Professional Documents

Culture Documents

Citric Acid

Uploaded by

Md Tanvir FarabiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Citric Acid

Uploaded by

Md Tanvir FarabiCopyright:

Available Formats

Australian Journal of Basic and Applied Sciences, 7(5): 366-372, 2013

ISSN 1991-8178

Simulation Of Xylitol Production: A Review

1

N. Alnur Auli, 2M. Sakinah, 1A.M. Mustafa Al Bakri, 1H. Kamarudin & 3M.N. Norazian

Center of Excellence Geopolymer and Green Technology (CEGeoGtech), School of Materials

Engineering, Universiti Malaysia Perlis (UniMAP), P.O. Box 77, D/A Pejabat Pos Besar, 01000,

Kangar, Perlis, Malaysia

2

Faculty of Chemical and Natural Resources Engineering, Universiti Malaysia Pahang (UMP),

Lebuhraya Tun Razak, 26300 Gambang, Kuantan, Pahang, Malaysia

3

School of Environmental Engineering, Universiti Malaysia Perlis (UniMAP), P.O. Box 77, D/A

Pejabat Pos Besar, 01000, Kangar, Perlis, Malaysia

Abstract: This paper reviews a recent research development on simulations biological conversion of

hemicellulosic biomass towards commercial scale production of xylitol by taking advantage of power

of biotechnology. Xylitol is a five-carbon sugar alcohol that is found in small quantities in many fruits

and vegetables. Xylitol is nearly as sweet as table sugar sucrose. Unlike sucrose, xylitol is well

tolerated by diabetics and does not cause tooth decay. As a consequence, xylitol is in demand in sugarfree confectionery. In the present paper, a continuous enzyme-catalyzed xylitol commercial scale using

the lignocellulosic biomass,was simulated by a commercial bioprocess simulator (SuperPro

Designer). In continuous mode, the objective is to maximize the amount of desired product per unit

time, whereas in batch or fed-batch modes the goal is to maximize product at the end of each batch,

leading to control challenges of a different nature. The development of computer-aided design tools for

bioprocessing began in the mid 1980s. Mathematical modelling (in the subsequent text simply

modelling) and simulation are widely used for optimally designing and operating production facilities

in most industrial sectors such as the chemical and biotechnological process industries. Study of xylitol

in continuous process using enzymes is too complex to be given tractable mathematical formulations.

In the context of optimizing simulations, a complex evaluation refers to the execution of a simulation

model (which can be extremely time-consuming). Established tool simulators for these processes

include: Aspen Plus (from Aspen Technology, Inc.), ChemCAD (from Chemstations, Inc.), Aspen

HYSYS (from Hyprotech, Ltd./AEA Engineering Software), and PRO/II (from Simulation Sciences,

Inc.). The three bioprocess simulators, Aspen Plus, HYSYS and SuperPro Designer, will be review

and compared in this research. The proposed simulator; SuperPro Designer will be selected as the best

simulator tool for production of xylitol in commercial scale.

Key words: xylitol; bioprocessing; simulation; SuperPro Designer

INTRODUCTION

The low cost and renewable nature of lignocellulosic biomass such as sugarcane bagasse, wheat straw, rice

straw, corn stover, etc. represent the ideal feedstock for their conversion into value-added products by

biotechnological routes. This lignocellulosic biomass is the most promising feedstock considering its great

availability and low cost; constituted primarily of lignin, hemicellulose(s) and cellulose (Cardona, 2007). The

carbohydrate fraction (hemicellulose and cellulose) can be depolymerised into sugars which act as a primary

carbon source for the microbial biocatalysts for the production of xylitol, ethanol, organic acids, industrial

enzymes, etc (Chandel, 2007). Xylitol is a five-carbon sugar alcohol that is found in small quantities in many

fruits and vegetables (Sirisansaneeyakul, 2009). It is one of the most expensive polyol sweeteners and has

specific health claims in the world market. It is suitable for diabetes, recommended for oral health and paranteral

nutrition. On an industrial scale, xylitol is currently produced through chemical reduction of xylose derived from

saw dust and sugarcane baggase hemicellulose hydrolysate. It is relatively expensive by about $7 kg-1

comparatively with other natural sweeteners (Rao, 2006).

In the world of software development, systems often begin as simple and well understood, and normally

contain elements such as creation of process flow diagrams, and generation of material and energy balances. To

meet the ultimate requirements, models become more complex to include calculations such as equipment sizing,

and capital and operating cost estimation. Simulation is becoming a requirement for all major process designs.

Using simulation, bioprocess engineers can identify potential problems ahead of time and take corrective action.

A common use for bioprocess simulation is for process mapping and cost analysis. Process mapping enables

investigators to analyze or predict the action of organisms in response to certain specific inputs. Cost analysis

Corresponding Author: N. Alnur Auli, Center of Excellence Geopolymer and Green Technology (CEGeoGtech), School of

Materials Engineering, Universiti Malaysia Perlis (UniMAP), P.O. Box 77, D/A Pejabat Pos

Besar, 01000, Kangar, Perlis, Malaysia

E-mail: nurauli@gmail.com

366

Aust. J. Basic & Appl. Sci., 7(5): 366-372, 2013

identifies the expensive process steps and other cost items that have major impacts overall process economics.

In addition, one of the challenges for users when using such simulation tool is accumulation of the appropriate

data. Simulation can only be run until all the data is collected and put into the system (Thien, 2011). The first

step in building a simulation model is collection of information about the process.

