Professional Documents

Culture Documents

3M DP125

Uploaded by

echobravo1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3M DP125

Uploaded by

echobravo1Copyright:

Available Formats

3

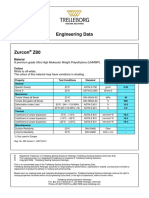

Scotch-Weld

TM

Epoxy Adhesives

DP125 Translucent and Gray

Technical Data

Product Description

February, 2004

3M Scotch-Weld Epoxy Adhesive DP125 Translucent is a faster curing version

of the 3M Scotch-Weld Epoxy Adhesive 2216 Translucent B/A. The worklife

and cure time has been reduced from hours and days for the Scotch-Weld epoxy

adhesive 2216 Translucent B/A to minutes and hours. Final shear and peel strengths

remain similar or even slightly improved compared to the Scotch-Weld epoxy

adhesive 2216 Translucent.

Scotch-Weld epoxy adhesive DP125 Gray is a filled, pigmented version of the

Scotch-Weld epoxy adhesive DP125 Translucent and has similar performance and

flexibility properties.

Available in bulk containers as 3M Scotch-Weld Epoxy Adhesive 125 B/A

Translucent and 125 B/A Gray.

Features

25 minute worklife

Flexible

Translucent or Gray

High peel and shear strength

Controlled flow (gray)

1:1 mix ratio

Typical Uncured

Properties

Note: The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

Base Resins

1,

Viscosity Approximate Base (B)

@ 80F

Accelerator (A)

Scotch-Weld

Epoxy Adhesive

DP125 Translucent

Scotch-Weld

Epoxy Adhesive

DP125 Gray

Epoxy/Amine

Epoxy/Amine

2,000-8,000 cps

22,000-33,000 cps

35,000-75,000 cps

45,000-65,000 cps

Net Weight

(Lbs./gal.)

Base (B)

Accelerator (A)

9.3-9.7

8.4-8.6

10.3-10.7

8.5-8.9

Color

Base (B)

Accelerator (A)

Clear

Amber

Gray

Amber

Mix Ratio (B:A)

By Volume

By Weight

1:1

1.10:1

1:1

1.2:1

Worklife2

@ 73F

2 gram

20 gram

25 min.

18 min.

25 min.

15 min.

Footnotes:

1. Viscosity determined using 3M test method C-1d. Procedure involves Brookfield RVF, #7 spindle, 20 rpm and 80F.

Measurement taken after 1 minute.

2. Worklife determined using 3M test method C-3180. Procedure involves periodically measuring a 2 gram mixed mass for self

leveling and wetting properties. This time will also approximate the usable worklife in an 3M EPX Applicator mixing nozzle.

Scotch-Weld

TM

Epoxy Adhesives

DP125 Translucent and Gray

Typical Cured

Properties

Note: The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

Physical

Footnotes:

2. Worklife determined using 3M test

method C-3180. Procedure involves

periodically measuring a 2 gram

mixed mass for self leveling and

wetting properties. This time will

also approximate the usable

worklife in an 3M EPX

Applicator mixing nozzle.

3. Tack-free time determined per 3M

test method C-3173. Involves

dispensing 0.5 gram amount of

adhesive onto substrate and

testing periodically for no adhesive

transfer to metal spatula.

4. Handling strength determined per

3M test method C-3179. Time to

handling strength taken to be that

required to achieve a 50 psi OLS

strength using aluminum

substrates.

5. The cure time is defined as that

time required for the adhesive to

achieve a minimum of 80% of the

ultimate strength as measured by

aluminum-aluminum OLS.

6. Tensile and Elongation. Used

procedure in 3M test method

C-3094/ATSM D 882. Samples

were 2 in. dumbbells with .0125 in.

neck and .030 in. sample

thickness. Separation rate was 2

inches per minute. Samples cured

2 hrs RT plus 2 hrs/160F.

7. Weight loss by TGA reported as

that temperature at which 5%

weight loss occurs by TGA in air at

5C rise per minute per ASTM

1131-86.

8. TCE determined using TMA

Analyzer using a heating rate of

10C per minute. Second heat

values given.

9. Glass Transition Temperature (Tg)

determined using DSC Analyzer

with a heating rate of 20C per

minute. Second heat values given.

