Professional Documents

Culture Documents

RA 002 - Engine Casing Exhaust Funnel - Hot Work

Uploaded by

dassi99Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA 002 - Engine Casing Exhaust Funnel - Hot Work

Uploaded by

dassi99Copyright:

Available Formats

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

RISK MANAGEMENT

Operation / Work activity being assessed:

Generated by: Vessel

RA Code number:

Hot Work at Engine Casing Exhaust Funnel Boiler 1

Routine

Non-routine

Office

(record the name)

ALTERNATIVE WAYS TO CONDUCT THE WORK (Prior to deciding to proceed with the work always ensure that all other alternatives methods

for carrying out the job have been identified and documented )

No alternative way to conduct this task available.

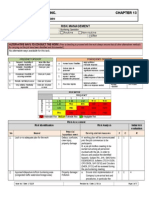

FREQUENCY CATEGORY

CONSEQUENCE CATEGORY

Frequent - Possibility of

repeated incidents

Probable - Possibility of

isolated incidents

More often than

once per voyage

Once per year

Occasional- Possibility of

occurring sometime

Once per 5 years

Remote- Not likely to occur

Once per 10 years

Very unlikely- Practically

impossible

Once per 30 years

or more

CECONSEQUEN

1

2

3

4

Human losses / fatalities

Major pollution /

Full scale response

Serious injury to

personnel

Moderate pollution/

Significant resources commitment

Number of minor

injuries / Medical

treatment for personnel

Little pollution /

Limited response of short duration

Little cost or damage

($10000 $ 100000)

Slight impact

Few minor injuries

Minimum pollution /

Little or no response needed

Minimum cost /

damage

< $10000

Zero impact

1

L (1)

L (2)

RISK MATRIX

FREQUENCY

2

3

L (2)

L (3)

M(4)

M(6)

4

M (4)

H(8)

5

M (5)

H(10)

L(3)

M(6)

H(9)

H(12)

H(15)

M(4)

H(8)

H(12)

H(16)

H(20)

Excessive/ high cost

damage >$1000000

Moderate cost or

damage

(100000 1000000$)

Major national &

international impact

Considerable

impact

High=Intolerable Risk Medium=Tolerable Risk Low=Negligible Risk

Risk Assessment

Risk Identification

No

Hazard

Inadequate planning / competence /

experience.

Issue No. / Date: 1 / 02.07

Risk Analysis

Potential

hazardous event

Personal injury /

property

damage

Initial risk

evaluation

Existing control measures

- Necessary competence/experience

as per SMS 7.9.14

Competent Person; a person who

has, through a combination of

experience and education acquired

knowledge and skills to perform at

the expected level

- A pre job safety meeting will take

place, with all personnel involved with

the job. Present RA and P006 will be

communicated to all persons involved

in the job.

- Stby personnel will be available

- Contingency plan and rescue team

Revision No. / Date: 2 / 05.14

Page 1 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Presence of flammable vapors /

Combustible materials in the working area.

Spark / melting steel flying in the area.

Issue No. / Date: 1 / 02.07

Risk Analysis

Potential

hazardous event

Fire explosion.

Fire explosion.

Existing control measures

to be available at all times.

- Read makers manual

- Ensure that all required materials

are available onboard

- The person assigned by chief

engineer to carry out the hot work

must be experience and qualified.

- The chief engineer or the 2nd

engineer (if designated) should

supervise the work.

After work break, the work will be

resumed only after the supervisor

ensures that control measures are

still valid

- Hot work inside a designated space

(ISGOTT 9.4.2/3) SMS 7.9 App I

- Any combustible materials to be

removed in a safe box and kept in

safe distance from the working area

- Controls of the relevant JHA/P002

occupational hazard in place to be

strictly followed.

- Fire hoses will be connected to

main line and pressurized

- Hot work (SMS 7.9.3).

- Procedure for intentional and

temporary disconnection of a fire

detector (SMS 10.1.15. & 10.1.6)

Below measures also apply to

Hazard No.2.

a. The hot work NOT be carried

out concurrently with any

cargo / tank cleaning / gas

freeing / purging / inerting /

bunkering operation.

b. Work should be carried out in

the space with shield or curtain

erected and the ventilation

switched on.

c. The atmosphere in the space to

be monitored by a multigas

detection instrument so as to

ensure that is maintained less

that 1% LFL.

