Professional Documents

Culture Documents

Procedure: Menu Path

Uploaded by

AVRajan69Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure: Menu Path

Uploaded by

AVRajan69Copyright:

Available Formats

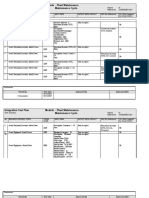

Procedure

1. Use the following procedure to call the transaction:

Menu Path

Logistics Plant Maintenance Preventive Maintenance Maintenance

Planning Maintenance Plans Create Strategy Plan

Transaction Code

IP42

2. Enter the following data:

Field

Data

Maint. plan cat.

Plant maintenance

Strategy

3. Choose

Description

Key date scheduling

The Create Maintenance Plan: Strategy plan screen appears.

4. Enter the following data:

Field

Data

Maintenance plan text

Calibrate multimeter

Equipment

10003540

Multimeter, analog

Order type

PM06

Calibration order

5. Choose

Description

6. Choose the Maintenance plan scheduling parameters tab page.

7. Enter the following data:

Field

Data

Description

Call horizon (%)

90

Determines when the PM order should be generated for

the maintenance call.

Scheduling period

365

The scheduling period during which the system generates

maintenance calls.

Start of cycle

8. Choose

One month before The system generates a maintenance order from the

todays date

maintenance plan every 30 days, so you set the cycle start

one month in the past. This ensures that an order is

available after scheduling.

9. Do not leave this screen.

Creating a Single Cycle Plan

1. Choose Logistics Quality Management Test Equipment Management Calibration Planning

Maintenance Planning Maintenance Plan Create Single Cycle Plan.

The initial screen for creating a maintenance plan appears.

2. Enter a

maintenance plan category and choose

You must choose an order type which is coupled with QM for the calibration inspection.

The single cycle plan appears.

3. Enter data as required.

If you specify a service unit for the cycle, the system automatically selects the first suitable counter for the

reference object as a default value.

4. On the Scheduling parameters tab page, maintain the

if required.

scheduling parameters for the maintenance plan,

You can only maintain the scheduling parameters for the maintenance plan if you have entered a

unit for the cycle in the Interval section. The system can recognize from the unit whether it is a

performance-based or time-based single cycle plan and provides the appropriate scheduling

parameters.

5. Enter data as required for the maintenance item.

6. Assign a task list to the maintenance plan. Note the prerequisites described in Assigning a Task List to a

Maintenance Plan.

o

To assign a task list, choose

To create a task list, choose

with quick info Create task list/general task list.

7. If necessary, you can assign additional technical objects to the maintenance item using the Object list tab

page (see Object List).

8. If you want to create additional maintenance items, choose

with quick info Create maintenance item.

9. Save the maintenance plan.

Creating a Time-Based Strategy Plan

1. Choose Logistics Quality Management Test Equipment Management Calibration Planning

Maintenance Planning Maintenance Plan Create Strategy Plan.

The initial screen for creating a maintenance plan appears.

2. Enter data as required:

Enter a maintenance plan category. You must choose an order type which is coupled with QM for the

calibration inspection.

Enter a time-based

3. Choose

maintenance strategy.

The strategy plan appears.

4. Enter data as required for the maintenance plan header and maintenance item.

5. Assign a task list to the maintenance plan. Note the prerequisites described in Assigning a Task List to a

Maintenance Plan.

o

To assign a task list, choose

To create a task list, choose

with quick info Create task list/general task list. Assign

maintenance packages to the operations for the task list.

After you have assigned a task list, the system displays the following data:

o

On the Item tab page the assigned task list

On the Maintenance plan cycles tab page the maintenance packages from the strategy which

are assigned to the operations in the task list

6. If necessary, use the Object list tab page to assign additional technical objects to the maintenance item

(see Object List).

7. If you want to create additional maintenance items, choose

8. On the Scheduling parameters tab page, maintain the

if required.

with quick info Create maintenance item.

scheduling parameters for the maintenance plan,

9. Save the maintenance plan.

Creating a Performance-Based Strategy Plan

1. Choose Logistics Quality Management Test Equipment Management Calibration Planning

Maintenance Planning Maintenance Plan Create Strategy Plan.

The initial screen for creating a maintenance plan appears.

2. Enter data as required:

Enter a maintenance plan category. You must choose an order type which is coupled with QM for the

calibration inspection.

Enter a performance-based

strategy.

The strategy that you enter here must contain the scheduling indicator Performance and a

dimension other than time.

3. Choose

The strategy plan appears.

