Professional Documents

Culture Documents

Kni

Uploaded by

RakeshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kni

Uploaded by

RakeshCopyright:

Available Formats

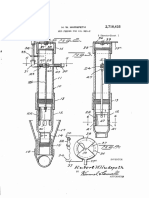

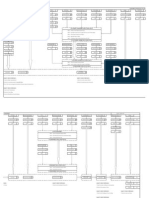

Aug. 22, 1939.

. F. A. MIRANDO ET- AL

2,170,537

KNIFE HANDLE AND COMPONENT PARTS THEREOF

Filed my 6, 1958 _

2 Sheets-Sheet 1

6X25:

Aug. 22, 1939.

7

2,170,531

F. A. MIRANDO ET AL

KNIFE HANDLE AND COMPONENT PARTS THEREOF

'2 Sheets-Sheet 2

Filed Julys} 1938

\\

Q

?aw as? 75747754

1916777 3706-4767;

- 47 775m 0.

'

a? 0777?

Patented Aug. 22, 1939

2,170,531

UNITED STATES PATENT OFFICE.

2,170,537 .

KNIFE HANDLE AND COMPONENT PARTS

THEREOF

Felix A. Mirando and Henry Vossler, Providence,

R. 1., assignors to Imperial Knife 00., Inc.,_

Providence, R. 1., a corporation of Rhode Is

land

Application July 6, 1938, Serial No. 217,826

.3 Claims. (Cl. 30-_-164)

Our invention relates to improvements in knife 'bination scale holding and bolster or tip forming

member after the scale forming plastic sheet has

handles.

v

been wrapped over the inset center portion and

One of the objects of our invention is to pro

vide an improved ornamental knife scale adapted around the edges thereof in accordance with our

improved method to provide a scale portion.

5 to be secured to a scale supporting member hav

Fig. 6 is a perspective view of a combination

ing tips or bolsters.

'

scale holding and tip or bolster forming member

.Still another object of our invention is to pro

with a sheet of scale forming plastic material

vide a knife handle which shall comprise rela

tively few and simple parts and which shall be __wrapped around the inset center portion thereof

10 simple to assemble, rugged in construction, eco

nomical to manufacture, and which shall "at the

same time present a general improvement in the

art.

' In attaining the objects of this invention, a

1 scale member is formed from plastic composition

material and. is so constructed that it may be

readily attached to asupporting member having

tips or bolsters and held secured to said support

.

ing member by pressure or force applied during

20 the attaching operation. In this way the scale

member is, so to speak, self-holding, requires no

separate means for securing the same in place,

and is secured simultaneously with the assembl

ing of the supporting member and scale member.

26 Apartfrom' the simplicity of construction and

about ,to be attached to an assembled knife 10

handle frame employing our'preferred means of

attachment.

Figs. '7, 8 and 9 are vertical sectional views

taken through a suitable type of press and il

lustrating a means for securing the scale member

to the scale'holding member.

_ Fig. 10 is a vertical sectional view of a suitable

heating oven having a hotter zone for heating

the scale holding members and a less hot zone

for heating the plastic sheets and adapted in use 20

to be adjacent the press.

In the drawings, whereinlike characters of

reference generally indicate like parts through

out, l0 generally indicates a jack knife con

structed in accordance with the principles of our 25

ease of amembly, the invention makes it possible . invention.

for the scale member to have any ornamental

appearance or decoration since that can/be easily

_ controlled by varying the mixture of the plastic

30 composition and thus producing ornamental ef

fects of the kind well known in such materials.

Other objects of our invention will in part be

obvious and in part hereinafter pointed out.

The invention accordingly consists in the fea

-. 35 tures of construction, combinations of elements,

sheets l4, l5 and i3, respectively, having a pivot

rivet 20 joining said lining sheets together at one

end thereof and the large and small knife blades

22 and 24 each having a mounting end pivotally

mounted on said pivot rivet 20, saidmounting

end being 'arcuately curved as at 26 as usual.

and arrangement of parts which will be exempli

?ed .in the construction hereinafter described,

Each blade contains an opposite pointed end 28,

and of which the scope of application will be

32. .The outer blunt edge 30 is inset as at 34

from a point interior of said pivot rivet to said

. indicated in the claims.