Revision No. / Date: 2 / 05.14

Initial risk

evaluation

F

Page 2 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

High temperature in the working area.

Issue No. / Date: 1 / 02.07

Risk Analysis

Potential

hazardous event

Fire explosion.

Existing control measures

d. Cargo tanks pressure should be

kept in normal operating

condition and below 180Mbar. A

poster on the CCR and Bridge

will inform the officers that a hot

work is in progress and rise of

the tanks pressure above

180Mbar, should not be

allowed. If in any case the cargo

tanks pressure is out of control,

job will be seized.

e. To extent possible any

prefabrication work (e.g.

pipework and supports) should

be carried out in E/R work shop.

f. Adequate firefighting equipment

must be prepared and laid out

and be ready for immediate

use.

g. A fire watch must be

established for the area of hot

work and for adjacent, space

where the transfer of heat, or

accidental damage might create

hazard e.g. damage to hydraulic

line, electrical cables, thermal

oil lines etc. The fire watch will

monitor the work and take

action in case of ignition of

residues or paint coating.

h. No hot work should be carried

out on bulkheads of bunkers

tanks, or within 500 mm of such

bulkheads, unless that tank is

cleaned to hot work standard.

i. Do not operate tags will be

posted and MGM Safe isolation

procedures will be followed

(LOTO System)

In addition to the above, the

portable fire extinguishers should

be readily available for use.

Hot work (SMS 7.9.3).

- In order to avoid high temperature

Revision No. / Date: 2 / 05.14

Initial risk

evaluation

F

4

Page 3 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Adverse weather.

Lifting / transferring heavy objects.

Risk Analysis

Potential

hazardous event

Personal injury /

property

damage

Personal injury /

property

damage

Work at height.

Personal injury.

Leakage of O2/Acetylene

Fire explosion

Issue No. / Date: 1 / 02.07

Existing control measures

in the area, will stop grinding time to

time, in order to cooling down the

grinding area.

- Precaution against dehydration

should be taken

Weather conditions will be monitored

during the job.

The work should be carried out under

favorable sea condition; in case of

weather deterioration the job should

be stopped.

Lifting appliances / lifting operation

(SMS 7.9.11).

Safety Bulletin 02/2009

- During lifting of heavy object all

personnel should keep clear of the

dangerous zone,. Lifting equipment

appliances to be inspected in order

their condition to be verified prior to

their use. Lifting equipment must

have adequate SWL for the weight of

the object handled.

- Assessment of the weight of the

object that will be handled should be

made in advance according to

packing details or equipment weight

as per manufacturer.

Additional lifting moving equipment

(i.e. trolley) to be used if the weight

cannot be handled by manpower only.

Working over side or aloft (SMS

7.9.7).

Periodic inspection of the

O2/Acetylene fixed piping system (as

per PMS)

a. The gas supply flexible hoses

should be inspected to confirm

their good condition (i.e.

extensive wear & tear, no kinks,

no cuts etc.)

b. The welding torch and associated

fittings should be inspected to

confirm their good condition (i.e.

nozzle / isolation valve in good

Revision No. / Date: 2 / 05.14

Initial risk

evaluation

F

Page 4 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

10

11

12

13

Hazard

Flame flashback in the gas piping

Crew Fatigue

Risk Analysis

Potential

hazardous event

Fire explosion

Personal injury

Un-expected oil leakage from a pipe/pump

inside purifier room.

Brake of Grinding Wheel

Electrocution caused by the welding cables

Fire due to oil

stains at purifier

room floor.

Crew Injury

Crew Injury

Initial risk

evaluation

Existing control measures

condition, no broken parts, no

mechanical damage etc)

In case of temporary suspension and

after completion of the work, supply

valve on gas cylinder and gas mains

should be securely closed and flexible

hose de-pressurized

Welding / cutting work (SMS 7.9.3)

It should be ensured that flashback

arresters fitted at the work station and

the bottles storage space are in good

order

Only well rested personnel will

participate in the job. Work rest

periods should be provided prior job

commence.

Any involved personnel showing sign

of fatigue should be released form

duty and replaced at once.

In case of unexpected oil leakage, job

will be immediately ceased.

Area will be cleaned and hazards will

be reassessed in order job to be

continued.

1.

PPE appropriate for the task

carried out to be used all the time

2.

Trained personnel to be used

for the task

3.

