Professional Documents

Culture Documents

TerraEffekt Drip Off Primer 1260

Uploaded by

Tomislav Rogić0 ratings0% found this document useful (0 votes)

179 views2 pageslak

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentlak

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

179 views2 pagesTerraEffekt Drip Off Primer 1260

Uploaded by

Tomislav Rogićlak

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

ACTEGA Terra GmbH

Industriestrae 12, 31275 Lehrte, Germany

Tel +49 51 32 50 09-0, Fax +49 51 32 50 09-1 45

office.actega.terra@altana.com, www.actega.com/terra

Technical Datasheet

23.07.2014

1/2

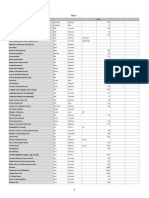

Drip Off Primer 1260

Product description

Printing varnish for the ink duct to get glossy-, matt

and/or trickle down effects by the inline coating with

water based coatings in offset printing machines with

integrated coating unit. The effect depends on the

used material, the combination of primer and coating

and their film weights.

Material characteristics

Delivery viscosity: pasty

Solids: ./.

Specific weight: ./.

Packaging unit

2,5 kg tin

Field of application

Application

Sheet fed offset, ink duct (with fountain solution)

drying: IR and hot air

wet-in-wet

wet-on-dry

Substrates

coated paper

coated board

cast-coated substrates

Printing products

folding box

labels

commercial prints, covers

Food legislation classification

Based on our current knowledge that arises from

the product information given by our raw material

suppliers and the used raw materials, this coating

is suitable for the application on the outside of food

packagings, if used as intended and appropriately

processed.

The coating correspond to the Swiss Ordinance

(SR 817.023.21 - ordinance of the Swiss

Confederation on materials & articles in contact

with food).

A definitive food legal evaluation is only possible

on the basis of migration investigations on the

finished product. The responsibility of testing the

suitability of the packaging for the planned filled

goods, including the possible interactions between

both, is with the marketer.

Processing recommendations

Recommended film weight: 1 2 g/m/wet

The printing inks should be suitable for coating.

The resistance against alkali, alcohol and solvents

should be given according to DIN ISO 2836,

formerly DIN 16524, in order to exclude any colour

change.

Glue flaps should be uncoated.

The optical appearance of the matt, glossy or

trickle down effect is defined in the last ink duct of

the offset printing plate and depends on film weight

of primer and following coating. The uncoated

areas are coated with primer and applied on the

sheet. The areas which should appear glossy

arent be coated. The effect varnish is applied

in the last ink duct. In the following coating unit

a suitable coating will be applied full area with a

suitable coating plate. Rejections and trickle down

effects appear on areas where the sheet is coated

with primer. Small coating drops are the result

which form an open and uneven coating layer

where the light is reflected irregulary and it appears

matt then. On the uncoated areas (free of primer)

the gloss coating creates an even coating film. The

full area overcoating with a gloss coating offers a

sufficient rub resistance also on the areas which

appear matt.

Recommended pile temperature: not 35C

Please pay attention, that the drying speed of the

combination primer + coating is noticeably reduced

in case of non absorbent surfaces. Therefore

appropriate pile temperatures and immediate airing

are necessary.

In case of an insufficient airing we can't exclude

yellowing.

For the further processing of the sheets under

mechanical strain and/or the influence of humidity

a suitable high basic stability of the substrate and

used printing ink is provided.

ACTEGA Terra GmbH

Industriestrae 12, 31275 Lehrte, Germany

Tel +49 51 32 50 09-0, Fax +49 51 32 50 09-1 45

office.actega.terra@altana.com, www.actega.com/terra

Technical Datasheet

23.07.2014

2/2

Drip Off Primer 1260

The complete property profile of the coating film is

given in case of a complete drying.

Cleaning

Please clean maschines and tools with commercial

cleaning agents.

Storage

Shelf-life from date of dispatch 6 months

Keep from freezing, heat and solar radiation.

Applies to closed original containers at 5C up to

30C.

Do not pollute the varnish with washing water,

cleaning agent or other varnishes.

Safety instructions

Clean and rinse immediately with water and soap if

the varnish comes into contact with the skin.

Do not use solvents or dilutions.

Please pay attention to the information given in the

material safety data sheet.

Environmental recommendation

Do not give the varnish into lakes and rivers or the

sewage system.

Remainders must be disposed professionally in

compliance with valid instructions.

Please pay attention to the information given in the

material safety data sheet.

Please be advised

All information provided on this product (in this

sheet or elsewhere) are made to the best of our

knowledge.

This data sheet does not claim to be complete.

All information are technical quality descriptions,

advisory and due to the wide range of materials,

production conditions, operations and processes

do not release from own tests and examinations in

customer-specific circumstances.

