Professional Documents

Culture Documents

Bekomat Int 2013 12

Uploaded by

kaicyemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bekomat Int 2013 12

Uploaded by

kaicyemCopyright:

Available Formats

Products

BEKOMAT

Condensate drainage

Economic efficiency

is a question of quality

Level-controlled condensate drainage without compressed-air losses

products | Condensate drainage | BEKOMAT

Save resources, increase efficiency:

the BEKOMAT principle

Condensate drainage without loss of compressed air

The generation and processing of compressed air always gener

ates liquid condensate. In most cases this condensate contains oil

and is contaminated with dirt particles. Condensate will also dis

perse over the entire compressed-air network. A system problem

which can cause costs and damage. In addition, condensate does

not accumulate regularly but varies depending on the climate,

temperature, season, time of day or on the capacity utilisation of

the compressor.

The amount is the criterion

Costly damage to compressed air equipment and products can

only be effectively minimised by installing automatic conden

sate drainage equipment. BEKOMAT condensate drains there

fore function with a capacitive sensor. The intelligent electronics

prevent compressed-air losses and minimise the energy input. For

this reason, the B

EKOMAT often pays off within half a year al

ready, compared with units with time-controlled drain valves.

Economic efficiency in new dimensions

The costs for the compressed-air energy consumption can

account for up to 20% of the operational energy expenses.

BEKOMAT offers a clear cost-saving potential.

Costs for BEKOMAT

Costs through

pressure losses

caused by conven

tional drains

Costs >

During compressed-air generation and processing, the optimum quality for the respective application should be achieved.

The most important target is to remove contaminations and

moisture from the compressed air, as these can lead to quality

deteriorations, failures, production downtimes or even defective products.

0

2

10

11

12

Month >

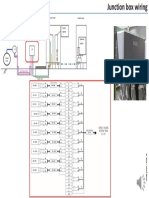

3 Pilot supply line

4 Solenoid valve

6 Capacitive level sensor

1 Feed line

Condensate outlet

2 Container

5 Membrane

B

7 Membrane seat

8 Outlet line

Condensate inlet

Level-controlled condensate drainage:

the operating principle of BEKOMAT

The condensate trickles through the feed line (1) and collects in

the container (2). First, the valve is closed as, via the pilot supply

line (3) and the solenoid valve (4), pressure compensation above

the membrane (5) is effected. The larger surface above the mem

brane results in a high closing force. The membrane seat remains

closed and leak-proof.

More than

3 million

worldwide

BEKOMAT

condensate drains

With a total of three million units sold since its presentation in 1982,

the electronically level-controlled BEKOMAT

condensate drain now achieved another international top mark.

3

When the container is filled with condensate, so that the capaci

tive level sensor (6) signals at the maximum point, the solenoid

valve switches over and the area above the membrane is ventilat

ed. As a result of the decreasing pressure above the membrane,

the latter lifts off the membrane seat (7) and the overpressure in

the housing forces the condensate into the outlet line (8).

products | Condensate drainage | BEKOMAT

BEKOMAT standard units

BEKOMAT special units

In use everywhere:

BEKOMAT types and applications

Condensates can be aggressive, contaminated or they can contain oil. The BEKOMAT range of products offers the right solution for every case of application. All model variants can be

adapted to any common supply voltage. The control elements

and the control itself are impermeable to splash water, in accordance with IP 65 or IP 55.

BEKOMAT standard units

BEKOMAT 12, 13, 14, 16 and 20

Compressors

In the aftercooler of the compressor, approximately 60 per cent

of the condensate accumulates.

Tank

More than 10 per cent of the condensate accumulates in the tank.

Dryer

Refrigeration dryers separate up to 25 per cent of the condensate.

Therefore, effective drying is only possible in combination with ef

fective condensate drainage.

Filter

BEKOMAT 20 FM with filter management, which was especially

developed for the monitoring of the filter service life, automatical

ly determines the point in time for replacing the filter.

