Professional Documents

Culture Documents

Electrodeposition of Co, SM and SmCo From A Deep Eutectic Solvent

Uploaded by

JohnSmithOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrodeposition of Co, SM and SmCo From A Deep Eutectic Solvent

Uploaded by

JohnSmithCopyright:

Available Formats

Journal of Electroanalytical Chemistry 658 (2011) 1824

Contents lists available at ScienceDirect

Journal of Electroanalytical Chemistry

journal homepage: www.elsevier.com/locate/jelechem

Electrodeposition of Co, Sm and SmCo from a Deep Eutectic Solvent

E. Gmez a,, P. Cojocaru b, L. Magagnin b, E. Valles a

a

b

Departament de Qumica Fsica and Institut de Nanocincia i Nanotecnologia (IN2UB), Universitat de Barcelona, 08028 Barcelona, Spain

Dipartimento di Chimica, Materiali e Ingegneria Chimica Giulio Natta, Politecnico di Milano, 20131 Milano, Italy

a r t i c l e

i n f o

Article history:

Received 1 March 2011

Received in revised form 15 April 2011

Accepted 19 April 2011

Available online 28 April 2011

Keywords:

Electrodeposition

Cobalt

Samarium

Deep Eutectic Solvent

a b s t r a c t

The suitability of 1 choline chloride:2 urea mixture, Deep Eutectic Solvent (DES) for the electrodeposition

of cobalt, samarium and cobaltsamarium system has been studied. Its electrochemical window permits

deposition analysis to be carried out without interference from parallel reactions. Deposition was studied

at 70 C in order to stimulate mass transfer and to lower solution viscosity.

Cobalt deposits according to a nucleation and three dimensional growth mechanism, all its characteristic features do appear for all cases studied. Samarium deposition takes place through a more complex

process in which a rst potential range is found where the species formed limit the conductive character

of the substrate. When potential becomes more negative, normal behaviour is observed. When both

cobalt and samarium are present in the solution, codeposition occurs, at no potential value, any current

diminution of the current was recorded under stirred conditions. Deposits of SmCo show different morphology and composition depending on applied potential. Nodular cobalt-rich deposits are obtained at

low deposition potentials whereas ne grained samarium-rich ones are obtained at more negative deposition potentials.

2011 Elsevier B.V. All rights reserved.

1. Introduction

Electrodeposition of some metals has been restricted in aqueous

solutions at moderate temperatures to those presenting a standard

potential less negative than that of water reduction. Some of these

metals could be deposited, albeit expensively, using either organic

solvents or more drastic conditions such as molten salts [15].

In the last decade research in ionic liquids (ionic materials with

melting point below 100 C), with a wide electrochemical window,

has made it possible to deposit metals with very negative standard

potentials and their alloys [614]. Metallic coatings that up to then

had been impossible to deposit became obtainable. Different generations of ionic liquids have been developed widening the spectrum of depositable metals [1519]. However, many of them do

require a complex synthesis and a very accurate electrochemical

work, since the majority of the ionic liquids present high sensibility

to water or degradation by oxygen.

It has been shown recently that it is possible to create an ionic

uid mixing quaternary ammonium halides with an amide, carboxylic acid or alcohol moiety [2023]. Such mixtures are not,

strictly speaking, room-temperature ionic liquids (RTIL) since in

general contain an uncharged molecular component, so that, the

term Deep Eutectic Solvent (DES) was coined by Abbott [24].

Unlike the ionic liquids these room-temperature eutectic mixtures

Corresponding author.

E-mail address: e.gomez@ub.edu (E. Gmez).

1572-6657/$ - see front matter 2011 Elsevier B.V. All rights reserved.

doi:10.1016/j.jelechem.2011.04.015

are easy to prepare in pure state. They are not water reactive and

their biodegradability is proven. Moreover, the economic investment involved is much lower than that incurred using roomtemperature ionic liquids. However, little information is available

about their physicchemical properties [25].

The microelectronic industry employs many kinds of coatings in

specic parts of the devices, magnetic materials being the most popular ones. Important advances has been achieved in the preparation

of soft magnetic materials but the electrodeposition of hard magnetic ones is still restricted to a few ones [2628]. The challenge

in preparing such alloys by electrodeposition is that these alloys

contain metals that have electrocatalytic character to hydrogen

evolution, very negative standard potential, or both. Then, the use

of water-free solvents with a wide electrochemical window is welcome in this eld and its possibilities are worthy of study.

In this work we select to study the cobaltsamarium electrodeposition processing possibilities in DES medium, as this alloy is

potentially a hard magnetic material depending on the metal ratio

[2931]. Few studies of SmCo electrodeposition have been performed in aqueous medium [32] since samarium has a very

negative standard potential leading to simultaneous hydrogen evolution. A study about the preparation of SmCo by electrodeposition

in urea-acetamide-NaBr-MClx melts has been performed by Liu et

al. [33]. Our interest is to analyse the possible electrodeposition of

cobalt, samarium and cobaltsamarium systems using the eutectic

1 choline chloride:2 urea mixture as solvent due to its easy preparation, good working conditions and non aggressive nature.

E. Gmez et al. / Journal of Electroanalytical Chemistry 658 (2011) 1824

19

capillary containing the DES solvent. Stable and reproducible values of the potential were obtained with this reference electrode.

Voltammetric experiments were carried out at 50 mV s 1, scanning at rst to negative potentials. Only one cycle was run in each

voltammetric experiment. Before and during experiments solutions were de-aerated with argon. Work temperature was kept

constant at 70 C to favour low viscosity and high conductivity of

the solvent. Magnetic stirrer was used when the agitation effect

was tested.

Deposits morphology were observed using Hitachi S-2300 scanning electron microscope. Elemental composition was determined

with an X-ray analyser incorporated in Leica Stereoscan S-360

equipment and by X-ray uorescence (XRF).