. 40

Our improved construction employs av stand

and type of knife handle frame I2, comprising

spaced top, bottom and intermediate lining

an outer blunt edge 30 and an inner sharp edge .

In the accompanying drawings, in which is ' curved mounting end 26 to provide at this point 40

shown one of the various possible embodiments - a stop shoulder 34. The standard type of knife .

handle frame also includes the block spacing

of this invention,

Fig. 1.is a perspective view of a jack knife members 33, one for each blade interposed be-.

tween- said lining sheets l4, l6 and I8, each hav

' constructed in accordance with our invention.

_45,' Fig. 2 is a cross sectional view therethrough ing a cut out portion at one side thereof extend

ing vcc-ncavely inwardly as at 40 at one end

taken along the line 2-2 of Fig. 1.

Fig. 3 is a longitudinal sectional view taken thereof to receive the pointed end 23 of its re- ]

spective blade, and then substantially parallel to .

therethrough along the line 3-3 of Fig. 1.

Fig. 4 is a disassembled perspective view illus

50 trating a sheet of flat ornamental scale forming

the opposite side wall 42 thereof as at 44 to pro

vide a compartment 4| for holding the sharp edge

32 of the knife blade in closed position and to

the center inset portion of the combination scale provide a resilient leaf 46 to yieldingly resiliently

holding and bolster or tip forming member with ' abut the curved mounting end 26 of each blade

plastic material in position to be wrapped around

said member inverted.

55

Fig. 5 is a perspective view of an inverted com

- and terminating near the mounting pivot end of"

said lining member as at 48 to abut said-blade 65

2,170,537

stop shoulder 34 near the curved mounting end

of said blade to retain said blade in open position

in line with said handle frame i2. Supplemental

rivets 59 are also provided extending through

said lining sheets I4, I6 and I8 and block spacing

members 38 to join said sheets and members to

gether to provide a'knife handle frame. Inythe

While our improved combination members 54

are preferably constructed of stamped or pressed

metal, it is apparent they may be constructed of

plastic or any other suitable material. While any

means may be employed for securing our im-_

proved combination members 54 to the top and

bottom surfaces of the knifchandleframe 12, in

prior art both the joining rivets 5i) and the pivot ' our preferred embodiment we preferably provide

rivet 2!] have had to be of relatively small size

10 so that the heads 52 thereof could be ground

~ 16

down to be-ilush with the top and bottom surfaces

of said respective lining members 14 and E8, to

receive the inner flat surfaces of the flat scales

and tips or bolsters formerly employed evenly

thereon.

Employing our invention, as shown more par- '

ticularly in Figs. 2 and 3 we may employ larger

size pivot and other rivets 2i) and '59 which may

be provided with large upset heads projecting

20 outwardly from the outer surfaces of the top and

bottom lining sheets 14 and I8 respectively.

With the exception of the size of the rivets, we

have described hitherto a standard type of knife

handle frame commonly used in the art.

