Professional Documents

Culture Documents

The Air Start Valve

Uploaded by

RejoGevargheseRajanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Air Start Valve

Uploaded by

RejoGevargheseRajanCopyright:

Available Formats

The Air Start Valve

Operational Information

The Air Start Valve

Menu

Menu

The valve is fitted into the cylinder head. It is opened by control air from the

starting air distributor.

The valve shown is from a slow speed MAN-B&W two stroke engine

but a lot of

modern engines have valves working on similar principles and design.

Materials

The body of the valve could be of mild steel, the spindle of high tensile or

stainless steel, and the valve and seat could have the contact faces stellited or

hardened.

How it works

Main starting air at about 30 bar from the manifold enters the chamber above the

valve via the circumferential ports in the valve body.

The air pressure will not open the valve because a spring is holding the valve shut,

an the area of the balance piston is the same as that of the valve lid so the valve is

pneumatically balanced.

When the valve is required to open, air at 30 bar from the air start distributor enters

the the top of the valve body and acts on a piston. This force overcomes the spring

force holding the valve shut, and the valve opens. When the air signal from the air

start distributor is vented, the spring closes the valve

When the start sequence is finished the main air start pressure is vented through

holes in the main start air manifold.

The Sulzer RTA air start valve

http://www.marinediesels.info/2_stroke_engine_parts/Other_info/air_start_valve.htm[05-12-2014 00:21:25]

The Air Start Valve

The Sulzer air start valve uses air on both sides of the operating

piston to maintain positive closing. The piston is stepped. The

reason for this is so the starting air valve will not open when the

gas pressure in the cylinder is higher than the starting air pressure;

i.e. when the cylinder is firing. Once the valve starts to open then

the opening is accelerated when the larger diameter piston has the

opening air acting on it

The stepped piston also means that closing of the valve is damped

as air gets trapped in the annular space formed when the smaller

diameter piston enters the upper part of the cylinder.

The air to operate the valve comes from the main air start supply.

The distributor pilot air operates the pneumatic change over valve.

The Sulzer RTA Air Start Valve operating principle.

MAINTENANCE

After certain periods of service starting air valves are changed and overhauled. If piston rings are fitted, care must be

taken to ensure that they are free in their grooves. Should it be necessary to fit new rings, the butt clearances of the rings

must be carefully checked by placing the ring into the operating cylinder and measuring the clearance. This is especially

important if they are usually made of brass which has a larger coefficient of expansion than the other parts of the valve.

The valve and valve seat are ground with grinding paste and finished to a fine surface with lapping paste. It is essential to

ensure that all parts of the valve are scrupulously clean before reassembly. Lubricate all sliding surfaces sparingly with a

molybdenum disulphide grease.

HOW DOES THE STARTING AIR BRAKE THE ENGINE WHEN CHANGING DIRECTION?

If

the engine is required to reverse whilst there is still way on the ship,

the engine will be driven by the propeller, and it

may be a while before

it comes to a halt, and is thus able to start in the reverse direction..

To speed up the process,

starting air is admitted whilst the engine is

still running ahead although the start air distributor will have been

retimed to

admit air for reverse running.

Because

of this, starting air flows into the cylinder half way up the compression stroke. Towards the end of the

compression stroke (no ignition, fuel injection cut off by the running direction cut-out), compressed air, (at a pressure

which has increased above that of the starting air), then flows through the starting air valve, which is still being held

open, into the starting air distribution pipe. If the starting air valve is then closed, there will be less air within the cylinder

than at the beginning. In this way, considerably less expansion work is done than for compression, i.e. the engine is

braked. The engine will come to a standstill and then start to turn in the opposite direction, since the control elements are

set for this.

WHAT CAUSES AN AIR START VALVE TO STICK?

Leakage of a starting air valve is usually caused by sluggish valve action preventing fast closure of the valve, or by dirt or

http://www.marinediesels.info/2_stroke_engine_parts/Other_info/air_start_valve.htm[05-12-2014 00:21:25]

The Air Start Valve

foreign particles from the starting air supply lodging on the valve seat and so preventing the valve from closing fully.

