Professional Documents

Culture Documents

Multiphase Pump

Uploaded by

bobcyliaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multiphase Pump

Uploaded by

bobcyliaoCopyright:

Available Formats

Franh Hartley .

Houston

Multiphase pump

A recenflydevelopedmultiphasenampump

boosterhas increasedproductionby more

than 5 MMcf/d for two wells in the Neurfield

Exploration'sEugeneIslandfield in the Gulfof

Mo<ico,GlenCurtis,BusinessDevelopmen!

WeatherfordInternational,said.

ln August of 2003,thesewells were identified as liquid loaded.One of the wells was

shut in, and the other was producingintermittenfly.The operatorneededan economic

solutionthat wouldallowthe wellsto produce

with a reducedwellheadpressure(WHp) to

unloadthe fluid columnfrom the loaded-up

wells.Glensaidthat the restoredproduction

from thesewellswould kanslatedirecfly into

increasedreserve recovery of the field.

Severaloptionswere considered,including

the installationof a conventionallow-pressure (LP) system(thatwould require i gu.

compressor),an LP separator,and liquid

pumps.Associatedhigh capitale:<penditures,

spacerequirements,andpotentialincreasein

operatingexpensesled to an ultimate decisionagainstthis option.

The booster system was introduced as an alternative to the conventional process of adding a

separator, compressor, and pumps.

The boostersystemwasintroducedas an

alternativeto the conventionalprocessof

addinga separator,compressor,andpumps.

This systemwouldessentiallyoperateasthe

intermediate-pressure

(IP) or Lp production

systemneededto help boost the non-producingwellsby creatinga low-pressuresuction to which both wells could flow, Glen

said.

The firstwell wasa liquid-loadedsatellite

gaswell that wasproducinga high volume

of water beforeloadingup. Accordingto

Weatherford,

awellin this conditionbecomes

problematicaswater cut increasesand bottomholepressuredeclines.Eventually,as

the well experiencesshort-term shut-ins,

resultingfrom processupsetsor monthly

equipmenttesting,unloadingthe well to

the high-pressure(HP) systembecomes

increasinglydifficult. The operatorwas no

longerableto restorethe well to production

in the HP systemoperatingat 1,150psig, HPU allowsthe pump to provide a 0 to 100%

and it remainedshut in. Upon installation furndown of the flow volume,a benefitthat

of the RamPump,the well was unloaded most multiphasepumps are unableto offer,

continuouslyat 30Gto 400-psisuctionpres- evenwith a variablefrequency drive (WD)

sure. In less than a week, the well started or conventionalcompressorsoperatingin

making enoughgas at a high enoughflow- recycle mode.The HPU, driven by a gas

ing tubing pressure(FTP) to allow discon- engine, diesel engine, or electric-motor

nection of the multiphasebooster and to prime mover,canbe mountedon the same

flow naturally into the HP system, Glen skid or on separateskids to meet spaceand

said.Onceunloaded,the well continuedto cranelift weight limitations.This flexibility

produce at rates of 3,168 Mcf/d, l2g allowsfor future interchangeabilityof variBOPD, and 877 bw/d, with a 2,550-psig ouspump systemsand HPU sizesas condi,

FTP.Newlield cannow divert this well into tionschange.

the same system,as needed,if the well

Typically,dischargepressurefor a 12-in.

loadsup during any unscheduledshut-in pumpfor HP applications

is up to 1,200psig

period.

but can be rated as high as 2,000psig if

In anothercase,where low bottomhole required,the companysaid.Sizesup to lGin.

pressurepreventedawell from flowinginto plunger diametercan alsobe ratedup to 900

the HP system,the A-15well was directed lb ANSI with up to 2,00Gpsigdischarge.Both

to the boostersystemoperatingat a suction the pump and its sealsystemare fully rated,

pressure of 450 psig, which boostedthe staticallyand operationally,for ANSI class

flow into the HP systemat 1,150psig. By 30G,60G,or 90Glbpressurelevels,dependearly October2003,the well waspioducing ing on the systemrequirements.Units up to

