Professional Documents

Culture Documents

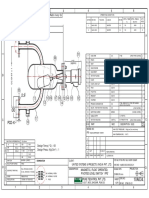

ID Fan

Uploaded by

nishant361Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ID Fan

Uploaded by

nishant361Copyright:

Available Formats

FIELD QUALITY ASSURANCE PLAN

Sl.No

II

Component& Operation

Storage of Material

Assembly

1.0

Assembly lower half/upper half of

RH inlet box with LH Inlet box

Assembly of lower half/upper half

Diffuser segment I with Diffuser

segment II

IV

Errection

1.0

Foundation Check

2.0

3.0

Type of

Check

Inspected By

Quantum Ref Document Format of

of check & Accep. Std

record Contractor

BGR

Customer

Visual Check

Visual

100%

Consigment

Document

Register/GR

--

Physical Verification with Despatch documents

Verification

100%

Consigment

Document

Register/GR

--

Material are properly stored at site

Visual

100%

--

Check Dimension prior to assembly or verify

component indentification mark

Visual,

Measurement

100%

Drg/Consignme

Log book

nt document

--

Check fitment of assembly and ensure bolts are

properly tightned

Visual

100%

Drg

Log book

RW

Check Dimension prior to assembly or verify

component indentification mark

Visual,

Measurement

100%

Drg/Consignme

Log book

nt document

--

Check assembly bolts are properly tightned

Visual

100%

Drg

Log book

RW

Check elevation level

Visual

100%

Drg

Log book

Verify foundation bolt size & Pitch

Visual

100%

Drg

Log book

Check Dimension of pedestall/support prior to

erection or verify component indentification

mark

Visual,

Measurement

100%

Drg/Consignme

Log book

nt document

--

Check location & Orientation

Visual,

Measurement

100%

Drg

Log book

--

Check Horizontal & Vertical axis levelness

Visual

100%

Drg

Log book

Verify Dimension prior to erection or Verify

component indentification mark

Visual,

Measurement

100%

Drg/Consignme

Log book

nt document

--

Check location & Orientation

Visual,

Measurement

100%

Drg

Log book

--

Check Horizontal & Vertical axis levelness

visual

100%

Drg

Log book

Check water level & Verticality

Measurement

100%

Drg

Log book

Receipt inspection

III

2.0

Characteristics

Fixing of Pesdetal/Support

--

Remarks

By Sprit level

Fixing of casing

Page 1 of 4

By Sprit level

FIELD QUALITY ASSURANCE PLAN

Sl.No

4.0

5.0

6.0

6.1

6.2

6.3

7.0

Component& Operation

Fixing of lower half of small

collector/ adjustable guide

vane/big collector

Fixing of lower half Inlet box

assembly with big collector

Characteristics

Type of

Check

Inspected By

Quantum Ref Document Format of

of check & Accep. Std

record Contractor

BGR

Customer

Verify Dimension prior to erection or Verify

component indentification mark

Visual,

Measurement

100%

Drg/Consignme

Log book

nt document

--

Check location & Orientation

Visual,

Measurement

100%

Drg

Log book

--

Check assembly bolts are properly tightned

Visual

100%

Drg

Log book

--

Check Horizontal & Vertical axis levelness

visual

100%

Drg

Log book

Check water level, verfy casing centre with fan

axis & verticality

Measurement

100%

Drg

Log book

Check location & Orientation

Visual,

Measurement

100%

Drg

Log book

--

Check assembly bolts are properly tightned

Visual

100%

Drg

Log book

--

Check Horizontal & Vertical axis levelness

visual

100%

Drg

Log book

Check water level

visual

100%

Drg

Log book

Verify component indentification mark

Visual

100%

Drg/Consignme

Log book

nt document

Check location, Orientation & Fitment

Visual

100%

Drg

Log book

Ensure bolts are properly tightened

Visual

100%

Drg

Log book

Check Horizontal & Vertical axis levelness

Visual

100%

Drg

Log book

Verify component indentification mark

Visual

100%

Drg

Log book

Check Orientation & fitment with main bearing

assembly

Visual

100%

Drg

Log book

Ensure bolts are properly tightened

Visual

100%

Drg

Log book

Verify component indentification mark

Visual

100%

Drg/Consignme

Log book

nt document

--

Check Fitment of coupling with bearing assembly Visual

100%

Drg

Log book

Ensure bolts are properly tightened

Visual

100%

Drg

Log book

--