Sluggish valve action may be caused by dirty pistons or valve spindle guides and the like. In newly overhauled valves

sluggish valve action may be caused by parts fitted with inadequate clearances.

HOW CAN I TELL IF AN AIR START VALVE IS LEAKING OR HAS JAMMED OPEN?

When an engine is in operation leakage of starting air valves is shown by overheating of the branch pipe connecting the

starting air valve to the starting air rail. The heating occurs due to the leakage of hot gases from the engine cylinder into

the starting air line connected to the starting air rail. During periods of manoeuvring the temperature of each supply pipe

from the air rail to the starting air valve should be checked by feeling the pipe as close to the valve as possible.

WHAT SHOULD I DO IF AN AIR START VALVE JAMS OPEN WHILST MANOEUVRING?

The fuel pump should be lifted (fuel rack zeroed, puncture valve

operated or whatever) on the affected unit and the

bridge informed. The

load should be kept at a minimum, as one unit is now out of operation.

As soon as safe to do so, the

engine should be stopped and the air start

valve replaced.

This

article and the following articles can be found in the members

section under

"Starting

and Reversing".

MAN

B&W Air Start Distributor

The

Sulzer Air Start Distributor

The

Sulzer Automatic Valve

The

Sulzer Reversing Servomotor

The

Sulzer Air Start System

The

ZA40 Air start system

DHTML Menu / JavaScript Menu Powered By OpenCube

http://www.marinediesels.info/2_stroke_engine_parts/Other_info/air_start_valve.htm[05-12-2014 00:21:25]

Sulzer Air Start Distributor | Marinesite

Home

E Pareeksha (MCQ)

Class 4 Orals

Discuss

Join With Us

Contact Us

Follow Us On G+

Please Donate A Like

Marinesite

Sulzer Air Start Distributor

1,669

Marinesite-

Facebook social plugin

The air start distributor is driven from the main camshaft.

The pilot valves, one for each

cylinder, are arranged radially

around a cam

profile. When not in use, the pilot valve followers are held off the cam by

springs.

Popular Posts

http://www.marinesite.info/2013/10/sulzer-air-start-distributor.html[05-12-2014 00:22:44]

Sulzer Air Start Distributor | Marinesite

Emergency Fire Pump Regulation

What is Tappet

Clearance? How to

check And Adjust

tapper clearance?

SOPEP - Ship Oil Pollution

Emergency Plan and List of

Equipment Requirement.

How Does Brushless

Alternator Works?

(With Diagram)

When an

ahead start signal is given, air at 30 bar enters the space above the

servomotor piston,

and passes through the start cut off valve to actuate the

pneumatic valve, which allows air from

the air start manifold to the pilot

valves. The air pushes the pilot valves against the cam, and

when each pilot

valve is on the base of the cam, air can pass through to operate the main air

start valve. As the cam pushes the pilot valve into the closed position, the

line to the main air

start valve is vented

Simple Explanation Of

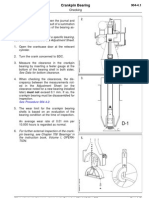

Crankshaft

Deflections,

Measurement

Procedure,

Readings,Curves

Help Others

Vineeth

About The Author:

He is a marine engineer sailing with British Petroleum.He has keen interest on compiling marine

exam notes.

You can catch him on Google+

SHARE THIS

Tweet

http://www.marinesite.info/2013/10/sulzer-air-start-distributor.html[05-12-2014 00:22:44]

You might also like

- Air Start SystemDocument5 pagesAir Start SystemPaolo FerjančićNo ratings yet

- Marine BoilersDocument16 pagesMarine BoilersPawan Beniwal100% (1)

- Operational Information The Air Start ValveDocument5 pagesOperational Information The Air Start ValveHrishikesh More100% (1)

- Air Start ExplosionDocument12 pagesAir Start ExplosionsahilimuNo ratings yet

- Starting & Reversing Problems in Marine EnginesDocument6 pagesStarting & Reversing Problems in Marine EnginesUjjwal SinghNo ratings yet

- Air Starting System Slide Set 3Document11 pagesAir Starting System Slide Set 3Jigar PatelNo ratings yet