10. Thermal conductivity determined

using ASTM C177 and C-matic

Instrument using 2 in. diameter

samples.

11. Thermal shock resistance run per

3M test method C-3174. Involves

potting a metal washer into a 2 in.

x 0.5 in. thick section and cycling

this test specimen to colder and

colder temperatures.

Color

Hardness (ASTM D 2240)

Shore D

Worklife2

3M Scotch-Weld

Epoxy Adhesive

DP125 Translucent

3M Scotch-Weld

Epoxy Adhesive

DP125 Gray

Translucent

Gray

55

70

20-30 minutes

20-30 minutes

2 hrs

2 hrs

2.5 hrs

2.5 hrs

Full Cure Time5

7 days

7 days

Elongation6

150%

120%

2500 psi

3300 psi

Scotch-Weld

Epoxy Adhesive

DP125 Translucent

Scotch-Weld

Epoxy Adhesive

DP125 Gray

1% @ 164C

5% @ 301C

1% @ 176C

5% @ 303C

112 (5-20C range)

190 (65-140C range)

98 (5-20C range)

187 (65-140C range)

Glass Transition Temperature

(Tg) by DCS 9

Onset

Mid-Point

3C

15C

12C

23C

Thermal Conductivity10

(@ 110F on .250 in. samples)

BTU - ft./ft.2 - hr. - F)

Cal./sec. - cm - C)

Watt/m - C

.089

.37 x 10-3

.154

.087

.36 x 10-3

.151

Pass 5 cycles

without cracking

Pass 5 cycles

without cracking

Scotch-Weld

Epoxy Adhesive

DP125 Translucent

Scotch-Weld

Epoxy Adhesive

DP125 Gray

6.3

6.3

0.14

0.13

765 volts/mil

680 volts/mil

1.2 x 1011 ohm-cm

1.0 x 1011 ohm-cm

Tack-free Time3

Time to Handling Strength4

Tensile Strength

Thermal

Weight Loss by Thermal Gravimetric

Analysis (TGA)7

Thermal Coefficient of Expansion (TCE)

by TMA8 ( x 10 -6 units/unit/C)

Below Tg

Above Tg

Thermal Shock Resistance11

Potted Washer Olyphant Test

(3M Test Method C-3174)

+100C [air] to -50C [liquid])

Electrical

Dielectric Constant @ 1 KHZ @ 23C

(ASTM D 150)

Dissipation Factor @ 1 KHZ @ 23C

(ASTM D 150)

Dielectric Strength

(ASTM D 149) Sample Thickness Approx. 30 mil

Volume Resistivity

(ASTM D 257)

-2-

Scotch-Weld

TM

Epoxy Adhesives

DP125 Translucent and Gray

Typical Adhesive

Performance

Characteristics

The following product performance data was obtained in the 3M laboratory under the

conditions specified. The following data show typical results obtained with the 3M

Scotch-Weld Adhesives when applied to properly prepared substrates, cured, and

tested according to the specifications indicated. The data was generated using the 3M

EPX Applicator System equipped with an EPX applicator static mixer, according to

manufacturers directions. Thorough hand mixing should afford comparable results.

Note: The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

Overlap Shear Strength (OLS) to12

(Bonds cured 24 hrs @ RT + 2 hrs 160F)

Footnotes:

12. Overlap shear (OLS) strengths

were measured on 1 in. wide 1/2

in. overlap specimens. These

bonds were made individually

using 1 in. x 4 in. pieces of

substrate. The thickness of the

bond line was 0.005-0.008 in. All

strengths were measured at 70F

except were noted. (Test per ASTM

D 1002-72.)

The separation rate of the testing

jaws was 0.1 in. per minute for

metals, 2 in. per minute for plastics

and 20 in. per minute for rubbers.

The thickness of the substrates

were: steel, 0.060 in.; other metals,

0.05-0.064 in.; rubber, 0.125 in.;

plastics, 0.125 in.