4. Enter data as required for the maintenance plan header and maintenance item.

5. Assign a task list to the maintenance plan. Note the prerequisites described in Assigning a Task List to a

Maintenance Plan.

o

To assign a task list, choose

To create a task list, choose

with quick info Create task list/general task list. Assign

maintenance packages to the operations in the task list.

After you have assigned a task list, the system displays the following data:

o

On the Item tab page the assigned task list

On the Maintenance plan cycles tab page the maintenance packages from the strategy which

are assigned to the operations in the task list

6. If necessary, use the Object list tab page to assign additional technical objects to the maintenance item

(see Object List).

7. If you want to create additional maintenance items, choose

8. On the Scheduling parameters tab page, maintain the

if required.

9. Save the maintenance plan.

with quick info Create maintenance item.

scheduling parameters for the maintenance plan,

You might also like

- Nikos MIDI Pack - Chord Progression GuideDocument5 pagesNikos MIDI Pack - Chord Progression GuideSamuel ThompsonNo ratings yet

- Pmcon03 - BSPHCL - SP - PM - Maintenance Order - V1.1Document31 pagesPmcon03 - BSPHCL - SP - PM - Maintenance Order - V1.1Pankaj KumarNo ratings yet

- 12035PMSP Functional Specification DOA Work Order Approval Rev 1Document18 pages12035PMSP Functional Specification DOA Work Order Approval Rev 1bhupathyraja0% (1)

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesFrom EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNo ratings yet

- Detail Design Drawings: OCTOBER., 2017 Date Span Carriage WayDocument26 pagesDetail Design Drawings: OCTOBER., 2017 Date Span Carriage WayManvendra NigamNo ratings yet

- User Manual: (BSNL - PM - UM - 01 - Preventive - Maintenance - V2.0Document71 pagesUser Manual: (BSNL - PM - UM - 01 - Preventive - Maintenance - V2.0anjitachinkiNo ratings yet

- SAP Calibiration ProcesDocument20 pagesSAP Calibiration ProcesTarun ShakyaNo ratings yet

- SAP - PM Module Question & Answers With ExplainationDocument19 pagesSAP - PM Module Question & Answers With ExplainationShashanka KshetrapalasharmaNo ratings yet

- Sap PMDocument2 pagesSap PMr.m.ram2340% (1)

- Catalogs and Codes in SAP PMDocument1 pageCatalogs and Codes in SAP PMRah1985010130% (1)

- SAP PM BenefitsDocument1 pageSAP PM BenefitskdgkamlakarNo ratings yet

- L3 Training Part 4 Predictive MaintenanceDocument12 pagesL3 Training Part 4 Predictive MaintenanceSrinivas N GowdaNo ratings yet

- SAP PM Configuration 3Document30 pagesSAP PM Configuration 3hari.s.sNo ratings yet

- Sap Dismantling An EquipmentDocument2 pagesSap Dismantling An EquipmentaliNo ratings yet

- ECC 6.0 PM Testing Cs Wo Amc STPDocument9 pagesECC 6.0 PM Testing Cs Wo Amc STPMarco Aurélio Afonso AbipNo ratings yet

- PM01 - PM Master DataDocument32 pagesPM01 - PM Master DataSandeepNo ratings yet

- Create Equipment in SapDocument5 pagesCreate Equipment in SapTamer FaroukNo ratings yet

- Sreekanth-SAP PMDocument2 pagesSreekanth-SAP PMarpangupta007No ratings yet

- SPC - Control Charts in SAP QMDocument10 pagesSPC - Control Charts in SAP QMAnonymous IVxadA7HRNo ratings yet

- L3 Training Part 5 Capital OrderDocument10 pagesL3 Training Part 5 Capital OrderSrinivas N GowdaNo ratings yet

- PM 102 Certification ExamDocument7 pagesPM 102 Certification ExamGabriel SNo ratings yet

- SAP - T - Codes For PM ModuleDocument8 pagesSAP - T - Codes For PM Modulerhys_gauravNo ratings yet

- Performance Based Single Cycle PlanDocument14 pagesPerformance Based Single Cycle PlanDipak BanerjeeNo ratings yet

- Refurbishment Process Pre RequisitesDocument2 pagesRefurbishment Process Pre RequisitespraveenNo ratings yet

- ReportDocument23 pagesReportAshwini KanranjawanePasalkarNo ratings yet

- SAP PM Standard Reports: Damage Analysis Mci5Document19 pagesSAP PM Standard Reports: Damage Analysis Mci5Gowtham Krishna MagantiNo ratings yet

- Background Job Scheduling For IP30Document6 pagesBackground Job Scheduling For IP30Jawwad Ahmed KhanNo ratings yet