3. Results

Fig. 1. Cyclic voltammograms in DES solvent at: (a) black: immediately after

desoxigenation, (b) dashed: after two hours of rst scan, and (c) grey: after 50 h of

rst scan.

2. Experimental

Solvent was prepared using choline chloride (from Across

Organics) and urea (from Merck) of analytical grade. The solids,

in the molar proportion 1 choline chloride:2 urea, were warmed

and removed constantly to achieve the liquid state of the deep eutectic solvent (DES). Samarium nitrate from Aldrich, and cobalt

chloride from Fluka both of analytical grade were used as source

of electroactive species. Prior to dissolution, cobalt salt was maintained in a stove at 110 C in order to assure maximum dehydration. Solutions were prepared using the DES solvent.

A cylindrical three electrode cell of one single compartment was

used. Electrochemical experiments were carried out using an Autolab with PGSTAT30 equipment and GPES software. Working electrodes were vitreous carbon rods (from Metrohm). Vitreous

carbon electrode was polished to a mirror nish using alumina of

different grades (3.75 lm and 1.87 lm), cleaned ultrasonically

for 2 min in water and dried with air prior to be immersed in the

solution. The counter electrode was a platinum spiral. The reference electrode was an Ag|AgCl/NaCl 3 M mounted in a Luggin

Cyclic voltammetry was selected to perform the initial electrochemical study of the deposition processes. Firstly, the electrochemical response of the blank solution (DES solvent) was

recorded to establish its electrochemical window (Fig. 1) and to ensure reference electrode reproducibility in the DES medium. Fig. 1

shows the coincidence between voltammetric scans performed

immediate after electrode immersion and those made hours after.

A wide electrochemical window in vitreous carbon electrode was

observed between the reductionoxidation processes of the

solvent.

3.1. Cobalt deposition

A basic study of cobalt deposition was made using the habitual

electrochemical techniques.

Cyclic voltammetric scans were recorded at different negative

limits. By reversing the scan at very low negative overpotential,

nucleation loop was observed (Fig. 2A, curve a). For more negative

potential limits, a well dened reduction peak appeared previous

to a massive reduction current (Fig. 2A, curve b). For all the cathodic limits used, a single oxidation peak was recorded during the

positive scan.

Holding the scan in the potential range of the rst reduction

peak, an increase in the oxidation charge was recorded increasing

the hold time (Fig. 2B, curve b), as corresponds to deposition process. When the hold was made in the potential range of the

massive reduction during the same time, the oxidation charge increase recorded was less important and a widening of the peak

to positive potentials was observed (Fig. 2B, curve c).

Fig. 2. Cyclic voltammograms from CoCl2 0.113 M solution (A) at different cathodic limits, and (B) with potential holds of: (a) t = 0 s, (b) t = 30 s at

1.5 V.

1.25 V and (c) t = 30 s at

20

E. Gmez et al. / Journal of Electroanalytical Chemistry 658 (2011) 1824

Fig. 3. (A) jt transients at 1.2 V from different [Co(II)] solutions: (a) 0.019 M, (b) 0.036 M and (c) 0.113 M, (B) Et transients (a) [Co(II)] = 0.113 M at

the [Co(II)] = 0.036 M solution curves: (b) j = 8 mA cm 2, (c) j = 16 mA cm 2 and (d) j = 32 mA cm 2.

This general behaviour was similar using solutions with different Co(II) concentration, the only difference observed being the advance in the appearance of the reduction current and the increase

of the current recorded as the Co(II) concentration was increased.

For all the solutions tested, the potentiostatic experiments were

made stepping the potential from a potential value at which no

current was detected to different potentials values. All the jt transients recorded evolved to a maximum from which the current

8 mA cm

, and from

prole decays to attain a quasi stationary value. For a xed concentration, the maximum appeared a short deposition times as the potential applied was made more negative. By comparing the jt

curves obtained at xed potential from different cobalt (II) concentrations, a displacement of the maximum to low deposition times

and an increase in the recorded current was observed increasing

the concentration (Fig. 3A). Stirring the solutions, the current decay

after the maximum was reduced.

Fig. 4. (A) Cyclic voltammograms from different Sm(III) solutions: (a) 0.005 M, (b) 0.025 M and (c) 0.045 M, (quiescent conditions). Voltammetric potential holds under

stirred conditions from the [Sm(III)] = 0.025 M solution at: (B) 1.52 V during 60 s and (C) 1.78 and 2.34 V during 60 s.

E. Gmez et al. / Journal of Electroanalytical Chemistry 658 (2011) 1824

Galvanostatic experiments under stirring conditions revealed

that the system initially attained a minimum negative potential value (potential spike) that evolved to less negative values as the

deposition time increased (Fig. 3B, curve a). As the applied current

was made more negative, more negative potentials were associated (Fig. 3B, curves bd).

The shape of both voltammetric and potentiostatic curves and

the effect of the stirring over the voltammetric, potentiostatic

and galvanostatic responses to the Co deposition process in the eutectic 1 choline chloride:2 urea mixture reveals the transport control of the process, as in aqueous solutions [34]. The stirring of the

solution minimises the [Co(II)] depletion near the electrode,

although in this type of solvent vigorous agitation was needed to

appreciate the effect of the stirring arising difcult ion transport.

All the experimental results obtained, nucleation loop, maximum in the jt transient and nucleation spike in the Et transients

evidenced that the characteristic outputs observed in water dissolutions [3537] continue being valid in the DES solvent demonstrating that nucleation and growth process takes place for cobalt

deposition in this eutectic solvent.

3.2. Samarium process

For all the samarium (III) solutions tested, voltammetric experiments revealed similar features in the negative going sweep: at

21

rst a peak-band appeared, followed by a second peak developed

previous to massive current (Fig. 4A). The two reduction peaks

were advanced, enhanced and better dened as the Sm(III) concentration increased. By reversing the scan in none condition nucleation loop was recorded. During the positive scan no oxidation

current was recorded even when very low cathodic limits were

used.

