Professional Documents

Culture Documents

Automatic Punching Machine: A Low Cost Approach: Arun S, Sree Rajendra and Vijayavithal Bongale

Uploaded by

aktOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Punching Machine: A Low Cost Approach: Arun S, Sree Rajendra and Vijayavithal Bongale

Uploaded by

aktCopyright:

Available Formats

International Journal of Advanced Mechanical Engineering.

ISSN 2250-3234 Volume 4, Number 5 (2014), pp. 509-517

Research India Publications

http://www.ripublication.com

Automatic Punching Machine: A Low Cost Approach

Arun S1, Sree Rajendra2 and Vijayavithal Bongale3

1

IV Sem M.Tech (IAR), Malnad College of Engineering (MCE), Hassan,

Karnataka, India

2

Dept. of Mechanical Engineering, MCE, Hassan, Karnataka, India

3

Dept. of Mechanical Engineering, MCE, Hassan, Karnataka, India

Abstract

The proposed work describes the design and fabrication of prototype of

automatic punching machine controlled by PLC and shedding light on the

working principle and the hardware structure of the system. Punching or

pressing process is one of the most important and necessary processing step in

sheet metal industry. By automating this process one can have a greater

control over the process. Programmable Logic Controllers are used for the

control of the system. This system can replace existing manual feed and

operated punching and pressing machines. By interfacing PLC controls with

the conventional machines, it is possible to achieve good results in the form of

reduced manufacturing lead time, reduced cost and increased safety of the

worker.

Keywords Punching Machine, PLC, Pneumatics, Ladder logic.

Introduction

In todays practical and cost-conscious world, sheet-metal parts have already replaced

many expensive cast, forged, and machined products. The reason is obviously the

relative economy of operation, easier implementation for mass-production, as well as

greater control on the technical parameters. In most of the sheet metal operations

punching or pressing operation is the main or initial operation in the process

sequence. Automating this operation results in reduced lead time and also can reduce

human effort.

Automation can be defined as the technology concerned with application of

mechanical, electronic and computer-based systems to operate and control

production. There are many reasons for automating the process. The reason may be

to reduce manufacturing lead time, to increase labor productivity or to improve the

worker safety, etc.

510

Arun S, Sree Rajendra and Vijayavithal Bongale

Punching Process:

The press is the punching machine tool designed to punch blank of sheet by applying

mechanical force or pressure. The presses are exclusively intended for mass

production and they represent the fastest and more efficient way to form a metal into a

finished punched product. In manual or conventional methods of pressing the

disadvantages may be

angular misalignment of the sheet

higher material handling time and manufacturing lead times

reduced safety for the worker

Programmable Logic Controllers:

Fig. 1 PLC System block diagram

A Programmable controller is a solid state user programmable control system with

functions to control logic, sequencing, timing, arithmetic data manipulation and

counting capabilities. It can be viewed as an industrial computer that has a central

processor unit, memory, input output interface and a programming device. The

central processing unit provides the intelligence of the controller. It accepts data,

status information from various sensing devices like limit switches, proximity

switches, executes the user control program store in the memory and gives

appropriate output commands to devices like solenoid valves, switches etc.

In this project, sensors and PLC system is interfaced with the conventional

punching process for achieving the automation.

Automatic Punching Machine: A Low Cost Approach

511

Working Methodology:

There are three main components used in this system. They are Loading Cylinder,

Unloading Cylinder, and the Punching Cylinder. All these cylinders are operated in a

sequence in order to perform the required operation.

512

Arun S, Sree Rajendra and Vijayavithal Bongale

Design and modeling of the system:

Fig. 2 Model of the punching machine

Actual Component:

Figure shows the actual dimensions of the part needed to be punched.

Fig. 3 Blank before punching operation

Automatic Punching Machine: A Low Cost Approach

513

Fig. 4 Blank after punching operation

The component or blank that is needed to be punched is of dimension 50mm

length and 30mm breadth. The operation is planned to be carried on three types of

materials, like cardboard material, aluminium, and galvanized iron sheet. The

thickness of the material is less than 1mm and it depends on the load capacity of the

system. A hole of 20mm in diameter is to be punched on the blank as shown in fig.

Force or Load Calculations:

Fig. 5 Force exerted during extension stroke

514

Arun S, Sree Rajendra and Vijayavithal Bongale

The force that is generated by the punching cylinder can be calculated by using

the formula

Force, F = Pressure * Area N

Therefore F = P*d2/4

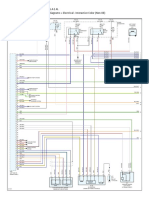

Design of Pneumatic circuit of the system:

Fig. 6 Pneumatic circuit of the system

Automatic Punching Machine: A Low Cost Approach

515

Fig. 7 Ladder diagram to control the pneumatic system

Sequence of Operation:

1. When the switch s1 is pressed, START solenoid is energized and the START

solenoid valve position changes. Thus air supply will flow to all the valves of the

system.

