Professional Documents

Culture Documents

Analysis McNeice Slab MSC-Marc

Uploaded by

David R. DearthCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis McNeice Slab MSC-Marc

Uploaded by

David R. DearthCopyright:

Available Formats

20 March 2015 : D2

Analysis of Reinforced Concrete (RC) McNeice Slab Using Nonlinear Finite Rev “x”

Element Techniques MSC/Marc

Prepared By:

David R. Dearth, P.E.

Applied Analysis & Technology, Inc.

16731 Sea Witch Lane

Huntington Beach, CA 92649

Telephone (714) 846-4235

E-Mail AppliedAT@aol.com

Web Site www.AppliedAnalysisAndTech.com

Applied Analysis & Technology © 2015 Slide 1 of 11

20 March 2015 : D2

Rev “x”

Introduction

McNeice (1.) tested a reinforced concrete (RC) slab in 1967.

The purpose of this summary is to present results of addressing this RC Slab and

computing the load deflection curve using MSC/Marc for comparison to the

experimental test data.

For comparison purposes the results from Abaqus example problem 1.1.5 using

Abaqus/Standard at tension stiffening case ε = 0.002 in/in are also compared.

For rectangular plates (or slabs) no general expression for deflection of plates with

corner supports as a function of central concentrated loading is available. The loading to

produce (a.) initial cracking and (b.) ultimate capacity is computed using the Marc

Vector plots of element cracking strain.

Applied Analysis & Technology © 2015 Slide 2 of 11

20 March 2015 : D2

McNeice Slab Geometry with Rebar Definition Rev “x”

from Reference 1 No Scale

3” o.c.

Figure 1.1.5-1 McNeice Slab steel reinforcement locations (not to scale)

(Abaqus Examples Manual 1.1.5 Collapse of Concrete Slab)

Applied Analysis & Technology © 2015 Slide 3 of 11

20 March 2015 : D2

Quarter Symmetric RC Slab with Boundary Conditions & Loading Rev “x”

Mesh size for the quarter

symmetric model is 12x12x4

Y-Z Symmetric

Plane, BC = Tx

Symmetric Loading,

Ptot/4 for Qtr Sym

Idealization

Corner Vertical

Reaction, BC=Tz

X-Z Symmetric

Plane, BC = Ty

Applied Analysis & Technology © 2015 Slide 4 of 11

20 March 2015 : D2

Quarter Symmetric RC Slab Rebar Idealization Rev “x”

3/16” dia.

Interior Rebar Rebar Spacing

Y-Z Symmetric

Area = 0.0276 in2 3” o.c. Typ

Plane, BC = Tx

3/16” dia. Rebar at

Plane of Symmetry

Area/2 = 0.0138 in2

X-Z Symmetric

Plane, BC = Ty

3/16” dia. Rebar at Rebar Size 3/16” Dia.

Plane of Symmetry Table 4.1 Slab No. 1 (1.)

Area/2 = 0.0138 in2

Rebar Material Properties; Mild Steel

Es= 29x 106 psi ν =0.3

Yield Stress Fty = 60,000 psi

Bi-Linear-Plastic Modulus = Perfectly Plastic

Applied Analysis & Technology © 2015 Slide 5 of 11

20 March 2015 : D2

Concrete : Isotropic Tension Properties Rev “x”

The concrete is idealized using 3D solid elements. Young’s modulus of elasticity for the concrete is given as:

Concrete Material Properties

Es= 4.150 x 106 psi ν =0.15

Critical Cracking Stress (Rupture Stress) fr = 460 psi(2.)

Tension Softening Strain at Failure, ε = 0.002 in/in(2.)

Note: Abaqus input is “strain at failure”.

Marc input is “tension softening slope”.

Applied Analysis & Technology © 2015 Slide 6 of 11

20 March 2015 : D2

Concrete : Isotropic Compression Properties Rev “x”

The concrete is idealized using 3D solid elements. Young’s modulus of elasticity for the concrete is given as:

Concrete Material Properties The compressive uniaxial stress-

Es= 4.150 x 106psi ν =0.15 strain relationship for the concrete

Compressive Failure Stress f ’c = 5,550 psi(2.) model was obtained using the multi-

Crushing Strain, εc = 0.003 in/in (assumed) linear isotropic stress-strain

equations for concrete from

MacGregor 1992(3.).