BEKOMAT special units

BEKOMAT 3, 6, 8 and 9

Multistage compressors

If the condensate from the intercoolers is not reliably drained in

multistage compressors, it will flow through to the next compres

sor stage. BEKOMAT LA/LP prevents damage through drop at

tacks, condensate build-up and water hammers.

Vacuum

Suitable for condensate drainage in vacuum or pressureless sys

tems at operating pressures from 0.1 to 1.8 bar (abs.).

Hazardous areas

BEKOMAT special units are also available for the application in

hazardous areas (II 2G EEX ib IIB T4/explosion class II B, tem

perature class T4) where ignition sources need to be prevented.

Permissible fluids are ethane, methane, town gas, diesel fuel,

ethylene, propane, fuel oil and compressor oil.

Stainless-steel versions

For the drainage of particularly aggressive condensates, the

BEKOMAT is also available as a stainless-steel version.

Our brochures and datasheets provide additional information on the BEKOMAT

special units.

A plus for sustainability:

the BEKOMAT by comparison

Once a float drain starts leaking, the leakages will sum up to

more than 700 Euro per annum. Compressed-air losses also oc

cur when using solenoid valves, as these do not discharge the

condensate according to the demand but in a time-controlled

manner. Expensively produced compressed air therefore escapes

into the environment without being used when the valve opens,

in particular during the cold season. On the contrary, the elec

tronic level-control of BEKOMAT guarantees discharge without

any loss of compressed air. This not only saves energy, and thus

costs, but also CO2 emissions which would otherwise occur dur

ing the generation of energy a win-win situation both for the

user and the environment.

Process-safe, reliable and efficient: the BEKOMAT advantages at a glance

No unnecessary

compressed-air losses

The sensor registers any type

of condensate

Low-maintenance

Drainage adapted to

condensate quantity

Dirt-resistant

Fully automatic monitoring

More than three million installed BEKOMAT units ensure reliable and cost-effective condensate drainage throughout the world.

products | Condensate drainage | BEKOMAT

BEKOMAT standard units 20 | 12

140

Dimensions in mm

Model

Max. compressor

performance

(m3/min)

Max. dryer

performance

(m3/min)

141

140

158

20

20 FM*

12

12 CO

12 CO PN 63

(5)

(4)

6.5

6.5

6.5

2.5

(2.5)

10

(10)

16

16

16

(8)

13

13

13

(5)

Max. filter

performance

(m3/min)

50

50

80

80

80

40

40

65

65

65

25

25

40

40

40

Min. working pressure (bar)

0.8

0.8

0.8

0.8

1.2

Max. working pressure (bar)

16

16

16

16

63

Weight (kg)

0.7

0.7

0.8

0.8

0.9

Field of application

a/b

a/b

a/b

a/b

Use

Special drain for separators and filters

(also suitable for other drainage points)

Suitable for all drainage points

Connections

Inlet

Outlet (hose connector)

Outlet (hose di)

1x G / 1x G

1x G / 1x G

1x G

1x G

810 mm

810 mm

1x G

1x G

1x G

1x G

1x G

1x G

1013 mm

1013 mm

13 mm

*BEKOMAT 20 FM with filter management and potential-free contact

CO: hard-coated | PN: design for operating pressures above 16 bar (PN 63: up to 63 bar) | a: oil-containing condensate | b: oil-free, often aggressive condensate

BEKOMAT is designed for a region by means of the three climatic zones:

e.g. Northern Europe, Canada, Northern USA, Central Asia

e.g. Central and Southern Europe, Central America

South-East Asian coastal regions, Oceania, Amazon and Congo region

Temperature range: +1 to +60 C | BEKOMAT 12, 13, 14, 16 employable down to 25 C with

a heating system and insulation according to good professional practice

BEKOMAT standard units 13 | 14 | 16

280

180

162

212

252

Dimensions in mm

286

13

13 CO

13 CO PN 25

13 CO PN 40

13 CO PN 50

14

14 CO

14 CO PN 25

16 CO

Model

35

35

35

35

35

150

150

150

1700

30

30

30

30

30

130

130

130

1400

20

20

20

20

20

90

90

90

1000

70

70

70

70

70

300

300

300

3400

60

60

60

60

60

260

260

260

2800

40

40

40

40

40

180

180

180

2000

350

350

350

350

350

1500

1500

1500

300

300

300

300

300

1300

1300

1300

200

200

200

200

200

900

900

900

0.8

0.8

1.2

1.2

1.2

0.8

0.8

1.2

0.8

16

16

25

40

40

16

16

25

16

2.0

2.0

2.2

2.2

2.2

2.9

2.9

3.1

5.9

Weight (kg)

a/b

a/b

a/b

a/b

a/b

a/b

a/b

Field of application

Max. compressor

performance

(m3/min)

