafts instrument panel

is tilted (pitched fore and aft). The tilt angle is any deviation from vertical of your instrument panel in level flight. Your instrument

needs to be calibrated to compensate for this angle.

My instrument is showing a turn in level flight, what can I do?

It is very important to have the instrument level (left and right) in your panel. If the instrument is not level, it will show a turn when

in level flight. To level the instrument place an L bubble level on the lip of the bezel at the bottom of the glass and adjust the

instrument until the bubble is centered.

How do I get my instrument repaired?

For any overhaul or repair questions you can contact Kelly Manufacturing Company. Our Service Center can repair or refurbish

any R.C. Allen instrument. The only thing really required is information. You can send us your instrument with a letter giving us

your name, return shipping address, phone number and a brief description of what is wrong with the instrument. Email us for more

information: SERVICE@KELLYMFG.COM.

Page 8 of 8

KMC Publication No.1403

Rev A

You might also like

- RCA2600 User Manual Rev C PDFDocument9 pagesRCA2600 User Manual Rev C PDFMarcus DragoNo ratings yet

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsFrom EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNo ratings yet

- Penn Avionics Autopilot repair procedures 11/26/2006Document3 pagesPenn Avionics Autopilot repair procedures 11/26/2006mahmoodchowdhuryNo ratings yet

- Popular Science - Volume 1 (1872)Document792 pagesPopular Science - Volume 1 (1872)Cem AvciNo ratings yet

- S-TEC 20-30 ManualDocument30 pagesS-TEC 20-30 ManualAlexNo ratings yet

- The ARC Navomatic 300A Autopilot: A Concise GuideDocument14 pagesThe ARC Navomatic 300A Autopilot: A Concise GuideJoão AlmeidaNo ratings yet

- Modeling BCI Setup for IC TestsDocument6 pagesModeling BCI Setup for IC TestsSanthosh LingappaNo ratings yet

- 2-4 Calibration of RF Attenuators - Katsumi FUJIDocument14 pages2-4 Calibration of RF Attenuators - Katsumi FUJIRafael GarzónNo ratings yet

- Directional Gyro Indicators: Handbook Operation - Service and Overhaul Instruction With Parts CatalogDocument192 pagesDirectional Gyro Indicators: Handbook Operation - Service and Overhaul Instruction With Parts CatalogsdghjaklNo ratings yet

- #&lliedsignal: Bendix/King"Document35 pages#&lliedsignal: Bendix/King"locoboeingNo ratings yet

- Automotive Component EMC Testing 2011Document9 pagesAutomotive Component EMC Testing 2011Bernardo NGNo ratings yet

- DO-160G Section 21 1Document1 pageDO-160G Section 21 1JizzPontesNo ratings yet

- S-Tec Servos CheckDocument2 pagesS-Tec Servos Checkthilo eckardtNo ratings yet

- S-TEC 55 TrainingDocument40 pagesS-TEC 55 TrainingbibiNo ratings yet

- 0903 Aircraft WiringDocument36 pages0903 Aircraft Wiringmatteo_1978No ratings yet

- 3300 Series Directional Gyro PDFDocument12 pages3300 Series Directional Gyro PDFHanh Trung Nguyen DucNo ratings yet

- Test PanelsDocument20 pagesTest PanelsumeshNo ratings yet

- Low-Cost Wearable Head-Up Display For Flight General AviationDocument144 pagesLow-Cost Wearable Head-Up Display For Flight General AviationManoj RaiNo ratings yet

- Manual of Avionics PDFDocument300 pagesManual of Avionics PDFJhony BhatNo ratings yet

- Flight Line Service Manual For Rate Based AutopilotsDocument115 pagesFlight Line Service Manual For Rate Based AutopilotsMark JuhrigNo ratings yet

- Sperry Attitude GyroDocument3 pagesSperry Attitude Gyroriggl100% (1)

- RadioLink AT10II User ManualDocument84 pagesRadioLink AT10II User ManualMiguel Sanchez100% (1)

- C406-2 570-5000 Rev LDocument65 pagesC406-2 570-5000 Rev LKumaraswamy RSNo ratings yet

- Type Cert A718Document6 pagesType Cert A718skatterbrainkidNo ratings yet

- Parts Catalog For Engine SeriesDocument72 pagesParts Catalog For Engine Seriesjuantalamera63299No ratings yet

- GPS ManualDocument8 pagesGPS ManualHenny FerijantoNo ratings yet

- Rate Based Autopilot Service ManualDocument115 pagesRate Based Autopilot Service ManualEdu Ortega100% (1)

