Professional Documents

Culture Documents

HW-03 1206291992

Uploaded by

Andaradhi NararyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HW-03 1206291992

Uploaded by

Andaradhi NararyaCopyright:

Available Formats

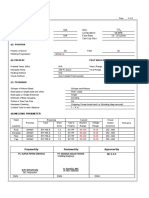

ASSIGNMENT-3 ENMT610029 WELDING

ANDARADHI NARARYA/1206291992

1. A. Explain briefly with schematic drawing for the metal transfer mode in MAG

welding.

B. Explain with schematic drawings for MAG welding at high current range, the

metal transfer mode globular of metal droplets when CO2 is fully used as a

shielding gas, while the mode of spray can be produced when the mixed gas of 80%

Ar + 20% CO2 are used.

METALLURGY AND MATERIALS ENGINEERING

ASSIGNMENT-3 ENMT610029 WELDING

ANDARADHI NARARYA/1206291992

2. A. Describe briefly the difference between AC and DC welding power source.

AC (Alternating Current): the flow of electric charge is happening in both

direction to the cathode and to the anode.

DC (Direct Current): the flow of electric charge is only happening in one

direction.

B. Briefly explain the term of cleaning action in TIG power source.

Cleaning action means the removing process of the aluminium oxide layer on the surface

of welding area.

3. A. Explain briefly the term of stiffness of arc.

Stiffness of arc means the tendency of the arc to directly through along the extended path

of electrode due to the effect of the plasma jet during welding process.

B. In the case of arc blow tends to occur in the arc welding of carbon steel? Give

two examples and explain the cause of arc blow with schematic drawing.

Arc blow is a magnetic area formed in the weld area. It will pull the arc back and forth

keeping it from being concentrated directly ahead of the electrode.

Two examples: magnetic arc blow and thermal arc blow

METALLURGY AND MATERIALS ENGINEERING

ASSIGNMENT-3 ENMT610029 WELDING

ANDARADHI NARARYA/1206291992

4. In MAG welding, the length of arc maintained stable through self-regulation in DC

power source. Describe the statement above about the mechanism of self-regulation

by schematic drawing.

5. Explain the principle of inverter welding machines and give two advantages of

inverter welding machine when it is compared with the conventional SCR-type.

Inverter welding machines is a type of welding power supply capable of providing a high

current for welding. It uses a series of rectifiers and solid-state switches to convert AC

input power into DC output power.

Advantages:

Light, give it possibility to operate mobile.

Compact, simple and easy to operate.

6. Explain the definition of duty cycle in the electric welding machine, and provide

the formulas or equation for estimating the performance of welding machine.

A duty cycle is the percentage of one period in which a signal is active, the formula of duty

cycle is given below:

METALLURGY AND MATERIALS ENGINEERING

ASSIGNMENT-3 ENMT610029 WELDING

ANDARADHI NARARYA/1206291992

Where:

T = Rated duty cycle (%)

Ta = Required duty cycle (%)

Ia = Maximum current at required duty cycle (A)

= Rated current at rated duty cycle (A)

B. Calculate: What is the maximum allowable current when welding machines

operated continuously for welding machine by using the capacity of welding power

source of 450A at 60% duty cycle?

Using duty cycle formula above:

Ia

= I x (T/Ta)1/2

Ia

= 450A x (60/100)1/2

Ia

= 450 x 0.775

Ia

= 348.75 Amps

So, the maximum allowable current if the welding machines operated continuously without

idle for welding machine by using the capacity of welding power source of 450A at 60%

duty cycle is 348.75 Amps.

7. A. Explain the function of voltage reducing device in AC welding power source.

The device reduces, when the arc is halted, the voltage between the electrode holder and

base metal to be 25V or less.

B. Explain the meaning of the electrode code of E6010, E7018, E7028-B3, ER70T-6

and F72-EM12K.

METALLURGY AND MATERIALS ENGINEERING

ASSIGNMENT-3 ENMT610029 WELDING

ANDARADHI NARARYA/1206291992

Electrode codes:

E6010

E = Electrode

60 = Minimum tensile strength of 60

= All position

= Cellulosic

E7018

E = Electrode

70 = Minimum tensile strength of 70

= All position

= Iron powder, low hydrogen, AC or DCEP

E7028-B3

E = Electrode

70 = Minimum tensile strength of 70

2

= Flats and horizontal position

= Iron powder, low hydrogen, AC or DCEP

B3 = Composition assumption from weld deposit 2.25% Cr and 1% Mo

ER70T-6

ER = Electrode or rod

70 = Minimum tensile strength of 70

T = Tubular

6

= Contains shielding without gas

METALLURGY AND MATERIALS ENGINEERING

ASSIGNMENT-3 ENMT610029 WELDING

ANDARADHI NARARYA/1206291992

8. Why are some types of electrodes for SMAW needed to be dried before use. What

factors should be considered and what happens when the electrodes were not dried in

welding for HSLA steel.

