Professional Documents

Culture Documents

3 - 46

Uploaded by

Rizky AnugrahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 - 46

Uploaded by

Rizky AnugrahCopyright:

Available Formats

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

Monazite- Uranium Separation and Purification Applying Oxalic- NitrateTBP Extraction

*

Rabie. K. A.; **S. M. Abdel-Wahaab; * K. F. Mahmoud; *A. E. M. Hussein

and Abd El-Fatah. A. I. L. ***

*

Nuclear Materials Authority

**

Faculty of Sciences, Ain -Shams University

*** The author to home all correspondence should be addressed at the following

email nuclic_science @ yahoo.com

Received: 5/6/2012

Accepted: 20/6/2012

ABSTRACT

This paper describes the process of uranium extraction from the sulfuric

liquor generated in the chemical monazite treatment through a solvent extraction

technique. The influence of the solvent concentration, effect of precipitating agent,

effect of temperature, effect of stirring time and effect of pH were investigated. The

results indicated the possibility of extracting completely, uranium by using tri-butyl

phosphate (TBP) as an extractant from leach liquor produced after sulfuric acid

monazite digestion. The stripping was carried out with cold water. After selecting

the best conditions for the process, which was 40-50% TBP/ kerosene (diluent)

extractant concentration, 1.5-2M oxalic acid concentration as a precipitant for

thorium (extracted with uranium), 45-60 minutes stirring time and temperature was

40-50 C. A loaded stripping solution containing 0.1986g of U3O8 from the starting

0.21 g with more than 99% purity and 99.3% recovery was obtained.

Keywords: monazite / uranium / separation / solvent extraction

INTRODUCTION

Of the 200 best known minerals containing rare earth (RE) elements, only three contain

significant amounts bastanite, monazite and xenotime, monazite being the second most important

source of rare earths (1). Monazite is a rare earth phosphate also containing thorium and uranium as

associated metals (2- 6). Its structural group consists of arsenate, phosphate and silicate, having the

general formula ABO4 , where A corresponds to RE, Th, U, Ca, Bi, etc. and B corresponds to As5+, P5+

or Si4+ (7, 8). The Egyptian black sand beach deposits are the chief thorium ore in Egypt due to the

presence of monazite (9). Gupta (10) studied the description of monazite breakdown via . acid and

alkali digestion and discussed the composition of the concentrates and their effect on solvent

extraction processes. These authors reported that TBP -nitrate system is the most industrially attractive

system. The processing of monazite leads to the generation of RE concentrates containing thorium

(Th), uranium (U) and phosphate (PO3 -4 ). Monazite is cracked through one of the two following

methods: (i) the basic process with a sodium hydroxide solution where Th and U are separated during

the process as a hydroxide; (ii) the acid process with concentrate sulfuric acid (H2 SO4 ) where a liquor

containing the RE elements, Th and U is generated (1, 11- 14). The recovery of mixed rare earths and

the removal of thorium and uranium from monazite are accomplished through a variety of methods

after chemically attacking the mineral with sulfuric acid or sodium hydroxide (15). The purification of

chemically similar substances through techniques involving repeated transitions between solid and

liquid phases has been replaced by a technologically simpler liquidliquid extraction.

30

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

A novel method for the separation of uranium from RE elements and thorium has been devised

by the authors and in the process; uranium is simultaneously extracted from the sulphuric liquor

generated in the monazite process with the use of Oxalic- Nitrate- TBP extraction method. Studies

involving discontinuous and continuous solvent extraction experiments have been carried out, in

which the parameters required for the extraction of uranium were determined.

The solvent extraction technique is actually well established for the recovery of nuclear pure

uranium and since thorium has certain chemical properties similar to those of uranium, recovery of

nuclear pure thorium by solvent extraction has quickly been achieved. In the same manner, cerium in

its tetravalent state has to some extent- certain similarities in chemical properties to those of uranium

and thorium.

Solvent extraction appeared therefore to be an excellent method adapted to the present situation

which is aimed to obtain a continuous production of highly pure uranium. By this method, the required

elements are allowed to be extracted from an aqueous nitrate solution into an organic solvent while the

impurities would be left behind in the aqueous phase.

Uranium is extracted from nitric acid leach liquors of concentrates by the following reaction (1):

(UO22+)aq + 2(NO3 -)aq + 2(TBP)org= (UO2 (NO3 )2 (TBP)2 )org

(1)

Regarding thorium, it is mainly extracted as Th (NO3 )4 .2TBP from dilute nitric acid solutions

with dilute TBP, according to the following equation (2):

(Th4+)aq + 4(NO3 -) aq + 2(TBP)org = Th (NO 3 )4.2TBP

(2)

However, in extraction at increasing acidities, there is evidence that 3 and even 4 moles of TBP

to 1 mole of thorium may be presented in the complex (16).