As stated hitherto, our invention particularly

25

relates to the type and means of ornamentation

we preferably provide for the top and bottom

surfaces of said jack knife frame l2. Instead of

providing the separate thick sheets or scale por

30 tions and separate tip or bolster end portions as

this means of ornamentation. which, as stated,

have been formerly separately riveted to the

knife handle frame, we provide combination scale

holding and bolster or tip'forming members 54

35 for covering the top and bottom surfaces of said

frame, said members being of the general con

?guration of the top and bottom walls of said

frame. While said members may be stamped,

molded or otherwise constructed of solid forma

40 tion, in our preferred embodiment, each prefer

ably comprises an elongated inverted oblong

cup of the con?guration of the top or bottom wall

of said frame, each member therefore being pro

vided with an interior cupped portion 55 forming

a space 55 between the outer wall 5? of each

member and the outer surface of the top and bot

tom lining sheets Id and E8 of the knife handle

frame 12 to receive therein the enlarged heads

52 of the large respective rivets 2t and 5B hitherto

described. It is apparent that our improved com

bination members may be readily stamped,

pressed or otherwise fabricated from sheet ma

terial in this cup formation. In our preferred

embodiment, each of said members is preferably

55 provided with an inset elongated scale holding

center portion 58 which may be readily stamped,

pressed, or otherwise formed in the fabrication of

our improved combination members, thereby pro

viding the bolsters or tips 60 at each end of our

improved combination member 55 projecting out- '

wards above said inset center portion 58'. If the

exposed metal surfaces 69 at the ends of said

combination members at are of considerable

length they have been called bolsters in the trade

but if they are of relatively short length they have

been called tips in the trade and it is immaterial

in so far as our invention is concerned whether

said end portions be of such a length as to pro

vide bolsters or tips.

70

as

We also provide scale forming coverings 82,

each comprising a sheet of covering material, in

our preferred embodiment shown, of ornamental

plastic material extending over the surface of

and secured to the center inset portion 58 of each

respective combination member 56.

the top and bottom lining sheets l5 and IS with

the raised longitudinal notch forming portions 54 10

at the center portion of eachend thereof which

notch forming portions may be readily stamped

in said lining sheets as they are being stamped

or otherwise fabricated, and we provide a. pro

jection 66 projecting downwardly from each end

of each member 55 adapted to be bent to slide into

each respective longitudinal frame notch 64 to

retain its respective member at to said handle

frame 52. It is apparent, however. that, if de

sired, other means may be employed for securing

the respective combination members to the top

and bottom surfaces of said knife handle frame

and for this purpose the ends of the combination

members 5d may, if desired, be alternatively

soldered or spot Welded to the ends of the respec

tive top and bottom surfaces of the. handle frame. -

While we preferably employ a plastic material,

such as ornamental Celluloid, synthetic resin of

the phenol or urea formaldehyde condensation or

other type, cellulose acetate, rubber or otherwise 0

as our improved plastic covering sheet 62, it is

apparent that the covering sheet may, comprise

any other suitable plasticizable resilient material.

While our improved covering sheet of thin

plastic material extending over said scale holding

member may be secured to or plasticized to said

scale holding member to extend inv shrunk, drum

tight condition over the surface thereof we pref

erably fold the edges 68 of said plastic sheet 62

under the inset edges of said center portion 58 of 40

said scale holding member 54 when in a plastic

condition along the respective lines of folding

only to retain said plastic sheet $2 over thev sur

face of the inset center portion 58 of said scale

holding member in. shrunk, drum tight condition

when. deplasticized without other retaining

45

means. In this manner the scale 62 may be sup

ported on the scale supporting member 58 in

dependent of all other agencies such as for ex

ample the knife frame I? and is thereby wholly 50

self-held to the said scale supporting member.

The plastic sheet 62 is preferably superim

posed over the surface of said center inset por

tion when in. a semi-plastic condition and the

edges 68 thereof readily folded over the inset

edges 59 of said center portion 58 and suitable

heat is provided along the fold lines i0 only by

means of applying greater pressure against said

fold lines to plasticize the covering along the fold

lines only so that it may be shrunk on said device 60.

along said fold lines only. As stated hitherto. we

have discovered that if the entire plastic sheet

be rendered plastic it will shrink so much on

cooling that gaps "will be left at each end of the

plastic sheet within the respective ends of the 65

inset portion 58. If, however, the plastic sheet

be rendered plastic along said fold lines only

there will be no appreciable longitudinal shrink

age thereof and only sufficient transverse

shrinkage to insure that the sheet will extend 70

in shrunk, drum tight condition over the surface

of said inset portion.