Process simulation and modelling is the application of a range of software tools to analyse individual unit

operations (or process stages) and their relationships within the overall process. Process simulation is defined as

the utilization of computer software resources to develop mathematical models for the construction of an

accurate, representative model of a chemical process in order to understand its actual behavior during regular

plant operations (Diwekar, 2005). These tools can be used at all stages of process development, from conceptual

design, through process operation and optimization. Process simulation of xylitol using enzymes in continuous

production will study. Today the largest supplier of simulation software to the biotech and pharmaceutical

industry is Microsoft, which offers several basic software tools that can be used for simulation: Visio Constructs flow sheets with a drawing package; Excel - Process calculations are performed with spreadsheets

and reported graphically; and Project - Constructs process schedules and labor assignments. The disadvantage

of these tools is that they are not designed for bioprocess simulation.

A bioprocess is a special type of chemical process that produces biochemical products (e.g. antibiotics,

xylitol, amino acids, etc.) from microorganisms or enzymes. Bioprocesses share some common features with

general chemical processes, but differ in their kinetics of product formation, process structure (unit operations

and procedures) and operating constraints (Brunet, 2012). Most biochemical products are produced by

fermentation. In fermentation, the products are formed by catalysts that catalyse their own synthesis. Enzymes

are biological catalysts and are produced as secondary metabolites of enzyme fermentation (Saarel.U., 2003).

Study of xylitol in continuous process using enzymes is too complex to be given tractable mathematical

formulations. As research by (Barradas, 2010), where biological production of xylitol from xylose it has been

demonstrated that a low-level supply of oxygen to the culture (0.1 volume of air per volume of culture

medium per minute) yields an increase of extracellular accumulated xylitol up to 0.65 gxylitol gxylose1 by using

software Matlab Release 12 (Math Works, Inc.). Mathematical function contains multiple nonlinearities,

combinatorial relationships and uncertainties inaccessible to modeling except by resorting to more

comprehensive tools like computer simulation (Fernandez. J. A., 2008). The complexities and uncertainties in

these systems are the primary reason that simulation is often chosen as a basis for handling the decision

problems associated with them.

Process simulators offer the opportunity to shorten the time required for process development. They allow

comparison of process alternatives on a consistent basis so that a large number of process ideas can be

synthesised and analysed interactively in a short time (Tochampa, 2005). Simulation of integrated processes

also enables the study of interactions that exist between upstream and downstream processes (Rouf, 2001). To

assess the technological feasibility and obtain material and energy balances for a preliminary economic analysis,

complete process simulations were performed. Despite some expected differences between a process simulation

and real-life operation, process simulators are commonly used to provide reliable information on process

operation, owing to their vast component libraries, comprehensive thermodynamic packages and advanced

computational methods.

Aspen Plus:

Advanced System for Process Engineering (ASPEN) is a process modelling software suite designed for

batch and continuous simulation (Farid, 2007). For continuous processes, it is possible to use the conventional

Aspen Plus simulator but this requires customization for many bioprocess operations (Gosling, 2005). Aspen

Plus (developed by Aspen Technology Incorporated), is a steady-state sequential modular simulation package

used as a tool to simulate and design chemical processes. It offers the possibility to simulate various

combinations of unit operations such as reactors, distillation towers, heat exchangers and compressors using the

built-in process models (Verhoef, 2008). The steady-state is a characteristic of a condition, such as value, rate,

periodicity, or amplitude, exhibiting only negligible change over an arbitrary long period of time (infinite). It is

one of the most important process simulators in the chemical industry and oil refining process, includes

standard, ideal unit operations, such as Gibbs reaction and heat exchange models (Ye, 2009).

Essentially, the Aspen Plus simulator is made up of: i) a rich databank with pure components, binary

parameters, reactions constants, etc; ii) a vast number of thermodynamic models for the physical and transport

properties calculation; iii) a unit operation model (U.O.M). It overall model consists of 33 unit operation blocks,

one design specification and five Fortran Calculator blocks (Cimini, 2005; Somers, 2011). It also includes a

library of standard unit operation blocks (eg. pumps, heat exchanger, reactors, splitters), which represent process

taking place in an actual chemical plant (Yun, 2013). Aspen Plus includes many basic units, such as distillation

towers, drums, pumps, and heat exchangers. It does not include many specialty unit operations that are used for

particular industries, such as conveyor belts or equipment necessary for the pre-treatment of solids (Bowen,

2010). Aspen Plus includes a wide variety of thermodynamic packages, which gives the user many options as to

367

Aust. J. Basic & Appl. Sci., 7(5): 366-372, 2013

which will most accurately model any process (Haydary, 2009).

Aspen Plus can be a difficult program to learn and work with because it contains so much information. This

makes the program complicated, but also an incredibly valuable resource. When given inappropriate information

about a system Aspen Plus will sometimes give nonsensical results, but more often it will simply give an error

message. This often catches user mistakes, which is helpful, if sometimes frustrating. Considerable knowledge

of thermodynamics, chemical equipment and processes is necessary to successfully work with Aspen Plus, or

the user will end up with many errors and little information. A Microsoft Excel VBA tool has been developed to

help the engineer when performing energy and thermoeconomic analyses of processes that have been simulated

using Aspen Plus. The application is needed because Aspen Plus does not have an integrated function to

calculate the energy of the streams presented in a process, nor to evaluate thermoeconomic costs, although it

gives enough thermodynamic data and can also estimate capital costs (Querol, 2011).

After the completion of process modelling and calculations of mass and energy balances, the simulation

results can be generated and sent to another Aspen utility, Aspen Icarus Process Evaluator or Aspen IPE, which

is specialized for further economical evaluations (Kumar, 2010). Aspen IPE is designed to automate the

preparation of detailed designs, estimates, investment analysis and schedules from minimum scope definition,

whether from process simulation results or sized equipment lists (Yu, 2011; Magnusson, 2005). From study of

(Posada, 2011), the economic analysis of poly-3-hydroxybutyrate (PHB) production from glyceol was estimated

by using Aspen Icarus. In economic terms the best technological scheme for PHB production from crude

glycerol includes three important features as follows: (i) purification of crude glycerol up to 98 wt%, (ii) a two

continuous fermentation stages, with operating times of 21 and 22.5, h respectively and finally (iii) the PHB

recovering performed with the Downstream Process I, which is similar to the BIOPOL flow sheet.

