Professional Documents

Culture Documents

00079846

Uploaded by

JohnSmithCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

00079846

Uploaded by

JohnSmithCopyright:

Available Formats

SPE/IADC 79846

Imaging unstable wellbores while drilling

Stephen Edwards, Bruce Matsutsuyu, Steve Willson, BP America

Copyright 2003, SPE/IADC Drilling Conference

This paper was prepared for presentation at the SPE/IADC Drilling Conference held in

Amsterdam, The Netherlands, 1921 February 2003.

This paper was selected for presentation by an SPE/IADC Program Committee following

review of information contained in an abstract submitted by the author(s). Contents of the

paper, as presented, have not been reviewed by the Society of Petroleum Engineers or the

International Association of Drilling Contractors and are subject to correction by the author(s).

The material, as presented, does not necessarily reflect any position of the SPE, IADC, their

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers or

the International Association of Drilling Contractors is prohibited. Permission to reproduce in

print is restricted to an abstract of not more than 300 words; illustrations may not be copied.

The abstract must contain conspicuous acknowledgment of where and by whom the paper

was presented. Write Librarian, SPE, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A.,

fax 01-972-952-9435.

Abstract

This paper presents a case study of borehole instability from 4

wellbores on the Gulf of Mexico (GOM) shelf, offshore

Louisiana. Logging while drilling (LWD) borehole images are

combined with observations of cavings and modeling of

borehole shear failure in order to diagnose the mechanisms of

instability and thus select the appropriate remedial action.

It is observed that instability due to shear failure of intact rock

(borehole breakout) can be suppressed by increasing mud

weight. However, where pre-existing planes of weakness such

as bedding planes and fractures dominate the mechanism of

instability, mud weight increases do not necessarily lead to a

more stable hole and can in fact further destabilize the

wellbore.

Introduction

Despite considerable effort from the drilling, subsurface and

geomechanics communities, many oil wells continue to suffer

from wellbore instability problems during drilling. Although

instability is quite common, in the majority of cases a

considerable amount of uncertainty exists around exactly

where, when and why the instability occurred.

Unfortunately, it is almost axiomatic that logs will not be run

in an unstable wellbore. Direct measurements of the borehole

shape and condition which can be obtained from caliper and

image logs are therefore rarely acquired in the wellbores

where (from a geomechanics point of view) they would be

most valuable. Modeling and cavings analysis alone, can leave

considerable uncertainty as to the location and to some extent

the mechanism of failure.

An exception to the axiom can be where LWD image data is

acquired. It is still unlikely that LWD imaging tools would be

run in a well where significant instability was expected.

However, LWD is often acquired in wells that turn out to be

less stable than anticipated. In these cases a rare glimpse of the

unstable wellbore wall in the early stages of collapse may be

captured. This is very useful information, which would

normally remain the secret of the well.

Mechanisms of wellbore instability

Mechanism of mechanical wellbore instability can be grouped

in two main classes.

1. Instability due to failure of intact rock (rock which is

unbroken and isotropic in strength)

2. Instability due to failure of rock containing pre-existence

planes of weakness (bedding planes, fractures, cleavage).

Rock containing pre-existing weaknesses such as bedding or

cleavage may be intact in the sense that it is unbroken.

However, for the sake of this discussion intact is defined as

above.

The majority of quantitative wellbore stability studies since

the 1979 paper by Bradley1 have modeled the wellbore wall as

intact rock subject to the stresses imposed from the far-field

and the wellbore fluid. This type of failure gives rise to

symmetrical breakouts in the wellbore walls. Breakouts can be

stabilized by increasing the mud weight, or may stabilize after

reaching a certain size under favorable combinations of stress

and strength. Breakouts are quite often observed in image and

multi-arm caliper log data and are clearly a common cause of

wellbore instability.

Other mechanisms of instability where pre-existing

weaknesses are present do not necessarily stabilize with time

or with increased mud weight. Instability due to such

mechanisms is therefore rarely calipered or imaged, making

the exact location and mechanism of instability uncertain.

Consideration of wellbore instability due to pre-existing

weaknesses in oil wells is for the most part relatively recent

2,3,4,5,6

. Evidence of these mechanisms came from observations

such as correlations of trouble time with wellbore trajectory

and the existence of pre-existing fracture planes, bedding

planes and cleavage in cavings.

Types of wellbore instability associated with pre-existing

weaknesses can be grouped into two classes.

EDWARDS, S.T., MATSUTSUYU, B., WILLSON, S.M.

SPE/IADC 79846

(A) Failure due to the existence of impermeable

pre-existing weaknesses.

In the case where the pre-existing weakness are not

preferentially permeable, increase in mud weight will tend to

further support the wellbore wall. An example of this type

might be where a single set of bedding planes is intersected.