Max. dryer

performance

(m3/min)

Max. filter

performance

(m3/min)

Suitable for all drainage points

Min. working pressure

(bar)

Max. working pressure

(bar)

Use

Connections

2x G

2x G

2x G

2x G

2x G

3x G

3x G

3x G

1x G

1x G

1x G

1x G

1x G

1x G

1x G

1x G

13 mm

13 mm

13 mm

13 mm

13 mm

13 mm

13 mm

13 mm

2x G / 1x

G1

1x G

CO: hard-coated | PN: design for operating pressures above 16 bar (PN 25: up to 25 bar | PN 40: up to 40 bar | PN 50: up to 50 bar)

a: oil-containing condensate | b: oil-free, often aggressive condensate

BEKOMAT

31 U |32 U|33 U

For minimum time requirements during installation and maintenance,

3 U units (with condensate receiver tank)

BEKOMAT 31 U / 32 U and 3

are additionally available.

The integrated service unit provides complete replacement of all wearing

and pressurised parts with a flick of the wrist.

For more information, simply request our brochure or get informed online

at www.beko-technologies.com.

Inlet

Outlet (hose connector)

Outlet (hose di)

products | Condensate drainage | BEKOMAT

Quality with a system. Worldwide

We at BEKO TECHNOLOGIES develop, manufacture and distribute products and systems for an optimised compressed-air and

compressed gas quality throughout the world. From the processing of compressed air and compressed gas through filtration, drying and the proven condensate technology, to instruments for the

quality supervision and measurement. From a simple compressedair application to demanding process technologies.

Since its founding, BEKO TECHNOLOGIES has continuously given

decisive impulses to compressed-air technology. Our groundbreaking ideas have exerted considerable influence on the development. In order to keep this going, more than 10% of our employees work in the field of innovation. With this potential and with

our personal commitment, we at BEKO TECHNOLOGIES stand

for trend-setting technologies, products and services.

CLEARPOINT

CLEARPOINT

BEKOMAT

CLEARPOINT

BEKOMAT

DRYPOINT M PLUS

DRYPOINT M PLUS

CLEARPOINT

DRYPOINT AC

CLEARPOINT BEKOMAT

BEKOMAT

DRYPOINT RA BEKOMAT CLEARPOINT

WAMAT

BEKOSPLIT

The product & system categories

Condensate drainage | BEKOMAT

BEKOMAT condensate drains for the electroni

cally level-controlled drainage of condensate in

the compressed-air/compressed-gas network

operate without unnecessary compressed-air

losses and at minimum energy costs.

Condensate processing

WAMAT | BEKOSPLIT

Measurement technology

METPOINT

Filtration | CLEARPOINT

Process technology

BEKOBLIZZ | BEKOKAT

Drying | DRYPOINT

BEKO TECHNOLOGIES GMBH

Im Taubental 7

D-41468 Neuss | Germany

Phone +49 2131 988- 0

Fax +49 2131 988-900

info@beko-technologies.com

www.beko-technologies.com

XP BM00 001 INT | Version 2013-12 Rev. 01

Subject to technical changes without prior notice. Specifications do not represent

physical c haracteristics in the sense referred to in the German Civil Code.