Finally cerium is also extracted as its tetravalent nitrate (which may be present) and trivalent rare earth

elements complex according to the following equations (3, 4):

(Ce4+)aq + 4(NO3 -) aq + 2(TBP)org = Ce (NO 3 )4.2TBP

(3)

(REE+3 )aq + 3(NO3 -) aq +2(TBP)org = REE (NO3)3 .2TBP

(4)

Since a high concentration of nitrate radical in the aqueous solution derives the above reaction

to the right, the loaded organic phase can be easily stripped with either water or dilute nitric acid

solutions whereby low nitrate concentration will drive the reaction to the left.

As a matter of fact uranium is actually much more readily extracted by TBP than thorium. This is due

to the great different between their respective distribution coefficients which can be advantageously

made use of strip selectively thorium from the solvent. Thus by using nitric acid solutions, thorium

could be stripped from the TBP extract leaving the uranium behind, which can later be recovered by a

simple strip with water.

Along the present experimental work which directed to preserve and attain most of uranium

contents of monazite in one purified concentrate and decontaminate the other monazite separated main

constituent from it with most available, economic and applicable procedures for up-scaling, an

invented process was adapted for such targets. The process summarized in combining a classical

uranium- thorium separation methods involving oxalate and tri-butyl phosphate separation methods in

an accurate, fast and in one step separation and simultaneous purification of uranium from other

contaminants e.g., thorium (major) and REEs (minor) as will be demonstrated and discussed here in

after.

During the present work there has been a great need for obtaining maximum separation of

thorium from uranium after separating them from REEs. It is therefore an object of the present part to

overcome the shortcomings from the prior common solvent extraction processes for recovering and

separating uranium from mixtures with thorium. It was also an object of the following work to provide

31

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

an improved and highly efficient process for effectively recovering and separating thorium from

mixtures with uranium.

EXPERIMENTAL

Chemicals and reagents

The chemicals and reagents in the present work were used as received. Kerosene (nonaromatic)

was supplied by Misr Petrol Ltd., Egypt. Tri-butyl phosphate, nitric acid was supplied by BDH,

England and sodium hydroxides and oxalic acid and sulphuric acid and ammonia were ADWIC

products. The monazite was supplied by the Nuclear Materials Authority, Egypt, as 50% concentrate.

Procedure

According to Cuthbert (17), a suitable pretreatment of TBP solvent consist of the following:

A wash with 0.2 vol. of 1.5 M nitric acid. Two washes with 0.2 vol. of 1 M sodium hydroxide.

Washes with water until the latter is neutral.

The process of the present section started after monazite mineral acid digestion and dissolution

at optimum conditions. The clear sulphate solution (liquor) is treated with sodium hydroxide after

precipitation with ammonia solution to prepare the mixed hydrous oxides of the three main mineral

cationic components namely rare earth elements as a group, thorium and uranium. The cake was

washed thoroughly to be free from excess soda and dried. The cake was dissolved completely in nitric

acid 1N with gentle stirring avoiding suspension for easier further filtration processes (filterable

rafinates). The aqueous acid solution was then precipitated at pH 5.5 with 10% sodium hydroxide. The

filterable mixture was then filtered of for clean pure rare earth nitrates and hydrated thorium &

uranium concentrate.

The produced precipitate contains mainly all thorium and uranium constituent of the mother

sulphate starting liquor with a minor rare earth percent. The precipitate was washed carefully then

redissolved again after drying in a slight excess of stiochiometric nitric acid and then heated till near

dryness. The applied separation process comprises and aims to selectively and simultaneously

extracting and precipitating thorium from uranium, where both elements are dissolved as their nitrates

in the organic solvent, and by contacting the organic solvent solution, containing the thorium and

uranyl nitrates dissolved therein, with an aqueous solution of an agent which selectively precipitates

the thorium as a crystalline compound which is insoluble in, but transferred to the aqueous phase.

Most of the uranium and trace of REEs remains in the organic phase, and can be recovered from it by

conventional methods e.g., stripping selectively with water or alkali carbonate solution followed by

diluted nitric acid stripping for the minor REEs contents. The small amount of uranium extracted

together with the thorium into the aqueous phase can be easily recovered by solvent extraction after or

before the filtration of thorium precipitates. The common selective precipitating agent useful for

application in the practice of the present process is oxalic acid. The free oxalic acid is preferred than

its water soluble salts (oxalates) as selective precipitating agent since it doesn't introduce any foreign

cations which might contaminate the separated elements in addition to the possibility of recovering the

released nitric acid( after thorium nitrate precipitation as oxalate) into the aqueous phase.