(B) Failure due to the existence of preferentially

permeable planes of pre-existing weaknesses.

Where the mud and filtrate preferentially enters pre-existing

planes of weakness, increasing the mud weight does not add

support to the wellbore wall and may increase instability.

Networks of pre-existing weakness (such as where two sets of

weakness - e.g. bedding and fractures intersect) are probably

more likely to be permeable than the single plane of weakness

(e.g. just bedding planes). In an extreme case, the body of rock

may actually be made up of many discrete rock fragments

with no cohesion between them, rather like a pile of rubble or

the material seen in brittle/semi-brittle fault zones. This type

of rock mass could be referred to as a rubble zone, the rock

having been effectively rubbelized. These pre-existing

weaknesses could be a combination of fractures, cracks,

bedding and cleavage planes. Naturally fissile rock, such as

thinly bedded shale, is likely to be particularly susceptible to

becoming rubbelized where it is affected by faulting.

Quantitatively including pre-existing weaknesses in the

wellbore stability models is difficult although recently

encouraging progress has been made for the case of a single

set of pre-existing non permeable weaknesses 7. This difficulty

in modeling, coupled with a lack of direct downhole

observations, has tended to bias the industry towards thinking

in terms of shear failure of intact rock. This bias may be partly

addressed if more direct observations of failure on pre-existing

planes of weakness are made. The emerging use of LWD

imaging tools provides such a possibility.

The following case study contains examples of instability due

to both shear failure of intact rock and failure due to preexisting weaknesses. Both modes of failure are imaged with

an LWD tool. Two distinct cavings types are linked to the 2

mechanisms. Mud weight increase is seen to suppress the

breakouts but increase instability on pre-existing weaknesses.

GOM shelf case study

This paper presents a wellbore stability case study from the

GOM shelf. The study looks at 4 wellbores: an original hole

and 3 sidetracks. The geological setting of the wells is shown

in figure 1. A detail of the well trajectories is shown in figure

2.

Wellbore 1

An original hole was drilled in 1993. This well is labeled

wellbore 1 in figure 1. It was drilled at an angle of 50 degrees

with mud weight of between 10 and 11.5 ppg in the equivalent

section to that described below for the wellbores 2-4.

Wellbore 1 did not encounter any significant instability.

Wellbore 2

In 2002, wellbore 1 was sidetracked. This sidetrack (wellbore

2 in Figure 2) was drilled at 60 degrees, down dip (i.e. subparallel to the dip of the bedding, or perpendicular to the strike

of the bedding). The bedding angle is 12 degrees. The relative

angle between the wellbore and bedding in the plane of the

wellbore (the attack angle) is therefore 18 degrees.

The 8 diameter section of wellbore 2 was drilled from

approximately 7100 MD to 13,427 MD (12,232 TVD). The

mud weight was increased in stages throughout the hole from

10 and 10.8 ppg in response to signs of instability (tight hole

and cavings). The first indications of instability occurred after

drilling to approximately 12,400 ft MD. Tight hole was noted

tripping back in and large pieces of shale (cavings) were seen

over the shakers. No cavings were kept or recorded in detail.

From the available descriptions however, a variety of shapes

and sizes of cavings were seen. The mud weight was increased

from 10 to 10.3 ppg at this stage. While drilling ahead to

13,300 ft MD, tight spots were encountered and

washing/reaming was required on trips. The mud weight was

raised again to 10.5 and then to 10.7 ppg in response to the

hole conditions, which did not appear to improve and cavings

continued to be seen on the shakers. Hole conditions appeared

to be worst below around 12,400 ft MD. On tripping back in

the hole, the BHA was unable to ream past 12,407 ft MD.

After more tight spots and over-pull while tripping out, it was

observed that the lower part of the BHA was left in the hole.

Some time was spent in fishing attempts (while continued

instability was experienced) before deciding to set a cement

plug and re-drill this wellbore from approximately 10,700 ft

MD.

LWD Borehole Images in wellbore 2.

The LWD tools were recovered and the memory data

downloaded. An Azimuth Density Neutron (ADN) tool was

included in the LWD suite. Details of the ADN tool are

available from Anadrill. In brief, the tool measures density as

a function of azimuth around the hole. Density measurements

are binned into 16 sectors (each sector covers a 22.56 degrees

arc) to create a density image.

Figure 3 shows the ADN image from wellbore 2 from 13000

to 13100 ft MD. The figure is from a standard field log ADN

presentation. The data displayed (from left to right) is as

follows:

1st track shows the rotational speed of the tool in RPM

2nd and 3 rd tracks show the raw photo-electric absorption

factor data

4th track is the azimuthal photo-electric factor image

5th track is the azimuthal density image and gamma ray

6th and 7th tracks are the raw density data

Drilling mud has a higher photo-electric absorption factor and

a lower density than the formation. Thus, where wellbore

instability has occurred and mud instead of formation is

adjacent to the tool, a high photo-electric factor and low

SPE/IADC 79846

IMAGING UNSTABLE WELLBORES WHILE DRILLING

density are recorded. In Figure 3, this correlates to dark areas

on the photo-electric factor image and light areas on the

density image. The photo-electric factor is considerably more

sensitive to the mud/formation contrast than the density.