Registered trademarks of BEKO TECHNOLOGIES GmbH, Neuss, Germany

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Martindale The Complete Drug Reference 38th Edition Free Download PDFDocument40 pagesMartindale The Complete Drug Reference 38th Edition Free Download PDFChristian Sosa0% (4)

- d5237 - Standard Guide For Evaluating Fabric SoftenersDocument5 pagesd5237 - Standard Guide For Evaluating Fabric SoftenersGabriela ZubietaNo ratings yet

- PM. Dozer D155A-6Document20 pagesPM. Dozer D155A-6Iqmal WahabNo ratings yet

- Intech Magazine April 2023 Issue Part5Document1 pageIntech Magazine April 2023 Issue Part5kaicyemNo ratings yet

- InTech March April 2019 - Part60Document1 pageInTech March April 2019 - Part60kaicyemNo ratings yet

- InTech March April 2019 Part34Document1 pageInTech March April 2019 Part34kaicyemNo ratings yet

- AN YOU Payfo R.. - F R O M RR OO MM: The #1 Value in AutomationDocument1 pageAN YOU Payfo R.. - F R O M RR OO MM: The #1 Value in AutomationkaicyemNo ratings yet

- Elopment Center and Warehouses: EhousesDocument1 pageElopment Center and Warehouses: EhouseskaicyemNo ratings yet

- 1451 Part4Document5 pages1451 Part4kaicyemNo ratings yet

- Intech Magazine April 2023 Issue Part10Document1 pageIntech Magazine April 2023 Issue Part10kaicyemNo ratings yet

- InTech March April 2019 Part37Document1 pageInTech March April 2019 Part37kaicyemNo ratings yet

- InTech March April 2019 Part40Document1 pageInTech March April 2019 Part40kaicyemNo ratings yet

- InTech March April 2019 Part36Document1 pageInTech March April 2019 Part36kaicyemNo ratings yet

- InTech March April 2019 Part39Document1 pageInTech March April 2019 Part39kaicyemNo ratings yet

- InTech March April 2019 Part38Document1 pageInTech March April 2019 Part38kaicyemNo ratings yet

- InTech March April 2019 Part35Document1 pageInTech March April 2019 Part35kaicyemNo ratings yet

- InTech March April 2019 Part33Document1 pageInTech March April 2019 Part33kaicyemNo ratings yet

- InTech March April 2019 - Part1Document1 pageInTech March April 2019 - Part1kaicyemNo ratings yet

- InTech March April 2019 Part31Document1 pageInTech March April 2019 Part31kaicyemNo ratings yet

- InTech March April 2019 - Part12Document1 pageInTech March April 2019 - Part12kaicyemNo ratings yet

- InTech March April 2019 - Part3Document1 pageInTech March April 2019 - Part3kaicyemNo ratings yet

- Manufacturing Tipping Points: Evolution or Revolution: Perspectives From The Editor - Talk To MeDocument1 pageManufacturing Tipping Points: Evolution or Revolution: Perspectives From The Editor - Talk To MekaicyemNo ratings yet

- InTech March April 2019 Part32Document1 pageInTech March April 2019 Part32kaicyemNo ratings yet

- InTech March April 2019 - Part9Document1 pageInTech March April 2019 - Part9kaicyemNo ratings yet

- InTech March April 2019 - Part4Document1 pageInTech March April 2019 - Part4kaicyemNo ratings yet

- InTech March April 2019 - Part2Document1 pageInTech March April 2019 - Part2kaicyemNo ratings yet

- InTech March April 2019 - Part8Document1 pageInTech March April 2019 - Part8kaicyemNo ratings yet

- Toaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part25Document1 pageToaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part25kaicyemNo ratings yet

- Toaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part22Document1 pageToaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part22kaicyemNo ratings yet

- Toaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part24Document1 pageToaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part24kaicyemNo ratings yet

- Letters: Setting The Standard For Automation™Document1 pageLetters: Setting The Standard For Automation™kaicyemNo ratings yet

- Toaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part23Document1 pageToaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part23kaicyemNo ratings yet

- Toaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part21Document1 pageToaz - Info Instrumentation Amp Control Knowledge Assessment Test PR - Part21kaicyemNo ratings yet

- Grain Dryer Patent ApplicationDocument5 pagesGrain Dryer Patent ApplicationJam PamaNo ratings yet