Etched Aluminum

Sanded Aluminum (60 grit)

Cold Rolled Steel

Wood, Fir

Glass, Borosilicate

Glass, +3M Scotch-Weld Primer 3901

Polycarbonate

Acrylic

Fiberglass

ABS

PVC

Polypropylene

3M Scotch-Weld

Epoxy Adhesive

DP125 Translucent

2500 psi

1400 psi

1500 psi

700 psi

250 psi

200 psi

700 psi

420 psi

1200 psi

460 psi

500 psi

25 psi

3M Scotch-Weld

Epoxy Adhesive

DP125 Gray

3400 psi

2200 psi

1900 psi

900 psi

400 psi

250 psi

880 psi

550 psi

1800 psi

520 psi

750 psi

60 psi

Scotch-Weld

Epoxy Adhesive

DP125 Translucent

100 psi

300 psi

1300 psi

1900 psi

2050 psi

Scotch-Weld

Epoxy Adhesive

DP125 Gray

250 psi

500 psi

1700 psi

2300 psi

3300 psi

Scotch-Weld

Epoxy Adhesive

DP125 Translucent

2300 psi

3300 psi

2600 psi

4600 psi

2100 psi

Scotch-Weld

Epoxy Adhesive

DP125 Gray

4500 psi

5000 psi

3500 psi

5400 psi

3000 psi

Rate of Strength Buildup

(OLS on Etched Aluminum)12

Bonds tested after:

3 hrs @ RT

6 hrs @ RT

1 day @ RT

1 wk @ RT

1 mo @ RT

Environmental Aging

(OLS on Etched Aluminum)12

Bonds tested after:

`

24 hrs RT + 2 hrs @ 160F

24 hrs RT + 2 hrs @ 240F

1 wk RT + 1 wk @ 90F/90% RH

1 wk RT + 1 wk 248F

1 wk RT + 1 wk H2O Immersion

-3-

Scotch-Weld

TM

Epoxy Adhesives

DP125 Translucent and Gray

Typical Adhesive

Performance

Characteristics

(continued)

Note: The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

Overlap Shear Strength vs Temperature12

(Bonds cured 24 hr @ RT + 2 hrs @ 160F)

Bonds tested at

3M Scotch-Weld

Epoxy Adhesive

DP125 Translucent

3M Scotch-Weld

Epoxy Adhesive

DP125 Gray

-67F

4000 psi

3400 psi

70F

2500 psi

4300 psi

120F

400 psi

700 psi

150F

190 psi

450 psi

180F

150 psi

400 psi

180 Peel Strength vs Temperature13

(Bonds cured 24 hr @ RT + 2 hrs @ 160F)

Scotch-Weld Epoxy Adhesive Scotch-Weld Epoxy Adhesive

DP125 Translucent

DP125 Gray

-67F

3 piw

3 piw

70F

35 piw

35 piw

120F

10 piw

18 piw

150F

3 piw

3 piw

180F

2 piw

2 piw

Solvent Resistance14

Scotch-Weld Epoxy Adhesive

DP125 Translucent

Scotch-Weld Epoxy Adhesive

DP125 Gray

One Hour/One Month

One Hour/One Month

Acetone

A/A

A/A

Isopropyl Alcohol

A/A

A/A

Freon TF

A/A

A/A

Freon TMC

A/B

A/B

1,1,1-Trichlorethane

A/A

A/A

RMA Flux

A/A

A/A

Key: A - Unaffected, B - Slight Attack, C - Moderate/Severe Attack

Footnotes:

12. Overlap shear (OLS) strengths were measured on 1 in. wide 1/2 in. overlap specimens. These bonds were made

individually using 1 in. x 4 in. pieces of substrate. The thickness of the bond line was 0.005-0.008 in. All strengths were

measured at 70F except were noted. (Test per ASTM D 1002-72.)

The separation rate of the testing jaws was 0.1 in. per minute for metals, 2 in. per minute for plastics and 20 in. per minute

for rubbers. The thickness of the substrates were: steel, 0.060 in.; other metals, 0.05-0.064 in.; rubber, 0.125 in.; plastics,

0.125 in.

13. T-peel strengths were measured on 1 in. wide bonds at 73F. The testing jaw separation rate was 20 inches per minute.

The substrates were 0.020 in. thick. (Tests per ASTM D 1876-61T.)