The image in Figure 3 is oriented relative to the borehole

geometry. For display purposes, the cylindrical hole is cut

down the axis of the hole (along the top) and unwrapped.

The top of the hole therefore lies on the far left and right-hand

sides of the unwrapped image and the bottom of the hole

(being 180 degrees from the top of the hole) lies in the center

of the image.

Any planar feature that the borehole intersects will appear in

the image as sinusoidal lines running from one side to the

other. Bedding planes can be seen as low amplitude sinusoids

in Figure 3. When the wellbore intersects planar features at

low angles, the amplitude of the sinusoid is usually high.

However, Figure 3 is presented at a compressed scale such

that the sinusoid amplitude is low, even though the angle

between the wellbore and bedding is only approximately 18

degrees.

Imaged modes of instability

The nature of the instability can be best seen in the photoelectric factor image in Figure 3. The dark areas are where the

wellbore wall has failed and the material has been removed. It

can be seen that the failed area is largely delimited by the

bedding planes and is located mainly on the wellbore roof, and

partly from the wellbore floor. The influence of the bedding

planes on the geometry of the hole failure indicates that they

are acting as pre-exiting planes of weakness. This interval can

be seen from the gamma ray to be a shale section which might

be expected to be somewhat fissile.

Instability dominated by failure on weak bedding planes in

fissile shale, where the wellbore is close to parallel with the

bedding planes has been observed in the laboratory. An

example from Okland and Cook4 is shown in Figure 4. From

their experiments and field data they suggest that the bedding

plane splitting or roof collapse mode of failure occurs where

the angle of attack is less than 10 to 20 degrees.

In most of the section shown in Figure 3, the sides of the hole

are seen to be intact (compare to Figure 4). We could therefore

describe this instability as predominantly a roof collapse

mechanism.

In a couple of places however (e.g. at approximately 13075 ft

MD) failure is seen to extend from the roof of the hole down

to the sides of the hole. The sides of the hole in a 60 degree

well where the maximum stress is vertical may be expected to

exhibit breakouts. It could be that one mode of failure triggers

or interacts with another mode of failure. This is discussed

further (below) with reference to the failed section shown in

Figure 5.

In figure 5, the mode of failure appears to be different to that

in Figure 3. The photo-electric factor image is saturated at the

high end in much of the failed section making details difficult

to discern. In this section, the density image is more revealing.

The density image reads beyond mud in the immediate

vicinity of the tool to show the lowest densities (the failed

section) to be on the sides of the hole.

In a normal faulting environment (where the maximum

principal stress is vertical) such as this part of the GOM shelf,

breakouts in intact rock would be expected to form on the

sides of a hole deviated at 60 degrees, as this is where the

maximum stress concentration would form. A simple

analytical model of shear failure in intact rock indicates that

such failure would be not be unexpected in this hole with the

relatively low mud weight (10 ppg) used to drill this interval.

The location of much of the failed zones in Figure 3 is

therefore probably controlled by the stress concentration rather

than the pre-existing planes of weakness. The angle between

wellbore and bedding is roughly the same in figures 3 and 5.

The bedding planes in figure 5 may not be so weak as in figure

3. The lithology in the failed section of figure 5 can also be

seen (from the gamma ray) to be more silty than that in Figure

2. A more silty rock is likely to be less fissile than a shale.

Although most of the failure in Figure 5 is on the sides of the

hole, it also clearly extends in some places to the roof of the

hole along bedding planes. Thus, there is some element of roof

collapse apparent in this section, which may have been

initiated by breakouts on the side of the hole.

Logging in the time domain.

When studying Figures 3 and 5, another factor that should be

kept in mind is time. The ADN tool is about 100 ft behind the

bit, therefore the well is typically logged approximately 1 hour

after being drilled. In the case of figure 3, about 5 hours

circulating time occurred between drilling the interval and

logging it. In the case of Figure 5, the well was drilled to

12,540 ft MD and then a trip was made to test equipment. The

interval 12,440 to 12,540 ft MD was therefore not logged until

approximately 2 days after it was drilled. On the trip out of

hole, it may also have experienced some swabbing which

would tend to induce instability.