For all Sm(III) concentrations, consecutive cyclic voltammetric

scans evidenced that as the number of scans increases, the onset

of the current appearance occurs at more negative potentials even

when the negative potential limit corresponds to low overpotentials. This is a rather unexpected behaviour. In general, increasing

the number of consecutive scans favours the onset of deposition

process when a previous deposit is present. Therefore, it seems

that in the potential range of the rst peak, the reduction process

is partially blocked for some reduction products.

This result was corroborated by a set of voltammetric experiments holding the scan along the potential range of the rst peak:

both under quiescent and stirred conditions the reduction current

decreased during the hold (Fig. 4B and C). Whereas when the

potential hold was made in the potential range of the second peak

predictable behaviour was recorded: a diminution of current was

observed under stationary conditions but important current increase occurred under stirring conditions (Fig. 4C). In none condition oxidation current was revealed during positive scan.

Fig. 5. (A) jt transients from the [Sm(III)] = 0.025 M solution at different potentials: (a) 1.3 V, (b) 1.4 V, (c) 1.5 V and (d) 1.6 V, the rst part of the curves recorded

under quiescent conditions and from symbol, under stirring. (B) Et transients from 0.045 M Sm(III) at j = 1.6 mA cm 2 using: (a) a polished substrate at stationary

conditions, (b) a polished substrate under agitation and (c) the substrate after experiment b, at stationary conditions. (C) Et transients from [Sm(III)] = 0.045 M (a)

j = 3.2 mA cm 2 under stirring, (b) j = 6.4 mA cm 2 under stirring, (c) j = 6.4 mA cm 2 quiescent solution, (d) j = 9.5 mA cm 2 under stirring, (e) j = 9.5 mA cm 2

quiescent solution, and (f) solvent response at j = 3.2 mA cm 2.

22

E. Gmez et al. / Journal of Electroanalytical Chemistry 658 (2011) 1824

Fig. 6. SEM images of Samarium deposits obtained during a voltammetric hold potential at 1.45 V under stirred conditions from the solution 0.045 M of Sm(III) after: (A)

15 min, (B) 25 min and (C) 80 min, and (D) SEM image of a deposit obtained at 1.9 V during 30 min under stirred conditions in a potentiostatic experiment.

The jt transients corresponded, in all applied potentials, to a

sudden current increase followed by a current decay. As the potential applied was made more negative the current recorded was

greater. The stirring of the solution lead to an increase in the recorded current but was not sufcient to maintain stationary value

and especially when the most negative potentials were applied, a

smooth current diminution was recorded.

Galvanostatic transients were recorded, in both stationary and

stirring conditions and applying wide current densities spectrum,

thus covering stabilization potentials corresponding to the two

reduction peaks. For currents that evolved to potentials corresponding to the rst voltammetric peak, stirring of the solution

lead the potential to more negative values than that corresponding

to quiescent conditions (Fig. 5B, curves a and b). Moreover, in case

that galvanostatic experiment was repeated on a substrate, which

has been maintained into the solution and thus with the deposit already formed present, the potential value achieved was more negative than the corresponding one to the polished substrate (Fig. 5B,

curve c). Nevertheless when the applied currents lead the system

to potentials corresponding to the second voltammetric peak, the

observed behaviour corresponds to a mass control transfer: the potential value achieved under stationary conditions was more negative than the corresponding under agitation (Fig. 5C). Similar

results were obtained when deoxygenation of solution was made

during 10 h prior to the experiment. This discards the possible effect of the oxygen presence.

In all conditions the potential value at which the solvent reduction takes place was very negative compared to the values where

the metallic cation reduced evidencing that in all cases the main

process corresponds to deposit formation (Fig. 5C, curve f).

Deposits prepared under agitation at different conditions were

analysed by scanning electron microscopy. The imaging of deposits

obtained after a voltammetric hold at potential values corresponding to the rst voltammetric peak, revealed that: low deposition

times lead to very ne grained deposits (Fig. 6A). Increasing deposition time the coverage increased and the deposit showed some

cracks and a new growth was observed on the rst deposit

(Fig. 6B). At long deposition times the deposit was cracked

(Fig. 6C). In these experiments low current were owed and the

time consuming to achieve sufcient coverage was important.

The deposits obtained potentiostatically in this zone present similar morphology.

Whereas if the potential applied corresponds to more negative

potential, the coating showed different morphology in which at

deposits were observed (Fig. 6D).

3.3. Samariumcobalt deposition

The effect of cobalt (II) in the samarium (III) deposition process

was studied using a solution containing 0.045 M Sm(III) + 0.018 M

Co(II).

Voltammetric scan evidenced a slight advance of the overall

deposition process (Fig. 7A, curve a) respect to that observed in

the free cobalt (II) solution (Fig. 7A, curve b). Scanning towards

negative potential a peak was detected followed by a close peak

that did not clearly developed since a current increase was observed. Reversing the scan at the current onset a nucleation loop

was recorded followed by an oxidation peak (Fig. 7A, inset as curve

c), it seems that this feature corresponds to cobalt deposition.

Enlarging the cathodic limit to more negative limits, it was not observed in any case the appearance of nucleation loop. Low or nor

oxidation current was detected in the positive scan. Independently

of the potential, with the stirring of the solution the charge involved in the reduction process was enlarged (Fig. 7B).

Galvanostatic experiments were made applying currents sufciently negative to allow codeposition of both metals. At quiescent

conditions no clear nucleation spikes were observed, although the

shape of the curve remembers the typical nucleation feature and

with the time the potential dropped smoothly to more negative

values. However when the solution was stirred the potential increased with the increase of deposition time making in evidence

the favourable stirring effect over the deposition process. The agitation effect was also stated in the potentiostatic curves, positive

difference in the charge recorded under agitation was observed

(Fig. 8A). In all potential range where codeposition occurs, the jt

transients recorded showed a previous current peak followed by

a smooth current increase; more evident when the solution was

stirred (Fig. 8A, curves c and d).