The employed organic solvent, in which the mixed thorium and uranyl nitrates can be dissolved,

is tri-butyl phosphate (TBP) as alkyl phosphate (ester of phosphoric acid diluted with kerosene as

available petroleum aliphatic solvent). The organic solvent and the organic solution should desirably

possess a specific gravity less than that of the aqueous extracting and precipitating agent, otherwise the

32

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

precipitate of thorium produced in the process remains in the organic phase and doesn't pass into the

aqueous phase. For each 100 gm sample batch of monazite mineral(-125 mesh ~ 50%), the Th &U

nitrate mixture produced after the aforementioned procedures contains 2.66 g thorium calculated as

ThO 2 , 0.21g uranium calculated as U3 O8 and 3.58g rare earth elements calculated as RE2 O3 . The

mixture was dissolved in different solvent concentrations and treated with different precipitant

concentration at different temperatures and stirring time to find the effect of each parameter beside the

pH effect. The study of each previous parameter separately while keeping the others constant was

fulfilled to find the optimum precipitation and separation parameter which attain the higher possible

purity and recovery percents for uranium.

For the rare earth elements present percents in the original nitrate mixture and transferred to the

organic solvent a pre-treatment steps for the solvent were carried out. The pre-treatment procedures

concised in contacting the solvent with 2M nitric acid solution containing H2 O2 with ratio 1 H2 O2 : 5

HNO3 (0.2 aqueous: 1 organic phase ratio) in one contact to remove the co-extracted trivalent rare

earth elements and tetravalent cerium which may be present.

After scrubbing (washing) of the loaded solvent the aqueous raffinate was analyzed for Th, U

and total rare earth elements. It was found that the solvent elemental components lost are 0.03 g. 0.01

g and 3.51g of ThO 2 , U3 O8 and RE2 O3 respectively. In other words the starting solvent elemental

components were 2.63g, 0.20g and 0.07g (700 ppm) of thorium as ThO 2, uranium as U3 O8 and rare

earth elements as RE2 O3 with scrubbing percent of REEs exceeded 98% and 4.7 % of uranium and

1.1% of thorium lost from the solvent starting composition. 3. Analytical Procedures. Analytical

procedures for thorium, rare earths and uranium are summarized as follows, gravimetric methods

analysis, spectrophotometric methods of analysis (JASCO V530) and titration method (18-22).

RESULTS AND DISSCUSIONS

From general overview on the effect of solvent concentration, precipitating agent concentration,

time of stirring and temperature on the extraction of thorium and uranium and the percent of recovery

of each in addition to their purity (decontamination of each from the other one), one can judge that, a

noticed increase in thorium values with solvent concentration, temperature, stirring time and

precipitant concentration till certain limit. While the case was reserved with uranium concentration

values in most cases. The noticeable variation in the experimental results will be declared separately

with the variation of each factor after presentation of the data here in after with probable interpretation

of the results. Before going to discuss the results, separation of thorium from uranium and vise versa is

made effective for their purification (via selective and simultaneous precipitation and extraction of

thorium oxalate) from each other and from the other co-existing elements such as few hundreds of part

per millions REEs which may be existed.

Since the use of the precipitating agent in the aqueous extracting phase makes it possible to

minimize the volume ratio of the aqueous to organic phases, and at the same time provide a high

acidity and / or concentration of nitrates in the aqueous extracting phase, this influences the

distribution of uranium nitrate is favor of the organic phase. This assists in the effectiveness of the

separation of the thorium from uranium, since the latter remains predominantly in the organic solvent,

thereby reducing the amount of uranium contaminating the thorium oxalate which is transferred to

aqueous phase.

All thorium and uranium recorded values were obtained after analysis of both elements in their

produced concentrates. In other words, thorium was determined in its crystalline oxalate precipitate

easily while uranium was determined in the final aqueous raffinate of stripping contact between water

and TBP after oxalate separation. At the same time the lower values of each element inside the other

33

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

after the process application were determined by substraction ( Ci - Cf) where Ci represent the initial

element concentration inside the solvent and Cf is the final concentration of the element inside its

concentrate after the process completion.

The process results make it possible to recover thorium without co-extracting more than 1% of

the original uranium present in the organic solvent starting solution. It is possible under certain

circumstances to recover up to 99.9% of the thorium originally present in the organic solvent starting

solution while , up to 99%of the initial uranium remains in the organic phase and is effectively

separated from the thorium.

The selected region of the applied conditions is dependent on the target whether thorium or

uranium preservation and purification. Experiment was carried out by contacting 25 ml solvent (TBP/

kerosene) of different concentrations containing nitrate salts of Th &U with 25ml aqueous oxalic acid

solution of different concentration and stirring was carried out for different time intervals and at

different temperatures which adjusted first for the oxalic acid solution then adapted via external hot

plate with stirrer to the desired temperature and keep it constant during the time of the experiment by

thermometer. The effect of each studied parameter will be demonstrated clearly through the discussion

of the experimental results in figures (1-8) for uranium and thorium extraction percents as will be seen

below.