Other disadvantages of Aspen Plus are the kinetic and models must define for simulation and in some cases

it is hard to converge. The model library of Aspen Plus is limited in type and number of models of process unit

operations (Larrson, 2011). The properties for components not included in the Aspen Plus database were

obtained from a custom property database developed by National Renewable Energy Laboratory (NREL). Heat,

work, and material stream flows, as well as process conditions from Aspen Plus simulations are imported into

Excel for use in the economic analysis.

Some research had used Aspen Plus for conversion of glycerol to added-value components. Because of both

the petrochemical character of Aspen Plus and its modular-sequential approach, there are not available kinetic

models describing the biotechnological processes such as fermentations or enzymatic reactions. Therefore, it is

required to work with the available interface between Aspen Plus and Excel. The specific compounds involved

in the different processes of raw glycerol conversion to added-value products such as: free fatty acids, alkyl

esters, proteins, salts, cell mass strains, enzymes, and other complex molecules produced by reactive-extractive

process are not available on the Aspen Plus Database (Duque, 2011).

Same study also by (Limniyakul, 2007), where due to unavailable structure of reactants and products in the

library of Aspen Plus, the major components of Jatropha which were triglyceride, diglyceride and

monoglyceride of oleic and linoleic acid were draw by GaussViewW. After drawing, the structures were

optimized by GAUSSIAN 03W in order to obtain the stable structure. All of these structures were used in Aspen

Plus for finding the parameter such as boiling point, molecular weight, heat capacity, coefficients for antoine

equation. The simultaneous production of bioethanol and xylitol from rye straw is investigated by (Franceschin,

2011) that was then implemented using the software Aspen Plus. The optimization of the process energy duties

is carried out by means of the pinch technology analysis. Mass balances from the simulation are used in order to

size the equipment and calculate the capital investment. As a result, 736 kg/h of xylitol, 82 kg/h of cells, 52 kg/h

of ethanol are obtained; in the product also arabitol, CO2, unreacted xylose and arabinose are present, according

to the yields reported.

Aspen HYSYS:

Aspen HYSYS (HYprotech SYStem) by Aspen Technology is one of the major process simulators that are

widely used in chemical and thermodynamic process industries today. It also specializes on steady state analysis

same as Aspen Plus (Dash, 2008). Aspen HYSYS is designed specifically for a continuous process of multiple

process units. It is not designed to handle batch, semi-batch, or semi-continuous process units (Hanyak, 2012).

Aspen HYSYS had to advantage to export the process design to Aspen Icarus Process Evaluator (Aspen IPE) for

cost estimation. The cost estimation was based on equipment costs given by Aspen IPE, raw material costs

provided by user and utility costs from Aspen IPE database. Otherwise, the thermodynamic packages

incorporated in Aspen HYSYS had limited thermodynamic data on the biomass components.

A difficulty in modelling the bioprocesses using HYSYS process simulation software was to obtain the

thermodynamic package that incorporated biological materials in the design. The fermentation, anaerobic

digestion and transesterification processes had least thermodynamics properties available for modelling. Most of

the biomass components were manually entered using the user-defined method and the structures of each

compound were constructed using standard software (SYMYX Draw 3.2). Property estimation methods for

368

Aust. J. Basic & Appl. Sci., 7(5): 366-372, 2013

HYSYS were used to predict the interaction parameters. Conversion reactors were used for single reactions.

Tanks were used for multiple reactions, as conversion reactors in HYSYS were incapable of handling multiple

reactions.

Study by (West, 2008), continuous biodiesel processes by using waste vegetable oil feedstock were

designed and simulated in HYSYS. HYSYS was selected as a process simulator for both its simulation

capabilities and its ability to incorporate calculations using the spreadsheet tool .Components not available in

the HYSYS library was specified using the Hypo Manager tool. However, specification of a component

requires input of a number of properties, such as normal boiling point, density, molecular weight, as well as the

critical properties of the substance were obtained from the ASPEN Plus component library. The initial cost

estimations of the processes were also exported to ICARUS Process Evaluator (IPE). As study by (Sengupta,

2010), the economic analysis was also performed in ICARUS for process for fermentation of biomass to

ethanol. The design has three sections, a pre-treatment section, a fermentation section and a purification section.

The total project capital cost was $20 million. The operating cost was $81 million per year which included raw

material costs of $54 million per year. A minimum product selling price computed from the operating cost was

set at $1.52/gallon for ethanol.

For process economics, Aspen In-Plant Cost Estimator was used. It has been used for over 30 years in

commercial plants and engineering designs, and provides more accurate estimation. Aspen In-Plant Cost

Estimator provides specifications for detailed design, estimation and economic data, allowing quick

modifications of the process equipment and sensitivity analysis. The alkali-catalyzed process using fresh

vegetable oil had the lowest total capital investment, but the supercritical process was the most economically

feasible overall, providing a lower manufacturing cost and higher net present value and a discounted cash flow

rate of return (Lee, 2011).

SuperPro Designer:

SuperPro Designer is a professional process simulator developed by Intelligen Incorporated, which

facilitates modeling, evaluation and optimization of integrated processes in a wide range of industries such as in

pharmaceutical industries, agrochemicals, food processes, water purification and end-of-pipe treatment

processes. It is also designed specifically for processes including biological components (Athimulam, 2006). It

combines the drawing, calculation and scheduling features of the three Microsoft packages; Excel, Project and

Visio into a single, moderately priced package (Gosling, 2003). SuperPro Designer can handle batch and

continuous processes equally well; whereas the other three tools are practically limited to batch or continuous

processes. (Petrides, 2002). Besides process modeling, Superpro Designer has many advanced convenient

features such as material and energy balances calculations, extensive databases for chemical component and

mixture as well as equipment and resource, equipment sizing and costing, thorough process economics, waste

stream characterization, etc (Ernst, 1996). This program is also capable of providing equipment cost used for the

plant (Qureshi, 2013). All these features are quite useful when analysing the process models (Yu, 2011).