The field log used for this study is a depth based drilling

log. That means that each time the well is deepened, the log

data over the new depth is spliced to the bottom of the

previous log. The measurements are originally recorded in the

time domain. It is converted to depth for presentation. For

most petrophysical applications to is desirable to obtain log

data acquired as soon after the well is drilled as possible in

order to measure undisturbed or uninvaded formation

properties. Where wellbore stability is the topic of interest, it

is instructive to see the state of the hole both directly after

being drilled and at later times. This is possible. It is called

time-lapse logging 8,9. Unfortunately in this case, time

restrictions and difficulty in retrieving the data has prevented

any time-lapse study. It would be extremely interesting

however to examine these and other sections at a latter time.

Wellbore 2 summary

Two modes of instability are apparent in the ADN images:

EDWARDS, S.T., MATSUTSUYU, B., WILLSON, S.M.

?? Roof collapse dominated by failure on bedding

planes in a section drilled close to parallel with

bedding in a shale.

?? Breakout on the sides of the hole also in a section

close to bedding parallel but more silty.

SPE/IADC 79846

suppressed the shear failure on the sides of the hole. However,

the higher mud weight in wellbore 3 seems to have worsened

the pre-existing weakness mode of failure. Normally,

increasing mud weight should add support to the wellbore wall

and prevent collapse. However, if the mud is able to penetrate

along pre-existing weaknesses the effect of the mud pressure

will be to destabilize the wellbore wall rather than support it.

A variety of cavings were reported but not collected or

recorded.

The imaged sections of unstable hole were both recorded some

time after having been drilled. Other parts of the wellbore may

also have been seen to be unstable had they also been logged

some time after drilling.

Wellbore 3

Wellbore 2 was abandoned due to the instability problem

encountered and a cement plug set at 10700 ft MD. Wellbore

3 was kicked off on the top of the cement plug. After steering

about 75 feet away from wellbore 2, wellbore 3 was drilled at

exactly the same azimuth and deviation (60 degrees towards

the east). Because of the instability experienced in wellbore 2,

the mud weight in wellbore 3 was increased to 11.7 ppg. This

is 1ppg more than the maximum mud weight used in wellbore

2. However, the stability problems in wellbore 3 were seen to

be worse than in wellbore 2, particularly in the interval below

12,400 ft MD. After drilling to 13,500 ft MD, multiple

packing-off events occurred even after further increases in

MW (to 11.9), which also resulted in lost circulation. After

more than a day of fighting the battle between instability and

lost returns (and losing on both sides) the drillstring became

irretrievably stuck.

The observation that increased mud weight in wellbore 3

increased instability implies that the mud filtrate was

penetrating the planes of weakness and destabilizing them.

Either the bedding planes themselves are preferentially

permeable, or there is an additional set of cracks and fractures

which provides the permeability, essentially interacting with

the bedding planes to creating a network of pre-existing

weaknesses.

There is no clear evidence of cracks or fractures in the ADN

images. However, they may be well below the resolution of

these images. Figure 1 shows the general structural setting of

the wells and figure 2 shows two mappable faults in close

proximity to the wells. The faulting occurred late in the

geological history and is related to movement of the salt

shown in figure 1. Although the sediments penetrated by these

wells are clearly not highly disturbed, they may have

experienced some degree of faulting/fracturing in response to

nearby fault movement.

Breakout of intact rock gives rise to angular cavings. Failure

dominated by planes of pre-existing weakness on the other

hand give rise to cavings which are delimited mainly by the

planes of pre-existing weakness and therefore tend to be

blocky to tabular and characteristically have parallel sides. We

would therefore expect a variety of cavings from wellbore 2.

On the other hand, the cavings in Figure 6 are the type of

cavings that might be expected from a zone dominated by

failure of bedding planes and roof collapse.

The LWD resistivity provides additional evidence that the

rock has some kind of additional permeability, which would

not be found in a normal (unfractured) shale. The LWD

resistivity tool measures many resistivities at different

spacings and frequencies. In a normal shale, all resistivities

read essentially the intrinsic resistivity of the formation such

that all resistivity curves more or less stack on top of each

other when plotted. Any curve separation indicates some

abnormality. Curve separation in a permeable rock is normal,

as the drilling fluid is expected to invade to some extent and

alter the resistivity. In a shale however, curve separation is

caused by either invasion into a fracture network (or other

path of preferential permeability), anisotropy, tool eccentricity

or hole enlargement. In much of the section showing curve

separation we know the hole to be in gauge from the ADN

tool. Tool eccentricity isnt a likely cause in an 8 hole.

Some of the curve separation is probably due to anisotropy in

the sections drilled at low attack angle to bedding. However,

the key observation is the comparison of the curves from

wellbore 2 and wellbore 3. In the interval shown in Figure 3,

the apparent invasion is greater in wellbore 3, where the

higher mud weight was used, even though it was logged

directly after being drilled as opposed to several hours after in

wellbore 2 (the resistivity tool is much closer to the bit than

the ADN tool so the time effect is not so great). The greater

invasion with the higher mud weight supports the idea that the

mud is penetrating the formation. In a shale, the only likely

mechanism of significant invasion is via some set of network

of pre-existing permeable planes of weakness.