E. Gmez et al. / Journal of Electroanalytical Chemistry 658 (2011) 1824

23

Fig. 7. (A) Comparison of cyclic voltammograms obtained from 0.045 M Sm(III) solution containing: (a) [Co(II)] = 0.018 M and (b) [Co(II)] = 0 M. Inset of the gure shows the

voltammogram recorded reversing the scan at the initio of the deposition and (c) [Co(II)] = 0.018 M. (B) Voltammograms obtained from the 0.045 M Sm(III) + 0.018 M Co(II)

solution under: (a) quiescent and (b) stirred conditions.

Deposits prepared at different potentials under stirred conditions were imaged and their samarium percentage was evaluated.

Fig. 8B shows a detail of the morphology of SmCo deposit obtained

in a potential near to the minimal necessary to induce codeposition. This deposit of 27 wt.% of Sm shows nodular morphology with

rounded grains. Low deposition rate was obtained in this case, after

one hour of deposition no complete coverage was allowed. When

the potential was made more negative, ne grained deposits with

homogeneous coverage were obtained (Fig. 8C). Increasing the

deposition time a new growth over the rst deposit was developed

(Fig. 8D). These deposits contain 75 wt.% of Sm independently of

the thickness.

In order to check the possibilities to deposit on a metallic substrate a Ni/Cu/Au slide was used. By applying similar, or even lower, deposition potentials than those over vitreous carbon, the

composition of the deposits corresponded always to 80 wt.% of Sm.

Fig. 8. (A) jt transients from 0.045 M Sm(III) + 0.018 M Co(II) solution under quiescent conditions at: (a) 1.8 V, (b) 1.9 V, and under stirred conditions at (c) 1.8 V and (d)

1.9 V and SEM pictures of deposits obtained over vitreous carbon at: (B) E = 1.3 V during 3600 s, (C) E = 1.6 V during 900 s and (D) E = 1.6 V during 2500 s.

24

E. Gmez et al. / Journal of Electroanalytical Chemistry 658 (2011) 1824

4. Conclusions

This study demonstrates the DES capability to permit the electrodeposition, in non aggressive conditions, of alloys containing

some transition metal. Cobalt deposition analysis in this DES solvent reveals that cobalt deposits through a typical nucleation and

three dimensional process. All the features related to this process

are observed: loop in voltammetric experiments, maximum in

potentiostatic experiments and the typical spike in the galvanostatic ones. This result conrms also that the nucleation-growth

models developed to describe the metal deposition processes could

be applied in this kind of solvents.

However, samarium deposition in DES solvent shows a less

standard behaviour, two clear reduction regions with diverse electrochemical behaviour being detected. At low overpotentials, a

clearly less conductive coverage than the vitreous carbon used as

substrate is formed during the reduction process. When the reduction progresses the recorded current diminishes, even under stirring conditions. Overcoming this potential range, samarium

deposition takes place as expected because the process is now

not inhibited and solution stirring leads to an increase of the current density. Then, during samarium deposition in this DES solvent,

intermediate samarium species formation can occur that lowers

the conductive character of the electrode. However, the morphology and the composition of the lms prepared at low deposition

potentials do not give any insight into such intermediate Sm species nature, since they do not entirely impede samarium deposit

formation. Work is in progress in order to elucidate the nature of

this lm.

When both cobalt and samarium salts are present in the 1 choline chloride:2 urea eutectic mixture, SmCo deposits can be formed

because the potential deposition range of the alloy is included in

the electrochemical window of the solvent.

From the Sm(III):Co(II) ratio used (around 4:1), SmCo deposits

with Sm percentages that exceed 70 wt.% of samarium are obtained, when metallic substrate is used or a sufciently negative

potential is applied over vitreous carbon. This percentage is higher

than that the corresponding to SmCo5 or Sm2Co17 magnetic alloys.

To decrease the samarium percentage in the deposits, experiments

at less negative potential were made, but then the time necessary

for a deposit to form was so inordinately long as to make the process economically unviable. Moreover, at these low potentials, on

metallic substrate, the deposits obtained contain high samarium

percentage. Having demonstrated the possibility of obtaining

CoSm deposits using a DES solvent, ulterior work will be carried

out to electrodeposit SmCo lms of lower Sm percentages which

could be useful as hard magnetic material.

Although the agitation effect is lesser than the observed in parallel studies at similar Co(II) concentrations in aqueous solutions,

the observed behaviour make in evidence that the transport in this

kind of systems is another parameter to consider.

Acknowledgements

This paper was supported by contract CTQ2010-20726 (subprogram BQU) from the Comisin Interministerial de Ciencia y

Tecnologa (CICYT). The authors wish to thank the Serveis Cienticotcnics (Universitat de Barcelona) for the use of their

equipment.

References

[1] Dawei Wei, Masazumi Okido, Curr. Top. Electrochem. 5 (1997) 2136.

[2] A. Etenko, T. McKechine, A. Shchetkovskiy, A. Smirnov, ECS Trans. 3 (14) (2007)

151157.

[3] M. Gibilaro, L. Massot, P. Chamelot, P. Taxil, Electrochim. Acta 54 (22) (2009)

53005306.

[4] E. Boland, A. Shchetkovskiy, A. Smirnov, Proc. Electrochem. Soc. 19 (2002) 97

802.

[5] D.J. Fray, G.Z. Chen, Mater. Sci. Tecnol. 20 (2004) 295.

[6] A. Lisenkov, M.L. Zheludkevich, M.G.S. Ferreiro, Electrochem. Comm. 12 (6)

(2010) 729732.

[7] Fei Xiao, Fagiong Zhao, Deping Mei, Zhirong Mo, Baizhao Zeng, Biosens.

Bioelectron. 24 (2009) 34813486.

[8] Jing-Fang Huang, I-Wen Sun, Electrochim. Acta 49 (19) (2004) 3251.

[9] A.P. Abbott, K.J. McKenzie, Phys. Chem. Chem. Phys. 8 (2006) 4265.