Employing our invention we are also enabled

to save a large amount of scale forming material

formerly thought necessary as we may employ 76

2,170,537

sheets of plastic material even of a thickness of

.010.03O inch.

- '

member are only yieldably held together with a

slight degree of pressure and tension leaving a

than that of said inset center portion 58 of said

scale holding member 54. We then as diagram

certain amount of occluded insulating gases be

tween them, which prevent su?icient rapid con

duction of heat to permit the entire surfaceof

the plastic sheet to become plastic. It is only

matically illustrated in Fig. 10 suitably heat

where su?icient pressure is applied against the in

said plastic sheets to a semi-plastic condition in

folded edges 10 of said plastic sheets to com

pressthem strongly against the'edges 59 of the

scale holding member 54 that any-substantial 10

We form an oblong, thin sheet of plastic cov

ering material '62 of- substantially greater width

and

the embodiment

saidscale holding

shown,members

tov aboutto100

a greater

to 120de

10

gree in the embodiment shown, to from 200 to

300 F. We then as shown in Fig. '7 relatively

superimpose said scale holding member 54 on a

sheet 62 and exertsu?lcientrelatively slightly

yieldable pressure against said scale holding

member and plastic sheet through a forming tool

l'44_to bend it against a heated surface, such as

that of the forming die 18 of substantially equal

width and length and substantially Qmilarly

20 transversely arched as the surface of the inset

center portion of said scale holding member to

similarly shape said plastic sheet in concave for

mation as shown in Fig. 8, permitting the edges

68 of said sheet to project obliquely upwardly

25 from said yieldingly compressed arched surfaces.

We then, by suitable means, bend the then up;

turned edges 68 of the covering sheet 62 inward

ly over the edges 59 of said scale holding member

and apply su?icient pressure against thevthus

30 formed fold lines 10 to render them plastic,

whereby on cooling said plastic sheet will shrink

laterally along said fold lines 10 only to retain

amount of heat conduction takes place.

While in the foregoing description our new.

knife handle coveringmeans has been described

with reference to one method and appartus for

producing the same, it willbe understood that the 15

present invention relates only to the article.

It is apparent,therefore, that we provide a

novel type of knife handle having novel types of

component ornamental parts with the advantages

described above and novel methods of and ap 20

paratus for its manufacture.

'

'

It is understood that our invention is not limit- ~

ed to the speci?c embodiments shown and that'

various deviations may be made'therefrom with

out departing from the spirit and scope of the 25

appended claims.

What we-claim is:

1. Covering means for a knife comprising an

elongated interiorly concaved member having a

middle portion and end portions, said end por 30

tions extending slightly above said middle por

tion, a resilient separable scale .member, and

said covering over the surface of the inset center , means to immovably secure said scale member

portion of said scale holding member in shrunk, to said concaved member in locked engagement

drum tight condition without other retaining therewith, said securing means comprising edge 35

means and without substantial longitudinal portions integral with said scale member and un

derlying said concaved member, said scale mem

shrinkage of said covering. To bend the up

ber abutting said end portions.

turned edges 68 of said covering material wepref

2. Covering means for a knife comprising an

erably move the heated members 80 obliquely lat

elongated interiorly concaved member having a

erally

and

downwardly

over

the

edges

of

said

in

40

40

set center portion of said scale holding member middle portion and end portions, said end por

tions

extending

slightly

above

said

middle

por

at a lesser distance than the thickness of said

> plastic sheet to fold' the edges of said plastic tion, a separable resilient scale member, and

sheet over the edges of said inset center portion means to immovably secure said scale member to

said concaved member in locked engagement

45 of said scale holding member. We thus apply therewith, said securing means comprising op 45

sumcient pressure between said plastic sheet and

the edges 59 of said center portion 58' of said posed portions of said scale member pressed

scale holding member to apply sumcient heat to against edges of said concaved member and said

the thus formed fold lines 10 to render them securing means additionally comprising scale

member portions underlying said concaved mem

plastic, whereby after removing said thus assem

55

to

bled means from said movable means on the

cooling or deplasticizing of said fold lines of said

ber. .

covering, the covering will shrink laterally along

separate supporting member having 'a bolster at

said folding lines only to achieve the afore-de

each end thereof and a resilient separable ona

mental scale member mounted on said supporting

scribed results.