- MX780HD ManualDocument50 pagesMX780HD Manualmjolly1045No ratings yet

- Cessna Aircraft Company: Wichita AnsasDocument252 pagesCessna Aircraft Company: Wichita AnsasFábio FariaNo ratings yet

- Me 1000RW PDFDocument25 pagesMe 1000RW PDFCarlaine Martins VieiraNo ratings yet

- Ac 43-13 2aDocument103 pagesAc 43-13 2aBoby1985No ratings yet

- Aircraft Electric Equipment Selection and Installation StandardsDocument26 pagesAircraft Electric Equipment Selection and Installation StandardsqingtaoNo ratings yet

- Installation Manual Installation Manual Installation Manual Installation ManualDocument74 pagesInstallation Manual Installation Manual Installation Manual Installation ManualversineNo ratings yet

- Avionic Repair Shop Manual Initial Draft Oct 2019Document30 pagesAvionic Repair Shop Manual Initial Draft Oct 2019Jake C Cee100% (1)

- NSD 360Document231 pagesNSD 360Sidinei Matucci100% (1)

- STC Directory - RevK March 20 2012Document152 pagesSTC Directory - RevK March 20 2012mahmoodchowdhury100% (1)

- Side Scan SonarDocument4 pagesSide Scan SonarMuh ItsnaniNo ratings yet

- E BasicsDocument18 pagesE BasicsEnache Daniel-EmanuelNo ratings yet

- Tcds Easa r009 Ahd Ec135 Issue 13Document102 pagesTcds Easa r009 Ahd Ec135 Issue 13forumid2697No ratings yet

- Installation Manual: 9900 Series Models 9900, 9900A and 9900BDocument68 pagesInstallation Manual: 9900 Series Models 9900, 9900A and 9900BRandy SharpNo ratings yet

- Cirrus DFC 90 Autopilot Pilots GuideDocument71 pagesCirrus DFC 90 Autopilot Pilots GuideGeorge MeierNo ratings yet

- Stalker Stationary Speed Sensor II Technical ManualDocument71 pagesStalker Stationary Speed Sensor II Technical ManualRenzo Ticona OlazabalNo ratings yet

- AST Composite Wing ProgrammeDocument98 pagesAST Composite Wing Programmeismailovic2No ratings yet

- Slaa 024Document1,088 pagesSlaa 024davidengautNo ratings yet

- Hoist GOODRICH 42325-R - Plaquette InfoDocument2 pagesHoist GOODRICH 42325-R - Plaquette InfoGmeweb GmeNo ratings yet

- DCS World List of All Available Beacons enDocument9 pagesDCS World List of All Available Beacons enJeremy GilesNo ratings yet

- AC 20-192 Draft Non-Rechargeable Lithium BatteriesDocument46 pagesAC 20-192 Draft Non-Rechargeable Lithium BatteriesK COXNo ratings yet

- An Arn 6Document2 pagesAn Arn 6Prinses1234567No ratings yet

- Balancing Tail RotorsDocument14 pagesBalancing Tail Rotorsjmam1992No ratings yet

- ABCD-SDE-24-00 - Electrical System Description and Load Analysis - 17.02.16 - V1Document9 pagesABCD-SDE-24-00 - Electrical System Description and Load Analysis - 17.02.16 - V1Edgar MartínezNo ratings yet

- Calibrate Your Airspeed IndicatorDocument2 pagesCalibrate Your Airspeed IndicatorReginaldoNo ratings yet

- Eaa Flight Reports - Aeronca ChampDocument4 pagesEaa Flight Reports - Aeronca ChampIdiosocraticNo ratings yet

- Sandel SN3500 IM CDocument133 pagesSandel SN3500 IM CHouvenaghel100% (1)

- Tso C139Document5 pagesTso C139Russell GouldenNo ratings yet

- Designing a Personal Aerial VehicleDocument86 pagesDesigning a Personal Aerial Vehicletdit84No ratings yet

- AMT110 Communication and Navigation Chapter 11Document94 pagesAMT110 Communication and Navigation Chapter 11Vy Thoai100% (1)

- Sensors for Automotive ApplicationsFrom EverandSensors for Automotive ApplicationsJiri MarekRating: 5 out of 5 stars5/5 (1)

- ENG DS 1-1773704-7 369series 1122Document24 pagesENG DS 1-1773704-7 369series 1122Marcus DragoNo ratings yet