[10] S. Zein El Abedin, A.Y. Saad, H.K. Farag, N. Bousenko, Q.X. Liu, F. Endress,

Electrochim. Acta 52 (8) (2007) 2746.

[11] Taku Oyama, Takeyoshi Okajima, Takeo Onsaka, J. Electrochem. Soc. 154 (6)

(2007) D322.

[12] F. Endres, D. MacFarlane, A. Abbott, Electrodeposition from Ionic Liquids,

Wiley-VCH Verlag GmbH, Weinheim, Germany, 2008.

[13] Jinwey Tang, Kazuhisa Azumi, Electrochim. Acta 56 (3) (2011) 1130.

[14] Hsin-Yi Huang, Chung-Jui Su, Chai-Liu Kao, Po-Yu Chen, J. Electroanal. Chem.

650 (1) (2010) 1.

[15] T. Welton, Chem. Rev. 99 (1999) 2071.

[16] J.S. Wilkes, M.J. Zaworotko, Chem. Commun. (1992) 965.

[17] J. Fuller, R.T. Carlin, R.A. Osteryoung, J. Electrochem. Soc. 144 (1999) 3881.

[18] A.P. Abbott, G. Capper, D.L. Davies, H. Munro, R. Rasheed, Inorg. Chem. 43

(2004) 3447.

[19] J.Z. Yang, W.G. Xu, P. Tian, L.L. He, Fluid Phase Equilib. 204 (2003) 295.

[20] A.P. Abbott, G. Capper, D.L. Davies, R. Rasheed, V. Tambyrajah, Chem. Commun.

(2003) 70.

[21] A.P. Abbott, G. Capper, B.G. Swain, D.A. Wheeler, Trans. Inst. Met. Finish. 83

(2005) 51.

[22] A.P. Abbott, G. Capper, K.J. McKenzie, K.S. Ryder, J. Electroanal. Chem. 599 (2)

(2007) 288.

[23] A. Florea, L. Anicai, S. Costonci, F. Golgovici, T. Visan, Surf. Interface Anal. 42

(2010) 1271.

[24] A.P. Abbott, D. Bothby, G. Capper, D.L. Davies, R. Rasheed, J. Am. Chem. Soc. 126

(2004) 9142.

[25] Tetsuya Tsuda, Laure E. Boyd, Susumu Kuwabata, Charles L. Hussey, J.

Electrochem. Soc. 157 (8) (2010) F96.

[26] G. Pattanaik, D.M. Kirkwood, X. Xu, G. Zangari, Electrochim. Acta 52 (2007)

27552764.

[27] N.M. Dempsey, P. de Rango (Eds.), in: Proceedings of the 18th Int. Workshop

on High Performance Magnets and their Applications, vol. 2, Section IX

MAGMAS Materials, Annecy, France, 2004.

[28] R. Hasegawa, Physica B 299 (2001) 199.

[29] Y.Q. Guo, W. Li, J. Luo, W.C. Feng, J.K. Liang, J. Magn. Magn. Mater. 303 (2006)

e367.

[30] O. Guteisch, K.-H. Mller, K. Khlopkov, M. Wolf, A. Yan, R. Schfer, T.

Gemming, L. Schultz, Acta Mater. 54 (2006) 997.

[31] A. Walther, D. Givord, N.M. Dempsey, K. Khlopkov, O. Guteisch, J. Appl. Phys.

103 (2008) 043911.

[32] J.C. Wei, M. Schwartz, K. Nobe, ECS Trans. 1 (4) (2006) 273.

[33] P. Liu, Y. Du, Q. Yang, Y. Tong, G.A. Hope, J. Electrochem. Soc. 153 (1) (2006)

C57.

[34] E. Gmez, M. Marn, F. Sanz, E. Valls, J. Electroanal. Chem. 422 (1997) 139.

[35] J.A. Harrison, H.R. Thirsk, in: A.J. Bard (Ed.), Electroanalytical Chemistry, vol. 5,

Marcel Dekker, New York, 1971, p. 67.

[36] S. Fletcher, C.S. Halliday, D. Gates, M. Westcott, T. Lwin, G. Nelson, J.

Electroanal. Chem. 159 (1983) 267.

[37] A. Milchev, M. Irene Montenegro, J. Electroanal. Chem. 333 (1992) 93.

You might also like

- Tian 2011 Vacuum 1Document7 pagesTian 2011 Vacuum 1momenziNo ratings yet

- 076 PDFDocument6 pages076 PDFprakush01975225403No ratings yet

- TMP 47 A7Document13 pagesTMP 47 A7FrontiersNo ratings yet

- Electrochemical Behavior of Layered Solid Solution Li Mno 2limo (M 5 Ni, MN, Co) Li-Ion Cathodes With and Without Alumina CoatingsDocument7 pagesElectrochemical Behavior of Layered Solid Solution Li Mno 2limo (M 5 Ni, MN, Co) Li-Ion Cathodes With and Without Alumina CoatingsEYERUSALEM TADESSENo ratings yet

- Electrodeposition of Zinc-Tin Alloys From Deep Eutectic Solvents Based On Choline ChlorideDocument7 pagesElectrodeposition of Zinc-Tin Alloys From Deep Eutectic Solvents Based On Choline ChlorideJohnSmithNo ratings yet

- Isotherm 1Document11 pagesIsotherm 1HemrajNo ratings yet

- Taylor 2017Document12 pagesTaylor 2017alvaro rodriguez molina do santosNo ratings yet

- Electrolyzer Modules A) Unipolar and B) Bipolar Cell ConfigurationsDocument8 pagesElectrolyzer Modules A) Unipolar and B) Bipolar Cell ConfigurationsAnuj ShahiNo ratings yet

- Study of Corrosion Inhibition of Mild Steel in Acidic Medium by 2-Propargyl-5-P-chlorophenyltetrazole - Part IDocument8 pagesStudy of Corrosion Inhibition of Mild Steel in Acidic Medium by 2-Propargyl-5-P-chlorophenyltetrazole - Part ILWYenNo ratings yet