3. A covering unit for a knife, comprising a

55

We may, however, render the entire covering member with its ends in abutting relationship

plastic during theheat treatment but if we do it with said bolster, said scale member additionally,

will tend to shrink longitudinally to have gaps having wholly self -contained means for maintain,

at the ends thereof and laterally so that the ing itself in substantially immovable attachment

edges may unbend. While the edges thereof -_ to said supporting member, said means com 60

prising opposed portions of said scale member in

may be bent without heating they will not re

tain a set position to shrink the covering over frictional engagement with said supporting

the surface of the holding member in drum tight

member.

condition. -

As stated, the plastic sheet and scale holding

'

FELIX A. MIRANDO.

HENRY VOSSLER.

You might also like

- Cooler Warm SeasonDocument13 pagesCooler Warm SeasonRakeshNo ratings yet

- Vernier DesignDocument9 pagesVernier DesignRakeshNo ratings yet

- Pen HolderDocument8 pagesPen HolderRakeshNo ratings yet

- Rechargable Cigrett LighterDocument6 pagesRechargable Cigrett LighterRakeshNo ratings yet

- PencilDocument1 pagePencilRakeshNo ratings yet

- Hybrid Topcoat Formulations For PaperDocument11 pagesHybrid Topcoat Formulations For PaperRakeshNo ratings yet

- Dynamic KeysDocument46 pagesDynamic KeysRakeshNo ratings yet

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- Cigar Holding ApparatusDocument1 pageCigar Holding ApparatusRakeshNo ratings yet

- Ornamenting A PaperDocument2 pagesOrnamenting A PaperRakeshNo ratings yet

- Process For Surface Sizing PaperDocument7 pagesProcess For Surface Sizing PaperRakeshNo ratings yet

- MicDocument7 pagesMicRakeshNo ratings yet

- Testing-Paper and Method of Making SameDocument2 pagesTesting-Paper and Method of Making SameRakeshNo ratings yet

- Froth Flotation Deinking Process For PaperDocument16 pagesFroth Flotation Deinking Process For PaperRakeshNo ratings yet

- Llo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterDocument3 pagesLlo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterRakeshNo ratings yet

- Comb FilterDocument5 pagesComb FilterRakeshNo ratings yet

- Buddhism VolDocument36 pagesBuddhism VolRakesh100% (1)

- Fountain Pen PatentDocument3 pagesFountain Pen PatentRakeshNo ratings yet

- CalDocument48 pagesCalRakeshNo ratings yet

- Sound Abs BarrDocument23 pagesSound Abs BarrRakeshNo ratings yet

- Toothbrush HolderDocument7 pagesToothbrush HolderRakeshNo ratings yet

- Pocket Lighter Patent from 1936 Describes Zippo DesignDocument3 pagesPocket Lighter Patent from 1936 Describes Zippo DesignRakeshNo ratings yet

- Sol StovDocument11 pagesSol StovRakeshNo ratings yet

- Sol ShieldDocument9 pagesSol ShieldRakeshNo ratings yet

- Sol LampDocument6 pagesSol LampRakeshNo ratings yet

- Solar PlantDocument12 pagesSolar PlantRakeshNo ratings yet

- Solar PlantDocument12 pagesSolar PlantRakeshNo ratings yet

- Interconnected Solar CellsDocument13 pagesInterconnected Solar CellsRakeshNo ratings yet

- Solar HarnDocument11 pagesSolar HarnRakeshNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 1,3,3-Trinitroazetidine (TNAZ) - Part I. Syntheses and PropertiesDocument23 pages1,3,3-Trinitroazetidine (TNAZ) - Part I. Syntheses and PropertiesThanh XomNo ratings yet