1,969Mcf/d,7 b/d of condensate,

and 2 20in. in diameterarelimited to 600IbANSI,

b/d of water, at 920-psigFTP.The multi- and24-to32-in.unitsaretypicallyratedat 300

phaseboostercontinuesto producethis IbAI{SI.

well at the reducedWHP and boostflow to

Newfield saysthat a single Rampump

the HP system.

unit can eliminatethe need for separators,

Multiphase pumping lowers WHp and compressors,pumps,and vapor recovery

minimizesequipmentrequirementsby cre- systemsat remoteonshorewell sitesor offating a low-pressurezonebetweenthe well shoreplafforms,thus savingspaceandcap

and the high backpressuresource,suchas ital.

a long flow line or downstreamseparator,

said the company.This technologyis used High.performance

to lower backpressurein flow lines from drilling fluid

wells and productiongatheringsystems,or

A new high-performancewater-base

to boost pressuregoing into higher-pres- drilling fluid has been introduced by

sure dischargeflow lines. It is most benefi- Baker Hughes Inteq Drilling Fluids. The

cial to productioncompaniesthat do not Performaxfluid is designedto deliverthe

havethe spaceto install separators,flash drilling characteristicsof emulsion-base

tanks, compressors,liquid pumps, and drilling fluids without sacrificingenvironvapor recovery units but still want to mentalcompliance.Accordingto Baker,

achievelower operatingpressureto main- benefitsincludeimprovedshaleinhibition

tain or improveproduction.

(reducedpore pressuretransmission),

Multiphasepumpingcould alsobe useful increased cuttings integrity, increased

in specialindustrial applicationswith low rates of penetration,and reducedtorqu

net positivesuctionhead available,suchas and drag.

operationswith fluids at flash point and

Sinceits introduction last year,the fluid

operationsusing compressiblefluids with hasbeenusedon a broadrangeof drilling

entrainedgas,which could damageconven- applicationsincluding onshore,continental

tionalpumps.

shelf, and deepwaterprojects.A few highAccording to the company,multiphase lights ffom thesewells include penetration

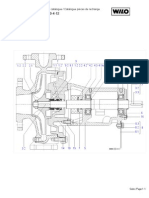

booster systemis a vertical, long-stroke, rates averaging90 ft/hr (28.6m/hr) with

duplex-pistonpositive-displacement

pump both PDC and rock bits, low dilution rates

that reciprocatesusing hydraulic cylinders and high solidsremovalefficiency,friction

actuatedby a hydraulic power unit (HpLD. factors equivalentto emulsion-base

mud,

The HPU designallowsthe pump to handle minimumbit ballingand accretion,eliminaflows ranging from wet gas streamsto 100% tion of rig set-upand wastemanagement

liquids,which coversa broad rangeof vis- costsassociatedwith emulsionmuds,and

cositiesand densities.The pump can also significantrigtime savingsduring clean-up

manageflow streamsthat containperiodic for completionsversus emulsionmuds.

slugsof fine solids,suchas sandor silt. The Bakersaid.O

20 OffshoreJuly2004.www.offshore-mag.com

You might also like

- The Value of Underground Storage in Today's Natural Gas IndustryDocument88 pagesThe Value of Underground Storage in Today's Natural Gas IndustrybobcyliaoNo ratings yet

- ReciprocatingcompressorsDocument13 pagesReciprocatingcompressorsasbuasbuNo ratings yet

- CAES Power PlantsDocument4 pagesCAES Power PlantsbobcyliaoNo ratings yet

- 2007 AGA 9.pdf AGA 9 - 2007 PDFDocument9 pages2007 AGA 9.pdf AGA 9 - 2007 PDFadactivatorNo ratings yet

- 天然氣水合物Document101 pages天然氣水合物bobcyliaoNo ratings yet

- The Basics of Underground Natural Gas Storage Natural GasDocument8 pagesThe Basics of Underground Natural Gas Storage Natural GasbobcyliaoNo ratings yet