- Drying Process of Berry Fruit by Vacuum Drying Equipment (Simulation Process Via Comsol)Document12 pagesDrying Process of Berry Fruit by Vacuum Drying Equipment (Simulation Process Via Comsol)SAJJAD KHUDHUR ABBASNo ratings yet

- Sigma Control Compresor KaesarDocument20 pagesSigma Control Compresor KaesartaufikNo ratings yet

- DLEX3360 DLGX3361 Spec SheetDocument2 pagesDLEX3360 DLGX3361 Spec SheetMalisa MaganaNo ratings yet

- Heatless Adsorption Dryers Ultrapac ClassicDocument4 pagesHeatless Adsorption Dryers Ultrapac ClassicДмитрий КоваленкоNo ratings yet

- HPR 5-10 - 15 7-06Document8 pagesHPR 5-10 - 15 7-06amijoski6051No ratings yet

- Hpet 4 Hpet 6 Hpet 7.5 Hpet 10Document16 pagesHpet 4 Hpet 6 Hpet 7.5 Hpet 10BASEM NOMAN ALI MOHAMMEDNo ratings yet

- Presentation 4 - Cooling Towers & DryersDocument18 pagesPresentation 4 - Cooling Towers & DryersdaanNo ratings yet

- Refrigeration Dryer CD-seriesDocument8 pagesRefrigeration Dryer CD-series1hamdijaNo ratings yet

- 2.1 Operating Instructions - SparepartlistDocument67 pages2.1 Operating Instructions - SparepartlistneonmagnoNo ratings yet

- DSP catalog-ENDocument6 pagesDSP catalog-ENJareem PeesNo ratings yet

- Kaesser Screw Kompressor 8095A0SC338Document156 pagesKaesser Screw Kompressor 8095A0SC338Sergei Bubka100% (2)

- MFL67731082 - Ensp - 170712 3Document100 pagesMFL67731082 - Ensp - 170712 3aeroscribbleNo ratings yet

- Mathematical Modeling of A Continuous Vibrating Fluidized Bed Dryer For GrainDocument13 pagesMathematical Modeling of A Continuous Vibrating Fluidized Bed Dryer For GrainRintoNo ratings yet

- PID Rotary Dryer PDFDocument6 pagesPID Rotary Dryer PDFLêNhậtMinhNo ratings yet

- Generator Selection Guide: For Motors, Remember That Initial Start-Up Will Take From 3x To 6x As Much PowerDocument3 pagesGenerator Selection Guide: For Motors, Remember That Initial Start-Up Will Take From 3x To 6x As Much PowerBittuNo ratings yet

- DENAIR Oil Free Scroll Compressor Operation ManualDocument23 pagesDENAIR Oil Free Scroll Compressor Operation ManualGrumetcomNo ratings yet

- Informacoes de ProdutoDocument196 pagesInformacoes de ProdutoGustavo CâmaraNo ratings yet

- HC-4000 - Air Dryer Instruction ManualDocument155 pagesHC-4000 - Air Dryer Instruction Manualpedro canulNo ratings yet

- ZR 75 90 VSD FF Product Description EN AntwerpDocument9 pagesZR 75 90 VSD FF Product Description EN Antwerper_bhavinNo ratings yet

- AristonDocument76 pagesAristonGustavo ValdezNo ratings yet

- ARROW RH203-RH224 Heatless Desiccant Air DryerDocument20 pagesARROW RH203-RH224 Heatless Desiccant Air DryerService DeskNo ratings yet

- Chapter 14 Crop DryingDocument74 pagesChapter 14 Crop DryingaudreyshanemarinoNo ratings yet

- Swiss Combi Belt DryerDocument4 pagesSwiss Combi Belt DryerkapokNo ratings yet

- HBP ManualDocument52 pagesHBP ManualRicardo Lopez PaduaNo ratings yet

- GTUP270 GE Repair ManualDocument101 pagesGTUP270 GE Repair ManualCarlos RosarioNo ratings yet

- Hed 13 Dryers PDFDocument12 pagesHed 13 Dryers PDFEmre AfacanNo ratings yet