Grinding equipment to be

confirmed in good operation

condition, prior the job

commenced.

1.

Tools will be checked by

Chief Eng & ETO.

2.

To consider the use of air

powered grinders

Note F: Frequency, C: Consequence, R: Risk

Notes: (1) This Form should be filed onboard in File M27 & E5.

Risk Treatment

Hazard

No.

Issue No. / Date: 1 / 02.07

Additional Risk Control Measures

Residual risk

evaluation

Responsible

Revision No. / Date: 2 / 05.14

*Action

Timeline

Page 5 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Note F: Frequency, C: Consequence, R: Risk

Contingency plans (to facilitate safe management and recovery of the situation in case of any unplanned occurrences)

Emergency case

Contingency Plans

SMS/Ch. 8 Emergency response 7, 9

Risk Assessment reviewed/approved by:

Name

Rank / Title

Signature

Date

Please enter below the persons who will be

involved in the job:

Remarks:

*Action timeline : Ensure the close out of the preventive actions prior to commencement of work.

Verification (Master and the Officer in Charge) that all control measure are fully implemented prior work commencing.

Name

Rank / Title

Signature

Date

Office verification reviewed/approved by:

Name

Issue No. / Date: 1 / 02.07

Rank / Title

Signature

Revision No. / Date: 2 / 05.14

Date

Page 6 of 6

You might also like

- RA 002 - D.O. Tank Inspection and CleaningDocument6 pagesRA 002 - D.O. Tank Inspection and Cleaningdassi99100% (1)

- RA 002 - HFO Line Pressure TestDocument4 pagesRA 002 - HFO Line Pressure Testdassi99100% (1)

- RA 002 - LPSG Steam Pipe Hot Work in ERDocument6 pagesRA 002 - LPSG Steam Pipe Hot Work in ERdassi99No ratings yet

- Conversion Table For PressureDocument4 pagesConversion Table For Pressuredassi99No ratings yet

- Ra02 - Container OffloadingDocument3 pagesRa02 - Container OffloadingSamNo ratings yet

- STC5 Risk Management and Safe Work ProcedureDocument36 pagesSTC5 Risk Management and Safe Work ProcedureDenise Isebella LeeNo ratings yet

- Job Safety Analysis (JSA)Document4 pagesJob Safety Analysis (JSA)Wisnu WicaksonoNo ratings yet

- No.21 Manual HandlingDocument6 pagesNo.21 Manual HandlingAbdul Hakam Mohamed Yusof100% (1)

- PPE MatrixDocument1 pagePPE MatrixMohamedSaidNo ratings yet

- Hot Work Procedures: PermitDocument8 pagesHot Work Procedures: PermitaskforraviNo ratings yet

- PTSB (Jsa Form)Document5 pagesPTSB (Jsa Form)hanujaNo ratings yet

- Risk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Document1 pageRisk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Devi Ratna Pratiwi0% (1)

- Risk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09Document2 pagesRisk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09sizwe0% (1)

- Risk Assessment - Working Ship SideDocument3 pagesRisk Assessment - Working Ship SideSatya SatishNo ratings yet

- Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX BDocument5 pagesRisk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX BDevi Ratna Pratiwi100% (2)

- Risk Assessment No. 46 PERSONNEL TRANSFER Rev. 02 20.03.09Document1 pageRisk Assessment No. 46 PERSONNEL TRANSFER Rev. 02 20.03.09Devi Ratna PratiwiNo ratings yet

- Pipelines and Flowlines Cold Cutting ProcedureDocument27 pagesPipelines and Flowlines Cold Cutting ProcedureSuresh Kumar GNo ratings yet

- Safety Organisation & Safety Committee MeetingDocument6 pagesSafety Organisation & Safety Committee MeetingVishu SharmaNo ratings yet

- HSEMS & Manual Rev 02, May 2018Document419 pagesHSEMS & Manual Rev 02, May 2018isaacNo ratings yet

- HSE Exception Request Form Rev.1Document1 pageHSE Exception Request Form Rev.1Dhimaz YudiNo ratings yet

- 6.2 - Hsse Risk ManagementDocument27 pages6.2 - Hsse Risk ManagementNwekeNwokomaAugustineNo ratings yet

- Risk Assessment No. 05 APPROACHING INSTALLATION Rev. 02 20.0Document2 pagesRisk Assessment No. 05 APPROACHING INSTALLATION Rev. 02 20.0Devi Ratna PratiwiNo ratings yet