2. Initially a1 and b1 magnetic position sensors are actuated because of retracted

position of loading and punching cylinder. Since these two sensors are actuated,

EXTEND1 solenoid is actuated and its valve position changes. Hence air is

supplied to the blank end of loading cylinder and loading cylinder takes the

extension stroke. During the extension stroke, loading cylinder pushed the blank

or workpiece into position for punching operation.

3. When the loading cylinder is fully extended, it actuates the magnetic position

sensor a2. When this sensor is actuated solenoid EXTEND3 is actuated and its

516

4.

5.

6.

7.

8.

Arun S, Sree Rajendra and Vijayavithal Bongale

valve position changes. Hence air is supplied to the blank end of unloading

cylinder and unloading cylinder takes the extension stroke.

When the loading cylinder and unloading cylinders are fully extended, they

actuate the magnetic position sensor a2 and c2.

When the workpiece is in position, capacitive sensor and inductive sensor senses

the presence and type of material. They actuate the proximity sensor switch and it

will adjust the pressure required for operation by sending signal to the electrically

controlled pressure regulator.

After the pressure adjustments are made, solenoid valve EXTEND2 is actuated

and the punching cylinder takes the extension stroke, thus punching the required

geometry.

When the punching cylinder is fully actuated, it actuates the magnetic position

sensor b2. When the magnetic sensor b2 is actuated, it actuates the solenoid valves

RETRACT1, RETRACT2, RETRACT3. All the three cylinders take the retraction

stroke simultaneously.

And hence the cycle repeats.

Sensors:

A sensor is a device which receives and responds to a signal. A sensor's sensitivity

indicates how much the sensor's output changes when the measured quantity changes.

The sensor play an important role in automation with regard to achieving important

criteria such as cost reduction, rationalization, automation, flexibility and

environmental protection. The sensors which are used in this project are capacitive

sensor, magnetic sensor and inductive sensor.

IndraControl L20:

Fig. 8: PLC kit

Automatic Punching Machine: A Low Cost Approach

517

The IndraControl L20 is a modular and scalable control. It combines the benefits

of a compact small control with a standardized I/O system on the basis of terminal

technology. It is a hardware platform that can be used for PLC applications. It

provides onboard interfaces, e. g. high-speed inputs and outputs (8 each) and

communication interfaces, such as Ethernet, PROFIBUS and RS232. The locally

available I/O units can be extended by the Rexroth Inline I/O system, just by simply

mounting the components side by side.

Ladder Logic Programming:

Ladder logic is a programming language that represents a program by a graphical

diagram based on the circuit diagrams of relay logic hardware. It was primarily used

to develop software for programmable logic controllers (PLCs) used in industrial

control applications. The name is based on the observation that programs in this

language resemble ladders, with two vertical rails and a series of horizontal rungs

between them.

Conclusion:

In this paper a method of controlling the operations of punching machines is

discussed. By using Programmable Logic Controllers as the controller of the system,

good control over the system can be achieved, manufacturing lead time of the system

can be reduced by developing automatic feeding mechanism and worker safety can be

increased by reducing the human participation in the process.

Reference

[1].

[2].

[3].

[4].

Aditya Polapragada, Sri Varsha, Pneumatic Auto Feed Punching and

Riveting Machine, International Journal of Engineering Research &

Technology (IJERT), Vol. 1 Issue 7, September 2012, ISSN: 2278-0181.

Vijaylaxmi.G.Biradar, Siddharam Patil , R M Lathe, Automation of Sheet

Bending Machine Using Electro Pneumatic Devices International Journal of

Scientific & Engineering Research Volume 3, Issue 9, September-2012 1

ISSN 2229-5518.

Handbook of die design, Second Edition, 2006, McGraw-Hill Handbooks,

Ivana Suchy.

Materials Handbook, Fifteenth Edition, 2008, Mc-Graw-Hill Handbooks,

George.S.Brady, Henry.R.Clauser.