14. Solvent resistance was determined using cured (24 hrs RT + 2 hrs 160F) samples (1/2 in. x 4 in. x 1/8 in. thickness)

immersed in the test solvent for 1 hour and 1 month. After the allotted period of time the sample was removed and visually

examined for surface attack as compared to the control.

-4-

Scotch-Weld

TM

Epoxy Adhesives

DP125 Translucent and Gray

3M EPX

Pneumatic Applicator

Delivery Rates

50 ml Applicator Maximum Pressure 50 psi

1/4 in. Nozzle

gms/minute

Adhesive*

3M Scotch-Weld Epoxy Adhesive DP125 Translucent

3M Scotch-Weld Epoxy Adhesive DP125 Gray

63.6

26.4

*Tests were run at a temperature of 70F 2F (21C 1C) and at maximum applicator pressure.

Handling/Curing

Information

Directions For Use

1. For high strength structural bonds, paints, oxide films, oils, dust, mold release agents

and all other surface contaminants must be completely removed. However, the

amount of surface preparation directly depends on the required bond strength and

the environmental aging resistance desired by user. For specific surface preparations

on common substrates, see the section on surface preparation.

2. Use gloves to minimize skin contact. Do not use solvents for cleaning hands.

3. Mixing.

For Duo Pak Cartridges

3M Scotch-Weld Epoxy Adhesives DP125 Translucent and Gray are supplied

in a dual syringe plastic duo-pak cartridge as part of the 3M EPX Applicator

System. To use, simply insert the duo-pak cartridge into the EPX applicator and start

the plunger into the cylinders using light pressure on the trigger. Next, remove the duopak cartridge cap and expel a small amount of adhesive to be sure both sides of the

duo-pak cartridge are flowing evenly and freely. If automatic mixing of Part A and

Part B is desired, attach the EPX applicator mixing nozzle to the duo-pak cartridge

and begin dispensing the adhesive. For hand mixing, expel the desired amount of

adhesive and mix thoroughly. Mix approximately 15 seconds after uniform color is

obtained.

For Bulk Containers

Mix thoroughly by weight or volume in the proportions specified in the typical

uncured properties section. Mix approximately 15 seconds after uniform color is

obtained.

4. For maximum bond strength, apply adhesive evenly to both surfaces to be joined.

5. Application to the substrates should be made within 20 minutes. Larger quantities

and/or higher temperatures will reduce this working time.

6. Join the adhesive coated surfaces and allow to cure at 60F (16C) or above until

completely firm. Heat up to 200F (93C), will speed curing. These products will

cure in 7 days @ 75F (24C).

7. Keep parts from moving during cure. Contact pressure necessary. Maximum shear

strength is obtained with a 3-5 mil bond line.

8. Excess uncured adhesive can be cleaned up with ketone type solvents.*

*Note: When using solvents, extinguish all ignition sources, including pilot lights, and

follow manufacturers precautions and directions for use.

Adhesive Coverage (typical): A 0.005 in. thick bondline will yield a coverage of

320 sq. ft./gallon.

-5-

Scotch-Weld

TM

Epoxy Adhesives

DP125 Translucent and Gray

Surface Preparation

For high strength structural bonds, paint, oxide films, oils, dust, mold release agents

and all other surface contaminants must be completely removed. However, the

amount of surface preparation directly depends on the required bond strength and the

environmental aging resistance desired by user.

The following cleaning methods are suggested for common surfaces:

Steel:

1. Wipe free of dust with oil-free solvent such as acetone, isopropyl or alcohol

solvents.*

2. Sandblast or abrade using clean fine grit abrasives.

3. Wipe again with solvent to remove loose particles.*

4. If a primer is used, it should be applied within 4 hours after surface preparation.

If 3M Scotch-Weld Structural Adhesive Primer EC1945 B/A two-part primer

is used, apply a thin coating (0.5 mils) on the metal surfaces to be bonded, air dry

for 10 minutes, then cure for 30 minutes at 180F (82C) prior to bonding.

Aluminum:

1. Alkaline Degrease: Oakite 164 solution (9-11 oz./gallon water) at 190F 10F

for 10-20 minutes. Rinse immediately in large quantities of cold running water.