- Exhaust Valve Overhaul (Two Stroke Engine)Document19 pagesExhaust Valve Overhaul (Two Stroke Engine)غازي عليNo ratings yet

- Cross Head Removal For Man B WDocument13 pagesCross Head Removal For Man B WMOHAN100% (1)

- Important Points While Carrying Out Power Balancing of Marine EnginesDocument5 pagesImportant Points While Carrying Out Power Balancing of Marine EnginesprabhudiwaNo ratings yet

- Stuffing BoxDocument2 pagesStuffing BoxMeghali Borle67% (3)

- Tie BoltsDocument31 pagesTie BoltsMuhammad Nasim AbbasNo ratings yet

- Meo Class 4Document55 pagesMeo Class 4adam shaneNo ratings yet

- Connecting Rod BoltsDocument2 pagesConnecting Rod BoltsRachitNo ratings yet

- Axial DistributorDocument1 pageAxial DistributorArun SNo ratings yet

- Scavenge FireDocument3 pagesScavenge FireVishu SharmaNo ratings yet

- Hfo To Mdo Change Over ProcedureDocument3 pagesHfo To Mdo Change Over ProcedureJanell Prince50% (2)

- What Is Bumping ClearanceDocument5 pagesWhat Is Bumping ClearanceAnurag KUMAR0% (1)

- Crank Case Inspection ProcedureDocument6 pagesCrank Case Inspection ProcedureSid ACHARYANo ratings yet

- Class 4 Frequent Asked Qs Shashwat000Document168 pagesClass 4 Frequent Asked Qs Shashwat000Lovy Singh100% (1)

- Mep Oral AnswersDocument28 pagesMep Oral AnswersAshjo Gamer100% (1)

- Man B&W: Starting Air DistributorDocument14 pagesMan B&W: Starting Air DistributorRajesh Sharma100% (1)

- Exhaust ValvesDocument3 pagesExhaust ValvesJitendra Kumar100% (1)

- Marine Engines NSKDocument31 pagesMarine Engines NSKJohn SnowNo ratings yet

- An Introduction To Vibration Aspects of Two-Stroke Diesel Engines I, N ShipsDocument11 pagesAn Introduction To Vibration Aspects of Two-Stroke Diesel Engines I, N Shipshpss77100% (1)

- Compressor SafetiesDocument2 pagesCompressor Safetiesvic.barca2012No ratings yet

- Actual Sysem Setup Alpha LubricatorDocument7 pagesActual Sysem Setup Alpha LubricatorRanjan DiptanshuNo ratings yet

- Cargo Oil Pump Turbine Operating Instructions: StartingDocument4 pagesCargo Oil Pump Turbine Operating Instructions: StartingSaratkumar RatnalaNo ratings yet

- Puncture ValveDocument1 pagePuncture ValveAnkit DedhiyaNo ratings yet

- Types Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersDocument7 pagesTypes Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersRicardo Garing100% (2)

- Marine Diesel Engine Starting System 2Document19 pagesMarine Diesel Engine Starting System 2Anonymous GFrM6XANo ratings yet

- Operational Information The Two Stroke Crosshead Engine The Stuffing BoxDocument6 pagesOperational Information The Two Stroke Crosshead Engine The Stuffing BoxAbhishek Singh ChauhanNo ratings yet

- Indicator Diagrams - Marine Engineering Study MaterialsDocument5 pagesIndicator Diagrams - Marine Engineering Study MaterialsRavi VikneshNo ratings yet

- Sketch and Describe A Two-Stage Air Compressor Suitable For Marine Use Up To 30 Bar PressureDocument4 pagesSketch and Describe A Two-Stage Air Compressor Suitable For Marine Use Up To 30 Bar PressureA NNo ratings yet

- Indicator Diagrams of Diesel EnginesDocument5 pagesIndicator Diagrams of Diesel EnginesAbdul Anis67% (3)

- 01 BedplateDocument11 pages01 BedplateVinay Kumar NeelamNo ratings yet

- Textbook For The Third Engineers (3648)Document29 pagesTextbook For The Third Engineers (3648)Sejo HodzicNo ratings yet