You might also like

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Advance Bio-Photon Analyzer ABPA A2 Home PageDocument5 pagesAdvance Bio-Photon Analyzer ABPA A2 Home PageStellaEstel100% (1)

- Multiple Choice Question (MCQ) of Alternator and Synchronous Motors PageDocument29 pagesMultiple Choice Question (MCQ) of Alternator and Synchronous Motors Pagekibrom atsbha0% (1)

- Motorised Screw JackDocument4 pagesMotorised Screw JackhidaiNo ratings yet

- 3.PLC Based Sorting System Using Metal DetectionDocument9 pages3.PLC Based Sorting System Using Metal DetectionSree Lakshmi Mani Priyanka100% (1)

- PLC Simulation ReportDocument62 pagesPLC Simulation ReportAsraful Goni NirabNo ratings yet

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960From EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960No ratings yet

- MechatronicsDocument264 pagesMechatronicschandra shekharNo ratings yet

- DSA NotesDocument87 pagesDSA NotesAtefrachew SeyfuNo ratings yet

- PLC and SCADA Automation ReportDocument48 pagesPLC and SCADA Automation ReportsubrampatiNo ratings yet

- DC Motor Speed C BcontrolDocument6 pagesDC Motor Speed C BcontrolRoger RozarioNo ratings yet

- CST Jabber 11.0 Lab GuideDocument257 pagesCST Jabber 11.0 Lab GuideHải Nguyễn ThanhNo ratings yet

- Industrial Automation Summer Training Report, PLC, SCADA, HMI Instrumentation - ShamsherDocument49 pagesIndustrial Automation Summer Training Report, PLC, SCADA, HMI Instrumentation - ShamsherMd Shamsher86% (28)

- Competency-Based Learning GuideDocument10 pagesCompetency-Based Learning GuideOliver BC Sanchez100% (2)

- C79 Service Kit and Parts List GuideDocument32 pagesC79 Service Kit and Parts List Guiderobert100% (2)

- Automatic Punching MachineDocument10 pagesAutomatic Punching MachineShailesh KmrNo ratings yet

- Automatic Pneumatic Machine Using PLCDocument5 pagesAutomatic Pneumatic Machine Using PLCApurva ShirbhateNo ratings yet

- Comparative Study of CNC Controllers Used in CNC Milling MachineDocument9 pagesComparative Study of CNC Controllers Used in CNC Milling MachineAJER JOURNALNo ratings yet

- Design and Fabrication of 3-Axis CNC Milling Machine: AbstractDocument5 pagesDesign and Fabrication of 3-Axis CNC Milling Machine: AbstractMohammedsaleemNo ratings yet

- Monitoring cutting signals in real timeDocument4 pagesMonitoring cutting signals in real timeToni MišićNo ratings yet

- REVIEW PAPERDocument7 pagesREVIEW PAPERRoch RonaldoNo ratings yet

- "Programmable Logic Controller": Degree of Bachelor of TechnologyDocument42 pages"Programmable Logic Controller": Degree of Bachelor of TechnologyVikas VermaNo ratings yet

- Automation Paper: (1) Power To Accomplish The Process and Operate The SystemDocument5 pagesAutomation Paper: (1) Power To Accomplish The Process and Operate The SystemAnmol SetiaNo ratings yet

- Design and Implement A Semi-Automatic Clutch System For Automobiles Using DCV and The Link Mechanism To Reduce Human Effort While IncreasingDocument6 pagesDesign and Implement A Semi-Automatic Clutch System For Automobiles Using DCV and The Link Mechanism To Reduce Human Effort While IncreasingIJRASETPublicationsNo ratings yet

- Development of A PLC Controlled Drilling Machine: November 2016Document7 pagesDevelopment of A PLC Controlled Drilling Machine: November 2016Anirudh KamaniNo ratings yet

- Automatic Pneumatic Pipe Cutting Machine: Mahesh Aher, Prasad Raut, Kishorvyavahare Omkar Nilkanth, Pallavi GadeDocument5 pagesAutomatic Pneumatic Pipe Cutting Machine: Mahesh Aher, Prasad Raut, Kishorvyavahare Omkar Nilkanth, Pallavi GadeJackson MtongaNo ratings yet

- Ushless DC Motor Speed Control Using Both PIDocument7 pagesUshless DC Motor Speed Control Using Both PINxj CfcNo ratings yet

- PLC Based Segregation of Scrap Material: Mangesh B. Nagapure, Dr. R. M. DeshmukhDocument5 pagesPLC Based Segregation of Scrap Material: Mangesh B. Nagapure, Dr. R. M. DeshmukhMayur PatelNo ratings yet

- CNC Fundamentals and Part ProgrammingDocument21 pagesCNC Fundamentals and Part ProgrammingKavin Kind1234No ratings yet

- Touch Screen Based Industrial Crane ControllingDocument3 pagesTouch Screen Based Industrial Crane ControllingijsretNo ratings yet