2. Acid Etch: Place panels in the following solution for 10 minutes at 150F 5F .

Sodium Dichromate

4.1 - 4.9 oz./gallon

Sulfuric Acid, 66Be

38.5 - 41.5 oz./gallon

2024-T3 aluminum (dissolved)

0.2 oz./gallon minimum

Tap water as needed to balance

3. Rinse: Rinse panels in clear running tap water.

4. Dry: Air dry 15 minutes; force dry 10 minutes at 150F 10F.

5. If primer is to be used, it should be applied within 4 hours after surface preparation.

Note: Read and follow suppliers environmental, health, and safety documentation for

these chemicals prior to preparation of this solution.

Plastics/Rubber:

1. Wipe with isopropyl alcohol.*

2. Abrade using fine grit abrasives.

3. Wipe with isopropyl alcohol.*

Glass:

1. Solvent wipe surface using acetone or MEK.*

2. Apply a thin coating (0.0001 in. or less) of primer such as 3M Scotch-Weld

Metal Primer EC3901 to the glass surfaces to be bonded and allow the primer to dry

before bonding.

*Note: When using solvents, extinguish all ignition sources, including pilot lights, and

follow manufacturers precautions and directions for use.

Application Equipment

Suggestions

For small or intermittent applications the 3M EPX Applicator System is a

convenient method of application.

For larger applications these products may be applied by use of flow equipment.

Two part meter/mixing/proportioning/dispensing equipment is available for

intermittent or production line use. These systems may be desirable because of their

variable shot size and flow rate characteristics and are adaptable to many applications.

-6-

Scotch-Weld

TM

Epoxy Adhesives

DP125 Translucent and Gray

Storage

Store products at 60-80F (16-27C) for maximum shelf life.

Shelf Life

These products have a shelf life of two years in their unopened original bulk

containers and 15 months in duo-pak cartridges.

Precautionary

Information

Refer to Product Label and Material Safety Data Sheet for health and safety information before using this

product. For additional health and safety information, call 1-800-364-3577 or (651) 737-6501.

For Additional

Information

To request additional product information or to arrange for sales assistance, call toll free 1-800-362-3550

or visit www.3M.com/adhesives. Address correspondence to: 3M Industrial Adhesives and Tapes Division,

Building 21-1W-10, 900 Bush Avenue, St. Paul, MN 55144-1000. Our fax number is 651-778-4244. In

Canada, phone: 1-800-364-3577. In Puerto Rico, phone: 1-787-750-3000. In Mexico, phone: 52-70-04-00.

Product Use

All statements, technical information and recommendations contained in this document are based upon

tests or experience that 3M believes are reliable. However, many factors beyond 3Ms control can affect

the use and performance of a 3M product in a particular application, including the conditions under

which the product is used and the time and environmental conditions in which the product is expected to

perform. Since these factors are uniquely within the users knowledge and control, it is essential that the

user evaluate the 3M product to determine whether it is fit for a particular purpose and suitable for the

users method of application.

Warranty and

Limited Remedy

Unless stated otherwise in 3Ms product literature, packaging inserts or product packaging for individual

products, 3M warrants that each 3M product meets the applicable specifications at the time 3M ships the

product. Individual products may have additional or different warranties as stated on product literature,

package inserts or product packages. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF

DEALING, CUSTOM OR USAGE OF TRADE. User is responsible for determining whether the 3M product

is fit for a particular purpose and suitable for users application. If the 3M product is defective within the

warranty period, your exclusive remedy and 3Ms and sellers sole obligation will be, at 3Ms option, to

replace the product or refund the purchase price.

Limitation of Liability

Except where prohibited by law, 3M and seller will not be liable for any loss or damage arising from the

3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory

asserted, including warranty, contract, negligence or strict liability.

ISO 9001

This Industrial Adhesives and Tapes Division product was manufactured under a 3M quality system registered to ISO 9001 standards.

3

Industrial Business

Industrial Adhesives and Tapes Division

3M Center, Building 21-1W-10, 900 Bush Avenue

St. Paul, MN 55144-1000

Recycled Paper

40% pre-consumer

10% post-consumer

-7-

Printed in U.S.A.