(a)

(b)

90

o

30

o

40

o

50

o

60

60

C

C

C

C

PERCENT EXTRACTION OF Th,%

PERCENT EXTRACTION OF Th,%

70

50

40

30

20

T i m e,1 5 m i n .

10

30 o

40 o

50 o

60 o

80

70

C

C

C

C

60

50

40

30

20

3 0 min .

10

10

20

30

40

50

60

70

10

20

30

TBP/ K

50

60

70

TBP / K

(d)

100

o

30

4 0o

5 0o

o

60

90

80

PERCENT EXTRACTION OF Th,%

100

PERCENT EXTRACTION OFTh,%

40

C

C

C

C

70

60

50

40

30

4 5 min .

20

30 C

40 o C

50 o C

o

60 C

90

80

70

60

50

40

60 m i n .

30

10

20

30

40

50

60

70

10

TBP / K

20

30

40

50

60

70

TBP / K

Figure (1):- Effect of solvent concentration (TBP/ kerosene) on 0.5M of oxalic acid on the

extractability of thorium at

a= stirring time 15 minutes

b= stirring time 30 minutes

C= stirring time 45 minutes

d= stirring time 60 minutes

34

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

(a)

(b)

101

101

PERCENT EXTRACTION OF U,%

PERCENT EXTRACTION OF U, %

30 o C

40 o C

50 o C

60 o C

100

99

30

40

C

C

o

o

50

60

C

C

100

99

T i m e , 3 0 min .

T i m e ,1 5 m i n .

98

98

0

10

20

30

40

50

60

70

10

20

30

40

PERCENT EXTRACTION OF U,%

70

(d)

PERCENT EXTRACTION OF U, %

30

60

TBP / K

TBP / K

C

o

40

C

o

50

C

O

60

C

99.8

50

99.6

99.4

99.2

99.0

T i m e ,4 5 m i n .

30

o

40

5 0

6 0

99.8

C

C

o

o

C

C

99.6

99.4

99.2

T i m e ,6 0 m i n .

98.8

99.0

0

10

20

30

40

50

60

70

10

20

3 0

TBP / K

4 0

5 0

6 0

7 0

TBP / K

Figure (2):- Effect of solvent concentration (TBP/ kerosene ) on 0.5M of oxalic acid on the

extractability of uranium at

a= stirring time 15 minutes

b= stirring time 30 minutes

C= stirring time 45 minutes

d= stirring time 60 minutes

(a)

(b)

120

PERCENT EXTRACTION OF Th,%

PERCENT EXTRACTION OF Th,%

90

3 0o C

40 o C

5 0o C

6 0o C

80

70

60

50

40

30

20

1 5 m i n.

30

40o

50o

60o

100

C

C

C

C

80

60

40

3 0 min .

20

10

10

20

30

40

50

60

10

70

20

30

40

60

70

TBP / K

TBP /K

(d)

110

PERCENT EXTRACTION OF Th,%

110

PERCENT EXTRACTION OF Th,%

50

3 0o C

100

40 C

5 0o C

90

6 0o C

80

70

60

50

40

4 5 min .

30

3 0o C

100

40 C

5 0o C

90

6 0o C

80

70

60

50

60 m i n .

40

10

20

30

40

50

60

70

10

TBP / K

20

30

40

50

60

70

TBP / K

Figure (3):- Effect of solvent concentration (TBP/ kerosene ) on 1M of oxalic acid on the

extractability of thorium at

a= stirring time 15 minutes

b= stirring time 30 minutes

C= stirring time 45 minutes

d= stirring time 60 minutes

35

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

(a)

(b)

101

3 0o C

30 C

40 o C

50 o C

o

60 C

100

PERCENT EXTRACTION OF U,%

PERCENT EXTRACTION OF U, %

101

99

98

97

40 o C

50 o C

100

60

99

98

T i m e, 15 min.

T i m e , 30 m i n .

96

97

10

20

30

40

50

60

70

10

20

30

TBP / K

40

50

60

70

TBP / K

(d)

101

PERCENT EXTRACTION OF U, %

PERCENT EXTRACTION OF U, %

30 C

40 o C

o

50 C

60 o C

100

99

30

40

50

60

99.8

C

C

C

C

o

o

o

99.6

99.4

99.2

99.0

T i m e, 6 0 m i n .

Time, 45 min.