SuperPro Designer includes unit operations specific to biological operations, such as fermentors and

strainers that Aspen lacks. As study by (Malakahmad, 2013; Vucurovi, 2012), the biodegradation process of a

small-scale anaerobic bioreactor was simulated using SuperPro Designer and process simulation flow sheet,

materials registration and process reactions were conducted during model setup However, SuperPro Designer

has significantly less rigorous thermodynamic packages and far less information about components in databases.

This often forces the user to research outside of the program in order to gather enough information for a

successful simulation. SuperPro Designer enables an easy and user-friendly approach than Aspen Plus (Biwer,

2004). However, much more care is required of the user to successfully run a simulation in SuperPro Designer

because it will give physically impossible results. SuperPro Designer also includes a costing feature that certain

versions of Aspen Plus lack. It is very helpful to get an approximate cost of equipment and plant operating cost

as the simulation is completed (Bowen, 2010).

SuperPro Designer also offers a database feature to log equipment and utility capacities. This package has

the added advantage that it was specifically developed for simulation of bioprocess unit operations and

processes. It is user friendly and set up to capture the unique unit operational data requirements of biological

processes (Gosling, et. al., 2003). SuperPro Designer is relatively simple and fast to set up a flowsheet for an

entire process where it does not require integration of differential equations (Kawachale, 2011). This shortens

the computation time and enables the user to evaluate a larger number of scenarios in a shorter period

(Trifkovic, 2000). It also had default values for many of the input data required for simulation that could be used

when experimental data were not readily available or as a reference to check against. However, one of the key

disadvantages was that it could not capture the desired dynamic behaviour capabilities related to time-dependent

operations (Farid, 2007). The main advantages of this simulator consist in a large data base of specific chemical

compounds and unit operations, and the evaluation of economical and ecological process performance indexes

(Taras, 2011). The unit operation models in SuperPro Designer are not very complex. If more accurate results

are desired, the solutions obtained with SuperPro Designer at the large scale of the entire process can be refined

369

Aust. J. Basic & Appl. Sci., 7(5): 366-372, 2013

at the small scale of unit operations. Most of all chemical and biochemical engineering simulators are not

equipped with optimization tools. In very few simulators (e.g. Aspen Plus) there are some optimization tools,

but the formulation of optimization problems and techniques are severely imposed. SuperPro Designer doesnt

contain any optimization tools for optimization purposes; this was linked with Matlab using automation Clientserver of Matlab Component Object Module (COM) technology (Woinoraso, 2009).

A study by (Rouf, 2001), production of tissue plasminogen activator (t-PA) from Chinese hamster ovary

(CHO) cells are using Aspen BPSTM and SuperPro Designer. However, the economic evaluator of Aspen

BPSTM, which has been derived from the chemical process simulator AspenPlusTM, is geared more towards

chemical processes. Its calculation mode is rigorous and requires a lot of data from a real project to make

appropriate use of the available options. SuperPro Designer on the other hand, has an economic evaluator that

is specifically developed for bioprocesses. It is simple and easy to use. (Vlysidis, 2011) have design and

simulation in HYSYS of biodiesel processes involving two different feedstocks (virgin vegetable oil and waste

cooking oil) catalysed by two different catalysts (alkali and acid catalyst). It has technically and economically

assessed and compared these schemes. They have performed sensitivity analysis and they have indicated that the

capacity and the prices of feedstock and products have a great impact on the plants profitability. A similar study

has studied and compared the economic viability of three biodiesel scenarios that use different catalysts by using

the process simulation software SuperPro.

Research by (Kawachale, 2011), the membrane based processes for the recovery of isoflavones from red

clover flowers shows purchasing cost of $3/kg and $0.75/kg was assumed for dry flowers and ethanol

respectively. Also, in order to keep the equipment costs lower, the ultrafiltration modules in the membrane

based processes were modelled to be constructed out of plastic, which was appropriate for moderate pressure

operations (550 kPa). The processes were evaluated for a 15 year project life time, assuming the plant to be

operational for 330 days/year. Alternatively, in a fed-batch process a constant substrate concentration can be

maintained during the fermentation. C. boidinii NRRL Y-17231 fermentations achieved 75% theoretical xylitol

yield in a fed-batch process compared to 53% theoretical yield in batch process. The maximum productivity

(0.46 g/l.h) in the fed-batch process was twice the maximum productivity observed in the batch process

(Rangaswamy, 2003).

(b)

Conclusions:

Process simulation is an important tool in bioprocess industry. The benefits of simulation for bioprocess

improvement, assessment and expand have been realized previously. Basically, process development is

shortened by application of process models and simulators. In simulation, the tasks provided such as; represent

the entire process on the computer, perform material and energy balances, estimate the size of equipment,

estimate the cycle time of the process and perform cost analysis. SuperPro Designeris windows-based software

which can be used to design and assess manufacturing of the product and decide on treatment methods,

pollution prevention and waste minimization approaches, at the same time. Application of SuperPro Designer

has been reported for process simulation in production of xylitol, pyruvic acid, monitoring of biopharmaceutical

facility, fuel ethanol production and biodiesel production costs analysis. As a conclusion, Super Pro Designer

can provide sophisticated modeling for bioprocess for a batch and continuous processes.

ACKNOWLEDGMENTS

King Abdul Aziz City Science and Technology (KACST) funded this study. Also, we extend our appreciation

to the Green Concrete@UniMAP and to all of the people who contributed to the successful completion of this

study.