Check Horizontal axis levelness

Visual

100%

Drg

Log book

RW

Verify component indentification mark

Visual

100%

Drg/Consignme

Log book

nt document

--

Check location, Orientation & Fitment

Visual

100%

Drg

Log book

--

Ensure bolts are properly tightened

Visual

100%

Drg

Log book

Remarks

By Sprit level

By Sprit level

Mounting of Rotor Parts

Main Bearing asembly

Impeller

Half coupling & Intermediate shaft

Mounting of Inlet guide vane

core/Takeup/Shaft protective

pipe/Guarding

Page 2 of 4

By Sprit level

By Sprit level

FIELD QUALITY ASSURANCE PLAN

Sl.No

8.0

9.0

10.0

11.0

12.0

Component& Operation

Characteristics

Mounting of upper half of Inlet box Check Orientation & Fitment

assembly/Big collector/Adjustable

Guide vane/small collector

Ensure bolts are properly tightened

Clearance

Fixing of Diffuser core /cone cool

wind enclosure/Straight

tube/Casing palte

Mounting of upper half diffuser

assembly

Mounting of Motor

14.0

Mounting of gude vane control

mechanism (actuator)

Inspected By

Quantum Ref Document Format of

of check & Accep. Std

record Contractor

BGR

Customer

Visual

100%

Drg

Log book

--

Visual

100%

Drg

Log book

Impeller to casing

Measurement

100%

Drg

Protocol

Impeller to guide vane core

Measurement

100%

Drg

Protocol

Inlet guide vane to casing

Measurement

100%

Drg

Protocol

--

Verify component indentification mark

Visual

100%

Drg/Consignme

Log book

nt document

Check fitment of assembly and ensure bolts are

properly tightned

Visual

100%

Drg

Log book

--

Impeller to diffuser core clearance

Measurement

100%

Drg

Log book

RW

Check Orientation & fitment

Visual

100%

Drg

Log book

--

Ensure bolts are properly tightened

Visual

100%

Drg

Log book

--

Ensure field welds are completed

Visual

100%

Drg

Log book

Verify component indentification mark

Visual

100%

Drg/Consignme

Log book

nt document

--

Visual

100%

Drg

Log book

--

Ensure bolts are properly tightened

Visual

100%

Drg

Log book

Check location, Orientation & elevation

Measurement

100%

Drg

Protocol

Check alignment of motor shaft with

intermediate shaft (Radial & Axial)

Measurement

100%

Drg

Protocol

Ensure coupling bolts are properly tightened

Visual

100%

Drg

Protocol

Ensure location, orientation & Fitment

Visual

100%

Drg

Log book

Mounting of Inlet/Outlet Expansion

Check orientation & fitment

joints

13.0

Type of

Check

Page 3 of 4

Remarks

FIELD QUALITY ASSURANCE PLAN

Sl.No

Component& Operation

Characteristics

15.0

Fixing of Cooling air fan/Cooling air

piping/Lubricating oil piping/Stall

Ensure location, orientation & Fitment

alarm measuremt

16.0

Insulation

17.0

18.0

Vi

Ducting

Silencer

Type of

Check

Inspected By

Quantum Ref Document Format of

of check & Accep. Std

record Contractor

BGR

Customer

Visual

100%

Drg

Log book

RW

Ensure hook fixed and spot welded

Visual

100%

Drg

Log book

--

Ensure wool laying thickness

Visual

100%

Drg

Log book

Ensure routing of duct

Visual

100%

Drg

Log book

--

Check duct joints are properly bolted

Visual

100%

Drg

Log book

Verify duct supports are completed

Visual

100%

Drg

Log book

Check location, Flow direction & Fitment

Visual

100%

Drg

Log book

Ensure all componets are assembled

Visual

100%

Drg

Log book

Ensure all filed welding are completed

Visual

100%

Drg

Log book

RW

Ensure foreign material are removed

Visual

100%

--

Log book

RW

Ensure electrical connetions are properly done

Visual

100%

Drg

Log book

Ensure lubrication level is enough

Precommissioning

Commissioning

Visual

100%

Drg

Log book

Conduct no laod test on motor and measurement

Visual

current & volt

100%

Drg/Datasheet

Log book

Start the fan & ensure fan is runing smooth

Visual

100%

--

Protocol

Run the fan and check any leakage in duct joints Visual

100%

No leakage

Protocol

Run the fan and check fan is runing smooth

Visual

100%

--

Protocol

Adjust IGV control mechanism to achieve

required flow (if required)

Visual

100%

Drg/Datasheet

Protocol

Measure vibration level

Measurement

100%

Drg/Datasheet/

Spec.