98.8

98

0

10

20

30

40

50

60

70

10

20

30

40

50

60

70

TBP / K

TBP / K

Figure (4):- Effect of solvent concentration (TBP/ kerosene ) on 1M of oxalic acid on the

extractability of uranium at

a= stirring time 15 minutes

b= stirring time 30 minutes

C= stirring time 45 minutes

d= stirring time 60 minutes

(a)

(b)

120

30o

40o

50o

60o

80

70

PERCENT EXTRACTION OF Th,%

PERCENT EXTRACTION OF Th,%

90

C

C

C

C

60

50

40

30

20

15 m i n .

30

40

50

60

100

C

C

C

o

o

80

60

40

30 min .

10

20

10

20

30

40

50

60

70

10

20

30

40

TBP / K

60

70

TBP / K

(d)

110

100

3 0o C

4 0o C

5 0o C

90

60 C

PERCENT EXTRACTION OF Th,%

110

PERCENT EXTRACTION OF Th,%

50

80

70

60

50

45 m i n .

40

30

100

40

50

60

90

o

o

o

o

C

C

C

C

80

70

60

50

60 min.

40

10

20

30

40

50

60

70

10

20

TBP / K

30

40

50

60

70

TBP / K

Figure (5):- Effect of solvent concentration (TBP/ kerosene ) on 1.5M of oxalic acid on the

extractability of thorium at

a= stirring time 15 minutes

b= stirring time 30 minutes

C= stirring time 45 minutes

d= stirring time 60 minutes

36

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

(a)

(b)

101

30o C

40o C

50o C

100

60

PERCENT EXTRACTION OF U, %

PERCENT EXTRACTION OF U, %

101

99

98

97

96

30

40 C

50 o C

6 0o C

100

99

98

T i m e, 15 m i n .

T i m e, 3 0 m i n .

95

97

0

10

20

30

40

50

60

70

10

20

30

TBP / K

40

50

60

70

TBP / K

(d)

101

101

PERCENT EXTRACTION OF U, %

PERCENT EXTRACTION OF U, %

30 C

40 o C

o

50 C

60 o C

100

99

30

40 o C

50 o C

60

100

99

T i m e, 45 min .

T i m e, 60 m i n .

98

98

10

20

30

40

50

60

70

10

20

TBP / K

30

40

50

60

70

TBP / K

Figure (6):- Effect of solve nt concentration (TBP/ kerosene ) on 1.5M of oxalic acid on the

extractability of uranium at

a= stirring time 15 minutes

b= stirring time 30 minutes

C= stirring time 45 minutes

d= stirring time 60 minutes

(a)

(b)

110

30o

40o

50o

60o

80

70

PERCENT EXTRACTION OF Th, %

PERCENT EXTRACTION OF Th, %

90

C

C

C

C

60

50

40

30

15 min .

30o

o

40

o

50

o

60

100

90

C

C

C

C

80

70

60

50

40

3 0 m i n.

20

30

10

20

30

40

50

60

70

10

20

30

TBP / K

40

50

60

70

TBP / K

(d)

3 0o

4 0o

5 0o

6 0o

100

90

110

C

C

C

C

PERCENT EXTRACTION OF Th,%

PERCENT EXTRACTION OF Th, %

110

80

70

60

50

4 5 min .

40

10

20

3 0

4 0

50

60

30o C

4 0 oC

50o C

60o C

100

90

80

70

60

6 0 min .

70

50

TBP / K

10

20

30

40

TBP / K

Figure (7):- Effect of solvent concentration

(TBP/ kerosene ) on 2M of oxalic acid on the extractability of thorium at

a= stirring time 15 minutes

b= stirring time 30 minutes

C= stirring time 45 minutes

d= stirring time 60 minutes

37

50

60

70

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

(a)

(b)

100

30o

40o

50o

60o

99

C

C

C

C

PERCENT EXTRACTION OF U,%

PERCENT EXTRACTION OF U,%

100

98

97

96

3 0o C

o

40 C

o

50 C

6 0o C

99

98

T i m e, 3 0 min .

T i m e , 15 min .

95

97

0

10

20

30

40

50

60

70

10

20

30

TBP / K

40

50

60

70

TBP / K

(d)

101

100

PERCENT EXTRACTION OF U, %

PERCENT EXTRACTION OF U,%

30 C

40o C

50o C

60o C

99

98

30

40 o

50 o

o

60

100

C

C

C

C

99

98

T i m e, 4 5 min.

T i m e,6 0 m i n .

97

97

0

10

20

30

40

50

60

70

10

20

30

40

50

60

70

TBP / K

TBP / K

Figure (8):- Effect of solvent concentration (TBP/ kerosene ) on 2M of oxalic acid on the

extractability of uranium at

a= stirring time 15 minutes

b= stirring time 30 minutes

C= stirring time 45 minutes

d= stirring time 60 minutes

The starting solvent concentration was 20% TBP in kerosene, from the data it's clear that,

partition of thorium was carried out by solvent and precipitating agent (oxalic acid) with different

values starting from 15% at 30C, 0.5M oxalic acid and 15 minutes stirring time, ended with 58-59%

at 45-60 minute stirring time, 50-60C and 1.5-2M oxalic acid. At the same time uranium was

recovered completely in the organic phase under most of the different applied separation conditions.

