Professional Documents

Culture Documents

Fisa Tehnica Produs Technical Product Datasheet

Uploaded by

Catalin OlteanuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fisa Tehnica Produs Technical Product Datasheet

Uploaded by

Catalin OlteanuCopyright:

Available Formats

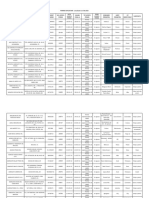

Fisa Tehnica Beton

Clasa C25/30I42.5RF6/16AGA*AGILIA ARHITEC

FISA TEHNICA PRODUS

Clasa beton proiectata :

C25/30

Ciment utilizat :

CEM I 42.5R

Granula maxima :

16

Raport maxim A/C*:

0.50

Dozaj minim de ciment*:

300

Clasa de cloruri*:

Cl 0.2

*conform CP012/1-2007

Aditivi utilizati:

Superfluidizant

Adaosuri utilizate:

filer de calcar

Clasa de raspandire:

F6 (SF2)

630mm

Valoare Raspandire [mm]:

Agregate utilizate :

de balastiera, conf. SR EN 12620

Densitate aparenta in stare proaspata

2,350-2,400

[kg/mc]

Mod vibrare :

NU SE VIBREAZA

Tip Transport:

Autobetoniera

CARACTERISTICI FIZICO-MECANICE

Durata de transport:

Tine seama de:

perioada anului & temperatura mediu exterior & tip ciment & tip aditiv & cerinte

max. 120 min 10C > T < 30C

max. 150 min T< 10C

Rezistenta la compresiune:

- la varsta de 3 zile :

min. 15 N/mmp

- la varsta de 7 zile :

min. 22.5 N/mmp

- la varsta de 28 zile :

min. 30 N/mmp

DOMENII DE UTILIZARE

Aplicatii la interioriorul cladirilor, unde umiditatea mediului ambiant este medie sau moderata.

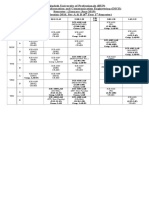

Technical Datasheet Concrete

Type C25/30I42.5RF6/16AGA*AGILIA ARHITEC

TECHNICAL PRODUCT DATASHEET

Designed concrete class:

Cement:

Max size of aggregates :

Max W/C Ratio*:

Min Cement Dosage*:

Chlorides*:

*according CP012/1-2007

Admixtures used:

Additives used:

Consistency range :

Slump-Flow Value [mm]:

Aggregates:

Fresh apparent density [kg/mc]:

Vibration mode:

Transport Type:

C25/30

CEM I 42.5R

16

0.5

300

Cl 0.2

Superplasticizer

calcar filler

F6 (SF2)

630mm

natural agg, according to SR EN 12620

2,350-2,400

NO VIBRATION

Mixer Truck

PHYSICO-MECHANICAL PROPERTIES

Elemente arhitecturale, constructii noi, transformari, reparatii.

Transport Time:

Take into account:

period of the year, average air temperature & cement type & admixture used & requirements

max. 120 min 10C > T < 30C

max. 150 min T< 10C

Compressive Strenght:

- at age of 3 days :

min. 15 N/mmp

- at age of 7 days :

min. 22.5 N/mmp

- at age of 28 days :

min. 30 N/mmp

APPLICATIONS

Indoor applications, in elements subjected to medium to moderate humidity.

Outdoor aplications but protected from the weather, in environments exposed to low chemical

aggression.

Suitable for architectural elements, new construction, transformation and repair works.

Suprafete verticale ale betonului expuse la ploaie si inghet; saturatie moderata cu apa fara

agenti de dezghetare.

Elemente si structuri de constructii civile si industriale, socio-culturale, cu sectiuni mai mici de

0.8m.

Se poate pune in opera cu pompa

DA

Clase de expunere :

XC4,XF1,XA1

RECOMANDARI

Vertical concrete surfaces exposed to rain and frost; moderate water saturation without deicing agents.

Elements of civil and industrial structures, socio-cultural structures with sections less than

0.8m.

Can be discharged by pump

YES

Exposure Class:

XC4,XF1,XA1

RECOMMENDATIONS

Temperatura beton proaspat la

inceperea lucrarii:

Fresh concrete temperature in

order to start work:

Aplicatii la exterior insa la adapost de intemperii, in medii cu agresivitate chimica scazuta.

5C > T Beton Proaspat < 30C

3

5C > T Fresh Concrete< 30C

Comandati o cantitate minima de 3 m , pentru a asigura calitatea si uniformitatea produsului.