If an application is intended to be made under

different conditions than those specified in this

sheet, we only assume liability after having

examined the respective different conditions.

We reserve the right to change product

characteristics because of technical progress,

amendment of applicable law and mandatory

production-related needs

You might also like

- Bodhicaryavatara Shantideva TranslTohSG Illustrated PieroSirianniDocument330 pagesBodhicaryavatara Shantideva TranslTohSG Illustrated PieroSirianniwu-weyNo ratings yet

- HP Fabric - Com Cozy-Cascade Shrug DOWNLOAD PDFDocument24 pagesHP Fabric - Com Cozy-Cascade Shrug DOWNLOAD PDFgurii_caNo ratings yet

- Poly SurfDocument13 pagesPoly SurfRajNo ratings yet

- Powder Coating Guide for Metal FinishingDocument31 pagesPowder Coating Guide for Metal FinishingNikhil OtavanekarNo ratings yet

- Overview On Basic Chemistry of UV-curing TechnologyDocument32 pagesOverview On Basic Chemistry of UV-curing TechnologyEugene PaiNo ratings yet

- Basell PP Homo Rafia Hp456j Mi 3 4Document2 pagesBasell PP Homo Rafia Hp456j Mi 3 4crawn06No ratings yet

- Synthesis and Properties of UV-cured Porous Polymeric CompositesDocument11 pagesSynthesis and Properties of UV-cured Porous Polymeric CompositesEugene PaiNo ratings yet

- Lead Drier Replacement in Solvent Based Alkyd Decorative PaintsDocument24 pagesLead Drier Replacement in Solvent Based Alkyd Decorative PaintsIwan TirtaNo ratings yet

- 93 PDFDocument20 pages93 PDFMariusDragoescuNo ratings yet

- Manufacturing of Printing Inks With FormulationDocument82 pagesManufacturing of Printing Inks With FormulationI Love MusicNo ratings yet

- Familiar Artifacts in Northern California's Baked Clay TraditionDocument35 pagesFamiliar Artifacts in Northern California's Baked Clay TraditionMarc LarreNo ratings yet

- Yamaha Music ClassDocument15 pagesYamaha Music Classhafiz_yaakop0% (1)

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- Unit 4Document70 pagesUnit 4Sasa PetrovicNo ratings yet

- Acrylic Resin Cytotoxicity For Denture Base - LiteDocument9 pagesAcrylic Resin Cytotoxicity For Denture Base - LiteMihai AlexNo ratings yet

- Internship Report 2010Document103 pagesInternship Report 2010Meer Salman Muddasar100% (3)

- Global Functional Printing Market - ElectronicsDocument21 pagesGlobal Functional Printing Market - ElectronicsSanjay MatthewsNo ratings yet

- Cyclodextrin PresentationDocument27 pagesCyclodextrin PresentationGeethika NelluveliNo ratings yet

- FPV FileDocument4 pagesFPV FileAgus Mustofa SolehNo ratings yet

- Carbon Black Ink Formulation OptimizationDocument8 pagesCarbon Black Ink Formulation OptimizationchalachewNo ratings yet

- Akzo Nobel's Duomeen TDO: PointDocument1 pageAkzo Nobel's Duomeen TDO: PointさいとはちこNo ratings yet

- Optimization of FRP Moulding ProcessDocument6 pagesOptimization of FRP Moulding ProcessVIVA-TECH IJRINo ratings yet

- Properties of PMMA Bone Cement Modified With Nano-Hydroxyapatite and AcetoneDocument8 pagesProperties of PMMA Bone Cement Modified With Nano-Hydroxyapatite and AcetoneIEREKPRESSNo ratings yet

- Nike Restricted Substances List (RSL) and Sustainable Chemistry Guidance (SCG)Document65 pagesNike Restricted Substances List (RSL) and Sustainable Chemistry Guidance (SCG)Badrun AhamdNo ratings yet

- List of Dyes Colours and Pigments Permitted in CosmeticsDocument5 pagesList of Dyes Colours and Pigments Permitted in Cosmeticsmarkandey guptaNo ratings yet

- Disparlon GuidelinesDocument6 pagesDisparlon GuidelinesPratik MehtaNo ratings yet

- Zinc PhosphateDocument10 pagesZinc PhosphateShrishma PaikNo ratings yet

- Zinc PhosphateDocument3 pagesZinc PhosphateSandeep BNo ratings yet

- Efka PX 4701Document3 pagesEfka PX 4701Victor LopezNo ratings yet

- Powder Coating: RAL Colour ChartDocument4 pagesPowder Coating: RAL Colour ChartmehrashashankNo ratings yet