The higher mud weight in wellbore 3 is likely to have

Figure 7 shows the resistivity data from wellbore 2 and 3. The

Many cavings were observed while drilling wellbore 3.

Fortunately, in this case they were saved and photographed

using a digital camera at the wellsite. This was an important

piece of information for the post-mortem diagnosis.

Unfortunately, as the BHA was lost, the ADN images from

this section were not retrieved. Only real-time LWD data was

recovered.

Figure 6 presents a sample of cavings recovered from wellbore

3. These were the dominant type of caving in this wellbore.

Although no record of cavings from wellbore 2 exists,

anecdotal information from the mud engineers and shaker

hands indicates that there was more of a mixture of cavings

type in wellbore 2. We know from the ADN image in wellbore

2 that 2 modes of instability were occurring.

SPE/IADC 79846

IMAGING UNSTABLE WELLBORES WHILE DRILLING

data from wellbore 3 has been depth shifted to match that of

wellbore 2. Normal shale resistivity in this interval is

approximately 0.8 ohmm. The data from wellbore 3 is realtime data and is therefore more coarsely sampled than the data

from wellbore 2, which is downloaded from the memory.

Time-lapse resistivity 8,9 through these zones of suspected

fracturing/invasion would be very instructive but has not been

performed in this case.

Summary of wellbore 3

Like wellbore 2, wellbore 3 was drilled at a low angle of

attack to bedding.

quantitative estimate was made) the instability was not

sufficient to impact drilling. No stuck pipe, packing-off or

significant tight spots were experienced.

Although the details are beyond the scope of this paper, the

simple analytical model of shear failure in intact rock

mentioned above was again run to predict the mud weight

required to prevent breakouts in this wellbore. As the hole has

a lower deviation angle than wellbores 2 and 3, less mud

weight is required to prevent breakout. However, the mud

weight used in this section was still relatively low for the insitu stress and strength conditions, and the observation of

breakouts is again not unexpected.

Wellbore 3 used a higher mud weight than wellbore 2,

however, instability worsened, leading to the loss of the BHA.

Cavings were predominantly blocky to tabular in wellbore 3

indicating failure associated with planes of pre-existing

weakness.

Real-time LWD resistivity indicates increased invasion

(compared to wellbore 2) of oil based mud into the unstable

shale sections.

Wellbore 4

Wellbore 4 was drilled after careful examination of all the data

available from wellbore 2 and 3 (presented above). A wellbore

stability study for this well had not previously been conducted.

The main conclusion drawn from the above observations is

that the majority of instability in wellbores 2 and 3 is due to

the low attack angle to bedding coupled with penetration of

mud into pre-existing weaknesses (either just bedding planes

or a network of bedding planes and fractures).

The key change in plan was therefore to increase the attack

angle. The trajectory of wellbore 4 is shown in Figure 2. As a

secondary precaution against destabilizing the pre-existing

planes of weakness, the mud weight was also lowered back to

10.5 PPG. Although this risked allowing the breakout mode of

failure to occur, this was thought preferable to risking the

more catastrophic bedding plane failure.

Having lost the BHA in wellbore 3, no LWD tools were run in

wellbore 4. However, evidence that the breakout mode of

failure was indeed active in wellbore 4 was obtained from the

cavings. Figure 8 shows cavings recovered from the shakers

while drilling wellbore 4. They are noticeably different to

those recovered from wellbore 3. There are no obviously

blocky or tabular cavings indicating the bedding plane failure

mode was not occurring extensively in this borehole. The

cavings are predominantly angular, consistent with the shear

failure of intact rock or breakout mode. The existence of preexisting fractures may have also played a role in the geometry

of the cavings. However, the dominant influence of the

bedding planes is not seen. Figure 9 attempts to summarize the

geological setting, location and modes of failure seen in

wellbore 1 to 4.

Although the volume of cavings was noticeable (no

Conclusions

Two modes of instability can occur in the same hole at the

same time but require different treatments. In this example the

two modes observed were:

Shear failure of intact rock at the point of maximum

stress concentration on the borehole wall.

Roof collapse due to splitting of weak (fissile shale)

bedding planes where the angle between the wellbore

and the bedding planes was approximately 18

degrees.

Increasing mud weight appeared to prevent the shear failure

mode but worsen the roof collapse mode. This implies that

mud was preferentially penetrating the bedding planes or other

pre-existing planes of weakness (such as fractures). This mud

penetration appears to have been detected from the resistivity

tool.