3M 2004 78-6900-9866-6

(2/04)

You might also like

- Doctor Atomic OperaDocument48 pagesDoctor Atomic OperaNachoAndrésLlorente100% (2)

- A Seminar Report OnDocument14 pagesA Seminar Report OnDevesh SharmaNo ratings yet

- The Public Eye and The Citizen Voyeur Photography As A Performance of Power PDFDocument18 pagesThe Public Eye and The Citizen Voyeur Photography As A Performance of Power PDFAndrea TesanovicNo ratings yet

- Livro - The Art of The Advanced Dungeons & DragonsDocument120 pagesLivro - The Art of The Advanced Dungeons & DragonsIndaBor75% (4)

- Neuschwanstein CastleDocument22 pagesNeuschwanstein Castleanon-555183100% (1)

- Resort Literature StudyDocument11 pagesResort Literature StudySoundar Rajan85% (33)

- DP8805NS + DP8810NS Tech Data SheetDocument6 pagesDP8805NS + DP8810NS Tech Data SheetPaul TushausNo ratings yet

- 3M™ Adhesive Transfer Tape 966 - 20231209Document10 pages3M™ Adhesive Transfer Tape 966 - 20231209Son NguyenNo ratings yet

- Scotch-Weld: Structural AdhesiveDocument4 pagesScotch-Weld: Structural AdhesiveAfzal ImamNo ratings yet

- TDS 3M Scotch-Weld Epoxy Adhesive DP125 Translucent - 30000622Document11 pagesTDS 3M Scotch-Weld Epoxy Adhesive DP125 Translucent - 30000622Akbar Perwira UtamaNo ratings yet

- 3M2216Document8 pages3M2216pat_kunal1601No ratings yet

- 3M Scotch 50 51 Data SheetDocument4 pages3M Scotch 50 51 Data SheetPedro Francisco Hernandez MendozaNo ratings yet

- 3M TC-2707-TDSDocument4 pages3M TC-2707-TDSJavierNo ratings yet

- 3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFDocument8 pages3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFFran GaritaNo ratings yet

- Selective Laser SinteringDocument12 pagesSelective Laser SinteringMihai CitcauanNo ratings yet

- Loctite 222MS™: Technical Data SheetDocument4 pagesLoctite 222MS™: Technical Data SheetbabshuagNo ratings yet

- DP8700NS Series Technical Data SheetDocument9 pagesDP8700NS Series Technical Data SheetdatkoloNo ratings yet

- 3M™ Scotch-Weld™ Epoxy Adhesive 2214 Hi-Temp New Formula - 20230926Document7 pages3M™ Scotch-Weld™ Epoxy Adhesive 2214 Hi-Temp New Formula - 20230926bnzelectricianshopNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- 3M Adhesive 08115Document4 pages3M Adhesive 08115Syavash EnshaNo ratings yet

- TDS Ec-3532baDocument3 pagesTDS Ec-3532baAndres Fdo Mora DNo ratings yet

- 3M Adhesive Transfer Tape 950Document6 pages3M Adhesive Transfer Tape 950Michael McQueenNo ratings yet

- Epofine 184-Finehard 907 - Acc 062Document4 pagesEpofine 184-Finehard 907 - Acc 062Karishma PrabhuNo ratings yet

- 3M™ Adhesive Transfer Tape 9471 - 20231201Document8 pages3M™ Adhesive Transfer Tape 9471 - 20231201dsfasdfafsNo ratings yet

- TDS 3M Scotch-Weld Epoxy Adhesive DP190 Gray - 30000376Document7 pagesTDS 3M Scotch-Weld Epoxy Adhesive DP190 Gray - 30000376Akbar Perwira UtamaNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- 3M™ High Temperature Aluminum Foil - Glass Cloth Tape 363 - 20230614Document4 pages3M™ High Temperature Aluminum Foil - Glass Cloth Tape 363 - 20230614Jorge EspinozaNo ratings yet

- Exceed™ S 9333 Series: Performance PolymerDocument2 pagesExceed™ S 9333 Series: Performance PolymerMaram YasserNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Polyolefin Copolymer Halogen Free Cable Insulation Compound: KI-LSHF-3401-ISDocument2 pagesPolyolefin Copolymer Halogen Free Cable Insulation Compound: KI-LSHF-3401-ISAMARENDRA SINo ratings yet