- Treatment of Wastewater by Electro Coagulation: A Review: ISO 9001:2008 CertifiedDocument7 pagesTreatment of Wastewater by Electro Coagulation: A Review: ISO 9001:2008 CertifiedImane BendarouachNo ratings yet

- AC DC Studies On CI of Low Carbon Steel in HCL by Succinic Acid 2008Document17 pagesAC DC Studies On CI of Low Carbon Steel in HCL by Succinic Acid 2008gabriel norbertNo ratings yet

- Cyclic Voltammetry and Scanning Electrochemical Microscopy of FerrocementhanolDocument9 pagesCyclic Voltammetry and Scanning Electrochemical Microscopy of Ferrocementhanolhongluc1991No ratings yet

- J Cattod 2011 07 008Document8 pagesJ Cattod 2011 07 008Syeda Ammara AnwarNo ratings yet

- A Quantitative Comparison Between Chemical Dosing and ElectrocoagulationDocument16 pagesA Quantitative Comparison Between Chemical Dosing and Electrocoagulationlusi.meliyanaNo ratings yet

- Electrowinning of Cobalt From Acidic Sulphate Solutions-Effect of Chloride IonDocument9 pagesElectrowinning of Cobalt From Acidic Sulphate Solutions-Effect of Chloride IontabatabayiNo ratings yet

- Electrochemical Degradability of Al-20% MG and Al-22% Si Alloys in An Acidic Environment in Relation With Their MicrostructureDocument20 pagesElectrochemical Degradability of Al-20% MG and Al-22% Si Alloys in An Acidic Environment in Relation With Their MicrostructureAishah SamNo ratings yet

- Biolix Calco A Distintas Temp.Document14 pagesBiolix Calco A Distintas Temp.Feña Aranda DelaFuenteNo ratings yet

- Study of The Underlying Electrochemistry of Polycrystalline GoldDocument13 pagesStudy of The Underlying Electrochemistry of Polycrystalline GoldAzucena osornio villaNo ratings yet

- 1 s2.0 S1452398123152849 MainDocument17 pages1 s2.0 S1452398123152849 MainKarolina GawlakNo ratings yet

- PH.D - Synopsis - M. Praveen KumarDocument12 pagesPH.D - Synopsis - M. Praveen KumaralexabcdxyzNo ratings yet

- Electrodeposition of Copper From Non-Cyanide AlkalineDocument20 pagesElectrodeposition of Copper From Non-Cyanide AlkalineDerdo ZulmuNo ratings yet

- A Carbon Electrode Fabricated Using A Poly (Vinylidene Fluoride) Binder Controlled The Faradaic Reaction of Carbon PowderDocument5 pagesA Carbon Electrode Fabricated Using A Poly (Vinylidene Fluoride) Binder Controlled The Faradaic Reaction of Carbon PowderAlice1923No ratings yet

- Energies 05 05363 v2Document9 pagesEnergies 05 05363 v2mevlut46No ratings yet

- I Nfluence of Pore Structure and Surface Chemistry On Electric Double Layer Capacitance in Non-Aqueous ElectrolyteDocument11 pagesI Nfluence of Pore Structure and Surface Chemistry On Electric Double Layer Capacitance in Non-Aqueous ElectrolyteJerusa Pacheco SampaioNo ratings yet

- Abraham, Yusuff - 2003 - Copper (II) Complexes of Embelin and 2-Aminobenzimidazole Encapsulated in Zeolite Y-Potential As Catalysts For RDocument9 pagesAbraham, Yusuff - 2003 - Copper (II) Complexes of Embelin and 2-Aminobenzimidazole Encapsulated in Zeolite Y-Potential As Catalysts For Rcukaasam123456No ratings yet

- Fundamentals Present and Future Perspect PDFDocument12 pagesFundamentals Present and Future Perspect PDFFebrianNo ratings yet

- Paper 6Document7 pagesPaper 6AdityaNo ratings yet

- Ion ExchangeDocument13 pagesIon Exchangebreadfalling752No ratings yet

- Electrochemical Impedance Models For Molten Salt Corrosion: C.L. Zeng, W. Wang, W.T. WuDocument15 pagesElectrochemical Impedance Models For Molten Salt Corrosion: C.L. Zeng, W. Wang, W.T. WuVictor SabNo ratings yet

- Applied Surface Science 347 (2015) 40-47Document8 pagesApplied Surface Science 347 (2015) 40-47Hugo DuarteNo ratings yet

- Electrochemical Performance of A Solvent-Free Hybrid Ceramic - Keller - J Power Sources 2017Document11 pagesElectrochemical Performance of A Solvent-Free Hybrid Ceramic - Keller - J Power Sources 2017I.T.S EnggNo ratings yet

- Electrochemistry Communications: Lin Yu, Jizhou Duan, Xiangqian Du, Yanliang Huang, Baorong HouDocument4 pagesElectrochemistry Communications: Lin Yu, Jizhou Duan, Xiangqian Du, Yanliang Huang, Baorong HouAnushri VaidyaNo ratings yet

- Lithium Air Battery ThesisDocument6 pagesLithium Air Battery Thesisalissacruzomaha100% (2)

- Electrochemistry Communications: Lin Yu, Jizhou Duan, Xiangqian Du, Yanliang Huang, Baorong HouDocument4 pagesElectrochemistry Communications: Lin Yu, Jizhou Duan, Xiangqian Du, Yanliang Huang, Baorong HouAnushri VaidyaNo ratings yet

- 25 - 2015 - Nat - Comm - Bifunctional Non-Noble Metal Oxide Nanoparticle ElectrocatalystsDocument9 pages25 - 2015 - Nat - Comm - Bifunctional Non-Noble Metal Oxide Nanoparticle ElectrocatalystsCB Dong SuwonNo ratings yet