It was evident from all the results of 20% TBP/K extraction experiments, that uranium can be

collected in one step but not pure while thorium may need many processes which mean the

unsuitability of solvent concentration for complete thorium recovery and for uranium purification

targets.

For 30% solvent concentration experiments thorium separation results were enhanced to reach

79% in some circumstances while uranium recorded more than 99% recovery under most applied

conditions for thorium and uranium percent extraction respectively.

From these results, one can judge that uranium final recovery is not hardly affected with stirring time,

oxalic acid concentration and temperature change while recorded thorium percents extraction was

increased in all cases by increase in solvent concentration, precipitating agent concentration increase,

time of stirring increase and temperature increase till 50 C then started to decrease again which may

be attributed to the harmful effect of higher temperature on the composition of solvent.

In spite of the higher attained extraction values for uranium and thorium, the worked solvent

concentration under all mentioned conditions did not give the highest desired uranium purity and

thorium recovery and purity. In other word uranium can be recovered completely but with high

thorium contamination percents.

Tri-butyl phosphate with 40% concentration gave higher extraction percents for thorium than

the previous concentration (30%). thorium recovery when using such concentration (40%) reach to

more than 99% under some experimental conditions such as, 1-2M oxalic acid , 50 C and 45-60

minute time of stirring figure. At the same time the highest uranium recovery and purity under the

38

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

aforementioned conditions (best for Th recovery)was gained with only 1M oxalic acid , 50 C and 45

minute time of stirring. Complete uranium recovery can be attained in many experimental points

through most of working conditions but the problem was the suspicious of the decontamination of

uranium with thorium. The same case was observed for thorium recovery and products, one can obtain

complete thorium recovery along many experiments but little points gave free thorium from uranium.

In general the case of thorium and uranium complete or near complete separation with highest

recovery and purity of each was close starting from 40% TBP/ Kerosene concentration.

The final conclusion was that more than 99% uranium content can be recovered nearly free from

thorium contamination with 40% TBP / K and 1-2 M oxalic acid concentration at 50 C with 60

minute stirring time, while more than 99% thorium content can be recovered nearly free from uranium

contamination with 40% TBP.

In spite of obtaining a good thorium extraction and purification from uranium in addition to the

better uranium recovery and purification percents during 40% TBP group of experiments and

measurements it was necessary to complete to the higher solvent concentration to obtain many

probable and promising experimental conditions to facilitate their separation and purification during

many points more than the previous concentration. 50% of solvent concentration group of extraction

experimental data prevails that, more than 99.9% of the thorium content can be recovered in the region

1-2M oxalic acid, 45-60 minutes stirring time under 40-50C with more than 99.5% uranium recovery.

One can obtain pure uranium concentrate free completely from any thorium contamination in the same

time; one can obtain thorium concentrate nearly free from uranium except from 5 to 15 ppm U. These

experiment results were recorded for thorium and uranium, from the figures it was obvious that, the

collapse in all recovery and as a result mutual purity percents for both elements. This may be

attributed to the higher viscosity of the organic phase and the adverse effect of temperature especially

at higher concentrations. Collecting the total effect of the organic concentration over the whole

experimental groups for thorium extraction and uranium recovery through figures (1-8), one can judge

that, a general positive increase in the thorium extraction and uranium recovery percents till 40-50%

solvent concentration over any particular experimental condition in evident.

Oxalic acid concentration effect as precipitating agent for thorium was discovered through

collecting the data in the previous different figures under various conditions of organic concentration,

time of stirring and temperature and to demonstrate the most active concentration of the precipitating

agent for the present thorium concentration separating by precipitation from various TBP

concentrations. Extraction of thorium was increased during the same temperature with oxalic acid

increase with all solvent concentration nearly except for high organic concentration. The same trend of

increase was observed when increasing the time of stirring under the same temperature and particular

organic concentration, till nearly a constant value which attained after about one hour. Moving from

one temperature to the next higher one, and comparing with preceding extraction percent, it was clear

that, the effect of increasing oxalic acid with temperature increase. In other words, at higher

temperatures the increasing in precipitating agent concentration was more effective in separating

thorium from uranium with different stirring time and organic concentration.