Presiunea pe cofraj:

- Proiectati coloane mici pentru a testa presiunea maxima a coloanei de lichid

- Pereti Nu depasiti rata proiectata de turnare (descresteti rata in conditii de temperaturi

scazute)

- Pentru preocupari specifice legate de presiune, contactati Lafarge pentru a obtine predictii

exacte ale acesteia.

Order a minimum quantity of 3 m3 to ensure the quality of the product.

Asigurati-va ca toate deschizaturile intre articulatii sunt sigilate si cofrajele sunt impermeabile.

Scurgerile vor cauza goluri, modificari in culoare, aspect de fagure.

Ensure all joints and holes are sealed and forms are water tight. Leaks will cause voids,

discoloration and honeycombing.

Asigurati-va ca partea de jos si colturile cofrajelor sunt bine fixate pentru a preveni cedarea

cofrajului.

Ensure the bottom and corners of formwork are well braced to prevent blowouts.

Nu turnati Agilia daca cofrajele sunt incalzite, aceasta poate cauza defecte de suprafata. Raciti

cofrajul prin umbrire sau stropire cu apa (inlaturati apa din cofraj). Asigurati-va ca nu exista apa

sau alte resturi in cofraje inainte de turnare (aceasta poate cauza dare de nisip sau striatii).

Do not place Agilia against hot formwork, as this may cause surface defects and pour lines.

Cool the formwork with shading or sprinkling with water (remove water from forms). Ensure

there is no water in forms to prevent sand streaking. Ensure no debris in forms.

Daca pompati betonul, asigurati-va ca tubulatura este amorsata inainte de inceperea turnarii.

Nu permiteti ca solutia de amorsare sa fie plasata in element. Pompati betonul pana ce apare

un produs consistent, altminteri poate aparea segregare.

If using pumps, ensure pump lines are primed prior to start. Do not allow priming water/grout

to be placed in forms. Pump off concrete until a consistent product is coming out of the line

otherwise segregation may occur.

Indiferent ca este pus in opera utilizand pompa sau bena, curgerea trebuie sa fie continua si

usoara. Este de preferat ca turnarea sa se realizeze cu ajutorul unor tevi si a benei. Bena va

trebui sa fie etansa.

Whether placed by bucket or pump, the flow must be continuous and steady. Placing with

Tremie pipes is preferred. Tremie must be tight.

Evitati stopirea Agilia de peretii cofrajului in timpul turnarii, acesta se poate usca si poate cauza

aparitia de gauri.

Avoid splashing Agilia on form walls while placing as this can dry and cause bug holes.

Cofrajele in straturi utilizate anterior dar aflate in stare buna pot oferi rezultate mai bune decat

unele noi, cele noi putand capta aer si umiditate.

Previously used form-ply in good condition provides a better finish than new form-ply, as it

can trap air and moisture.

Utilizati cofraje curate si unse cu decofranti sintetici sau vegetali NU UTILIZATI agenti

decofranti minerali. Inlaturati excesul de agent decofrant. Mai putin este mai bine. In functie de

materialul din care este confectionat cofrajul si temperatura mediului ambiant la care se toarna,

se pot face recomandari privind alegerea optima a acestuia.

Use clean formwork with a synthetic or Vegetable release agent DO NOT use mineral oil

release agents. Wipe off any excess form release. Less is better. Depending on the

formwork material and the ambient temperature at the moment of pouring, Lafarge can make

recommendations for its optimal choice.

Limitati intervalele in betonare, pentru a preveni rosturile dintre turnari.

Avoid long gaps in placing between lifts to prevent pour lines.

Pentru pereti mari, poate fi nececesara mutarea punctului de descarcare, in functie de debit,

temperatura si rata de plasare a betonului.

For large walls, moving the point of placement frequently may be required depending on flow,

temperature and rate of placement.

Evitati punerea in opera a Agilia Arhitectural cand temperatura mediului ambiant depaseste 27

grade Celsius.

Avoid placing Agilia Architectural when ambient temperatures exceed 27 degrees Celsius.

Se vor respecta cerintele privind transportul, punerea in opera - tehnica si echipamente,

tratarea betonului si decofrarea. Betonul se va proteja obligatoriu dupa turnare.

It will meet the requirements for transport, placing equipment, placing methods, finishing

method, curing and de-molding. It is necessarily to protect the concrete after casting.