- 107-116 Deu 369 SeriesDocument10 pages107-116 Deu 369 SeriesMarcus DragoNo ratings yet

- 1295 8 - Acusb OuDocument2 pages1295 8 - Acusb OuMarcus DragoNo ratings yet

- 1327-21 USBOU TypeC TypeA DatasheetDocument2 pages1327-21 USBOU TypeC TypeA DatasheetMarcus DragoNo ratings yet

- Ki 256 sb11Document7 pagesKi 256 sb11Marcus Drago100% (1)

- KFC 300 Flight Control System PA 42 CheyenneDocument38 pagesKFC 300 Flight Control System PA 42 CheyenneMarcus DragoNo ratings yet

- Cessna Citation II y VDocument657 pagesCessna Citation II y VJohnnys100% (3)

- SR22G3 WBDocument2 pagesSR22G3 WBMarcus DragoNo ratings yet

- 1215 CIM ATA 24 50 05 Rev 13Document115 pages1215 CIM ATA 24 50 05 Rev 13Marcus Drago100% (1)

- Lumatech Brochure King Air C90Document4 pagesLumatech Brochure King Air C90Marcus DragoNo ratings yet

- KFC-150 - Instalation Manual 006-10552-0003 - 3Document0 pagesKFC-150 - Instalation Manual 006-10552-0003 - 3Marcus DragoNo ratings yet

- Kap 140Document31 pagesKap 140Marcus DragoNo ratings yet

- 640f7196a2af9f6d051084fe - MC2 - Outlet Combination - 2019-09-17Document2 pages640f7196a2af9f6d051084fe - MC2 - Outlet Combination - 2019-09-17Marcus DragoNo ratings yet

- 014 KSN 780 - 8XX - 9XX AeroNav AML STC Installation Manual For HelicoptersDocument228 pages014 KSN 780 - 8XX - 9XX AeroNav AML STC Installation Manual For HelicoptersHuda LestraNo ratings yet

- KFC 150 Manual's GuideDocument117 pagesKFC 150 Manual's GuideJuan Sandoval SNo ratings yet

- Kap 140Document102 pagesKap 140alex castroNo ratings yet

- PDFDocument128 pagesPDFdaniNo ratings yet

- KFC-150 - Instalation Manual 006-10552-0003 - 3Document0 pagesKFC-150 - Instalation Manual 006-10552-0003 - 3Marcus DragoNo ratings yet

- KAP140, IM, 006 00991 0006, Rev.6, Oct2002Document94 pagesKAP140, IM, 006 00991 0006, Rev.6, Oct2002esedgarNo ratings yet

- Honeywell Employee Americas Document UP793797Document24 pagesHoneywell Employee Americas Document UP793797alex castroNo ratings yet

- Pilot Guide 006 08248 0003 - 3 PDFDocument34 pagesPilot Guide 006 08248 0003 - 3 PDFYuka ImaiNo ratings yet

- Kas 297aDocument4 pagesKas 297aMarcus DragoNo ratings yet

- Maintenance Manual: ServoDocument128 pagesMaintenance Manual: ServolocoboeingNo ratings yet

- CVII Honeywell NAVDocument412 pagesCVII Honeywell NAVFernando Galindez100% (1)

- N61 3130 000 000 AeroWave X v6Document2 pagesN61 3130 000 000 AeroWave X v6Marcus DragoNo ratings yet

- Kas 297a Maintenance Manual 006 05512 0003 3Document184 pagesKas 297a Maintenance Manual 006 05512 0003 3Marcus DragoNo ratings yet

- KS 270CDocument129 pagesKS 270CGeorge Cunha Lima100% (2)

- Kas297a Altitude Selector Im 006 00512 0002 2Document21 pagesKas297a Altitude Selector Im 006 00512 0002 2Marcus DragoNo ratings yet

- Point A: SPA-400 - King KMA 20 Audio Panel Installation Wiring DiagramDocument1 pagePoint A: SPA-400 - King KMA 20 Audio Panel Installation Wiring DiagramAdrian TodeaNo ratings yet

- KX 155 165 Installation ManualDocument56 pagesKX 155 165 Installation Manualalex castro100% (4)

- Performance Analysis of Airbus A380Document58 pagesPerformance Analysis of Airbus A380Fahad Ali100% (3)

- Eliiot STC-Avionics-Installation-Part-2 PDFDocument19 pagesEliiot STC-Avionics-Installation-Part-2 PDFslam1212533% (3)