A combination of LWD imaging, cavings analysis and

modeling is required to unambiguously diagnose the location

and mode of wellbore instability.

LWD imaging offers a rare glimpse at a severely unstable

wellbore. It is a key tool for any attempts at real-time wellbore

stability. There is enormous potential to improve our

understanding of wellbore instability from further LWD

imaging studies and in particular from time-lapse LWD

imaging.

Refrences

1. Bradley, W.B. Failure of inclined boreholes. Transactions

of the ASME Volume 101, December 1979.

2. Santarelli, F.J., Dahen. D., Baroudi, H., Silman, K.B.,

Mechanisms of borehole instability in heavily fractured rock

media. International Journal of Rock Mech. Min. Sci. and

Geochem. Abstracts. 1992 (29) 457 467.

3. Last, N., Plumb, R., Harkness, R., Charlez, P., Alsen, J.,

Mclean, M. An integrated approach to evaluating and

managing wellbore stability in the Cusiana field, Colombia.

1995. SPE 30464

EDWARDS, S.T., MATSUTSUYU, B., WILLSON, S.M.

4. Okland, D., Cook, J.M., Bedding related borehole

instability in high angle wells. Eurock, 1998. SPE 47285

5. Willson, S. M., Zoback, M.D., Moos, D. Drilling in South

America: A wellbore stability approach for complex geolgic

conditions. 1999. SPE 53940.

6. Chen, X., Tan, C.P., Detournay, C. The impact of mud

infiltration on wellbore stability in fractured rock masses.

Oilrock 2002. SPE 78241.

7. Crook, A.J.L., Yu, J., Willson, S.M. Development of an

orthotropic 3D elastoplastic material model for shale

Oilrocks 2002. SPE 78238.

8. Bratton, T.R., Rezmer Cooper, I.M., Desroches, J., Gille YE., Li, Q., McFayden, M. How to Diagnose Drilling Induced

Fractures in Wells Drilled with Oil-Based Muds with RealTime Resistivity and Pressure Measurements SPE/IADC

67742.

9. Edwards, S.T., Bratton, T.R., Standifird, W.B. Accidental

Geomechanics: Capturing in situ stresses from mud losses

encountered while drilling

SPE/IADC 79846

SPE/IADC 79846

IMAGING UNSTABLE WELLBORES WHILE DRILLING

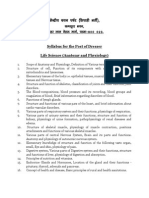

REGIONAL WEST-EAST SEISMIC LINE THROUGH THE SUBJECT WELLBORES

1-4 SHOWING THE RELATIONSHIP TO MAJOR STRUCTURAL ELEMENTS

WEST

EAST

LINE

SUBJECT WELLS

TOP OF 12.5#

PRESSURE

SALT

SALT

5000

Figure 1. Regional West-East seismic line showing the general structural setting of the discussed GOM shelf wellbores 1-4.

EDWARDS, S.T., MATSUTSUYU, B., WILLSON, S.M.

SPE/IADC 79846

DETAIL SEISMIC LINE PARALLEL TO WELLS SHOWING THE RELATIONSHIP

OF BORE HOLE ANGLE AND BED DIP (Some Vertical Exaggeration)

EAST

WEST

Shallower Target

Target Anomaly

Bed Dips ~12 Degrees

Fault

Wells 2&3:

60 Degrees

Fault

Well 4: 36 Degrees

Well 1: 50 Degrees

1000

Figure 2. Detail of structural setting of wellbores 1 -4. The angle between wellbore and bedding (for the bottom secti ons of wellbores 2 and 3 is

18 degrees.

SPE/IADC 79846

13000 MD

IMAGING UNSTABLE WELLBORES WHILE DRILLING

Bottom of Hole

Bedding Plane

13100 MD

Top of Hole

Figure 3. ADN image from wellbore 2 showing wellbore

instability on the roof and floor of the wellbore predominantly

related to bedding planes in this section. Angle between the

wellbore and bedding planes is 18 degrees. See text for

explanation of data in the display.

10

EDWARDS, S.T., MATSUTSUYU, B., WILLSON, S.M.

Bedding plane

orientation

Figure 4. Montage of scanning electron microscope image

of a laboratory hollow cylinder test in a fissile Jurassic North

Sea Shale showing catastrophic hole collapse dominated by

failure of bedding planes. The large cross cutting cracks

(running from one side of the sample to the other) are thought

to be pre-existing cracks roughly parallel to bedding. Original

hole diameter is 10mm. Taken from Okland and Cook4.