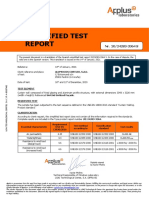

Produsul indeplineste Cerintele:

SR EN 206-1:2002; SR EN 206-9:2010

Directiva Europeana pentru Beton Autocompactant - Mai 2005, Anexa A

The Product meets the Requirements of:

SR EN 206-1:2002; SR EN 206-9:2010

The European Guidelines for Self Compacting Concrete - May 2005, Annex A

Form Pressure:

- Design small columns for full liquid head (already typical practice for regular concrete)

- Walls Do not exceed designed pour rate (decrease rate in cooler temperatures)

- For specific form pressure concerns, contact Lafarge for accurate form pressure predictions.

You might also like

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- Teava Neagra Rotunda ZimTubDocument4 pagesTeava Neagra Rotunda ZimTubAlex CătănescuNo ratings yet

- SM 04106016 Ic448 GBDocument290 pagesSM 04106016 Ic448 GBmohamed algharbiNo ratings yet

- Memoriu TehnicDocument31 pagesMemoriu TehnicOláhAttilaNo ratings yet

- Carte Tehnica ProceduraDocument16 pagesCarte Tehnica Procedurazamfi2011No ratings yet

- Caiet de Sarcini Privind Protectia Anticoroziva / Job Specification For Anticorrosive ProtectionDocument7 pagesCaiet de Sarcini Privind Protectia Anticoroziva / Job Specification For Anticorrosive ProtectionRazvan RaduNo ratings yet

- Arcelor Mittal Galati-Product CatalogDocument24 pagesArcelor Mittal Galati-Product CatalogkarnagamNo ratings yet

- C 230 - 1988 Gropi Stantate PTR FundatiiDocument76 pagesC 230 - 1988 Gropi Stantate PTR Fundatiihorea67No ratings yet

- Proiect Casa PrispaDocument319 pagesProiect Casa Prispaand.simonescuNo ratings yet

- Catalogue EKOVAL VALVEDocument4 pagesCatalogue EKOVAL VALVERoxy AksesoriesNo ratings yet

- Gard Strada - 39 PDFDocument1 pageGard Strada - 39 PDFAlina TNo ratings yet

- Anexa Coduri ConstructiiDocument4 pagesAnexa Coduri ConstructiiSilviu Adrian IANANo ratings yet

- Agenti Geodezi AutorizatiDocument1 pageAgenti Geodezi AutorizatiCiocarda AndreeaNo ratings yet

- Profil IPE: Dimensiuni Standard de Fabricatie / LivrareDocument1 pageProfil IPE: Dimensiuni Standard de Fabricatie / LivrarePal BarniNo ratings yet

- Rezumate AllDocument116 pagesRezumate AllraduonoNo ratings yet

- Permise Exploatare 14 03 2023Document66 pagesPermise Exploatare 14 03 2023Raul MiclăușNo ratings yet

- Konica-Minolta Bizhub 162-210 Service ManualDocument660 pagesKonica-Minolta Bizhub 162-210 Service Manualdevlin2427100% (7)

- Firme HorecaDocument28 pagesFirme HorecaDragos PatrinjelNo ratings yet

- Buletin Statistic de Preturi Nr11 1Document83 pagesBuletin Statistic de Preturi Nr11 1Adrian StanescuNo ratings yet

- AllPlan Nemetchek 3d Tutorial 2005Document190 pagesAllPlan Nemetchek 3d Tutorial 2005ČovjeknNo ratings yet

- Cortizo (Unit 66 Unitized Façade) - 20-24283-3364-S (EN)Document1 pageCortizo (Unit 66 Unitized Façade) - 20-24283-3364-S (EN)safdNo ratings yet

- Dictionar Termeni EconomiciDocument6 pagesDictionar Termeni EconomiciAnonymous Ly4B2gBXcTNo ratings yet

- Profil IPE - H Metal - Www.h-MetalDocument1 pageProfil IPE - H Metal - Www.h-MetalGrigoreOzonNo ratings yet

- Detalii Rigola Carosabila PDFDocument1 pageDetalii Rigola Carosabila PDFBarbulescu CiprianNo ratings yet

- Beton Translucid 2Document6 pagesBeton Translucid 2Nicoleta Diana DuiculeteNo ratings yet

- A-03 Plan ParterDocument1 pageA-03 Plan ParterMirunaNo ratings yet

- STAS-Uri Si Normative in VigoareDocument10 pagesSTAS-Uri Si Normative in Vigoarecristymarya4247100% (2)