- LSA & FFA MaintenanceDocument32 pagesLSA & FFA Maintenanceajinkyachaubal2No ratings yet

- #014 Working AloftDocument4 pages#014 Working AloftTolias EgwNo ratings yet

- HSM Manual 15 July 22Document308 pagesHSM Manual 15 July 22Rachit Sharma100% (1)

- RA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17Document9 pagesRA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17alla malik100% (1)

- DROPS Recommended Practice Mar2020Rev2Document58 pagesDROPS Recommended Practice Mar2020Rev2HunterNo ratings yet

- Marine Safety Management Plan: Kendall Bay Sediment Remediation ProjectDocument37 pagesMarine Safety Management Plan: Kendall Bay Sediment Remediation Projectkhabiran100% (1)

- 7105 JHRA 008 12 Pneumatic Testing ActivitiesDocument7 pages7105 JHRA 008 12 Pneumatic Testing Activitiesarnel sungkipNo ratings yet

- JSA - Blasting - EXTERNALDocument13 pagesJSA - Blasting - EXTERNALAzad pravesh khanNo ratings yet

- Tts Near Miss Booklets 2014Document3 pagesTts Near Miss Booklets 2014grandeNo ratings yet

- Hsi Investigation ProcedureDocument46 pagesHsi Investigation ProceduremohamedNo ratings yet

- Example Report SSA E Ver1Document20 pagesExample Report SSA E Ver1Cenk ÇobanNo ratings yet

- JHA - Manual TorquingDocument6 pagesJHA - Manual TorquingMohamadSyahmiNo ratings yet

- Risk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi100% (2)

- 04 Safety and Risk in The WorkingplaceDocument15 pages04 Safety and Risk in The WorkingplaceOleg KuchorenkoNo ratings yet

- Risk Assessment Non Routine - General JobDocument42 pagesRisk Assessment Non Routine - General JobGanesh Murugesan0% (1)

- PR-2352 - Greater Birba Emergency Response PlanDocument173 pagesPR-2352 - Greater Birba Emergency Response PlanSHRISH SHUKLANo ratings yet

- Risk Assessment Form Entry Into Enclosed Spaces 0119Document9 pagesRisk Assessment Form Entry Into Enclosed Spaces 0119Thurdsuk NoinijNo ratings yet

- JSA #34 - N2 PurgingDocument1 pageJSA #34 - N2 PurgingHelza RahmanniaNo ratings yet

- Internal AuditDocument3 pagesInternal AuditAvick TribediNo ratings yet

- Basic Safety ProceduresDocument20 pagesBasic Safety ProceduresRey Perez100% (1)

- RA Folder Jan 12Document83 pagesRA Folder Jan 12mouben100% (2)

- Document Title: HSE Standard Manual Sec. C.005 Confined Space Entry COPI Doc No.: ID-G-BU-00000-00000-00372Document11 pagesDocument Title: HSE Standard Manual Sec. C.005 Confined Space Entry COPI Doc No.: ID-G-BU-00000-00000-00372riskha100% (1)

- Near Miss ReportDocument15 pagesNear Miss ReportAyaz AhmadNo ratings yet

- Cold Cutting PDFDocument9 pagesCold Cutting PDFAshraf BottaniNo ratings yet

- Development and Validation of Three Step Risk Assessment Method For Ship Recycling Sector 2015 Safety ScienceDocument15 pagesDevelopment and Validation of Three Step Risk Assessment Method For Ship Recycling Sector 2015 Safety ScienceEvi SiswantoNo ratings yet

- Join DrillDocument2 pagesJoin Drillbinsar800% (1)

- Confined Space Entry Permit Model FormDocument2 pagesConfined Space Entry Permit Model Formramod100% (1)

- R1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingDocument3 pagesR1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingVineet Agrawal100% (1)

- Work at Heights PermitDocument4 pagesWork at Heights PermitFerdinand M. TurbanosNo ratings yet

- Code of Practice: Ref Cop Gra Issue 1, Dec 2003 Always Refer To Intranet For Latest Version 1Document15 pagesCode of Practice: Ref Cop Gra Issue 1, Dec 2003 Always Refer To Intranet For Latest Version 1etaNo ratings yet