SPE/IADC 79846

SPE/IADC 79846

IMAGING UNSTABLE WELLBORES WHILE DRILLING

11

Bottom of Hole

12500 ft

12550 ft

Breakouts on

side of hole

Top of Hole

Figure 5. ADN image from wellbore 2 showing failure

predominantly on the sides of the hole (clearest in the density

image). Although angle between wellbore and bedding is only

18 degrees in this section and bedding planes can still be seen,

it is more silty (note gamma ray) and therefore perhaps less

fissile than the interval in Figure 3. The failure on the sides of

the hole appears to be shear failure (breakout) of intact rock

rather than being dominated by the bedding planes. In some

places however, the bedding does clearly influence the failure.

It may be that breakout on the sides of the hole and bedding

plane failure on the roof of the hole are inter-related in this

section. See text for explanation of data in the display.

12

EDWARDS, S.T., MATSUTSUYU, B., WILLSON, S.M.

Figure 6. The predominant cavings type in wellbore 3 were

blocky to tabular shales as shown here. They are characterized

by parallel bounding surfaces, which by analogy to Figure 4

and from examination of Figure 3 are probably bedding

planes.

SPE/IADC 79846

SPE/IADC 79846

IMAGING UNSTABLE WELLBORES WHILE DRILLING

13

2.5

150

2.3

100

2.1

50

1.9

1.7

-50

1.5

-100

1.3

-150

1.1

0.9

WB2_LWD_Res_P40H

WB2_LWD_Res_A40L

0.7

WB3 LWD_Res_P40H_RT

WB3 LWD_Res_A40L_RT

WB2_LWD_GR

WB3_LWD_GR_RT

0.5

12800

12900

13000

Figure 7. Comparison of LWD resistivity in wellbores 2

and 3 (depth shifted to match). Higher resistivities in the

shaley sections in wellbore 3 may indicates greater invasion of

synthetic oil based mud.

13100

-200

-250

-300

13200

14

EDWARDS, S.T., MATSUTSUYU, B., WILLSON, S.M.

Figure 8. Cavings from wellbore 4 shown here were

noticeably different to those from wellbore 3. None of the

blocky tabular cavings were seen in wellbore 4. These

cavings are predominantly angular with bounding surfaces at

less than 90 degrees to each other. These are likely to be

caused by shear failure of intact rock. The presence of some

other set of pre-existing fractures is also apparent form the

shape of some of the cavings.

SPE/IADC 79846

SPE/IADC 79846

IMAGING UNSTABLE WELLBORES WHILE DRILLING

15

Shear failure on

sides of hole

produces angular

cavings

Wellbore 1

Wellbores 2 and 3

Possible fractures

related to Fault

Trend

B ed D

ip = 1

2 Deg

rees

X100

Roof collapse on

bedding planes

produces blocky tabular cavings

Figure 9. Summary of structural setting, instability

mechanism and resulting cavings in wellbores 1 to 4. The

ADN image shown here with wellbore 4 is actually from

wellbore 2 (see text) but the type of failure is interpreted to be

the same.

Wellbore 4

You might also like

- Selective Extraction of Neutral Nitrogen Compounds Found in Diesel Feed byDocument8 pagesSelective Extraction of Neutral Nitrogen Compounds Found in Diesel Feed byJohnSmithNo ratings yet

- Zn-Containing Ionic Liquids For The Extractive Denitrogenation of A Model Oil - A Mechanistic ConsiderationDocument7 pagesZn-Containing Ionic Liquids For The Extractive Denitrogenation of A Model Oil - A Mechanistic ConsiderationJohnSmithNo ratings yet

- Selective Adsorption For Removal of Nitrogen Compounds From Liquid HC Streams Over Carbon - and Alumina - Based AdsorbentsDocument10 pagesSelective Adsorption For Removal of Nitrogen Compounds From Liquid HC Streams Over Carbon - and Alumina - Based AdsorbentsJohnSmithNo ratings yet

- Inhibition Effects of Nitrogen Compounds On The HDS of Dibenzothiophene Part 2aDocument8 pagesInhibition Effects of Nitrogen Compounds On The HDS of Dibenzothiophene Part 2aJohnSmithNo ratings yet

- Science:, 792 (2003) Robin D. Rogers and Kenneth R. SeddonDocument3 pagesScience:, 792 (2003) Robin D. Rogers and Kenneth R. SeddonJohnSmithNo ratings yet

- Are Deep EutecticDocument3 pagesAre Deep EutecticJohnSmithNo ratings yet

- Electrodeposition of Co, SM and SmCo From A Deep Eutectic SolventDocument7 pagesElectrodeposition of Co, SM and SmCo From A Deep Eutectic SolventJohnSmithNo ratings yet

- Post-Etch Residue Removal Using Choline Chloride-Malonic Acid Deep Eutectic Solvent (DES)Document6 pagesPost-Etch Residue Removal Using Choline Chloride-Malonic Acid Deep Eutectic Solvent (DES)JohnSmithNo ratings yet