- DP490Document6 pagesDP490transervuk2013No ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalNo ratings yet

- Damping Foil: Technical Data January, 2012Document4 pagesDamping Foil: Technical Data January, 2012Nilma Rosa Barsallo PachecoNo ratings yet

- Rogers Corp Product Selector GuideDocument3 pagesRogers Corp Product Selector GuideGeorgios SarrisNo ratings yet

- Ki LSHF 3401 IsDocument2 pagesKi LSHF 3401 IsjamilNo ratings yet

- Turcite T51 Engineering DataDocument1 pageTurcite T51 Engineering DataAntonio Rivera VillavicencioNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Loctite Ea 9309.3naDocument5 pagesLoctite Ea 9309.3naechobravo1No ratings yet

- Zurcon Z80 PDFDocument1 pageZurcon Z80 PDFLuz SmithNo ratings yet

- TDS Loctite 3355 PDFDocument3 pagesTDS Loctite 3355 PDFffincher4203No ratings yet

- Thermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002Document5 pagesThermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002chayanunNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Document3 pagesMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNo ratings yet

- TDS For Rubber Lining 1056HTDocument2 pagesTDS For Rubber Lining 1056HTYao WangNo ratings yet

- Weko-Seal EPDM Material Specifications : Water/Waste Water ApplicationsDocument4 pagesWeko-Seal EPDM Material Specifications : Water/Waste Water ApplicationscarlosNo ratings yet

- Crestomer, Adhesivo Estructural de Alta ResistenciaDocument3 pagesCrestomer, Adhesivo Estructural de Alta ResistenciaTommy VargasNo ratings yet

- Exceed™ S 9272ML: Performance PolymerDocument2 pagesExceed™ S 9272ML: Performance PolymerMaram YasserNo ratings yet

- Scotchweld EC 2216BADocument8 pagesScotchweld EC 2216BAbenNo ratings yet

- Zalac 002Document4 pagesZalac 002Stevie Herman TDNo ratings yet

- 3M Scotch-Weld Polyurethane Reactive PUR Easy 250 Plastic Adhesive EZ250030.EZ250150Document5 pages3M Scotch-Weld Polyurethane Reactive PUR Easy 250 Plastic Adhesive EZ250030.EZ250150Paul TushausNo ratings yet

- Supreme foamSP-5015RDocument1 pageSupreme foamSP-5015RAdrian LeeNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- DUPAC-0521®: DescriptionDocument6 pagesDUPAC-0521®: DescriptionPablo TorresNo ratings yet

- Thermally Conductive Adhesive Transfer Tapes: Technical Data September, 2002Document6 pagesThermally Conductive Adhesive Transfer Tapes: Technical Data September, 2002Kozma BélaNo ratings yet

- 3M™ Adhesive Transfer Tape 950 - 20240112Document8 pages3M™ Adhesive Transfer Tape 950 - 20240112qualityNo ratings yet

- Epofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregDocument5 pagesEpofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregKarishma PrabhuNo ratings yet

- 3M VHB F9460PC F9469PC F9473PCDocument4 pages3M VHB F9460PC F9469PC F9473PCAdam RifferNo ratings yet

- Plumbshield: For Use With Potable & Non-Potable Water ApplicationsDocument5 pagesPlumbshield: For Use With Potable & Non-Potable Water ApplicationsMychloesNo ratings yet

- Exceed S 9243MLDocument2 pagesExceed S 9243MLzhen liuNo ratings yet

- Natural Rubber Lining: Technical Data SheetDocument2 pagesNatural Rubber Lining: Technical Data SheetJaveed KhanNo ratings yet

- Fuel Resistant Coatings: EC-776 EC-776SRDocument6 pagesFuel Resistant Coatings: EC-776 EC-776SRpokleNo ratings yet

- Woods: 3M Di-Noc Architectural FinishesDocument34 pagesWoods: 3M Di-Noc Architectural FinishesAmmierto BangiNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Radiall ARINC 600 (Quadrax)Document2 pagesRadiall ARINC 600 (Quadrax)echobravo1No ratings yet

- TE Connectivity 1811633-XDocument1 pageTE Connectivity 1811633-Xechobravo1No ratings yet