- AQUEOUS POLYMER COMPOSITIONS FOR PRINTING, DIGITAL INK JET INKS AND PRINTING ONTO TEXTILES - Lubrizol Advanced Materials, IncDocument25 pagesAQUEOUS POLYMER COMPOSITIONS FOR PRINTING, DIGITAL INK JET INKS AND PRINTING ONTO TEXTILES - Lubrizol Advanced Materials, IncAmbadas GarjeNo ratings yet

- Ceramic Tile Drying AnalysisDocument10 pagesCeramic Tile Drying Analysismap vitcoNo ratings yet

- Presentation - Final TintasDocument21 pagesPresentation - Final TintasJavier Martinez CañalNo ratings yet

- Asian & Nerolac PaintDocument81 pagesAsian & Nerolac PaintishahidNo ratings yet

- 10-Nuosperse Wetting Fa 196Document2 pages10-Nuosperse Wetting Fa 196profmgaNo ratings yet

- Use of The HLB System in Selecting Emulsifiers For Emulsion PolymerizationDocument14 pagesUse of The HLB System in Selecting Emulsifiers For Emulsion PolymerizationdiegojrendonbNo ratings yet

- 9 Komori-1Document92 pages9 Komori-1Tomislav RogićNo ratings yet

- General Issues and The Recommended StandardsDocument60 pagesGeneral Issues and The Recommended StandardsTomislav RogićNo ratings yet

- Bonnie Mak - How The Page MattersDocument161 pagesBonnie Mak - How The Page Matterslaura perez100% (2)

- Ancillary PackagingDocument27 pagesAncillary PackagingShahzaib khanNo ratings yet

- 07 Apr 2018 1600009675JRMYML2PFRBluetronFinal PDFDocument50 pages07 Apr 2018 1600009675JRMYML2PFRBluetronFinal PDFBimo Ary Pujangga PutraNo ratings yet

- Project 3Document18 pagesProject 3Jay ParekhNo ratings yet

- Color Stability, Water Sorption and Cytotoxicity Jap-7-278Document10 pagesColor Stability, Water Sorption and Cytotoxicity Jap-7-278drgunNo ratings yet

- MSC Dissertation Handbook 17-18 PDFDocument29 pagesMSC Dissertation Handbook 17-18 PDFAnonymous csuTTemMQlNo ratings yet

- 10SM2246 HealthySol LRDocument20 pages10SM2246 HealthySol LRHenry ScheinNo ratings yet

- Lawter Ink Resins, Alkyds, Varnishes and Additives Product GuideDocument20 pagesLawter Ink Resins, Alkyds, Varnishes and Additives Product GuideVingiu KatreNo ratings yet

- Asahi Songwon Colors Limited EIA PDFDocument214 pagesAsahi Songwon Colors Limited EIA PDFjyothiNo ratings yet

- FinalDocument52 pagesFinalhitesh_shihoraNo ratings yet

- Hard Ink RemoverDocument10 pagesHard Ink RemoverAlmajed firstNo ratings yet

- Paints and VarnishDocument46 pagesPaints and VarnishnasirNo ratings yet

- The Perception of Metallic Stearates As Acid Acceptors Revised PDFDocument53 pagesThe Perception of Metallic Stearates As Acid Acceptors Revised PDF10-priyankaNo ratings yet

- Colorants Portfolio For Sensitive Applications in Plastics EDC1114e 20140725 PDFDocument28 pagesColorants Portfolio For Sensitive Applications in Plastics EDC1114e 20140725 PDFAabraham Samraj PonmaniNo ratings yet

- 2014 Flint Group SustainabilityDocument44 pages2014 Flint Group Sustainabilitydrweb19No ratings yet

- New Stabilizer Solutions For Polyolefin Film GradesDocument52 pagesNew Stabilizer Solutions For Polyolefin Film GradesZirve Polimer100% (1)

- Studies On Cyclohexanone FormaldehydeDocument5 pagesStudies On Cyclohexanone FormaldehydeNanasaheb PatilNo ratings yet

- Tds Uk 905tx (Urethane Thinner A) v1Document1 pageTds Uk 905tx (Urethane Thinner A) v1HAFIDZ100% (1)

- M C PCN 102 2009Document11 pagesM C PCN 102 2009anon_872387960No ratings yet

- Cultured Marble Coloring TechniquesDocument40 pagesCultured Marble Coloring TechniquesjopiougNo ratings yet

- Nippon Road Line Paint TDSDocument2 pagesNippon Road Line Paint TDSfaridanurro100% (1)

- Film Formers PDFDocument1 pageFilm Formers PDFSiska PurwatiNo ratings yet

- D 2205 - 85 R98 - RdiymduDocument5 pagesD 2205 - 85 R98 - RdiymduphaindikaNo ratings yet

- Methods of Printing: Session 11Document33 pagesMethods of Printing: Session 11Vaisistha BalNo ratings yet