Protocol

Measure current,volt & power consumption

Measurement

100%

Drg/Datasheet

Protocol

Page 4 of 4

Remarks

You might also like

- CES Business PresentationDocument50 pagesCES Business PresentationGary David CrowhurstNo ratings yet

- D Detail D Detalle D: DISCO, VG 4 150 DISC, VG 4 150Document1 pageD Detail D Detalle D: DISCO, VG 4 150 DISC, VG 4 150tauasi_1No ratings yet

- Jam003mqn400 408Document1 pageJam003mqn400 408Sebastian Davila hernandezNo ratings yet

- ARKAN SHADES Welding Inspection & Paint InspectionDocument2 pagesARKAN SHADES Welding Inspection & Paint InspectionSpectex dubaiNo ratings yet

- Jam003mqn400 409Document1 pageJam003mqn400 409Sebastian Davila hernandezNo ratings yet

- Tug Fenders Form - Fill inDocument2 pagesTug Fenders Form - Fill inaNo ratings yet

- Dowelingjig Plans Cut TempDocument9 pagesDowelingjig Plans Cut TempKeith WesleyNo ratings yet

- 43 - Hofmann - Portable Machine Tools Brochure - A4Document2 pages43 - Hofmann - Portable Machine Tools Brochure - A4Jorge VillalobosNo ratings yet

- Modular Multi Cat 1205 Product SheetDocument2 pagesModular Multi Cat 1205 Product SheetAnonymous hlPPOmxXB7No ratings yet

- Role of ContainersDocument39 pagesRole of ContainersEliza PopaNo ratings yet

- Up Workshop Manual 2020Document62 pagesUp Workshop Manual 2020peniel ccNo ratings yet

- Cylinder Hyd SealDocument72 pagesCylinder Hyd SealrajualagNo ratings yet

- Project: Epc Contract For Dry Bulk Cargo Termnal Atsan Pedro Ivory CoDocument1 pageProject: Epc Contract For Dry Bulk Cargo Termnal Atsan Pedro Ivory Coaravind grandhiNo ratings yet

- Bsec Enterprises - CTG Dry DockDocument5 pagesBsec Enterprises - CTG Dry DockTasnova Shahreen ChowdhuryNo ratings yet

- Design Fabrication & Testing of Screw Conveyor: BY V. Durga Karthik A. Manoj Kumar G.I Manoj RamachandranDocument24 pagesDesign Fabrication & Testing of Screw Conveyor: BY V. Durga Karthik A. Manoj Kumar G.I Manoj RamachandranKing Maker100% (1)

- No.2 Wugang Road, Industrial Park, Botou City Hebei Province, China 062150 TEL: 86-317-8222761 8293066 8319026 FAX: 86-317-8319058Document160 pagesNo.2 Wugang Road, Industrial Park, Botou City Hebei Province, China 062150 TEL: 86-317-8222761 8293066 8319026 FAX: 86-317-8319058boris velastegui sanchezNo ratings yet

- Fishing Boat 5m Dili-1 General ArrangementDocument1 pageFishing Boat 5m Dili-1 General Arrangementganda irvanNo ratings yet

- Novaflow POM Industry Brochure PDFDocument36 pagesNovaflow POM Industry Brochure PDFJulhamEfendiNo ratings yet

- Excel Template Manpower Planning, Manpower Efficiency, Manpower RequirementDocument5 pagesExcel Template Manpower Planning, Manpower Efficiency, Manpower Requirementpankaj66668No ratings yet

- 0015-2 GL Guidelines For Approval of Construct, Towage and InstallDocument22 pages0015-2 GL Guidelines For Approval of Construct, Towage and InstalldamnagedNo ratings yet

- 2013 Container Information BulletinDocument13 pages2013 Container Information BulletinAaron Huaynate EspinozaNo ratings yet