Note: Plasticity definition data for MSC/Marc is defined as post-yield, or plastic, portion of the stress strain curve; e.g. yield

stress zero net plasticity. Typical engineering data for stress-strain curves are defined as total nominal strain.

Applied Analysis & Technology © 2015 Slide 7 of 11

20 March 2015 : D2

Concrete : Isotropic Properties Rev “x”

The concrete is idealized using 3D solid elements. Young’s modulus of elasticity for the concrete is given as:

Concrete Material Properties

Elastic : Ee= 4.15 x106 psi ν = 0.15

Cracking : Critical Cracking Stress (Rupture Stress) fr = 460 psi

Softening Modulus, Es= 243,495 psi [Failure Strain = 0.002 in/in]

Crushing Strain, εc = 0.003 in/in, Shear Retention : 20%

Plasticity : Elastic-Plastic, Isotropic Hardening, Buyukozturk Concrete

Concrete Isotropic Material Input Dialog

Applied Analysis & Technology © 2015 Slide 8 of 11

20 March 2015 : D2

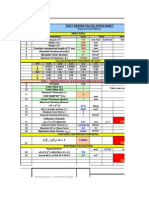

McNeice Slab Test Deflections vs MSC/Marc & Abaqus/Explicit Rev “x”

Applied Analysis & Technology © 2015 Slide 9 of 11

20 March 2015 : D2

Marc Concrete Crack Progression for McNeice Slab Rev “x”

1,940 lbs. Crack Propagation

660 lbs. Last Load Step Prior to Cracks 1,286 lbs. Crack Propagation

At Slab Center Out to Edges and

At Slab Center and Corner Support

Corner Support

832 lbs. Cracks Begin to Appear 1,532 lbs. Crack Propagation 3,498 lbs. Crack Propagation

At Slab Center and Corner Support At Slab Center Out to Edges and At Ultimate Load Prior to Full

Corner Support Collapse

Crack Progression vs. Slab Loading

Applied Analysis & Technology © 2015 Slide 10 of 11

20 March 2015 : D2

Rev “x”

References

1) McNeice, G.M., Elastic-Plastic Bending of Plates and Slabs by Finite Element

Method; Thesis Submitted to University of London for Degree Doctor of Philosophy,

Department of Civil and Municipal Engineering University College of London,

November 1967

2) Dassault Systems, 1.1.5 Collapse of Concrete Slab, Abaqus 6.11 Example Problems

Manual, Volume 1: Static and Dynamic Analyses, 2011

3) MacGregor, J.G. (1992), Reinforced Concrete Mechanics and Design, Prentice-Hall,

Inc., Englewood Cliffs, NJ.

Applied Analysis & Technology © 2015 Slide 11 of 11

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- TechArticle Dynamic Response Random 2DOFDocument17 pagesTechArticle Dynamic Response Random 2DOFDavid R. DearthNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Analysis Reinforced Concrete (RC) Beams Nonlinear - FEADocument27 pagesAnalysis Reinforced Concrete (RC) Beams Nonlinear - FEADavid R. DearthNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- NonLinear FEA Concrete Beam (RC) Epoxy Bonded Strengthening - WappendixDocument22 pagesNonLinear FEA Concrete Beam (RC) Epoxy Bonded Strengthening - WappendixDavid R. DearthNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- FEA Analysis Concrete Beam - No Shear Reinforcement - WappendixDocument17 pagesFEA Analysis Concrete Beam - No Shear Reinforcement - WappendixDavid R. DearthNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Analysis Petersson NotchedBeamDocument9 pagesAnalysis Petersson NotchedBeamDavid R. Dearth0% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Kachlakev - RC Control Beam MSC-Marc - WappendixDocument19 pagesKachlakev - RC Control Beam MSC-Marc - WappendixDavid R. DearthNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Analysis Reinforced Concrete (RC) Beams Nonlinear - FEA - MSC-MarcDocument27 pagesAnalysis Reinforced Concrete (RC) Beams Nonlinear - FEA - MSC-MarcDavid R. Dearth100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Properties of FluidDocument24 pagesProperties of FluidYash PatelNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Harmonic ElementsDocument6 pagesHarmonic ElementsSai KrishnaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Utilization of Ube Peel Waste Starch and Brown Seaweed Cellulose As A Bioplastic CompositeDocument51 pagesUtilization of Ube Peel Waste Starch and Brown Seaweed Cellulose As A Bioplastic CompositeMary Grace ProgellaNo ratings yet