- Apt 60928 Evs TM 08 1Document108 pagesApt 60928 Evs TM 08 1Mohan JhaNo ratings yet

- Pipeline Transportation of Heavy OilsDocument12 pagesPipeline Transportation of Heavy OilsbobcyliaoNo ratings yet

- Fundamentals of Multipath Ultrasonic Flow Meters For Gas MeasurementDocument23 pagesFundamentals of Multipath Ultrasonic Flow Meters For Gas MeasurementCarlos Melendez-CervantesNo ratings yet

- Earthquake Triggering and Large-Scale Geologic Storage of CO2Document5 pagesEarthquake Triggering and Large-Scale Geologic Storage of CO2bobcyliaoNo ratings yet

- 2007 AGA 9.pdf AGA 9 - 2007 PDFDocument9 pages2007 AGA 9.pdf AGA 9 - 2007 PDFadactivatorNo ratings yet

- Gas & Infrastructure Action GroupDocument100 pagesGas & Infrastructure Action GroupbobcyliaoNo ratings yet

- Engineering Standard For Process Design of Gas (Vapor) - Liquid SeparatorDocument45 pagesEngineering Standard For Process Design of Gas (Vapor) - Liquid SeparatorbobcyliaoNo ratings yet

- Complex Extraction of Thermal EnergyDocument7 pagesComplex Extraction of Thermal EnergybobcyliaoNo ratings yet

- Carbon Dioxide Pipeline-A Preliminary Review of Design and RisksDocument6 pagesCarbon Dioxide Pipeline-A Preliminary Review of Design and RisksbobcyliaoNo ratings yet

- Carbon Dioxide Pipeline-A Preliminary Review of Design and RisksDocument6 pagesCarbon Dioxide Pipeline-A Preliminary Review of Design and RisksbobcyliaoNo ratings yet

- Fundamentals of Multipath Ultrasonic Flow Meters For Gas MeasurementDocument23 pagesFundamentals of Multipath Ultrasonic Flow Meters For Gas MeasurementCarlos Melendez-CervantesNo ratings yet

- Sand Control OverviewDocument85 pagesSand Control OverviewAndrea Bandera100% (5)

- Biomethane HandoutDocument4 pagesBiomethane HandoutbobcyliaoNo ratings yet

- Inherent Safety in Process Plant DesignDocument129 pagesInherent Safety in Process Plant Designbobcyliao100% (1)

- Compressors and Compressed Air SystemsDocument24 pagesCompressors and Compressed Air SystemsDipaloy DattaNo ratings yet

- Natural Gas Transportation & Application of Gas HydratesDocument23 pagesNatural Gas Transportation & Application of Gas HydratesbobcyliaoNo ratings yet

- High-Efficiency Ethane & LPG Recovery ProcessDocument2 pagesHigh-Efficiency Ethane & LPG Recovery ProcessbobcyliaoNo ratings yet

- High-Efficiency Ethane & LPG Recovery ProcessDocument2 pagesHigh-Efficiency Ethane & LPG Recovery ProcessbobcyliaoNo ratings yet

- Engineering Standard For Process Design of Gas (Vapor) - Liquid SeparatorDocument45 pagesEngineering Standard For Process Design of Gas (Vapor) - Liquid SeparatorbobcyliaoNo ratings yet

- Natural Gas Liquefaction Processes ComparisonDocument10 pagesNatural Gas Liquefaction Processes ComparisonbobcyliaoNo ratings yet

- CO2 Injection Into Depleted Gas ReservoirsDocument15 pagesCO2 Injection Into Depleted Gas ReservoirsbobcyliaoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bahan Kuliah Pompa & Kompresor 2014Document54 pagesBahan Kuliah Pompa & Kompresor 2014Uoiiu WqeeqNo ratings yet

- Spesifikasi Pompa Pond & WWTPDocument4 pagesSpesifikasi Pompa Pond & WWTPManekGorisNo ratings yet

- Refrigerators April 2008Document172 pagesRefrigerators April 2008Edison EspinalNo ratings yet