- Roto 2002Document8 pagesRoto 2002k.suganeswaranNo ratings yet

- Waste Water ManagementDocument11 pagesWaste Water ManagementViknesh VikiNo ratings yet

- TMP 2 B55Document24 pagesTMP 2 B55FrontiersNo ratings yet

- Mass Loading Optimization For Ethylene Glycol Oxidation at Different Potential RegionsDocument9 pagesMass Loading Optimization For Ethylene Glycol Oxidation at Different Potential RegionsCB Dong SuwonNo ratings yet

- Hydrogen Evolution Reaction On NiCu Electrodeposited Electrodes in 6.0 M KOHDocument5 pagesHydrogen Evolution Reaction On NiCu Electrodeposited Electrodes in 6.0 M KOHVỹ UôngNo ratings yet

- Glassy Carbon ElectrodesDocument11 pagesGlassy Carbon ElectrodesTiana JovanovicNo ratings yet

- 1 s2.0 S0167273822000376 MainDocument7 pages1 s2.0 S0167273822000376 MainAkrithi AkrithiNo ratings yet

- Direct Electrochemical Reduction of Indigo: Process Optimization and Scale-Up in A Ow CellDocument5 pagesDirect Electrochemical Reduction of Indigo: Process Optimization and Scale-Up in A Ow CellKarrar HaiderNo ratings yet

- Resnik MEET2019Document7 pagesResnik MEET2019Surya Chandra NamahaNo ratings yet

- Anodic Reactions: 08Y506 - Corrosion EngineeringDocument5 pagesAnodic Reactions: 08Y506 - Corrosion Engineeringesakkibabu1987No ratings yet

- Graphene Oxide Modified Lini Co MN O As Cathode Material For Lithium Ion Batteries and Its Electrochemical PerformancesDocument14 pagesGraphene Oxide Modified Lini Co MN O As Cathode Material For Lithium Ion Batteries and Its Electrochemical Performancesआदित्य नारायण सिंहNo ratings yet

- Study of The Electrocoagulation of Electroplating Industry Wastewaters Charged by Nickel (II) and Chromium (VI)Document10 pagesStudy of The Electrocoagulation of Electroplating Industry Wastewaters Charged by Nickel (II) and Chromium (VI)Martin FernandezNo ratings yet

- 1 s2.0 S0013468613011997 MainDocument7 pages1 s2.0 S0013468613011997 MainDang MinhNo ratings yet

- Carbon Film Electrodes As Support of Metallic Particles: Int. J. Electrochem. Sci., 7 (2012) 150 - 166Document17 pagesCarbon Film Electrodes As Support of Metallic Particles: Int. J. Electrochem. Sci., 7 (2012) 150 - 166FelpnilNo ratings yet

- Assignment 2Document4 pagesAssignment 2tinashe tagariraNo ratings yet

- Antimicrobial and Anticorrosive Activity of Adsorbents Based On Chitosan Schiff's BaseDocument21 pagesAntimicrobial and Anticorrosive Activity of Adsorbents Based On Chitosan Schiff's BaseFernanda Stuani PereiraNo ratings yet

- Facile Synthesis of CuO - ITO Film Via The Chronoamperometric Electrodeposition For Nonenzymatic Glucose SensingDocument10 pagesFacile Synthesis of CuO - ITO Film Via The Chronoamperometric Electrodeposition For Nonenzymatic Glucose SensingDũng Quốc NguyễnNo ratings yet

- A Systematic Study On Electrolytic Production of Hydrogen Gas by Using Graphite As ElectrodeDocument5 pagesA Systematic Study On Electrolytic Production of Hydrogen Gas by Using Graphite As ElectrodeZahra AlifiaNo ratings yet

- GravimetricDocument20 pagesGravimetricHaniel FcNo ratings yet

- Materials LettersDocument4 pagesMaterials LettersSahin CoskunNo ratings yet

- Corrosion Inhibition of Copper in NitricDocument17 pagesCorrosion Inhibition of Copper in Nitriclorenaov177No ratings yet

- Amperometric End-Point Detection of ComplexometricDocument6 pagesAmperometric End-Point Detection of ComplexometricSteven John PadillaNo ratings yet

- Adsorption and Corrosion Inhibition of New Synthesized Pyridazinium-Based Ionic Liquid On Carbon Steel in 0.5 M H SODocument9 pagesAdsorption and Corrosion Inhibition of New Synthesized Pyridazinium-Based Ionic Liquid On Carbon Steel in 0.5 M H SOHyd BenNo ratings yet

- Biofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationFrom EverandBiofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationNo ratings yet

- Supercapacitors Based on Carbon or Pseudocapacitive MaterialsFrom EverandSupercapacitors Based on Carbon or Pseudocapacitive MaterialsNo ratings yet

- Selective Extraction of Neutral Nitrogen Compounds Found in Diesel Feed byDocument8 pagesSelective Extraction of Neutral Nitrogen Compounds Found in Diesel Feed byJohnSmithNo ratings yet

- Selective Adsorption For Removal of Nitrogen Compounds From Liquid HC Streams Over Carbon - and Alumina - Based AdsorbentsDocument10 pagesSelective Adsorption For Removal of Nitrogen Compounds From Liquid HC Streams Over Carbon - and Alumina - Based AdsorbentsJohnSmithNo ratings yet

- Zn-Containing Ionic Liquids For The Extractive Denitrogenation of A Model Oil - A Mechanistic ConsiderationDocument7 pagesZn-Containing Ionic Liquids For The Extractive Denitrogenation of A Model Oil - A Mechanistic ConsiderationJohnSmithNo ratings yet

- Inhibition Effects of Nitrogen Compounds On The HDS of Dibenzothiophene Part 2aDocument8 pagesInhibition Effects of Nitrogen Compounds On The HDS of Dibenzothiophene Part 2aJohnSmithNo ratings yet