Because the re-drying process is useful for enhancing and optimizing the performance level

of welding process.

9. What is the effect of electrode polarity (+ and -) on the weld penetration for (a)

consumable electrode (SMAW & GMAW) and (b) a non-consumable electrode

(GTAW & PAW). Give schematic drawing for them.

SMAW & GMAW

METALLURGY AND MATERIALS ENGINEERING

ASSIGNMENT-3 ENMT610029 WELDING

ANDARADHI NARARYA/1206291992

GTAW & PAW

10. Explain the advantages and disadvantages when using a gas mixture of AR + CO 2

compared with fully CO2.

Advantages:

High deposition rates

The sputtering is less

The fumes is less

Disadvantages:

More expensive

METALLURGY AND MATERIALS ENGINEERING

You might also like

- Cathelco Evac ICPP ManualDocument85 pagesCathelco Evac ICPP ManualВладимир ПетрукNo ratings yet

- Medium Voltage Technical GuideDocument84 pagesMedium Voltage Technical Guidechoban1984100% (4)

- Welding For Design EngineersDocument518 pagesWelding For Design EngineersHumberto Magno FukeNo ratings yet

- Journal RubellaDocument11 pagesJournal RubellaharryNo ratings yet

- Assignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Document8 pagesAssignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaNo ratings yet

- Welding MachineDocument19 pagesWelding MachineLuis Enrique Zapata ValenzuelaNo ratings yet

- Evaluation of Mathematical Models of Metal Oxide SurgeDocument4 pagesEvaluation of Mathematical Models of Metal Oxide Surgeadriasiq3068No ratings yet

- A7 Power Conversion EquipmentDocument21 pagesA7 Power Conversion EquipmentGOD MNo ratings yet

- Lec 5Document34 pagesLec 5Serhat ManulboğaNo ratings yet

- Welding BasicsDocument37 pagesWelding BasicsSnehal DeshmukhNo ratings yet

- Welder ArcDocument6 pagesWelder ArcIgnatious ChinjodziNo ratings yet

- Gtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWDocument19 pagesGtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWNachiket MujumdarNo ratings yet

- 1 - MMAW Process - PPT (Compatibility Mode)Document44 pages1 - MMAW Process - PPT (Compatibility Mode)Kumawat Prakash100% (1)

- Optimization of Process Parameters of MIG Welding To Improve Tensile Strength of Fe-415 Mild SteelDocument6 pagesOptimization of Process Parameters of MIG Welding To Improve Tensile Strength of Fe-415 Mild SteelIJRASETPublicationsNo ratings yet

- wj1106 54Document5 pageswj1106 54koner_debasishNo ratings yet

- Welding: Training Partner-Chameli Devi Group of Institutions, Indore QP Name-Welding Technician Lavel-4Document14 pagesWelding: Training Partner-Chameli Devi Group of Institutions, Indore QP Name-Welding Technician Lavel-4Bouzaida MaherNo ratings yet

- AC I DC ChokeDocument4 pagesAC I DC ChokeNedel LabileNo ratings yet

- MMAWDocument21 pagesMMAWAkash PandeyNo ratings yet

- 1.8.1 - MIG - MAG WeldingDocument88 pages1.8.1 - MIG - MAG WeldingReza DhonyNo ratings yet

- WWS Group An Introduction To Manual Metal Arc Stick WeldingDocument11 pagesWWS Group An Introduction To Manual Metal Arc Stick WeldingnamkvalNo ratings yet

- 5.arc WeldDocument40 pages5.arc Weldalinader20022No ratings yet

- Arc Welding Power SourcesDocument16 pagesArc Welding Power SourcesFahad AliNo ratings yet

- O.H.T.L: Over Head Transmission LineDocument24 pagesO.H.T.L: Over Head Transmission Lineprof-hamadaNo ratings yet