- Greutati SpecificeDocument1 pageGreutati SpecificeSpyros BibirisNo ratings yet

- Vane Fluture Si AdaptoareDocument32 pagesVane Fluture Si Adaptoarebotas georgianaNo ratings yet

- Extras Armatura ExempluDocument7 pagesExtras Armatura ExempluAdrian ScripcaruNo ratings yet

- Firme Agreate ApaservDocument3 pagesFirme Agreate ApaservCristinaSchiopuNo ratings yet

- Caiet de Sarcini Partea 1Document110 pagesCaiet de Sarcini Partea 1Florin Man100% (1)

- Armaturi Industriale FontaDocument15 pagesArmaturi Industriale FontaCarmen DanaNo ratings yet

- Bilant in EngDocument13 pagesBilant in EngDaniela BulardaNo ratings yet

- AntemasuratoriDocument58 pagesAntemasuratoriLelea EmanuelaNo ratings yet

- Eurocod 2Document358 pagesEurocod 2Don Adrián Oniga100% (1)

- Curs de Constructii AgricoleDocument112 pagesCurs de Constructii AgricoleOvidiu Hotca100% (1)

- Solutii Moderne Si Eficiente de Stabilizare A Terenurilor de Fundare - RevisDocument18 pagesSolutii Moderne Si Eficiente de Stabilizare A Terenurilor de Fundare - RevisAdrian Frantescu100% (1)

- Terasin HTDocument1 pageTerasin HTBazil1988No ratings yet

- Decizii Multicriteriale - Metoda LEADERDocument4 pagesDecizii Multicriteriale - Metoda LEADERAndreiNo ratings yet

- Sigma Epsilon BetonDocument8 pagesSigma Epsilon BetonOctavian CicuNo ratings yet

- Tarife Constructori Downloaded - FileDocument4 pagesTarife Constructori Downloaded - Filejulian nikoNo ratings yet

- Indicator Rpc-Reparatii in ConstructiiDocument1,130 pagesIndicator Rpc-Reparatii in ConstructiiRelu123No ratings yet

- Grafic Fizic Si ValoricDocument3 pagesGrafic Fizic Si ValoricVoicila CosminNo ratings yet

- Waste Management Research in Romania - 0Document72 pagesWaste Management Research in Romania - 0Bianca RadutaNo ratings yet

- Product SIKADocument75 pagesProduct SIKAZan PerzadaNo ratings yet

- Ocbre Spec.Document12 pagesOcbre Spec.Rana MahatoNo ratings yet

- Cementación de PozosDocument30 pagesCementación de PozosJesus BcNo ratings yet

- Sprayed ConcreteDocument27 pagesSprayed ConcreteSharanu PujariNo ratings yet

- Cmci Cmci: Euco-Weather GuardDocument2 pagesCmci Cmci: Euco-Weather Guardpravi3434No ratings yet

- Sikafill®-300 Thermic: Product Data SheetDocument4 pagesSikafill®-300 Thermic: Product Data Sheetmaga2292No ratings yet

- Inspection, Good Construction Practices, Workmanship and Codal ProvisionsDocument31 pagesInspection, Good Construction Practices, Workmanship and Codal ProvisionsThiyagarajan TiguNo ratings yet

- A Guide For Durable Quality Residential Concrete Flatwork 2016 RevisionDocument4 pagesA Guide For Durable Quality Residential Concrete Flatwork 2016 RevisionMICHAELNo ratings yet

- Dlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious GroutDocument4 pagesDlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious Grout4919404No ratings yet

- Plio CureDocument2 pagesPlio Curepravi3434No ratings yet

- SPE/IADC 119296 Zonal Isolation Achieved in Kashagan Field Through Integrated ApproachDocument11 pagesSPE/IADC 119296 Zonal Isolation Achieved in Kashagan Field Through Integrated ApproachPAOLA ANDREA DUARTE PRADANo ratings yet

- CEC2160-Compaction - CuringDocument9 pagesCEC2160-Compaction - CuringMohammad SalmanNo ratings yet

- The Interactive Workshop On The Latest Trends and Appropriate Use of Waterproofing and ConstructionDocument17 pagesThe Interactive Workshop On The Latest Trends and Appropriate Use of Waterproofing and ConstructionVishal TiwariNo ratings yet

- Waterproofing in ToiletDocument11 pagesWaterproofing in ToiletchaityaNo ratings yet

- Concrete in PracticeDocument78 pagesConcrete in PracticeRejoice Sambo100% (1)