- Are Deep EutecticDocument3 pagesAre Deep EutecticJohnSmithNo ratings yet

- Science:, 792 (2003) Robin D. Rogers and Kenneth R. SeddonDocument3 pagesScience:, 792 (2003) Robin D. Rogers and Kenneth R. SeddonJohnSmithNo ratings yet

- Post-Etch Residue Removal Using Choline Chloride-Malonic Acid Deep Eutectic Solvent (DES)Document6 pagesPost-Etch Residue Removal Using Choline Chloride-Malonic Acid Deep Eutectic Solvent (DES)JohnSmithNo ratings yet

- Molar Heat Capacities of Choline Chloride-Based Deep Eutectic Solvents and Their Binary Mixtures With WaterDocument25 pagesMolar Heat Capacities of Choline Chloride-Based Deep Eutectic Solvents and Their Binary Mixtures With WaterJohnSmithNo ratings yet

- A Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Document6 pagesA Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Vera Brok-VolchanskayaNo ratings yet

- Full Solution Manual For Chemistry For Changing Times 14Th Edition John W Hill Terry W Mccreary PDF Docx Full Chapter ChapterDocument34 pagesFull Solution Manual For Chemistry For Changing Times 14Th Edition John W Hill Terry W Mccreary PDF Docx Full Chapter Chapterseesaw.insearchd8k4100% (15)

- 2007 LE Mayer TwleveDocument5 pages2007 LE Mayer TwleveVictor ZhicayNo ratings yet

- Sci AvogadroDocument3 pagesSci AvogadroFiona Antoinette BesaNo ratings yet

- PH - Wikipedia, The Free EncyclopediaDocument11 pagesPH - Wikipedia, The Free EncyclopediaShikhar MahajanNo ratings yet

- BS en 10222-2 - 2017 PDFDocument32 pagesBS en 10222-2 - 2017 PDFАртем Титов75% (4)

- Chemistry Education in The 21st CenturyDocument106 pagesChemistry Education in The 21st CenturyAbhishek BansalNo ratings yet

- Chemistry Practical Exam TipsDocument12 pagesChemistry Practical Exam Tipshaya waqrNo ratings yet

- Year 9 Study Guide ChemistryDocument15 pagesYear 9 Study Guide Chemistryreem halawiNo ratings yet

- Modelling of Aluminium Scrap Melting in A Rotary FurnaceDocument10 pagesModelling of Aluminium Scrap Melting in A Rotary FurnaceestefanoveiraNo ratings yet

- Pre-IB Chemistry Mid-Term Review List (Nagel)Document3 pagesPre-IB Chemistry Mid-Term Review List (Nagel)Helie100% (1)

- Flowrate Calculation For A Draining TankDocument2 pagesFlowrate Calculation For A Draining TankAnonymous bHh1L1No ratings yet

- Finalreport PDFDocument47 pagesFinalreport PDFNelCamHerNo ratings yet

- StereochemistryDocument52 pagesStereochemistryTimmyNo ratings yet

- Reichold, Corrosion Guide 12.15.2010Document45 pagesReichold, Corrosion Guide 12.15.2010Pradeep Srivastava100% (1)

- LOVIBOND Reagents Suited For HachDocument6 pagesLOVIBOND Reagents Suited For HachKacem BenaoumeurNo ratings yet

- Stabilityindicating HPTLC Method For Simultaneous Estimation of Amoxicillin Trihydrate and Ambroxol Hydrochloride in Bulk and Pharmaceutical Dosage Form 2153 2435-4-261Document5 pagesStabilityindicating HPTLC Method For Simultaneous Estimation of Amoxicillin Trihydrate and Ambroxol Hydrochloride in Bulk and Pharmaceutical Dosage Form 2153 2435-4-261Fadhil Muhammad AwaluddinNo ratings yet

- CY100 Engineering Chemistry Syllabus 2016Document2 pagesCY100 Engineering Chemistry Syllabus 2016Siju N. AntonyNo ratings yet

- 2007 - Shellac in PolymerDocument43 pages2007 - Shellac in PolymerAnonymous x7VY8VF7No ratings yet

- SilaneCouplingAgents eDocument24 pagesSilaneCouplingAgents eElisabeth Kurnia Bloom100% (1)

- Lecture Notes On ThermoelectricityDocument21 pagesLecture Notes On ThermoelectricityBradley NartowtNo ratings yet

- PS1Document4 pagesPS1cptudorNo ratings yet

- Shell Gadus s1 Og 200 PDFDocument1 pageShell Gadus s1 Og 200 PDFMiskaDarainiNo ratings yet

- RioBooster SDSDocument10 pagesRioBooster SDSpepeNo ratings yet

- Microsoft Word - Slickline Mechanical CapibilitiesDocument7 pagesMicrosoft Word - Slickline Mechanical CapibilitiesRangga DraApNo ratings yet

- Full Download General Organic and Biological Chemistry 2nd Edition Janice Gorzynski Smith Test Bank PDF Full ChapterDocument36 pagesFull Download General Organic and Biological Chemistry 2nd Edition Janice Gorzynski Smith Test Bank PDF Full Chapternuggetessayistypcu100% (18)

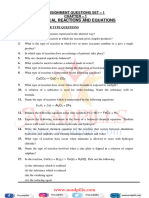

- Chemical Reactions and Equations Assignment Questions Set - 1Document6 pagesChemical Reactions and Equations Assignment Questions Set - 1kayace8055No ratings yet

- GUI Waste Incineration & Best Available Techniques (BAT) - Bref2004Document530 pagesGUI Waste Incineration & Best Available Techniques (BAT) - Bref2004susCities100% (7)

- Stainless Steel Braided Teflon Flexible Hoses Hht&Hhts SeriesDocument4 pagesStainless Steel Braided Teflon Flexible Hoses Hht&Hhts SeriesMKOZERDEMNo ratings yet

- Oxygen Unit Calculation Dv1 1Document2 pagesOxygen Unit Calculation Dv1 1Gisele CescuttiNo ratings yet