- DC Motor Speed Controller Design Using Pulse WidthDocument12 pagesDC Motor Speed Controller Design Using Pulse WidthHerman BachtiarNo ratings yet

- Wireless Speed Control of DC Motor Using PWM and UARTDocument3 pagesWireless Speed Control of DC Motor Using PWM and UARTElins Journal100% (1)

- Hritik Baral - ES - CaseStudyDocument10 pagesHritik Baral - ES - CaseStudyHemanga RanaNo ratings yet

- Implementation of Home Automation Safety Control Using Programmable Logic ControllerDocument10 pagesImplementation of Home Automation Safety Control Using Programmable Logic ControllerAnjaneyulu NaikNo ratings yet

- International Journal of Computational Engineering Research (IJCER)Document5 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- Embedded Fuzzy-Control System For Machining Processes Results of A Case StudyDocument14 pagesEmbedded Fuzzy-Control System For Machining Processes Results of A Case StudyMuhammad BagusNo ratings yet

- Design & Implementation of Motion Controller For Industrial Paper Cutting MachineDocument7 pagesDesign & Implementation of Motion Controller For Industrial Paper Cutting MachineEditor IJRITCCNo ratings yet

- Pneumatic Auto Feed Punching and Riveting MachineDocument7 pagesPneumatic Auto Feed Punching and Riveting MachineAkgec BoschNo ratings yet

- The Design of The CNC Milling Machine PDFDocument10 pagesThe Design of The CNC Milling Machine PDFFirdaus MikeNo ratings yet

- The Design of The CNC Milling Machine: Piotr BoralDocument10 pagesThe Design of The CNC Milling Machine: Piotr Boralnasir akhtarNo ratings yet

- An Overview of PLC Based Control Panel System For External Plunge Grinding Machine and CNC MachineDocument3 pagesAn Overview of PLC Based Control Panel System For External Plunge Grinding Machine and CNC MachineIJMERNo ratings yet

- 2 1 1620801086 Ijaerdjun20213Document6 pages2 1 1620801086 Ijaerdjun20213TJPRC PublicationsNo ratings yet

- Color Making and Mixing Process Using PLCDocument5 pagesColor Making and Mixing Process Using PLCInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Industrial Automation and Control Sample Paper with AnswersDocument3 pagesIndustrial Automation and Control Sample Paper with AnswersMatthew SibandaNo ratings yet

- hệ thống kích từ trong nhà máy thủy điệnDocument344 pageshệ thống kích từ trong nhà máy thủy điệnTung NguyenNo ratings yet

- Synopsis Stamping Mechine1Document12 pagesSynopsis Stamping Mechine1Nayan JainNo ratings yet

- BLDC Motor Speed Control using PI and Fuzzy PIDocument8 pagesBLDC Motor Speed Control using PI and Fuzzy PIDrishyaNo ratings yet

- New Microsoft Word DocumentDocument10 pagesNew Microsoft Word DocumentTejas KadamNo ratings yet

- Arduino-Controlled Automatic Pneumatic SystemDocument31 pagesArduino-Controlled Automatic Pneumatic Systemnklharish1No ratings yet

- Automating drilling machine using pneumatic devicesDocument7 pagesAutomating drilling machine using pneumatic devicesdevang mishraNo ratings yet

- PLC Installation On Inner Ring Bore SHG Grinding MachineDocument5 pagesPLC Installation On Inner Ring Bore SHG Grinding MachineEditor IJRITCCNo ratings yet

- Automatic Gear Transmission in Two Wheelers Using Embedded SystemDocument12 pagesAutomatic Gear Transmission in Two Wheelers Using Embedded Systemgriffin9dhavarevNo ratings yet

- PLC Operated Cutting MachineDocument9 pagesPLC Operated Cutting MachineIJRASETPublicationsNo ratings yet

- 1.4 Principles of Control: CNC Machining TechnologyDocument12 pages1.4 Principles of Control: CNC Machining TechnologyEulerNo ratings yet

- 09 1361685115 Initial Face of AutomationDocument13 pages09 1361685115 Initial Face of AutomationMohammed SelmanNo ratings yet

- Prototype CNC Machine DesignDocument7 pagesPrototype CNC Machine DesignSuprapto ToNo ratings yet

- PLC Monitoring and Sequence ControlDocument9 pagesPLC Monitoring and Sequence ControlMohammed SelmanNo ratings yet

- Aditya'sDocument5 pagesAditya'saditya060848No ratings yet

- New9000English Mannual PDFDocument344 pagesNew9000English Mannual PDFLe Chi Pham100% (1)

- A Real Time Novel Technique For Controlling CNC SystemDocument9 pagesA Real Time Novel Technique For Controlling CNC SystemakashlogicNo ratings yet