- Chapter Two: General Design ConsiderationsDocument27 pagesChapter Two: General Design ConsiderationsTeddy Ekubay GNo ratings yet

- Bamboo People - An Interdisciplinary Unit For High SchoolDocument6 pagesBamboo People - An Interdisciplinary Unit For High SchoolChipo Jean MarundaNo ratings yet

- Solar-range-brochure-all-in-one-Gen 2Document8 pagesSolar-range-brochure-all-in-one-Gen 2sibasish patelNo ratings yet

- 22 Thành NG Quen Thu C Trên Ielts - FirefighterDocument2 pages22 Thành NG Quen Thu C Trên Ielts - FirefighterNinh NguyễnNo ratings yet

- HP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningDocument2 pagesHP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningParesh BabariaNo ratings yet

- Progressive Muscle Relaxation ExerciseDocument2 pagesProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- LQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQDocument5 pagesLQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQSAJAL KOIRALANo ratings yet

- Analyst - Finance, John Lewis John Lewis PartnershipDocument2 pagesAnalyst - Finance, John Lewis John Lewis Partnershipsecret_1992No ratings yet

- Class Routine Final 13.12.18Document7 pagesClass Routine Final 13.12.18RakibNo ratings yet

- Dissertation MA History PeterRyanDocument52 pagesDissertation MA History PeterRyaneNo ratings yet

- Updated WorksheetDocument5 pagesUpdated WorksheetJohn Ramer Lazarte InocencioNo ratings yet

- 2011 Frequency AllocationsDocument1 page2011 Frequency Allocationsculeros1No ratings yet

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryDocument19 pagesAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000No ratings yet

- Ship Recognition Manual TOSDocument138 pagesShip Recognition Manual TOSCody Lees94% (17)

- READMEDocument2 pagesREADMEtushar patelNo ratings yet

- 61annual Report 2010-11 EngDocument237 pages61annual Report 2010-11 Engsoap_bendNo ratings yet

- A First Etymological Dictionary of BasquDocument29 pagesA First Etymological Dictionary of BasquDaily MailNo ratings yet

- T54125ADocument64 pagesT54125ARaúl FroddenNo ratings yet

- IU IIDC Time Management and Organizational SkillsDocument40 pagesIU IIDC Time Management and Organizational SkillsAsger HamzaNo ratings yet

- Field and Laboratory Evaluation of A Soft Clay Southern IraqDocument14 pagesField and Laboratory Evaluation of A Soft Clay Southern Iraqvidyaranya_bNo ratings yet

- OB Case Study Care by Volvo UK 2020Document1 pageOB Case Study Care by Volvo UK 2020Anima AgarwalNo ratings yet

- Aicte Internship Approval Pending 1Document7 pagesAicte Internship Approval Pending 1Anisha KumariNo ratings yet

- Biography Worksheet: Name: Gerardo Angeles MartinezDocument1 pageBiography Worksheet: Name: Gerardo Angeles MartinezAlejandro AngelesNo ratings yet

- GE Uno Downlight Backlit BLDocument2 pagesGE Uno Downlight Backlit BLChen KengloonNo ratings yet

- Career Orientation QuestionnaireDocument5 pagesCareer Orientation QuestionnaireApple May100% (1)

- Summative Test in Foundation of Social StudiesDocument2 pagesSummative Test in Foundation of Social StudiesJane FajelNo ratings yet

- Permanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Document2 pagesPermanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Carla Ayelen Chorolque BorgesNo ratings yet

- Aectp 300 3Document284 pagesAectp 300 3AlexNo ratings yet

- Unit 7 ActivitiesDocument8 pagesUnit 7 ActivitiesleongeladoNo ratings yet

- Design of Footing R1Document8 pagesDesign of Footing R1URVESHKUMAR PATELNo ratings yet

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactFrom EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactRating: 5 out of 5 stars5/5 (5)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeFrom EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeRating: 5 out of 5 stars5/5 (1)

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- It's Elemental: The Hidden Chemistry in EverythingFrom EverandIt's Elemental: The Hidden Chemistry in EverythingRating: 4 out of 5 stars4/5 (10)

- Taste: Surprising Stories and Science About Why Food Tastes GoodFrom EverandTaste: Surprising Stories and Science About Why Food Tastes GoodRating: 3 out of 5 stars3/5 (20)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 5 out of 5 stars5/5 (4)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeFrom EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNo ratings yet

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (90)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideFrom EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNo ratings yet

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsFrom EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)