- Hydraulic PumpDocument15 pagesHydraulic PumpAnas Abandeh100% (1)

- Pump Handbook GroundfosDocument160 pagesPump Handbook GroundfosWolf1604No ratings yet

- Schematic Diagram of Basic Elements of Centrifugal PumpDocument17 pagesSchematic Diagram of Basic Elements of Centrifugal Pumpahsanul haqueNo ratings yet

- AscueDocument1 pageAscueFiqri Permana MohamadNo ratings yet

- Wil o 497026Document9 pagesWil o 497026carlos yepezNo ratings yet

- Directory of Pump ManufacturersDocument36 pagesDirectory of Pump ManufacturersAvijitSinharoyNo ratings yet

- 1 Types: 1.1 Positive Displacement PumpDocument15 pages1 Types: 1.1 Positive Displacement Pumpwasim92khanNo ratings yet

- Types of PumpsDocument18 pagesTypes of PumpsAhmed Adel Ibrahim100% (1)

- NL125 400 30 4 12 - 4109417Document5 pagesNL125 400 30 4 12 - 4109417nino16041973No ratings yet

- Types of PumpsDocument26 pagesTypes of PumpsMaunish Shah100% (3)

- Pump Classification & Designation According To HIDocument13 pagesPump Classification & Designation According To HIHaryadiNo ratings yet

- Filter Feed PumpDocument1 pageFilter Feed Pumpnas_mech8208No ratings yet

- Ebara Catalogo GeneralDocument87 pagesEbara Catalogo GeneralJuan DavidNo ratings yet

- LT Drive List of PCH, Cosp, SCH, Fob Area: Sr. No Tag No Description Location Make KW RPMDocument34 pagesLT Drive List of PCH, Cosp, SCH, Fob Area: Sr. No Tag No Description Location Make KW RPMpitambervermaNo ratings yet

- Advanced Artificial Lift Methods - PE 571: Chapter 1 - Electrical Submersible PumpDocument26 pagesAdvanced Artificial Lift Methods - PE 571: Chapter 1 - Electrical Submersible PumpNirmal JayanthNo ratings yet

- US Seal MFG Pump Manufacturers Cross-ReferenceDocument97 pagesUS Seal MFG Pump Manufacturers Cross-Referencekikokiko KarimNo ratings yet

- Weatherford TWS600S - Or00021889 2.75Document26 pagesWeatherford TWS600S - Or00021889 2.75SERGIO ARMANDO SANCHEZ ROQUENo ratings yet

- ERIKC Update CRDi Catalog-Diesel Injector Spare PartsDocument63 pagesERIKC Update CRDi Catalog-Diesel Injector Spare PartsЕкатерина КалашниковаNo ratings yet

- PDF Piston Pumps Parker Pvplus Remote Pressure ControlDocument6 pagesPDF Piston Pumps Parker Pvplus Remote Pressure ControlENEKO DIEZ ALVAREZNo ratings yet

- Positive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitDocument9 pagesPositive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitMerie Ann Aumentado CallejaNo ratings yet

- List Spare Part: Description Type Part NumberDocument11 pagesList Spare Part: Description Type Part NumberYen NguyenNo ratings yet

- Problem Set 2 - Fluid MachineryDocument1 pageProblem Set 2 - Fluid MachineryRonard Pa–aNo ratings yet

- Alpha1 2060 N 150 GreensDocument8 pagesAlpha1 2060 N 150 GreensRicardoNo ratings yet

- Calculating Stuffing Box PressuresDocument2 pagesCalculating Stuffing Box PressuresEdson França RodriguesNo ratings yet

- KSB Family CurvesDocument1 pageKSB Family CurvesHarshad Athawale100% (1)

- Durco Mark2and3 50Hz60Hz CurvesDocument60 pagesDurco Mark2and3 50Hz60Hz Curvesfagb1978100% (1)

- Curvas Características: Performance CurvesDocument8 pagesCurvas Características: Performance Curvesnefrain muchoNo ratings yet