- Bottem End Bearing RemovalDocument8 pagesBottem End Bearing RemovalRohit Mishra100% (2)

- NewDocument4 pagesNewPrakhyati Raut100% (1)

- Operational Information The MAN B&W MC Engine VIT Fuel PumpDocument16 pagesOperational Information The MAN B&W MC Engine VIT Fuel PumpAbhishek Singh Chauhan100% (2)

- 2.stern Tube Seals & LinersDocument9 pages2.stern Tube Seals & LinersNAGENDRA KUMAR D100% (1)

- Power CardDocument6 pagesPower CardArun SNo ratings yet

- Purifier OverhaulDocument27 pagesPurifier OverhaulMedha Jog KatdareNo ratings yet

- MAN B&W Diesel A/S: Service LetterDocument5 pagesMAN B&W Diesel A/S: Service LetterParthiban NagarajanNo ratings yet

- Thrust BlockDocument2 pagesThrust Blockkyaw yaNo ratings yet

- Ce Handing OverDocument10 pagesCe Handing OverAkhilvjohnNo ratings yet

- IMP Main Engine and Aux EngineDocument37 pagesIMP Main Engine and Aux EngineLOKINo ratings yet

- Cylinder Liner Cold Corrosion ControlDocument8 pagesCylinder Liner Cold Corrosion ControlarunNo ratings yet

- Starting Air System For Diesel Engine Man B&WDocument5 pagesStarting Air System For Diesel Engine Man B&WAkshay Ankit100% (1)

- Safety Margin PropellerDocument2 pagesSafety Margin PropellerJaspal Singh Sahota100% (2)

- Piston Ring PDFDocument3 pagesPiston Ring PDFArun SNo ratings yet

- List The Starting Procedure You Are Doing To Start The Fresh Water Generator Using Main Engine Jacket Heating - Nclude All The Checks You Are MakingDocument2 pagesList The Starting Procedure You Are Doing To Start The Fresh Water Generator Using Main Engine Jacket Heating - Nclude All The Checks You Are MakingDen EdiNo ratings yet

- Pilgrim NutDocument2 pagesPilgrim NutJitendra KumarNo ratings yet

- Stuffing BoxDocument6 pagesStuffing BoxrajishrrrNo ratings yet

- 7 - Quick Closing ValveDocument4 pages7 - Quick Closing ValveRanjan DiptanshuNo ratings yet

- 6 Checking and Adjustment of Exhaust Cam LeadDocument8 pages6 Checking and Adjustment of Exhaust Cam LeadJomari Saligan100% (1)

- CH2 - DKN 5162 Marine Engineering Practice and Legislation - CHAPTER 2 - BEDPLATE-1Document34 pagesCH2 - DKN 5162 Marine Engineering Practice and Legislation - CHAPTER 2 - BEDPLATE-1Priya Sweetie100% (1)

- 2) Air Start VV & Indicator VVDocument13 pages2) Air Start VV & Indicator VVHrishikesh MoreNo ratings yet

- 10 - Starting and ReversingDocument4 pages10 - Starting and ReversingAisha Zaheer100% (3)

- 09 Air Start SystemDocument41 pages09 Air Start SystemJaimin TandelNo ratings yet

- Blow-Down Procedure For Marine Boilers PDFDocument7 pagesBlow-Down Procedure For Marine Boilers PDFRejoGevargheseRajanNo ratings yet

- Engine Bearing - Procedures For Inspection and CalibrationDocument11 pagesEngine Bearing - Procedures For Inspection and CalibrationRejoGevargheseRajanNo ratings yet

- Incinerator Maintenance ChartDocument1 pageIncinerator Maintenance ChartRejoGevargheseRajanNo ratings yet

- 200 Oral Question and AnswersDocument198 pages200 Oral Question and AnswersRejoGevargheseRajan50% (4)

- Catalogo ConautDocument20 pagesCatalogo Conautthiago_juliao1984No ratings yet

- Quincy QR-25 Series Model 390: Parts Manual Record of Change 108Document32 pagesQuincy QR-25 Series Model 390: Parts Manual Record of Change 108SergeyNo ratings yet