- Protective Epoxy Coating for TanksDocument4 pagesProtective Epoxy Coating for TanksShravana PrasadNo ratings yet

- Graphit 33Document2 pagesGraphit 33Manuel Armindo RibeiroNo ratings yet

- HermifoodDocument1 pageHermifoodTomislav RogićNo ratings yet

- Guyana TFO PKG W'SHP Session 3 - Paper and BoardDocument34 pagesGuyana TFO PKG W'SHP Session 3 - Paper and BoardfrestloviNo ratings yet

- Guyana TFO PKG W'SHP Session 3 - Paper and BoardDocument34 pagesGuyana TFO PKG W'SHP Session 3 - Paper and BoardfrestloviNo ratings yet

- Climate and Paper in The Press RoomDocument22 pagesClimate and Paper in The Press RoomTomislav RogićNo ratings yet

- Umka GD2 Final Umka ColorDocument1 pageUmka GD2 Final Umka ColorTomislav RogićNo ratings yet

- Personal Information Marko MarićDocument2 pagesPersonal Information Marko MarićTomislav RogićNo ratings yet

- DH-IPC-HFW2431T-AS-S2: 4MP Lite IR Fixed-Focal Bullet Network CameraDocument3 pagesDH-IPC-HFW2431T-AS-S2: 4MP Lite IR Fixed-Focal Bullet Network CameraZelaya DudNo ratings yet

- Print ProductionDocument2 pagesPrint Productionapi-78718745No ratings yet

- Reflection On The Movie 5 Centimeters Per SecondDocument4 pagesReflection On The Movie 5 Centimeters Per SecondJeanoRusticoCruzNo ratings yet

- For The LOVE of Figurative Language: Ms GilesDocument9 pagesFor The LOVE of Figurative Language: Ms Gilesapi-488069675No ratings yet

- Put the words in order to form sentencesDocument4 pagesPut the words in order to form sentencesRakhi Goel100% (1)

- 6 Sunday of Easter: Our Lady of Perpetual Help Church - Fujairah, UAEDocument1 page6 Sunday of Easter: Our Lady of Perpetual Help Church - Fujairah, UAEEmmanuel ToretaNo ratings yet

- Alno July-2011Document46 pagesAlno July-2011Swapnil WellingNo ratings yet

- Top 5 Best Photo Editing App in HindiDocument3 pagesTop 5 Best Photo Editing App in HindiTech Kashif0% (1)

- Dota 2 Item List PricesDocument3 pagesDota 2 Item List PricesLabador LeoNo ratings yet

- P4 MathDocument7 pagesP4 MathJeslynNo ratings yet

- Shattered Pixel Dungeon The Newb Adventurer's Guide: Chapter I: The BasicsDocument15 pagesShattered Pixel Dungeon The Newb Adventurer's Guide: Chapter I: The BasicsFishing ManiaNo ratings yet

- Music, The Medium of Music Written ReportDocument2 pagesMusic, The Medium of Music Written ReportAld Dla100% (1)

- I Belog-Story Telling ScriptDocument1 pageI Belog-Story Telling ScriptVan Wahyu Widnyana100% (1)

- Zaha Hadid From WikipediaDocument2 pagesZaha Hadid From WikipediaLilyNo ratings yet

- Theocritus Idyll 07 NotesDocument2 pagesTheocritus Idyll 07 Notespm5rNo ratings yet

- Islamic Architecture (Wallpapers)Document14 pagesIslamic Architecture (Wallpapers)Максим Трефан100% (1)

- Tongue TwistersDocument2 pagesTongue TwistersBojan BojanicNo ratings yet

- AZEVEDO, Aina - Drawing Close - On Visual Engagements - in PDFDocument26 pagesAZEVEDO, Aina - Drawing Close - On Visual Engagements - in PDFedgarcunhaNo ratings yet

- Math 5Document22 pagesMath 5JANICE G. FELIPENo ratings yet

- The 4Ps of InnovationDocument9 pagesThe 4Ps of Innovationpavie raja100% (1)

- Review of Joan Stambaugh-The Other NietzscheDocument3 pagesReview of Joan Stambaugh-The Other NietzscheBabette BabichNo ratings yet

- 6.2.7 Packet Tracer - Investigate NAT Operation - ILMDocument4 pages6.2.7 Packet Tracer - Investigate NAT Operation - ILMDaniel LemaNo ratings yet

- Animation Composition TipsDocument35 pagesAnimation Composition TipsFrancisco Javier Chávez BarriosNo ratings yet

- Zillion TV CorporationDocument1 pageZillion TV Corporationmdaniels1901No ratings yet

- Alvar AaltoDocument3 pagesAlvar AaltoChristinaNo ratings yet

- Proteus LabDocument6 pagesProteus LabMuhammad Sheharyar JavedNo ratings yet