- 2 WeldingDocument24 pages2 WeldingpriyanshuvraoNo ratings yet

- Design and Construction of Hybrid Arc Welding MachineDocument15 pagesDesign and Construction of Hybrid Arc Welding MachinePascu AurelNo ratings yet

- Magnetic Blowout Coil. Vacuum Contactor.: Figure 6-19 Figure 6-20Document42 pagesMagnetic Blowout Coil. Vacuum Contactor.: Figure 6-19 Figure 6-20Fajar Haris Fauzi fajarharis.2019No ratings yet

- EE 410 Lab1 Fall10-1305411901Document27 pagesEE 410 Lab1 Fall10-1305411901Mohamad SyazwanNo ratings yet

- BEEI PaperDocument9 pagesBEEI PaperABDULLAH MUNIR PKE183017No ratings yet

- SmawDocument15 pagesSmawchella_pandianNo ratings yet

- 3RD QTR Exam Grade 11-PearlDocument4 pages3RD QTR Exam Grade 11-PearlemmabentonioNo ratings yet

- EDM1Document6 pagesEDM1Omar LeonNo ratings yet

- Power Source Lecture 1Document8 pagesPower Source Lecture 1Sutanwi LahiriNo ratings yet

- Burca MirceaDocument5 pagesBurca MirceaSai VikramNo ratings yet

- MCW Arc WeldingDocument28 pagesMCW Arc WeldingNeelove SharmaNo ratings yet

- Design and Construction of An Electric Arc Welding Machine With Digital Display.Document11 pagesDesign and Construction of An Electric Arc Welding Machine With Digital Display.michael gorgeNo ratings yet

- Coated Electrode Manual-Metal Arc Welding With High Frequency Welding Inverter Power SourcesDocument6 pagesCoated Electrode Manual-Metal Arc Welding With High Frequency Welding Inverter Power Sourcessapreswapnil8388No ratings yet

- A Two-Stage Power Converter For Welding Applications With Increased Efficiency and Reduced FilteringDocument6 pagesA Two-Stage Power Converter For Welding Applications With Increased Efficiency and Reduced FilteringIrshad NabiNo ratings yet

- Arc Welding-1Document14 pagesArc Welding-1m9966822No ratings yet

- Paper - 5QA 002 SA1Document12 pagesPaper - 5QA 002 SA1kreksomukti5508100% (1)

- AMTED300014ENDocument84 pagesAMTED300014ENAmol KhanvilkarNo ratings yet

- Mo 201Document53 pagesMo 201Fatin Nur AshyqinNo ratings yet

- Set-Up Welding EquipmentsDocument37 pagesSet-Up Welding EquipmentsEvan Jared L. GalvezNo ratings yet

- Miller Submerged Arc HandbookDocument32 pagesMiller Submerged Arc Handbookbjrhunter0% (1)

- I. Welding: (What About Flux Cored Arc Welding??)Document4 pagesI. Welding: (What About Flux Cored Arc Welding??)Ravi PoudelNo ratings yet

- Fcaw & Saw W: EldingDocument47 pagesFcaw & Saw W: Eldingprabhatkumar_6657012No ratings yet

- Composite Overhead ConductorsDocument21 pagesComposite Overhead ConductorsEnrique Garcia100% (1)

- T127 - Question Bank - Basic Electrical EngineeringDocument6 pagesT127 - Question Bank - Basic Electrical Engineeringharish babu aluruNo ratings yet

- Electromagnet QuestionDocument18 pagesElectromagnet QuestionAtikah Abd RahmanNo ratings yet

- La4 140404092322 Phpapp01Document87 pagesLa4 140404092322 Phpapp01parameshoq8No ratings yet

- Lecture 24 - ECMDocument32 pagesLecture 24 - ECMDivyam GargNo ratings yet

- Ieee STD c37Document11 pagesIeee STD c37vigneshwarannn0% (1)

- Part 32 Welding RelatedDocument8 pagesPart 32 Welding Relatedravindra_jivaniNo ratings yet

- AN3200 Application Note: 2.5 KW MMA Welding MachineDocument19 pagesAN3200 Application Note: 2.5 KW MMA Welding MachinePascu AurelNo ratings yet

- 9A02401 Principles of Electrical EngineeringDocument4 pages9A02401 Principles of Electrical EngineeringsivabharathamurthyNo ratings yet