REFERENCES

Athimulam, A., S. Kumaresan, 2006. Modelling and Optimization of Eurycoma Longifolia Water Extract

Production. Food and Bioproducts Processing, pp: 139-149.

Barradas, J.S., C.G. Orijel, 2010. A stoichiometric Analysis of biological Xylitol Production. Biochemical

Engineering Journal, pp: 1-9.

Biwer, A., E. Heinzel, 2004. Enzyme and Microbial Technology, pp: 642-650.

Bowen, E., S.C. Kennedy, 2010. Ethanol from Sugar Beets: A Process and Economic Analysis. United

States: Worcester Polytechnic Institute.

Brunet, R., G.G. Gosalbez, 2012. Hybrid Simulation-optimization Based Approach for The Optimal Design

of Single-product Biotechnological Processes. Computers and Chemical Engineering, pp: 125-135.

Cardona, C., A. Autunes, 2007. Fuel Ethanol Production: Process Design Trends. Bioresource Technology,

pp: 2415-2457.

370

Aust. J. Basic & Appl. Sci., 7(5): 366-372, 2013

Chandel, A.K., S. Antunes, 2007. Dilute Acid Hydrolysis of Agro-Residues for the Depolymerization of

Hemicellulose: State-of-the-Art. Biotechnology, pp: 201-208.

Cimini, S., M. Prisciandaro, 2005. Simulation of a Waste Incineration Process with Flue-gas Cleaning and

Heat Recovery Sections Using Aspen Plus. Waste Management, pp: 171-175.

Dash, S.M., 2008. Study of Cryogenic Cycles with Aspen- HYSYS Simulations. India: University Rourkela.

Diwekar, U., 2005. Green Process Design, Industrial Ecology, and Sustainability: A Systems Analysis

Perspective. Resources, Conservation and Recycling, pp: 215-235.

Duque, J.A., 2011. Design and Analysis of Technological Schemes for Glycerol Conversion to Added Value

Products. Columbia: Universidad Nacional de Colombia.

Eliassona, A., J.H.S. Hofmeyrc, 2001. The Xylose Reductase/Xylitol Dehydrogenase/Xylulokinase Ratio

Affects Product Formation in Recombinant Xylose-utilising Saccharomyces Cerevisiae. Enzyme and Microbial

Technology, pp: 288-297.

Ernst, S., O.A. Garro, 1996. Process Simulation for Recombinant Protein Production: Cost Estimation and

Sensitivity Analysis for Heparinase I Expressed in Escherichia coli. Biotechnology and Bioengineering, pp:

575-582.

Farid, S.S., A. Washbrook, 2007. Modelling Biopharmaceutical Manufacture: Design and Implementation

of SimBiopharma. Computers and Chemical Engineering, pp: 1141-1158.

Fernandez, J.A., J. Banga, 2008. Scatter Search for Chemical and Bio-Process Optimization. Spain:

Instituto de Investigaciones Marinas.

Franceschin, G., M. Sudiro, 2011. Conversion of Rye Straw Into Fuel and Xylitol: A Technical and

Economical Assessment Based on Experimental Data. Chemical Engineering Research and Design, pp: 631640.

Gosling, I., 2005. Process Simulation and Modeling for Industrial Bioprocessing:Tools and Techniques.

Industrial Biotechnology, pp: 1-7.

Guo, C., M. Jiang, 2005. Screening and Characterization of Yeasts for Xylitol. Journal of Applied

Microbiology, pp: 1364-5072.

Hanyak, M.E., 2012. Chemical Process Simulation and The Aspen HYSYS Software. Lewisburg: Bucknell

University.

Haydary, J., 2009. Steady-State and Dynamic Simulation of Crude Oil Distallation Using Aspen Plus and

Aspen Dynamics. Petroleum & Coal, pp: 100-109.

Kawachale, N., A. Kumar, 2011. Simulation, Scale-up and Economics of Adsorption and Membrane Based

Processes for Isoflavones Recovery. Chemical Engineering Research and Design, pp: 428-435.

Klemola, K., I. Turenan, 2001. State of Mathematical Modelling and Simulation in the Finnish Process

Industry, Universities and Research Centres. Technology Review, pp: 124-130.

Kumar, S., 2010. Modelling and Simulation of Ethyl Acetate Reactive Distillation Column Using ASPEN

PLUS. Chemical Engineering, pp: 10-17.

Larrson, M., 2011. Evaluation of Research Method. German: Energisystem.

Lee, S., D. POSARAC, 2011. Process Simulation and Economic Analysis of Biodiesel Production

Processes using Fresh and Waste Vegetable Oil and Supercritical Methanol. Chemical Engineering Research

and Design, pp: 2626-2642.

Limniyakul, W., 2007. Application of Reactive Distillation for Biodiesel Production Enhancement. India,

Kasetsart University.

Magnusson, H., 2005. Process Simulation in Aspen Plus of an Integrated Ethanol and CHP Plant.

Maldives: Energy Engineering.

Malakahmad, A., N.E.A. Basri, S.M. Zain, 2013. Design and Process Simulation of a Small Scale WasteTo-Energy Bioreactor . Journal of Applied Sciences, pp: 2586-2591.

Papavasileiou, V., A. Koulouris, 2007. Optimize Manufacturing Pharmaceutical Products With Process

Simulation and Production Schedulling Tools. Chemical Engineering Research and Design, pp: 1086-1097.

Petrides, P., A. Koulouris, 2002. The Role of Process Simulation in Pharmaceutical Process Development

and Product Commercialization. Pharmaceutical Engineering, pp: 1-8.

Posada, A., M. Naranjo, 2011. Design and analysis of poly-3-hydroxybutyrate production processes from

crude glycerol. Process Biochemistry, pp: 310-317.

Querol, E., B.G. Reugueral, 2011. Novel Application for Energy and Thermoeconomic Analysis of

Processes Simulated with Aspen Plus. Energy, pp: 964-974.