- 2015 Container Exam BulletinDocument14 pages2015 Container Exam BulletinAndrés Falla VictoriaNo ratings yet

- EGP3-01.16 Welding For Skids and Miscellaneous SteelDocument10 pagesEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodeNo ratings yet

- Format Time Frame Penggantian & Service PKS 2021 & StandardDocument66 pagesFormat Time Frame Penggantian & Service PKS 2021 & StandardSalim SiregarNo ratings yet

- Work Method StatementDocument9 pagesWork Method StatementdjvhNo ratings yet

- Miter Gauge PDFDocument8 pagesMiter Gauge PDFJesus MachadoNo ratings yet

- Quality Control System in The Fabrication of Heat ExchangersDocument5 pagesQuality Control System in The Fabrication of Heat ExchangersCorine CaracasNo ratings yet

- Komatsu Undercarriage Inspection: #SerieDocument1 pageKomatsu Undercarriage Inspection: #SerieCiro RodasNo ratings yet

- FQP 16.11.18 Vol-I - BoilerDocument90 pagesFQP 16.11.18 Vol-I - Boilerashis chatterjeeNo ratings yet

- Ventilation FansDocument39 pagesVentilation FanskalaiNo ratings yet

- Lathe MachineDocument12 pagesLathe MachineHermilih SiregarNo ratings yet

- Boiler Hydrostatic TestingDocument2 pagesBoiler Hydrostatic Testingbonginkosi mathunjwaNo ratings yet

- All About Floating SealsDocument6 pagesAll About Floating SealsBipin KumarNo ratings yet

- Asigmnet 1 - ShipyardDocument28 pagesAsigmnet 1 - Shipyardulzzang looNo ratings yet

- LSM Product Flyer 2021Document4 pagesLSM Product Flyer 2021JohnsonNo ratings yet

- Floating DrydockDocument1 pageFloating DrydockAhmed TarekNo ratings yet

- Barge Inspection Book: United States Coast GuardDocument34 pagesBarge Inspection Book: United States Coast GuardNMHaNo ratings yet

- Screener Catalog 209Document18 pagesScreener Catalog 209Kumar GalipellyNo ratings yet

- Identification of Risk and Providing GuiDocument5 pagesIdentification of Risk and Providing GuiJay PanitanNo ratings yet

- Quality Standars of ShipbuildingDocument60 pagesQuality Standars of ShipbuildingMohamed HassanNo ratings yet

- Inspection & Test Plan: Dangote Oil Refinery CompanyDocument7 pagesInspection & Test Plan: Dangote Oil Refinery CompanyGowtham VenkatNo ratings yet

- PE ASME Boiler Initial Report NB-405Document3 pagesPE ASME Boiler Initial Report NB-405Jeanette BeukesNo ratings yet

- Shimano XTR M980 Shift Lever Set ManualDocument4 pagesShimano XTR M980 Shift Lever Set ManualNick SpeisNo ratings yet

- JMT Welding Positioner CatalogDocument8 pagesJMT Welding Positioner Catalogazeez basha100% (1)

- Safety & Maintenance Checklist-Wheel LoadersDocument4 pagesSafety & Maintenance Checklist-Wheel LoadersHariyanto oknesNo ratings yet

- List of Gear Motor & Elektro MotorDocument23 pagesList of Gear Motor & Elektro MotorChandra AndrikaNo ratings yet

- Inspection and Test Plan: Page 1+0 of 7Document7 pagesInspection and Test Plan: Page 1+0 of 7Jamal Mohamed Rahamathullah100% (1)

- Astm MaterialsDocument13 pagesAstm Materialssathish_iyengarNo ratings yet

- Belt Tension RecommendationsDocument2 pagesBelt Tension RecommendationsW MoralesNo ratings yet

- Dockwise Case StudyDocument2 pagesDockwise Case StudyJEORJENo ratings yet

- 3 - SELECTION OF WELDING ELECTRODES - StudentDocument15 pages3 - SELECTION OF WELDING ELECTRODES - Studentrazlan ghazaliNo ratings yet

- Boiler Hydro TestDocument35 pagesBoiler Hydro TestMoez HamoudiNo ratings yet

- Social Internship Report (25,36,46) PDFDocument34 pagesSocial Internship Report (25,36,46) PDFRomit Patel0% (1)