- Design Calculation and Performance Testing of Heating Coil in Induction Surface Hardening Machine PDFDocument5 pagesDesign Calculation and Performance Testing of Heating Coil in Induction Surface Hardening Machine PDFMohammedNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusFrom EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusNo ratings yet

- WeldMet ExerciseDocument4 pagesWeldMet ExerciseAndaradhi NararyaNo ratings yet

- Assignment-2 Enmt610029 Welding ANDARADHI NARARYA/1206291992Document11 pagesAssignment-2 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaNo ratings yet

- Andaradhi Nararya 1206291992Document17 pagesAndaradhi Nararya 1206291992Andaradhi NararyaNo ratings yet

- Copper ExtractionDocument16 pagesCopper ExtractionAndaradhi NararyaNo ratings yet

- Laser Welding of Magnesium AlloysDocument4 pagesLaser Welding of Magnesium AlloyskefneiNo ratings yet

- Lincoln Idealarc DC-600Document114 pagesLincoln Idealarc DC-600Juan G. Gonzalez F.No ratings yet

- Precautions and Safe Practices For Arc Welding Cutting and GougingDocument36 pagesPrecautions and Safe Practices For Arc Welding Cutting and GougingbkrentzspNo ratings yet

- User Manual: MIG 200GW /250GW /300GW Welding MachineDocument44 pagesUser Manual: MIG 200GW /250GW /300GW Welding MachinemmNo ratings yet

- CSWIP QUESTIONIOUR TextDocument29 pagesCSWIP QUESTIONIOUR TextrammohanNo ratings yet

- Bastidor D10T (Radiador)Document10 pagesBastidor D10T (Radiador)Israel MirandaNo ratings yet

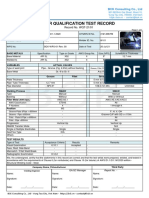

- Rke PQR 01Document2 pagesRke PQR 01Satish KeskarNo ratings yet

- Welder: Craftsmen Training Scheme (CTS) NSQF Level-4Document44 pagesWelder: Craftsmen Training Scheme (CTS) NSQF Level-4Loganathan KNo ratings yet

- Weld Set Reference: Z194539 Power Wave® S350 (Imperial Units)Document4 pagesWeld Set Reference: Z194539 Power Wave® S350 (Imperial Units)Cristhian De La BarraNo ratings yet

- 1 - Introduction To Laser WeldingDocument7 pages1 - Introduction To Laser WeldingmarcosilleraNo ratings yet

- Welding Prosedur ScaniaDocument74 pagesWelding Prosedur ScaniaMuh tiadiNo ratings yet

- Ajp Module-2Document75 pagesAjp Module-2Naveen S BasandiNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- Ijett V50P205Document8 pagesIjett V50P205Ronald AranhaNo ratings yet

- WeldingDocument4 pagesWeldingsaravanan_c1No ratings yet

- Welding & Fabrication PDFDocument96 pagesWelding & Fabrication PDFVicente Banda ZuñigaNo ratings yet

- Big Blue 400X ProDocument8 pagesBig Blue 400X Prohari balakrishnanNo ratings yet

- Welding QuestionnaireDocument4 pagesWelding QuestionnaireRai Singh Malhi100% (3)

- PowerMTS 252stiDocument72 pagesPowerMTS 252stiKale Arbrough100% (1)

- Robotic Interfase Digipulse ESABDocument28 pagesRobotic Interfase Digipulse ESABJohan ZraghozNo ratings yet

- Machote WPQ SoldadoresDocument17 pagesMachote WPQ SoldadoresAries MarteNo ratings yet

- Welding and NDT of Alloy 625 As CRA in Offshore Pipelines and RisersDocument9 pagesWelding and NDT of Alloy 625 As CRA in Offshore Pipelines and RisersKevin Huang100% (1)

- 4.1 Weldwell ElectrodesDocument10 pages4.1 Weldwell Electrodesg_sanchetiNo ratings yet

- Tech AlloyDocument2 pagesTech AlloyDave MulvihillNo ratings yet

- Iso TR 25901 4 2016Document10 pagesIso TR 25901 4 2016RAHINE AmineNo ratings yet

- WQT Aws D1.1Document1 pageWQT Aws D1.1Ali HammoudaNo ratings yet

- MTK 3032Document9 pagesMTK 3032Aina NadhirahNo ratings yet

- 64-2103 Tweco Supra XT SEDHDocument2 pages64-2103 Tweco Supra XT SEDHcarlosNo ratings yet