- HSE PresentationDocument46 pagesHSE Presentationshan123455555555No ratings yet

- HIRA No. 08 Rev 04 - Adverse WeatherDocument5 pagesHIRA No. 08 Rev 04 - Adverse WeatherVenkadesh PeriathambiNo ratings yet

- Contractor Health Safety Information BookletDocument14 pagesContractor Health Safety Information BookletDharmendra Khatri100% (1)

- Confined Space Entry Procedure WorksheetDocument5 pagesConfined Space Entry Procedure WorksheetToma AdrianaNo ratings yet

- Risk Assessment No 01 Anchor Handling in General Rev 03Document5 pagesRisk Assessment No 01 Anchor Handling in General Rev 03Bhaskar AgnihotriNo ratings yet

- Emcy Resp PlanDocument40 pagesEmcy Resp PlanredchaozNo ratings yet

- Planning and Procedures: Pdo Hse Management System Manual (CP-122)Document10 pagesPlanning and Procedures: Pdo Hse Management System Manual (CP-122)AHMEDNABTNo ratings yet

- RA 002 - BunkeringDocument5 pagesRA 002 - Bunkeringdassi99No ratings yet

- Qual 001 Supplier-Subcontractor Quality HistoryDocument1 pageQual 001 Supplier-Subcontractor Quality Historydassi99No ratings yet

- Qual 002 Evaluation of Supplier - SubcontractorDocument1 pageQual 002 Evaluation of Supplier - Subcontractordassi99No ratings yet

- E1 - Purging & Gas Leakage Test SequencesDocument6 pagesE1 - Purging & Gas Leakage Test Sequencesdassi99No ratings yet

- Installation Guide EnglishDocument11 pagesInstallation Guide Englishdassi99No ratings yet

- All About ECDISDocument12 pagesAll About ECDISdassi99No ratings yet

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pages06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- Final Impa Pilot Ladder PosterDocument1 pageFinal Impa Pilot Ladder Posterdassi99No ratings yet

- Quick Reference - EnglishDocument44 pagesQuick Reference - Englishdassi99No ratings yet

- Piezoelectricity:: Principle Knock SensorsDocument1 pagePiezoelectricity:: Principle Knock Sensorsdassi99No ratings yet

- Gas System Double WallDocument1 pageGas System Double Walldassi99No ratings yet

- JAN 701B HandoutsDocument22 pagesJAN 701B Handoutsdassi990% (1)

- DNV CertificateDocument1 pageDNV Certificatedassi99No ratings yet

- Point Fortin - Umm Bab Port OptimoorDocument7 pagesPoint Fortin - Umm Bab Port Optimoordassi99No ratings yet

- WISE Cargo User Manual - Ver 6 (A4)Document36 pagesWISE Cargo User Manual - Ver 6 (A4)dassi9950% (2)

- Cause and Effect Diagram - HHISHI (01-LIST - 1040438Document2 pagesCause and Effect Diagram - HHISHI (01-LIST - 1040438dassi99No ratings yet

- Shipping Law Handbook - Part E CollisionDocument21 pagesShipping Law Handbook - Part E Collisiondassi99No ratings yet

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pages06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- 4.10.1 Ramp Up-Ramp Down Plan-AsclepiusDocument1 page4.10.1 Ramp Up-Ramp Down Plan-Asclepiusdassi99100% (1)

- Practical TestDocument4 pagesPractical Testdassi99100% (1)

- Calculating Damages by Clive AstonDocument10 pagesCalculating Damages by Clive Astondassi99100% (1)

- The Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding ContractDocument3 pagesThe Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding Contractdassi99No ratings yet

- RTCM Auto Acquisition Vs Manual Guard Ring ARPADocument10 pagesRTCM Auto Acquisition Vs Manual Guard Ring ARPAdassi99No ratings yet

- Owners' Damages For Repudiation by CharterersDocument16 pagesOwners' Damages For Repudiation by Charterersdassi99No ratings yet

- Winch Drum SpoolingDocument2 pagesWinch Drum Spoolingdassi99No ratings yet

- Mount Kenya University: Department: School of Social SciencesDocument4 pagesMount Kenya University: Department: School of Social SciencesLETISIA FATUMANo ratings yet

- C783 - Intake Manifold 1 Temperature-Abnormal Rate of ChangeDocument4 pagesC783 - Intake Manifold 1 Temperature-Abnormal Rate of ChangeLucas CamposNo ratings yet