- Unit#2 Turbine Mov/Actuators S.No Valves Name KKSDocument22 pagesUnit#2 Turbine Mov/Actuators S.No Valves Name KKSAmaresh NayakNo ratings yet

- Report 1Document117 pagesReport 1geetanjalinitkNo ratings yet

- Fuel Oil Handling System (FOHS) - HFO - LDO - LSHSDocument8 pagesFuel Oil Handling System (FOHS) - HFO - LDO - LSHSCHHABIKANT SAHUNo ratings yet

- Triple Duty Valve BrochureDocument8 pagesTriple Duty Valve Brochuresas999333No ratings yet

- Features and ComponentsDocument11 pagesFeatures and ComponentsJay SuguitanNo ratings yet

- BigJoe S22Document162 pagesBigJoe S22martinNo ratings yet

- Test Bank For Equipment Theory For Respiratory Care 5th Edition by WhiteDocument28 pagesTest Bank For Equipment Theory For Respiratory Care 5th Edition by WhiteJohn Smoldt100% (29)

- Instrument Manifold Systems: Instrument, Direct, and Remote-Mount Manifolds and Modular SystemsDocument30 pagesInstrument Manifold Systems: Instrument, Direct, and Remote-Mount Manifolds and Modular Systemskumar100% (1)

- Cylinder Head Service ReportDocument5 pagesCylinder Head Service ReportPablo Cesar Martinez ArcosNo ratings yet

- QTN 2336Document2 pagesQTN 2336shahkunal11No ratings yet

- V60i MCV-1500-2000iMachine Instruction ManualDocument71 pagesV60i MCV-1500-2000iMachine Instruction ManualsunhuynhNo ratings yet

- TSSA Safety Info Bulletin SB12-01 - Venting-DischargeDocument3 pagesTSSA Safety Info Bulletin SB12-01 - Venting-DischargemurigurNo ratings yet

- Jt8 Engine 2Document100 pagesJt8 Engine 2ccoyure100% (9)

- SAGD Where Valves Are UsedDocument4 pagesSAGD Where Valves Are UsedAnonymous ntK705RtNo ratings yet

- Experiment No. 1 Measurement of Heating Surface of A Firetube BoilerDocument24 pagesExperiment No. 1 Measurement of Heating Surface of A Firetube BoilerAli Requiso MahmudNo ratings yet

- Burnertronic Bt300: Quick Reference For EndusersDocument48 pagesBurnertronic Bt300: Quick Reference For Endusersjesus paezNo ratings yet

- Manual de Entrenamiento Ipm - Pse: IndiceDocument17 pagesManual de Entrenamiento Ipm - Pse: Indicejamex vasquezNo ratings yet

- Vent User Manual Iss1Document121 pagesVent User Manual Iss1Chris Valdez DrumsNo ratings yet

- College - Be - 2010 - 2010nov - Mech - Me 2305 - Applied Hydraulics and PneumaticsDocument3 pagesCollege - Be - 2010 - 2010nov - Mech - Me 2305 - Applied Hydraulics and Pneumatics9600257003No ratings yet

- Question Bank 2015Document74 pagesQuestion Bank 2015Jayakumar ViswanathanNo ratings yet

- Equipment Electrical LayoutDocument25 pagesEquipment Electrical LayoutAgus Dani100% (1)

- API-521 Flare KOD Design and Even More - Part 1Document6 pagesAPI-521 Flare KOD Design and Even More - Part 1Said Ahmed Salem100% (1)

- 2005-001 CK20 Engine Workshop Manual MiswritingDocument3 pages2005-001 CK20 Engine Workshop Manual MiswritingDmitryNo ratings yet

- Coway Bedienungsanleitung chp250l 1497518818Document52 pagesCoway Bedienungsanleitung chp250l 1497518818lapintacdNo ratings yet

- Acoples Hidraulicos Serie 60 ParkerDocument2 pagesAcoples Hidraulicos Serie 60 ParkerAntonio MoralesNo ratings yet

- Hydraulic System: DescriptionDocument59 pagesHydraulic System: DescriptionKristian FonNo ratings yet

- Single PumpDocument1 pageSingle PumpbmanojkumarNo ratings yet