- Assessment 3: Bearing Stress: InstructionsDocument5 pagesAssessment 3: Bearing Stress: InstructionsRaynier LigayaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Analysis of A Tunnel Failure Caused by Leakage ofDocument10 pagesAnalysis of A Tunnel Failure Caused by Leakage ofMichael HurtadoNo ratings yet

- Sacs Manual - Psi-PileDocument65 pagesSacs Manual - Psi-PileChristian Ammitzbøll0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Workshop 6 PDFDocument3 pagesWorkshop 6 PDFkadir demirciNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Belt Failure AnalysisDocument8 pagesBelt Failure AnalysisDavid ChandlerNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- International Journal of Plasticity: Luiz Carneiro, Qin Yu, Yanyao JiangDocument17 pagesInternational Journal of Plasticity: Luiz Carneiro, Qin Yu, Yanyao JiangBangjian YangNo ratings yet

- Machinist Course - Metal Properties, Characteristics, Uses, and CodesDocument98 pagesMachinist Course - Metal Properties, Characteristics, Uses, and Codesmerlinson1100% (5)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ME 408 Lecture2Document47 pagesME 408 Lecture2reader1900No ratings yet

- Strut and TieDocument15 pagesStrut and TierajivkannanNo ratings yet

- Ce6702 Pcs Civil Viist Au Unit VDocument16 pagesCe6702 Pcs Civil Viist Au Unit VraviciviltNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Effect of Friction Factor On Barrelling in Elliptical Shaped Billets During Cold Upset ForgingDocument8 pagesEffect of Friction Factor On Barrelling in Elliptical Shaped Billets During Cold Upset ForgingbahmanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- AASHTO LRFD Bridge Design Specifications 7th Ed. 2014 CL 5.11.5.3Document3 pagesAASHTO LRFD Bridge Design Specifications 7th Ed. 2014 CL 5.11.5.3JohnNo ratings yet

- Pressure Vessels: Horizontal On Two Saddles - DesignDocument20 pagesPressure Vessels: Horizontal On Two Saddles - DesignInamullah KhanNo ratings yet

- Design A Playground ProjectDocument3 pagesDesign A Playground Projectapi-77017198No ratings yet

- WB VMDocument184 pagesWB VMVijay Kr GuptaNo ratings yet

- Duct Design Calculation Sheet: Note:-Take the Value of α & β from above table use in the calculationDocument9 pagesDuct Design Calculation Sheet: Note:-Take the Value of α & β from above table use in the calculationchagar_harshNo ratings yet

- Ch6 TorsionDocument12 pagesCh6 TorsionrkNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Simple Stresses From MathalinoDocument58 pagesSimple Stresses From MathalinoGien Lim100% (5)

- Chapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Document80 pagesChapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Dr. Aung Ko LattNo ratings yet

- Application of Piezoelectric Transducer in Energy Harvesting in PavementDocument8 pagesApplication of Piezoelectric Transducer in Energy Harvesting in PavementvisionNo ratings yet

- VRM KL RDM: Hydraulic Casing Oscillator Hydraulic Casing RotatorDocument4 pagesVRM KL RDM: Hydraulic Casing Oscillator Hydraulic Casing RotatorАнтонNo ratings yet

- CST Mphysics StudioDocument57 pagesCST Mphysics StudioHernán Lucema67% (3)

- Eurocode 2 Part 1,4 - DDENV 1992-1-4-1994 PDFDocument26 pagesEurocode 2 Part 1,4 - DDENV 1992-1-4-1994 PDFmarineugen0% (1)

- 1.M.E. StructuralDocument70 pages1.M.E. StructuralVignesh DhuruvanNo ratings yet

- Learn Steel 2007 Limit State Design of Structural Steel MembersDocument31 pagesLearn Steel 2007 Limit State Design of Structural Steel MembersshaikcivilNo ratings yet

- Mechanics of Materials: ReferencesDocument15 pagesMechanics of Materials: Referencesعبدالله خيريNo ratings yet

- Otc 10979 MS PDFDocument8 pagesOtc 10979 MS PDFChinmaya Ranjan JenaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)