In the same time oxalic acid concentration increase was not so effective for uranium recovery

during most of variable experimental conditions. This may be attributed to the definite oxalic acid rule

in uranium recovery, (only reduce uranium inside organic phase leaving it and searching for thorium

to precipitate). In other words it affect uranium purity more than recovery via complete or near

complete thorium recovery. Increasing temperature effect on each extraction experiment was observed

from the figures, it is clear that, extraction of thorium increased with temperature increase within the

same experiments till 50C then the stop and the starting decrease again which may be attributed to the

solvent nature as mentioned before. Increasing the stirring time enlarge temperature effect within the

same experiment under particular TBP and oxalic acid concentration.

39

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

In other words one can say, the effect of temperature increase on the thorium extraction was

enhanced with increasing stirring time during most of experiments.

The same effect and correlations were noticed under all tried organic concentration till 60% in

addition to all precipitant concentrations. Uranium recovery percents were slightly changed with

temperature change or increase during most experimental conditions and the decreasing effect in its

recovery was observed specially with organic condition increase.

In other words, and in general, temperature increasing effect, affect only thorium recovery in most

cases and in turn uranium purity.

Stirring time increasing effect can be noticed through all previously presented thorium

extraction data and figures. Within the same experiment of the same temperature, it was found that a

noticed increase in thorium extractability while a very slight uranium recovery change was observed

under the experimental precipitating conditions. The change in thorium extraction behavior with

increase of stirring time was nearly the same as temperature increase, under all experimental data of

60% solvent and 50C. Uranium recovery discussion is more or less similar to the previous discussion.

Some selected experiments at different working regions were repeated at different pH values. The

results of all pH variation experiments gave no pronounced effect in thorium separation from uranium

over the normal experiment without pH control i.e., the pH of the medium is the most suitable pH for

each experiment without any further adaptation.

CONCLUSION

From the previous results and discussions for extraction and recovery of uranium in their

highest possible purity and recovery percents applying TBP/K extraction thorium oxalate precipitation

uranium water stripping is a new adapted scheme, where uranium can be extracted with more than

99.5% percent recovery and more than 99.9% purity. The best experimental extraction-precipitation

stirring condition to obtain the aforementioned recovery and purity percents for uranium were:Opening: - conc. H 2 SO4 (W /V) (acid / ore ratio) 1: 1.6

Dissolution: - ice water 1:20

First Precipitation: - NH4OH 1:1

Caustification: - 10% excess of 18% NaOH

Dissolution: 1M HNO3

Second precipitation: 10% NaOH at pH 5.5-6

Dissolution: 7M HNO3

Drying

Organic concentration: - 40-50% TBP/K

Scrubbing: - scrub solution 5 (2M HNO3 ): 1 (H2O2 )

Aqueous: organic ratio: - 1:5

Precipitant concentration: - 1.5-2 M oxalic acid

Stirring time: - 45-60 minutes

Temperature: - 40-50 C

Stripping: - strip solution cold water (1:1)

Last precipitation: - 10% NaOH, pH 6

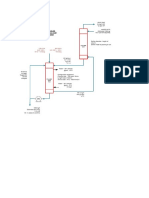

The previous conclusion and optimum results and parameter for the whole process from the

starting monazite mineral was collected and summarized in the schematic diagram (figure 9)

representing the partially mass balanced flow diagram for 100 gm mineral (un-ground~ 50%) digested

by H2 SO4 (98%) and dissolution with cold water (1 : 20) then precipitated with ammonia (1:1)

solution. The precipitate was treated as mentioned before till starting our new adapted extractionprecipitation- stripping scheme.

40

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

Figure (9):- schematic flow diagram for complete uranium and thorium separation and

purification from native Egyptian monazite mineral after sulfuric acid opening process.

REFRENCES

1- Thompson, R., Speciality Inorganic Chemicals. University of Salford, September Special

Publication; 40, 403443 (1980).

2- Abro, A., Qu? mica e tecnologia das terras raras. Srie Tecnologia Mineral, 66, Rio de Janeiro:

CETEM/CNPq.; 212 (1994).

3- Loureiro, F.E.V.L., Terras raras no Brasil; dep?sitos, recursos identificados, reservas. Rio de

Janeiro: CETEM/CNPq/MCT, (Estudos e documentos, 21).; 183 (1994).

41

Arab Journal of Nuclear Science and Applications, 46(1), (30-42) 2013

4- Miyawaki, R., Nakai, I., Crystal chemical aspects of rare earth minerals. In: Jones, A.P., Wall, F.,

Williams, C.T. (Eds.), Rare Earth Minerals: Chemistry, Originand Ore Deposits, The Mineralogical

Society Series, vol. 7. Chapman and Hall,London; 2140 (1996).

5- Sundaram, C.V., Chemistry and metallurgy of rare earth metal extraction and applications.

Transactions of the Indian Institute of Metals; (40), 457477 (1987).