Qureshi, N., B.C. Saha, 2013. An Economic Evaluation of Biological Conversion of Wheat Straw to

Butanol: A biofuel. Energy Conversion and Management, pp: 456-462.

Rao, R.S., P. Joythi, 2006. Xylitol Production from Corn Fiber and Sugarcane Bagasse Hydrolysates by

Candida Tropicalis. Bioresource Technology, pp: 1974-1978.

Rouf, S.A., P.L. Douglas, M.M. Young, 2001. Computer Simulation for Large Scale Bioprocess Design.

Biochemical Engineering Journal, pp: 229-234.

371

Aust. J. Basic & Appl. Sci., 7(5): 366-372, 2013

Saarel, U., K. Leiviska, 2003. Modelling of A Fed- Batch Fermentation Process. Finland: Control

Engineering Laboratory.

Sengupta, D., 2010. Integrating Bioprocess Into Industrial Complexes For Sustainable Development.

Jadavpur: Graduate Faculty of the Louisiana State University and Agricultural and Mechanical College.

Sirisansaneeyakul, S., R. Chainoy, 2009. Xylitol Production by Liquid Emulsion Membrane Encapsulated

Yeast Cells. Journal Chem Technol Biotechnol, pp: 1218-1221.

Somers, B., A. Mortazi, 2011. Modeling Water/ Lithium Bromide Absorption Chillers in ASPEN Plus.

Applied Energy, pp: 4127-4232.

Taras, S., A. Woinaroscomy, 2011. Multi- Objective Optimization of Pyruvic Acid Bioprocess with A

Mathlab-SuperPro Designer Interface. Scienece Bulletin, pp: 1454-2331.

Thien, Y.N., 2011. BioMASS v2.0: A New Tool For Bioprocess Simulation. Biosystems Engineering, pp:

1-19.

Tochampa, W., A. Sirisansaneeyakul, 2005. A model of Xylitol Production by The Yeast Candida Mogii.

Bioprocess Biosyst Eng, pp: 175-183.

Trifkovic, M., S. Cardoso, 2000. Model Assisted Design and Simulation of a Pharmaceutical Batch Process;

Manufacturing of Clopidogrel Bisulfate. Chemical Engineering, pp: 100-106.

Verhoef, A., J. Degreve, 2008. Simulation of a Hybrid PervaporationDistillation Process. Computers and

Chemical Engineering, pp: 1135-1146.

Vlysidis, A., N. Binns, 2011. Techno-economic Analysis of Biodiesel Biorefineries: Assessment of

Integrated Designs for The Co-production of Fuels and Chemicals. Energy, pp: 4671-4683.

Vucurovi, D.G., S.N. Dodic, 2012. Process Model and Economic Analysis of Ethanol Production from

Sugar Beet Raw Juice as Part of the Cleaner Production Concept. Bioresource Technology, pp: 367-372.

West, A.H., D. Posarac, 2008. Assessment of Four Biodiesel Production Processes using HYSYS.Plant.

Bioresource Technology, pp: 6587-6601.

Woinoraso, A., S. Taras, 2009. Simulation and Optimization of Citric Acid Production with SuperPro

Designer using a Client-Server Interface. Chimie, pp: 978-986.

Ye, G., D. Xie, 2009. Modeling of Fluidized Bed Membrane Reactors for Hydrogen Production from Steam

Methane Reforming with Aspen Plus. International Journal of Hydrogen Energy, pp: 4755-4765.

Yu, F., 2011. Process Modeling of Very-high-gravity Fermentation System Under Redox Potentialcontrolled Conditions. Canada: University of Saskatchewan.

Yun, H., M. Wang, 2013. Process Simulation and Energy Optimization of The Enzyme-catalyzed Biodiesel

Production. Energy, pp: 84-96.

372

You might also like

- Determination of Toxic Organic Chemicals In Natural Waters, Sediments and Soils: Determination and AnalysisFrom EverandDetermination of Toxic Organic Chemicals In Natural Waters, Sediments and Soils: Determination and AnalysisRating: 3 out of 5 stars3/5 (1)

- Development of Solvay Clusters of Chemical Reactions PDFDocument11 pagesDevelopment of Solvay Clusters of Chemical Reactions PDFJordan Lopez FernandezNo ratings yet

- Ion Exchange TechnologyFrom EverandIon Exchange TechnologyF.C. NachodNo ratings yet

- Lab 4 Cobalt LabDocument10 pagesLab 4 Cobalt LabadfsgsgsNo ratings yet

- Production of Naphthalene.Document101 pagesProduction of Naphthalene.زهراء عادل عبد الزهرة إسماعيلNo ratings yet

- Cyclohexane ProductionDocument12 pagesCyclohexane ProductionDoctor LiaqatNo ratings yet

- Final Project2Document135 pagesFinal Project2Mr NU KHANNo ratings yet

- Development of An ASPEN PLUS Physical Property Database For Biofuels ComponentsDocument36 pagesDevelopment of An ASPEN PLUS Physical Property Database For Biofuels ComponentsoslemmNo ratings yet

- Engenharia Ambiental SM SampleDocument10 pagesEngenharia Ambiental SM SampleJocirlei Felicio0% (1)

- Overall Flowsheet Simulation Benzene Cyclohexane TW6Document7 pagesOverall Flowsheet Simulation Benzene Cyclohexane TW6Mitesh ParmarNo ratings yet

- Aspen Repot Lab 4Document8 pagesAspen Repot Lab 4Mohd Hisyamuddin Mohd AminudinNo ratings yet

- Operating Instructions: For The 1108 Oxygen Combustion BombDocument12 pagesOperating Instructions: For The 1108 Oxygen Combustion Bombsonico197710No ratings yet

- EPA Chlorobenzene Fact SheetDocument17 pagesEPA Chlorobenzene Fact SheetmojexNo ratings yet