- SAP PM BenefitsDocument9 pagesSAP PM Benefitsvjeevan5No ratings yet

- IW32 - SAP Change PM OrderDocument1 pageIW32 - SAP Change PM Ordersaifrahman1234No ratings yet

- PM User Manual AdvikDocument117 pagesPM User Manual Advikkannan.unisoft100% (7)

- Priti Chandna Resume PM PDFDocument5 pagesPriti Chandna Resume PM PDFSonia Sachdeva Chandna100% (1)

- Plant Maintenance: Section I Organization Structure in SAP Plant MaintenanceDocument3 pagesPlant Maintenance: Section I Organization Structure in SAP Plant MaintenanceKirti PradhanNo ratings yet

- MEFCO - L3 - Training - Part 2 - Corrective MaintenanceDocument19 pagesMEFCO - L3 - Training - Part 2 - Corrective MaintenanceSrinivas N GowdaNo ratings yet

- C TPLM30 65 Sample QuestionsDocument4 pagesC TPLM30 65 Sample QuestionsMenchu100% (1)

- Measuring Points Questions in SAP PMDocument3 pagesMeasuring Points Questions in SAP PMRajuNo ratings yet

- Sap PM QuestionsDocument14 pagesSap PM QuestionsFrancisco Coutinho JuniorNo ratings yet

- Eam Linear Asset ManagementDocument13 pagesEam Linear Asset ManagementrohitNo ratings yet

- Study Paper Sap Plant MaintananceDocument2 pagesStudy Paper Sap Plant MaintananceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- BlueprintSession4 PMWorkCompletionProcessDocument21 pagesBlueprintSession4 PMWorkCompletionProcessDhiraj PatilNo ratings yet

- ETM-Generating SD OrdersDocument2 pagesETM-Generating SD OrdersRamesh BalajiNo ratings yet

- Cut Over Activities - Plant Maintenance - SAP Easy Access - SAP BlogsDocument7 pagesCut Over Activities - Plant Maintenance - SAP Easy Access - SAP BlogsOmprakashNo ratings yet

- Work Center Capacity and SchedulingDocument1 pageWork Center Capacity and SchedulingmsandeeprajaNo ratings yet

- Gui MaskingDocument32 pagesGui MaskingNunoNo ratings yet

- Suraj PM Consultant DankosysDocument3 pagesSuraj PM Consultant DankosysSigitek Software ServicesNo ratings yet

- Sap PM BajajDocument4 pagesSap PM BajajrakeshranNo ratings yet

- Training Manual Sap MM Techvantage It Solutions PVT LTD: Maintain Source ListDocument2 pagesTraining Manual Sap MM Techvantage It Solutions PVT LTD: Maintain Source ListDipeshNo ratings yet

- CS Service MGMT Config IMC - Print Out TakenDocument65 pagesCS Service MGMT Config IMC - Print Out TakenImtiaz KhanNo ratings yet

- SAP PM Alternate LabellingDocument7 pagesSAP PM Alternate LabellingSaif Ali Momin100% (1)

- Notification and Orders Completion in SAP Plant MaintenanceDocument10 pagesNotification and Orders Completion in SAP Plant MaintenanceZahidRafiqueNo ratings yet

- Questionnaire PMDocument97 pagesQuestionnaire PMMithun RoyNo ratings yet

- Overview of SAP PM: End User TrainingDocument3 pagesOverview of SAP PM: End User TrainingKapil SharmaNo ratings yet

- PM - Order - ManualDocument20 pagesPM - Order - ManualArslan MalikNo ratings yet

- 400.05.PM.03 - Predictive Maintenance - V - 0.1Document39 pages400.05.PM.03 - Predictive Maintenance - V - 0.1Neeraj TiwariNo ratings yet

- Usage of Permits in SAP Plant MaintenanceDocument15 pagesUsage of Permits in SAP Plant MaintenanceJawwad Ahmed Khan100% (1)

- Production Resources/Tools (PRT) : PurposeDocument18 pagesProduction Resources/Tools (PRT) : PurposefamicarellaNo ratings yet

- PM FioriDocument10 pagesPM FioriDINESH SINGH BHATINo ratings yet

- Sap PM RequirementDocument2 pagesSap PM RequirementSridhar KalyanNo ratings yet

- T-Code PMDocument6 pagesT-Code PMRabindra DasNo ratings yet

- BSNL PM UM 02 Preventive Maintenance V2.0Document83 pagesBSNL PM UM 02 Preventive Maintenance V2.0Jonnalagadda Lakshman100% (1)

- Split Vauation: IMPORTANT: It Is Possible To Change A Valuation Category If No Stock and PO Were CreatedDocument2 pagesSplit Vauation: IMPORTANT: It Is Possible To Change A Valuation Category If No Stock and PO Were CreatedAVRajan69No ratings yet