- A380 Aircraft Prototype DesignDocument34 pagesA380 Aircraft Prototype DesignAdithya Das B SNo ratings yet

- An Introduction To GNSSDocument70 pagesAn Introduction To GNSSHakim Fahmi100% (2)

- Aerospace Engineering UNS - WalesDocument2 pagesAerospace Engineering UNS - WalestarunNo ratings yet

- For Refeence Only: Bell 412ep With BLR Fastfin™ SystemDocument3 pagesFor Refeence Only: Bell 412ep With BLR Fastfin™ SystemHerlambang Surya100% (1)

- Descending in VNAV for Dummies - A SummaryDocument3 pagesDescending in VNAV for Dummies - A SummaryPaul LiewNo ratings yet

- Autopilot E11Document40 pagesAutopilot E11Jacob Malcolm100% (1)

- Survey Accurately with SIRIUS UAS FactsDocument2 pagesSurvey Accurately with SIRIUS UAS FactsAdrian Guerra MedranoNo ratings yet

- Clark RPLCDocument12 pagesClark RPLCDavid van TeeselingNo ratings yet

- USAF Stability and Control Datcom Methods SummaryDocument70 pagesUSAF Stability and Control Datcom Methods SummaryYi Cheng ChanNo ratings yet

- Modeling and Flight Dynamics of A Projectile With Nonlinear, Roll-Dependent AerodynamicsDocument24 pagesModeling and Flight Dynamics of A Projectile With Nonlinear, Roll-Dependent Aerodynamicscacak283No ratings yet

- Equal Transit Theory:: Why This Is Wrong?Document4 pagesEqual Transit Theory:: Why This Is Wrong?Ritwick Nandi100% (1)

- 208comp 08 00Document133 pages208comp 08 00mothboy100% (1)

- SBSP Rnp-Y-Rwy-17r Iac 20210520Document1 pageSBSP Rnp-Y-Rwy-17r Iac 20210520brunogasperinNo ratings yet

- Textron Crash InfoDocument16 pagesTextron Crash InfoCourtney NicoleNo ratings yet

- Learjet 35 Panel ArtDocument2 pagesLearjet 35 Panel ArtBrendanRatchford100% (1)

- 65 - Aerospace Engineering E-Books ListDocument48 pages65 - Aerospace Engineering E-Books ListKabir Sai Prasanna Suryavansh100% (2)

- Aircraft Manual ContentsDocument14 pagesAircraft Manual Contentsnarenivi67% (3)

- Aircraft wing and flight test questionsDocument9 pagesAircraft wing and flight test questionsmarcoNo ratings yet

- Drag of A SphereDocument4 pagesDrag of A SphereJean-Franz Baschube100% (1)

- Afwal TR 81 3109 Guide For Mil F 8785cDocument255 pagesAfwal TR 81 3109 Guide For Mil F 8785cminyshow23No ratings yet

- (Crowood Aviation Series) Kev Darling - Concorde-Crowood Press (2004)Document103 pages(Crowood Aviation Series) Kev Darling - Concorde-Crowood Press (2004)André ProvensiNo ratings yet

- Santa Marta, Colombia SKSM/SMR RNAV (RNP) Rwy 19: Burdu SM4 5 SM4 6Document1 pageSanta Marta, Colombia SKSM/SMR RNAV (RNP) Rwy 19: Burdu SM4 5 SM4 6Guillermo Serrano KelcyNo ratings yet

- VFR MINIMADocument12 pagesVFR MINIMASofikitisNo ratings yet

- C-130 Tutorial PDFDocument20 pagesC-130 Tutorial PDFDaniMuñoz100% (1)

- Checklist Cessna C-152 Checklist Cessna C-152: Forwx& Rnwy ConditionDocument2 pagesChecklist Cessna C-152 Checklist Cessna C-152: Forwx& Rnwy ConditionWilliam Rios100% (1)

- LTN-92 Pilots GuideDocument185 pagesLTN-92 Pilots GuideInterogator5100% (3)

- AIRLAW AND OPERATION PROCEDURES SUMMARYDocument74 pagesAIRLAW AND OPERATION PROCEDURES SUMMARYMoslem Grimaldi88% (8)

- 'Final' CM-PIFS-010 Issue - 01 - Turbine Engine Relighting in Flight - PUBLDocument6 pages'Final' CM-PIFS-010 Issue - 01 - Turbine Engine Relighting in Flight - PUBLbykr aknNo ratings yet