- Itp For Tank Fabrication & Installation Work1 - Rev02Document22 pagesItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemsP SHANKAR BABU100% (16)

- HRSG ITP (Rev E)Document5 pagesHRSG ITP (Rev E)rvsreddysena100% (5)

- Air Cooled Heat Exchanger Inspection and Test Plan SampleDocument4 pagesAir Cooled Heat Exchanger Inspection and Test Plan Samplemkash028No ratings yet

- ITP-001 Steelwork Fabrication Rev ADocument5 pagesITP-001 Steelwork Fabrication Rev AMarcus Cox100% (2)

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertNo ratings yet

- Siemens: 1200 MW DGEN Mega Power ProjectDocument4 pagesSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaNo ratings yet

- Structural Steel ErectionDocument17 pagesStructural Steel ErectionHemanth KumarNo ratings yet

- Flange TypesDocument1 pageFlange TypesHadi UtomoNo ratings yet

- Contractor Safety RequirementsDocument32 pagesContractor Safety Requirementsask1400No ratings yet

- Elbow For Dedusting DuctDocument1 pageElbow For Dedusting Ductnishant361No ratings yet

- Work Item Description UOM Scope Achieved Progress Planned Start Actual Start Planned Finish Actual Finish RemarksDocument2 pagesWork Item Description UOM Scope Achieved Progress Planned Start Actual Start Planned Finish Actual Finish Remarksnishant361No ratings yet

- Hydrogen Cracks in Steels TWIDocument5 pagesHydrogen Cracks in Steels TWInishant361No ratings yet

- Tank JackingDocument1 pageTank Jackingnishant361No ratings yet

- Chapter 1Document6 pagesChapter 1D.RameshkumarNo ratings yet

- Pressure Testing SafetyDocument4 pagesPressure Testing Safetyapi-26143956100% (2)

- Dimension Tolerance (Coal Mill)Document4 pagesDimension Tolerance (Coal Mill)nishant361No ratings yet

- Chapter 5CDocument6 pagesChapter 5Cnishant361No ratings yet

- Coal Mill Field Quality PlanDocument3 pagesCoal Mill Field Quality Plannishant361No ratings yet

- English - Compact Inspector's ManualDocument16 pagesEnglish - Compact Inspector's Manualnishant361No ratings yet

- Chapter 11 Radiography in Modern IndustryDocument7 pagesChapter 11 Radiography in Modern Industrynishant361No ratings yet

- Bhel Welding GuidelinesDocument64 pagesBhel Welding Guidelinesashutoshsachan100% (3)

- En 12068Document48 pagesEn 12068pametnjakovicmladji100% (12)

- VTG Iom 2013 0815Document96 pagesVTG Iom 2013 0815nishant361No ratings yet

- Real Time Radiography Course BookletDocument48 pagesReal Time Radiography Course BookletAnonymous gFcnQ4goNo ratings yet

- CoatingDocument8 pagesCoatingAbhinav GoyalNo ratings yet

- 10 - RT SG IiDocument120 pages10 - RT SG Iinishant361No ratings yet

- Chapter 4 Radiography in Modern IndustryDocument11 pagesChapter 4 Radiography in Modern Industrynishant361No ratings yet

- Mess Bill For The Month of SEPTEMBER-2012: TotalDocument2 pagesMess Bill For The Month of SEPTEMBER-2012: Totalnishant361No ratings yet

- Chapter 10 Radiography in Modern IndustryDocument17 pagesChapter 10 Radiography in Modern Industrynishant361No ratings yet

- 1booked Tickets History PDFDocument1 page1booked Tickets History PDFnishant361No ratings yet

- IndiaMike PDFDocument7 pagesIndiaMike PDFnishant361No ratings yet

- Heat Treatment ManualDocument25 pagesHeat Treatment Manualraj101086100% (1)

- Heat Treatment ManualDocument25 pagesHeat Treatment Manualraj101086100% (1)

- Pure Protect BrochureDocument6 pagesPure Protect Brochuredhuaraaj212No ratings yet

- Reaction Rates Worksheet-1452167356Document6 pagesReaction Rates Worksheet-1452167356feta cumaniNo ratings yet