- Report On Scada Based ProjectDocument38 pagesReport On Scada Based ProjectAictDurgapurNo ratings yet

- Automated Drilling MachineDocument14 pagesAutomated Drilling MachineVardhan ChipperNo ratings yet

- Design and Implementation of 8 Bit Asynchronous MicrocontrollerDocument5 pagesDesign and Implementation of 8 Bit Asynchronous MicrocontrollerShakeel RanaNo ratings yet

- Automation of Sectional Drive Paper Machine Using PLC and HMIDocument6 pagesAutomation of Sectional Drive Paper Machine Using PLC and HMImanoj kumarNo ratings yet

- Calculation For Checking The MechanicalDocument6 pagesCalculation For Checking The MechanicalAura RNo ratings yet

- Fall 2014 ResultsgDocument363 pagesFall 2014 ResultsgAnkur KulkarniNo ratings yet

- Pneumatic HammerDocument45 pagesPneumatic HammerKarthi KeyanNo ratings yet

- Slider Crank Power Hammer Mechanism Project ReportDocument33 pagesSlider Crank Power Hammer Mechanism Project ReportYemmina Madhusudhan80% (15)

- Slider Crank Power Hammer Mechanism Project ReportDocument33 pagesSlider Crank Power Hammer Mechanism Project ReportYemmina Madhusudhan80% (15)

- Design and Fabrication of Drop Forging Machine for Nonferrous MaterialsDocument2 pagesDesign and Fabrication of Drop Forging Machine for Nonferrous MaterialsaktNo ratings yet

- John GokongweiDocument14 pagesJohn GokongweiBela CraigNo ratings yet

- Comparing Time Series Models to Predict Future COVID-19 CasesDocument31 pagesComparing Time Series Models to Predict Future COVID-19 CasesManoj KumarNo ratings yet

- Sapkale Sandspit 2020Document5 pagesSapkale Sandspit 2020jbs_geoNo ratings yet

- Discretionary Lending Power Updated Sep 2012Document28 pagesDiscretionary Lending Power Updated Sep 2012akranjan888No ratings yet

- Arizona Supreme CT Order Dismisses Special ActionDocument3 pagesArizona Supreme CT Order Dismisses Special Actionpaul weichNo ratings yet

- MSDS Summary: Discover HerbicideDocument6 pagesMSDS Summary: Discover HerbicideMishra KewalNo ratings yet

- Ten Golden Rules of LobbyingDocument1 pageTen Golden Rules of LobbyingChaibde DeNo ratings yet

- Department of Ece Vjec 1Document29 pagesDepartment of Ece Vjec 1Surangma ParasharNo ratings yet

- Resume Ajeet KumarDocument2 pagesResume Ajeet KumarEr Suraj KumarNo ratings yet

- 2022 Product Catalog WebDocument100 pages2022 Product Catalog WebEdinson Reyes ValderramaNo ratings yet

- BAM PPT 2011-09 Investor Day PDFDocument171 pagesBAM PPT 2011-09 Investor Day PDFRocco HuangNo ratings yet

- Ju Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperDocument11 pagesJu Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperBiponjot KaurNo ratings yet

- MCDO of Diesel Shed, AndalDocument12 pagesMCDO of Diesel Shed, AndalUpendra ChoudharyNo ratings yet

- Insulators and Circuit BreakersDocument29 pagesInsulators and Circuit Breakersdilja aravindanNo ratings yet

- Continue: Adobe Project Voco DownloadDocument3 pagesContinue: Adobe Project Voco DownloadLazlo SecretNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument4 pagesEngine Controls (Powertrain Management) - ALLDATA Repairmemo velascoNo ratings yet

- Instrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1ZDocument24 pagesInstrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1Zmicmarley2012No ratings yet

- SyllabusDocument4 pagesSyllabusapi-105955784No ratings yet

- Rencana Pembelajaran Semester Sistem Navigasi ElektronikDocument16 pagesRencana Pembelajaran Semester Sistem Navigasi ElektronikLastri AniNo ratings yet

- ECON Value of The FirmDocument4 pagesECON Value of The FirmDomsNo ratings yet

- Analyze Oil Wear DebrisDocument2 pagesAnalyze Oil Wear Debristhoma111sNo ratings yet

- Law of TortsDocument22 pagesLaw of TortsRadha KrishanNo ratings yet

- Marketing ManagementDocument14 pagesMarketing ManagementShaurya RathourNo ratings yet

- MSBI Installation GuideDocument25 pagesMSBI Installation GuideAmit SharmaNo ratings yet