- Molar Heat Capacities of Choline Chloride-Based Deep Eutectic Solvents and Their Binary Mixtures With WaterDocument25 pagesMolar Heat Capacities of Choline Chloride-Based Deep Eutectic Solvents and Their Binary Mixtures With WaterJohnSmithNo ratings yet

- Electrodeposition of Zinc-Tin Alloys From Deep Eutectic Solvents Based On Choline ChlorideDocument7 pagesElectrodeposition of Zinc-Tin Alloys From Deep Eutectic Solvents Based On Choline ChlorideJohnSmithNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Outdoor Air Pollution: Sources, Health Effects and SolutionsDocument20 pagesOutdoor Air Pollution: Sources, Health Effects and SolutionsCamelia RadulescuNo ratings yet

- Leigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Document6 pagesLeigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Lue SolesNo ratings yet

- Tribal Banditry in Ottoman Ayntab (1690-1730)Document191 pagesTribal Banditry in Ottoman Ayntab (1690-1730)Mahir DemirNo ratings yet

- WebLMT HelpDocument12 pagesWebLMT HelpJoão LopesNo ratings yet

- Human EpigenomicsDocument234 pagesHuman EpigenomicsHeron HilárioNo ratings yet

- Environmental Economics Pollution Control: Mrinal Kanti DuttaDocument253 pagesEnvironmental Economics Pollution Control: Mrinal Kanti DuttashubhamNo ratings yet

- Prelim Examination MaternalDocument23 pagesPrelim Examination MaternalAaron ConstantinoNo ratings yet

- Activity # 1 (DRRR)Document2 pagesActivity # 1 (DRRR)Juliana Xyrelle FutalanNo ratings yet

- How To Identify MQ Client Connections and Stop ThemDocument26 pagesHow To Identify MQ Client Connections and Stop ThemPurushotham100% (1)

- FDA Approves First Gene Therapy, Betibeglogene Autotemcel (Zynteglo), For Beta-ThalassemiaDocument3 pagesFDA Approves First Gene Therapy, Betibeglogene Autotemcel (Zynteglo), For Beta-ThalassemiaGiorgi PopiashviliNo ratings yet

- Leak Detection ReportDocument29 pagesLeak Detection ReportAnnMarie KathleenNo ratings yet

- Dynamics of Machinery PDFDocument18 pagesDynamics of Machinery PDFThomas VictorNo ratings yet

- Organizational ConflictDocument22 pagesOrganizational ConflictTannya AlexandraNo ratings yet

- UC 20 - Produce Cement Concrete CastingDocument69 pagesUC 20 - Produce Cement Concrete Castingtariku kiros100% (2)

- MGMT Audit Report WritingDocument28 pagesMGMT Audit Report WritingAndrei IulianNo ratings yet

- Career Level Diagram - V5Document1 pageCareer Level Diagram - V5Shivani RaikwarNo ratings yet

- Soosan Crane Training: (Principles)Document119 pagesSoosan Crane Training: (Principles)Boumediene CHIKHAOUINo ratings yet

- Syllabus DresserDocument2 pagesSyllabus DresserVikash Aggarwal50% (2)

- Electro Fashion Sewable LED Kits WebDocument10 pagesElectro Fashion Sewable LED Kits WebAndrei VasileNo ratings yet

- Monkey Says, Monkey Does Security andDocument11 pagesMonkey Says, Monkey Does Security andNudeNo ratings yet

- CAT 320D2: Hydraulic ExcavatorDocument5 pagesCAT 320D2: Hydraulic Excavatorhydeer 13No ratings yet

- GT-N7100-Full Schematic PDFDocument67 pagesGT-N7100-Full Schematic PDFprncha86% (7)

- BNF Pos - StockmockDocument14 pagesBNF Pos - StockmockSatish KumarNo ratings yet

- Chronic Kidney DiseaseDocument15 pagesChronic Kidney Diseaseapi-270623039No ratings yet

- Opc PPT FinalDocument22 pagesOpc PPT FinalnischalaNo ratings yet

- E Flight Journal Aero Special 2018 Small PDFDocument44 pagesE Flight Journal Aero Special 2018 Small PDFMalburg100% (1)

- Snapdragon 435 Processor Product Brief PDFDocument2 pagesSnapdragon 435 Processor Product Brief PDFrichardtao89No ratings yet

- Dalasa Jibat MijenaDocument24 pagesDalasa Jibat MijenaBelex ManNo ratings yet

- ReadmeDocument3 pagesReadmedhgdhdjhsNo ratings yet

- in Strategic Management What Are The Problems With Maintaining A High Inventory As Experienced Previously With Apple?Document5 pagesin Strategic Management What Are The Problems With Maintaining A High Inventory As Experienced Previously With Apple?Priyanka MurthyNo ratings yet