- Hopf Cole BrownDocument21 pagesHopf Cole BrownRoberticoZeaNo ratings yet

- MWH S Water Treatment Principles and Design Third Edition - 2012 - Crittenden - Appendix C Physical Properties of WaterDocument2 pagesMWH S Water Treatment Principles and Design Third Edition - 2012 - Crittenden - Appendix C Physical Properties of WaterbastianpurwaNo ratings yet

- ME355 NotesDocument147 pagesME355 NotesrogerfisicaNo ratings yet

- Modelling of Combined Vacuum and Surcharge PreloadDocument6 pagesModelling of Combined Vacuum and Surcharge PreloadAdriel ElezarNo ratings yet

- How To Extract The Maximum Information From Dma TestsDocument13 pagesHow To Extract The Maximum Information From Dma TestsGyörgy BánhegyiNo ratings yet

- 018 10Document3 pages018 10ilkerkozturkNo ratings yet

- PVC PDFDocument15 pagesPVC PDFsrabon1059No ratings yet

- Paper 2 1Document16 pagesPaper 2 16brk8sjszqNo ratings yet

- SSC JE Mechanical Study Material Strength of Materials PDFDocument13 pagesSSC JE Mechanical Study Material Strength of Materials PDFSameer ShahNo ratings yet

- Emm Question Bank Unit3Document3 pagesEmm Question Bank Unit3MANOJ MNo ratings yet

- Heat ExchangerDocument11 pagesHeat ExchangerLouise DimaunahanNo ratings yet

- ManualDocument7 pagesManualAsri GaniNo ratings yet

- HOW TO DESIGN AMMONIA REFRIGERATION PLANT USING AAR STANDARD 1 2016 by Ramesh ParanjpeyDocument7 pagesHOW TO DESIGN AMMONIA REFRIGERATION PLANT USING AAR STANDARD 1 2016 by Ramesh ParanjpeyMark Anthony CentenoNo ratings yet

- Welding Technology Revision Question Sans ReponseDocument15 pagesWelding Technology Revision Question Sans ReponsedeliNo ratings yet

- Agma 930-A05Document86 pagesAgma 930-A05Mehul Bansal100% (1)

- 6 Cooling TowerDocument8 pages6 Cooling TowerMico Sylvester100% (3)

- Organograma ASME IX Art. I PDFDocument4 pagesOrganograma ASME IX Art. I PDFfabiocorreasilvaNo ratings yet

- Mock XM CPC Science Paper 1Document17 pagesMock XM CPC Science Paper 1nurNo ratings yet

- 1.1 Fluid Power Defined: 1.2 Hydraulics Versus PneumaticsDocument2 pages1.1 Fluid Power Defined: 1.2 Hydraulics Versus Pneumaticsswami061009No ratings yet

- Numerical Simulation of Two-Dimensional Laminar Slot-Jet Impingement Flows Confined by A Parallel WallDocument19 pagesNumerical Simulation of Two-Dimensional Laminar Slot-Jet Impingement Flows Confined by A Parallel WallAENo ratings yet

- Water Chiller: No Unnecessary Water Consumption Due To A Closed Water Circuit Operating PrincipleDocument2 pagesWater Chiller: No Unnecessary Water Consumption Due To A Closed Water Circuit Operating Principleludo-du-67No ratings yet

- Interference - Division of AmplitudeDocument9 pagesInterference - Division of AmplitudeJRonald85No ratings yet

- Polarimetry: Theory & Principle Instrumentation Applications DisadvantagesDocument23 pagesPolarimetry: Theory & Principle Instrumentation Applications DisadvantagesVanessa LimNo ratings yet

- Trox - Slot Diffucer - VSD 50Document30 pagesTrox - Slot Diffucer - VSD 50AkilaJosephNo ratings yet

- A Review of Photovoltaic Performance of Organicinorganic SolarDocument53 pagesA Review of Photovoltaic Performance of Organicinorganic SolarChristhy Vanessa Ruiz MadroñeroNo ratings yet

- Caltrans Bridge SpecificationDocument29 pagesCaltrans Bridge SpecificationsamratkadamNo ratings yet

- CompositePro Users GuideDocument146 pagesCompositePro Users GuidebnidhalNo ratings yet

- Re.6th - Ch24 25Document6 pagesRe.6th - Ch24 25Henry Palomino CutireNo ratings yet