- Us 20120035390Document18 pagesUs 20120035390sariNo ratings yet

- Styrene From Ethane and BenzeneDocument6 pagesStyrene From Ethane and BenzeneAmy Puah100% (2)

- Church 1951Document8 pagesChurch 1951Evan DulayNo ratings yet

- Production of Isopropyl Palmitate-Experimental StudiesDocument12 pagesProduction of Isopropyl Palmitate-Experimental Studiesikaw_3No ratings yet

- SugarDocument19 pagesSugarashutoshNo ratings yet

- Process Description DmeDocument3 pagesProcess Description DmeFirdaus YahyaNo ratings yet

- Synthesis of Dioctyl Sebacate From Sbacaic Acid and 2-Ethylhexyl Alcochol.Document93 pagesSynthesis of Dioctyl Sebacate From Sbacaic Acid and 2-Ethylhexyl Alcochol.Gaurang PatankarNo ratings yet

- Kinetic Modelling at The Basis of Process Simulation For Heterogeneous Catalytic Process DesignDocument31 pagesKinetic Modelling at The Basis of Process Simulation For Heterogeneous Catalytic Process DesignDanielle BarkerNo ratings yet

- Exam 3 SolDocument3 pagesExam 3 SolHungDoNo ratings yet

- Production of IsopropanolDocument9 pagesProduction of IsopropanolJohanNo ratings yet

- Sample Chemical Engineering Student Team Powerpoint For AnalysisDocument25 pagesSample Chemical Engineering Student Team Powerpoint For Analysisishhh12No ratings yet

- Thermodynamic Analysis of The Soda AshDocument10 pagesThermodynamic Analysis of The Soda AshbenaliNo ratings yet

- Simulation and Analysis of A Reactive Distillation Column For Removal of Water From Ethanol Water MixturesDocument9 pagesSimulation and Analysis of A Reactive Distillation Column For Removal of Water From Ethanol Water MixturesBryanJianNo ratings yet

- Lecture 18: Isopropanol and Acetone From Propylene: Module 3: PetrochemicalsDocument2 pagesLecture 18: Isopropanol and Acetone From Propylene: Module 3: Petrochemicalsshamsullah hamdardNo ratings yet

- Plant Uti Task 3Document17 pagesPlant Uti Task 3Ezzati AzizNo ratings yet

- Assignment 2 With SolutionsDocument4 pagesAssignment 2 With SolutionsVenkat MacharlaNo ratings yet

- Kinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystDocument8 pagesKinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystTaylor PennaNo ratings yet

- Mass BalanceDocument5 pagesMass BalanceSidharth RazdanNo ratings yet

- Process Development For Metal SoapsDocument98 pagesProcess Development For Metal SoapsAlex RichardNo ratings yet

- Cyclohexane PDFDocument14 pagesCyclohexane PDFsushant kadamNo ratings yet

- Bio GlassDocument7 pagesBio GlassAndu1991100% (1)

- Acetone Introduction ChapterDocument2 pagesAcetone Introduction Chaptervisran100% (1)

- Deshidratación y Purificación (Alcohol Absoluto)Document4 pagesDeshidratación y Purificación (Alcohol Absoluto)Jordan Venegas100% (1)

- AspirinDocument4 pagesAspiringenelleestremos100% (1)

- Co (NH3) 6Document1 pageCo (NH3) 6Ayotunde OnasanyaNo ratings yet

- Production of N Octane From Ethylene and I ButaneDocument2 pagesProduction of N Octane From Ethylene and I ButaneRamyaNo ratings yet

- Ethylene Oxide AppDocument2 pagesEthylene Oxide AppSyifa AnggrainiNo ratings yet

- Report 1Document2 pagesReport 1Shafiq AhmadNo ratings yet

- Semibatch UniDocument22 pagesSemibatch UniMelgi159100% (1)

- Kinetics of Catalytic Dehydrogenation of Ethylbenzene To StyreneDocument5 pagesKinetics of Catalytic Dehydrogenation of Ethylbenzene To Styreneibrahim3318No ratings yet

- Aceton PlantDocument25 pagesAceton PlantMaryam AlqasimyNo ratings yet

- Solutions Manual For Analysis Synthesis and Design of Chemical Processes 4th Edition PDFDocument14 pagesSolutions Manual For Analysis Synthesis and Design of Chemical Processes 4th Edition PDFNathalia DelgadoNo ratings yet

- Assg 4Document18 pagesAssg 4Fitria HasanahNo ratings yet

- FILE 20220921 173401 Homogeneously Catalyzed Industrial ProcessesDocument31 pagesFILE 20220921 173401 Homogeneously Catalyzed Industrial ProcessesPham ThaoNo ratings yet

- Research ProjectDocument30 pagesResearch ProjectYasser AshourNo ratings yet

- EtanolDocument57 pagesEtanolexe241293No ratings yet

- Tutorial Answers - Separation B Tutorial - Combined Tutorial Solutions PDFDocument38 pagesTutorial Answers - Separation B Tutorial - Combined Tutorial Solutions PDFBuyuNo ratings yet

- Aspen Plus Tutorial ÿËÈøË ÖÝÁ Óñ Ì° Texsas - University - Aspen - Plus - TutorialDocument55 pagesAspen Plus Tutorial ÿËÈøË ÖÝÁ Óñ Ì° Texsas - University - Aspen - Plus - TutorialrajindoNo ratings yet

- CRE Notes 13-A Methanol ReactorDocument11 pagesCRE Notes 13-A Methanol ReactorjoeNo ratings yet

- POLYMATHDocument9 pagesPOLYMATHBigNo ratings yet

- Wacker Process Slides 2008Document5 pagesWacker Process Slides 2008Zakariya AdamNo ratings yet