- Vismat Material V-Ray For SketchupDocument19 pagesVismat Material V-Ray For SketchupAmer GonzalesNo ratings yet

- NOX Reduction EPADocument399 pagesNOX Reduction EPApartha6789No ratings yet

- What Is A Gantt Chart - Gantt Chart Information, History and SoftwareDocument3 pagesWhat Is A Gantt Chart - Gantt Chart Information, History and SoftwareShaikh Saeed AlamNo ratings yet

- Custom Validation ExampleDocument4 pagesCustom Validation ExampleAbdul Bais StanikzaiNo ratings yet

- Process Level ChartDocument2 pagesProcess Level ChartzaidinNo ratings yet

- EML 4507 Spring 2017 HW11 SolutionDocument7 pagesEML 4507 Spring 2017 HW11 SolutionUnmil PatelNo ratings yet

- Presentation FileDocument10 pagesPresentation FileInnoVentureCommunityNo ratings yet

- Boiler MaintenanceDocument144 pagesBoiler Maintenanceaziz100% (2)

- Ee09 704 - Electrical Machine Design Model QPDocument2 pagesEe09 704 - Electrical Machine Design Model QPGīřïşh McNo ratings yet

- Pco2Document55 pagesPco2camdentownNo ratings yet

- LB2 UC30 Data Sheet enUS 80218564235Document5 pagesLB2 UC30 Data Sheet enUS 80218564235Ahmed ShawkyNo ratings yet

- Using Semi Circular Bending Test To Evaluate Low Temperature Fracture Resistance For Asphalt ConcreteDocument10 pagesUsing Semi Circular Bending Test To Evaluate Low Temperature Fracture Resistance For Asphalt Concreteappu140688No ratings yet

- Construction of Multistoried Boys Hostel by Kanwarjot SinghDocument22 pagesConstruction of Multistoried Boys Hostel by Kanwarjot SinghvipinNo ratings yet

- G.25-GEMSS-G-02 Rev 01plant Design CriteriaDocument13 pagesG.25-GEMSS-G-02 Rev 01plant Design Criteriamohammad kassarNo ratings yet

- Electrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caDocument9 pagesElectrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caTimothy Murray HenleyNo ratings yet

- Elevator Installation Contract - 2022 - CNMDocument5 pagesElevator Installation Contract - 2022 - CNMsolid groupNo ratings yet

- Vista 128BPT Program ManualDocument72 pagesVista 128BPT Program ManualyalmanzaNo ratings yet

- PL-BRICK HP 2850 740 2X6: Product DatasheetDocument4 pagesPL-BRICK HP 2850 740 2X6: Product DatasheetAbhilash ThomasNo ratings yet

- Metronidazole AnalysisDocument5 pagesMetronidazole AnalysisHendri WasitoNo ratings yet

- American English File Starter Ichecker - File 3Document3 pagesAmerican English File Starter Ichecker - File 3Daniel AugustoNo ratings yet

- Why and Wherefores of Power System BlackoutsDocument6 pagesWhy and Wherefores of Power System BlackoutsmentongNo ratings yet

- DatasheetDocument13 pagesDatasheetebertecnicoNo ratings yet

- Schedule of Floor Finishes: Code Description Area (SQM) FF101 FF102Document5 pagesSchedule of Floor Finishes: Code Description Area (SQM) FF101 FF102Camille ArielNo ratings yet

- SLTRT Service Level Testing Reporting ToolDocument110 pagesSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- 3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureDocument4 pages3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureMohammed MustafaNo ratings yet

- SSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Document60 pagesSSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Jose Ramón Orenes ClementeNo ratings yet

- As 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisDocument7 pagesAs 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisSAI Global - APAC0% (1)

- Acee 2018 039Document13 pagesAcee 2018 039threedlabsNo ratings yet

- Listado Articulos PVPDocument116 pagesListado Articulos PVPfausto.ca68No ratings yet