- Questions We Are Frequently AskedDocument12 pagesQuestions We Are Frequently AskedAVRajan69100% (1)

- Understanding The SDocument3 pagesUnderstanding The SAVRajan69No ratings yet

- Process EngineeringDocument34 pagesProcess EngineeringAVRajan69No ratings yet

- Process EngineeringDocument34 pagesProcess EngineeringAVRajan69No ratings yet

- The Rise of Australian NovelDocument412 pagesThe Rise of Australian NovelSampath Kumar GummadiNo ratings yet

- Lab 3 Arduino Led Candle Light: CS 11/group - 4 - Borromeo, Galanida, Pabilan, Paypa, TejeroDocument3 pagesLab 3 Arduino Led Candle Light: CS 11/group - 4 - Borromeo, Galanida, Pabilan, Paypa, TejeroGladys Ruth PaypaNo ratings yet

- A.meaning and Scope of Education FinalDocument22 pagesA.meaning and Scope of Education FinalMelody CamcamNo ratings yet

- Toh736 - 84000 The Dharani of Parnasavari PDFDocument24 pagesToh736 - 84000 The Dharani of Parnasavari PDFJames LeeNo ratings yet

- ST Arduino Labs CombinedDocument80 pagesST Arduino Labs CombineddevProNo ratings yet

- Toolbox TalkDocument14 pagesToolbox Talkcall_mustafas2361No ratings yet

- ICMApprovedCentres - Ghana PDFDocument8 pagesICMApprovedCentres - Ghana PDFPrince Kelly100% (2)

- Ch-10 Human Eye Notes FinalDocument27 pagesCh-10 Human Eye Notes Finalkilemas494No ratings yet

- Crypto Wall Crypto Snipershot OB Strategy - Day Trade SwingDocument29 pagesCrypto Wall Crypto Snipershot OB Strategy - Day Trade SwingArete JinseiNo ratings yet

- GPP Calendar of Activities 2022 23 SdoDocument5 pagesGPP Calendar of Activities 2022 23 SdoRomel GarciaNo ratings yet

- The Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityDocument7 pagesThe Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityIJAR JOURNALNo ratings yet

- Enlightened ExperimentationDocument8 pagesEnlightened ExperimentationRaeed HassanNo ratings yet

- Tangerine - Breakfast Set Menu Wef 16 Dec UpdatedDocument3 pagesTangerine - Breakfast Set Menu Wef 16 Dec Updateddeveloper louNo ratings yet

- Pathogenic Escherichia Coli Associated With DiarrheaDocument7 pagesPathogenic Escherichia Coli Associated With DiarrheaSiti Fatimah RadNo ratings yet

- Reference Paper Literature ReviewDocument5 pagesReference Paper Literature ReviewAani RashNo ratings yet

- Img 20150510 0001Document2 pagesImg 20150510 0001api-284663984No ratings yet

- 02 Object Modeling TechniqueDocument50 pages02 Object Modeling TechniqueMuhammad Romadhon Batukarang EsdNo ratings yet

- SW OSDocument11 pagesSW OSErnest OfosuNo ratings yet

- Day6 7Document11 pagesDay6 7Abu Al-FarouqNo ratings yet

- Smartfind E5 g5 User ManualDocument49 pagesSmartfind E5 g5 User ManualdrewlioNo ratings yet

- (20836104 - Artificial Satellites) Investigation of The Accuracy of Google Earth Elevation DataDocument9 pages(20836104 - Artificial Satellites) Investigation of The Accuracy of Google Earth Elevation DataSunidhi VermaNo ratings yet

- BBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)Document2 pagesBBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)NinaNo ratings yet

- Engleza Referat-Pantilimonescu IonutDocument13 pagesEngleza Referat-Pantilimonescu IonutAilenei RazvanNo ratings yet

- SIVACON 8PS - Planning With SIVACON 8PS Planning Manual, 11/2016, A5E01541101-04Document1 pageSIVACON 8PS - Planning With SIVACON 8PS Planning Manual, 11/2016, A5E01541101-04marcospmmNo ratings yet

- Nantai Catalog NewDocument30 pagesNantai Catalog Newspalomos100% (1)

- Traditional Perceptions and Treatment of Mental Illness in EthiopiaDocument7 pagesTraditional Perceptions and Treatment of Mental Illness in EthiopiaifriqiyahNo ratings yet

- Manuel SYL233 700 EDocument2 pagesManuel SYL233 700 ESiddiqui SarfarazNo ratings yet

- Gis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaDocument9 pagesGis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaGrantNo ratings yet