- Sodium Gluconate and Potassium Gluconate As Substitutes For Sodium Chloride in Breadmaking PDFDocument5 pagesSodium Gluconate and Potassium Gluconate As Substitutes For Sodium Chloride in Breadmaking PDFLaura SalgarNo ratings yet

- Hydrogenation of Fatty Acid Methyl Esters To FattyDocument9 pagesHydrogenation of Fatty Acid Methyl Esters To FattyYulius Harmawan Setya PratamaNo ratings yet

- Lab 4 SimulationDocument8 pagesLab 4 SimulationaziziNo ratings yet

- 5.2. Classification of FuelsDocument16 pages5.2. Classification of FuelsadiNo ratings yet

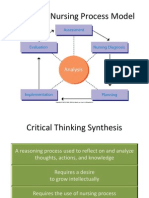

- NUR 104 Nursing Process MY NOTESDocument77 pagesNUR 104 Nursing Process MY NOTESmeanne073100% (1)

- Understanding PumpDocument113 pagesUnderstanding Pumpnyr1981_942955963100% (5)

- Cpa f1.1 - Business Mathematics & Quantitative Methods - Study ManualDocument573 pagesCpa f1.1 - Business Mathematics & Quantitative Methods - Study ManualMarcellin MarcaNo ratings yet

- Store Docket - Wood PeckerDocument89 pagesStore Docket - Wood PeckerRakesh KumarNo ratings yet

- Cross CultureDocument134 pagesCross CulturePhương AnnhNo ratings yet

- Bachelors of Engineering: Action Research Project - 1Document18 pagesBachelors of Engineering: Action Research Project - 1manasi rathiNo ratings yet

- Happiest Refugee Coursework 2013Document10 pagesHappiest Refugee Coursework 2013malcrowe100% (2)

- Final ExamDocument2 pagesFinal ExamblacmsNo ratings yet

- High School Department PAASCU Accredited Academic Year 2017 - 2018Document6 pagesHigh School Department PAASCU Accredited Academic Year 2017 - 2018Kevin T. OnaroNo ratings yet

- MINDSET 1 EXERCISES TEST 1 Pendientes 1º Bach VOCABULARY AND GRAMMARDocument7 pagesMINDSET 1 EXERCISES TEST 1 Pendientes 1º Bach VOCABULARY AND GRAMMARanaNo ratings yet

- Guru ShishyaDocument3 pagesGuru ShishyacktacsNo ratings yet

- The Roti Canai StoryDocument5 pagesThe Roti Canai StoryDr Bugs TanNo ratings yet

- Serie10 User Man ProgDocument1,042 pagesSerie10 User Man Progfahmi derbel100% (1)

- Lesson 7Document6 pagesLesson 7Jeya Plays YTNo ratings yet

- Solutions For Tutorial Exercises Association Rule Mining.: Exercise 1. AprioriDocument5 pagesSolutions For Tutorial Exercises Association Rule Mining.: Exercise 1. AprioriMarkib Singh AdawitahkNo ratings yet

- Adel Lock ManualDocument1 pageAdel Lock Manual24245677843No ratings yet

- Ias Book 2015Document49 pagesIas Book 2015Rahul SharmaNo ratings yet

- Math Cad 15Document3 pagesMath Cad 15Kim ChanthanNo ratings yet

- The Senior High School in The Phillipines: The Way To The WorldDocument5 pagesThe Senior High School in The Phillipines: The Way To The WorldRodel Ramos DaquioagNo ratings yet

- TML IML DefinitionDocument2 pagesTML IML DefinitionFicticious UserNo ratings yet

- CompTIAN10 004Document169 pagesCompTIAN10 004Ian RegoNo ratings yet

- Marisa Wolf Final New ResumeDocument2 pagesMarisa Wolf Final New Resumeapi-403499166No ratings yet

- Pavlishchuck Addison - 2000 - Electrochemical PotentialsDocument6 pagesPavlishchuck Addison - 2000 - Electrochemical PotentialscomsianNo ratings yet

- 12.3 What Is The Nomenclature System For CFCS/HCFCS/HFCS? (Chemistry)Document3 pages12.3 What Is The Nomenclature System For CFCS/HCFCS/HFCS? (Chemistry)Riska IndriyaniNo ratings yet

- ASC 2020-21 Questionnaire PDFDocument11 pagesASC 2020-21 Questionnaire PDFShama PhotoNo ratings yet

- Cisco Nexus 7000 Introduction To NX-OS Lab GuideDocument38 pagesCisco Nexus 7000 Introduction To NX-OS Lab Guiderazzzzzzzzzzz100% (1)

- Accenture MockDocument1 pageAccenture Mockrajyogesh487No ratings yet

- Po 4458 240111329Document6 pagesPo 4458 240111329omanu79No ratings yet

- How To Connect To iSCSI Targets On QNAP NAS Using MPIO On Windows 2008Document30 pagesHow To Connect To iSCSI Targets On QNAP NAS Using MPIO On Windows 2008Jazz OberoiNo ratings yet

- Text Descriptive Tentang HewanDocument15 pagesText Descriptive Tentang HewanHAPPY ARIFIANTONo ratings yet

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Piping Engineering Leadership for Process Plant ProjectsFrom EverandPiping Engineering Leadership for Process Plant ProjectsRating: 5 out of 5 stars5/5 (1)

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- The Perfumed Pages of History: A Textbook on Fragrance CreationFrom EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationRating: 4 out of 5 stars4/5 (1)

- Fundamentals of Risk Management for Process Industry EngineersFrom EverandFundamentals of Risk Management for Process Industry EngineersNo ratings yet

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksFrom EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNo ratings yet

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksFrom EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksNo ratings yet

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsFrom EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottRating: 4 out of 5 stars4/5 (6)

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionFrom EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNo ratings yet

- Bioinspired Materials Science and EngineeringFrom EverandBioinspired Materials Science and EngineeringGuang YangNo ratings yet