- Ms 27488Document9 pagesMs 27488echobravo1No ratings yet

- Loctite Adhesive SourcebookDocument212 pagesLoctite Adhesive Sourcebookechobravo1No ratings yet

- Click Bond CB309Document2 pagesClick Bond CB309echobravo1No ratings yet

- Loctite Ea 9309.3naDocument5 pagesLoctite Ea 9309.3naechobravo1No ratings yet

- Final Surface Prep For Structural AdhesivesDocument11 pagesFinal Surface Prep For Structural AdhesivesAnca AnghelNo ratings yet

- 3M-460DP Joining AdhesiveDocument8 pages3M-460DP Joining AdhesiveAvdhesh KhaitanNo ratings yet

- FreeNAS BuildDocument2 pagesFreeNAS Buildechobravo1No ratings yet

- 3M Selection GuideDocument4 pages3M Selection Guideechobravo1No ratings yet

- Click Bond CB200Document2 pagesClick Bond CB200echobravo1No ratings yet

- 3M DP100 FRDocument6 pages3M DP100 FRechobravo1No ratings yet

- 3M DP420Document8 pages3M DP420echobravo1No ratings yet

- Forum TipsDocument1 pageForum Tipsechobravo1No ratings yet

- Moscow in Your Pocket October-November 2013Document35 pagesMoscow in Your Pocket October-November 2013Russia In Your PocketNo ratings yet

- Proposal FarizDocument15 pagesProposal FarizTara ChenqNo ratings yet

- Charles Correa Design Techniques by ACHIN BossDocument13 pagesCharles Correa Design Techniques by ACHIN BossAshish HoodaNo ratings yet

- Vallejo Model Air Paint ChartDocument1 pageVallejo Model Air Paint ChartSirus ChappellNo ratings yet

- DissertationDocument47 pagesDissertationJuan SpearsNo ratings yet

- Anonymous Art Reconsidered Anonymity and The Contemporary Art InstitutionDocument11 pagesAnonymous Art Reconsidered Anonymity and The Contemporary Art Institutionlivros do desassossegoNo ratings yet

- Chadwick RenacimientoDocument16 pagesChadwick RenacimientoLoveless MichaelisNo ratings yet

- A Passage To IndiaDocument4 pagesA Passage To IndiaMacrina CasianaNo ratings yet

- Peter and The Wolf Teacher's GuideDocument47 pagesPeter and The Wolf Teacher's GuideThiago AraújoNo ratings yet

- Portfolio Ramshi HamzaDocument18 pagesPortfolio Ramshi HamzaramsheesNo ratings yet

- Chapter 7Document15 pagesChapter 7Ryan SuarezNo ratings yet

- 018 Fab Indexing Table For Vertical Milling 2010MCDocument40 pages018 Fab Indexing Table For Vertical Milling 2010MCSelva GanapathyNo ratings yet

- Central Laboratories Spec: TDC FIDocument17 pagesCentral Laboratories Spec: TDC FIAkmal NizametdinovNo ratings yet

- Sample Bid DocumentDocument13 pagesSample Bid Documentapi-245558208No ratings yet

- CatalogoDocument174 pagesCatalogoClaudio PinoNo ratings yet

- Qcs 2010 Part 24.07 Stone FlooringDocument3 pagesQcs 2010 Part 24.07 Stone FlooringRotsapNayrbNo ratings yet

- Hardtop Optima Alu PDFDocument5 pagesHardtop Optima Alu PDFBiju_PottayilNo ratings yet

- Handbook of The Antiquities in The Naples MuseumDocument174 pagesHandbook of The Antiquities in The Naples MuseumEduardo CastellanosNo ratings yet

- Yatin S PanditDocument1 pageYatin S PanditShivani MaratheNo ratings yet

- Sankey XPM MeshDocument12 pagesSankey XPM MeshAllen NeohNo ratings yet

- Autonomous Region: AR MMDocument32 pagesAutonomous Region: AR MMBea Dacillo BautistaNo ratings yet

- Select Works by Cesare SyjucoDocument19 pagesSelect Works by Cesare SyjucoDaniel DevelaNo ratings yet

- SKP CHROMA ID Service ManualDocument13 pagesSKP CHROMA ID Service Manualdaniel blagaNo ratings yet