- Itopride HCL Pynetic 50mg TabDocument2 pagesItopride HCL Pynetic 50mg TabAusaf AhmadNo ratings yet

- Start A Quick Budget Start A Budget by MonthDocument13 pagesStart A Quick Budget Start A Budget by MonthMichelle PadillaNo ratings yet

- Lean Six Sigma Green BeltDocument7 pagesLean Six Sigma Green Beltmulpuru sai snehaNo ratings yet

- Peter H. Rossi - Mark W. Lipsey - Howard E. Freeman - Evaluation - A Systematic ApproachDocument417 pagesPeter H. Rossi - Mark W. Lipsey - Howard E. Freeman - Evaluation - A Systematic ApproachHector Urzua50% (2)

- Plumbing Engineering Design Handbook, Vol 1 ASPEDocument422 pagesPlumbing Engineering Design Handbook, Vol 1 ASPEMichelle NataliNo ratings yet

- Diesel Engine Lab ReportDocument27 pagesDiesel Engine Lab ReportParadoodleNo ratings yet

- Long Term LiabilitiesDocument21 pagesLong Term Liabilitiesnioriatti8924No ratings yet

- Tutorial 2 Organizing DataDocument2 pagesTutorial 2 Organizing Datazurila zakariaNo ratings yet

- Grade-9-Parallel-Test-LAS-1.2 CDocument2 pagesGrade-9-Parallel-Test-LAS-1.2 CArth Renier MinaNo ratings yet

- Instructions For Assembling Your Owners ManualDocument8 pagesInstructions For Assembling Your Owners ManualJim PowersNo ratings yet

- Geared Motor Device 100/130V E1/6-T8Document2 pagesGeared Motor Device 100/130V E1/6-T8seetharaman K SNo ratings yet

- Icu2 Vol22 Sepsisincriticalcare 29marchDocument52 pagesIcu2 Vol22 Sepsisincriticalcare 29marchricardoatejassNo ratings yet

- Eaton 092394 T5B 3 7 E en - GBDocument6 pagesEaton 092394 T5B 3 7 E en - GBJorge AmayaNo ratings yet

- Cleaning Disinfecting School ClassroomsDocument2 pagesCleaning Disinfecting School ClassroomsFitz JaminitNo ratings yet

- 1402AHS Prac Manual - 2023 - FINALDocument200 pages1402AHS Prac Manual - 2023 - FINALRuan BritsNo ratings yet

- ISO 9001: 2015 Certified Semen Freezing LaboratoryDocument43 pagesISO 9001: 2015 Certified Semen Freezing LaboratoryShubhamNo ratings yet

- Fdocuments - in From The Margins To The Mainstream Disaster Research at The CrossroadsDocument26 pagesFdocuments - in From The Margins To The Mainstream Disaster Research at The CrossroadsHanan M. HadidiNo ratings yet

- vdYoyHdeTKeL7EhJwoXE - Insomnia PH SlidesDocument40 pagesvdYoyHdeTKeL7EhJwoXE - Insomnia PH SlidesKreshnik IdrizajNo ratings yet

- LEEDDocument161 pagesLEEDjeruelNo ratings yet

- College RecipesDocument29 pagesCollege RecipeskrunziNo ratings yet

- Design of Marina Structures and FacilitiesDocument23 pagesDesign of Marina Structures and FacilitiesAhmed Balah0% (1)

- Arecanut DiseasesDocument22 pagesArecanut Diseases314 Bhagyalakshmi SNo ratings yet

- Wastewater Treatment Lab TestDocument8 pagesWastewater Treatment Lab TesthuyNo ratings yet

- Carjackked TrainingDocument7 pagesCarjackked TrainingErios 50No ratings yet

- JETIR1904787Document3 pagesJETIR1904787RONAL SALAS CONTRERASNo ratings yet

- QMS - 001 Compliance of RecordsDocument4 pagesQMS - 001 Compliance of Recordsedgardovrgs3169No ratings yet

- MR Afnan CVDocument3 pagesMR Afnan CVShazada Dauod Khan100% (1)

- Hindustan Coca-Cola Beverages PVT LTD B-91 Mayapuri Industrial Area Phase-I New DelhiDocument2 pagesHindustan Coca-Cola Beverages PVT LTD B-91 Mayapuri Industrial Area Phase-I New DelhiUtkarsh KadamNo ratings yet