6- Wall, F., Mariano, A.N., Rare earth minerals in carbonatites a discussion centre the Kangankunde

carbonatite, Malawi. In: Jones, A.P., Wall, F., Willians, C.T. (Eds.), Rare Earth Minerals

Chemistry, Origin and Ore Deposits. London Chapman and Hall; 193226 (1996).

7- Fleiscer, M., Rosenblum, S., Woodruff, M., The distribution of la nthanides andyttrium in the

minerals of the monazite family. Geological Survey ProfessionalPaper, File Report; 91, 125

(1990).

8- Toledo, M.C.M., Pereira, V.P., 2003. Ocorrncia e variabilidade de composi ?o dos fosfatos do

grupo da monazita em carbonatitos. Pesquisas em Geocincias; 30(1), 8395 (2003).

9- Farrag, A.K., PhD thesis, Ain Shams University (1979).

10Gupta, V.V., Keni, V.S., Ghosh, S.K., Thorium purification by solvent extraction. Symposium

on Solvent Extraction of Metals, Bombay, India, (12 Feb.) (1979).

11Deqian, L., Yong, Z., Shulan, M., Separation of thorium(IV) and extracting rare earths from

sulfuric and phosphoric solutions by solvent extraction method. Journal of Alloys and Compounds

374, 431 (2004).

12Habashi, F., Hand Book of Extractive Metallurgy. Wiley-VCH.; 16491684 (1997).

13Vijayalaskshmi, R., Mishra, S.L., Singh, H., Gupta, C.K., Processing of xenotime concentrate

by sulfuric acid digestion and selective thorium precipitation for separation of rare earths, India.

Hydrometallurgy; 7580 (2001).

14Silva, A.S., Almendra, E.R.E., Ogasawara, T., Andrade, M.C., Lixivia?o sulf?rica da monazita

em autoclave: an?lise termodinmica. Anais do III Encontro de Metalurgia, Minera?o e Materiais,

vol. 1. UFMG, Belo Horizonte/MG, Brasil ; 223234 (1995).

15Gupta, C.K., Krishnamurthy, N., Extractive metallurgy of rare earths. International Materials

Reviews; 5 (37), 204207 (1992).

16Kolthoff, I. M., and Elving, P. S., "Treatise on analytical chemistry", Part II; Inter-science

Publishers, New York; 5 (1961).

17Cuthbert, F.L., "Thorium production technology" Addison- Wesley Publishing Co., Inc., U. S.

A.; (1958).

18Marczenko." Spectrophotometric determination of elements". John Wiley and sons Inc. New

York; (1986).

19Marczenko, Z., Spectrophotometric determination of ele ments Ellis Harwood. U.K, 643

(1976)

20- Moneir Adel Hamed et. Al, "Internal Scientific Report, Nuclear Materials Authority, under

Publication.

21R. W. URIE, J. SOC. Chem. Ind. (London); 66,437 (1947).

22Rabie, K. A. studies on the Separation of some Rare Earth Elements From Egyptian Monazite

sand, Ph.D., Cairo University, faculty of science, A. R. Egypt; (1996).

42

You might also like

- PFD 16 - 224 Rev00Document1 pagePFD 16 - 224 Rev00Rizky AnugrahNo ratings yet

- 101 Excel Tips Tricks Time SaversDocument88 pages101 Excel Tips Tricks Time SaversM O'Gbenga Mabinuori-DawoduNo ratings yet

- Teori Radiokimia Pertemuan Ke 7Document25 pagesTeori Radiokimia Pertemuan Ke 7Rizky AnugrahNo ratings yet

- 0125 3395 31 2 195 203Document9 pages0125 3395 31 2 195 203Rizky AnugrahNo ratings yet

- Ammonia Plant Retrofit Reactor OptimizationDocument13 pagesAmmonia Plant Retrofit Reactor OptimizationAhmed AliNo ratings yet

- Simple Thermodynamics of Jet EnginesDocument6 pagesSimple Thermodynamics of Jet EnginesKok CheongNo ratings yet

- Img NewDocument1 pageImg NewRizky AnugrahNo ratings yet

- LicenseDocument1 pageLicenseRizky AnugrahNo ratings yet

- CUPLIKANDocument2 pagesCUPLIKANRizky AnugrahNo ratings yet

- Simulation of Methane Steam ReformingDocument9 pagesSimulation of Methane Steam ReformingswarhiliNo ratings yet

- 1 s2.0 S1876610212010971 MainDocument12 pages1 s2.0 S1876610212010971 MainRizky AnugrahNo ratings yet

- 62861135Document46 pages62861135hamedronaldoNo ratings yet

- Matbal 001H Flowsheet CycloHexaneDocument29 pagesMatbal 001H Flowsheet CycloHexaneRizky AnugrahNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Soil Settlement ElasticityDocument10 pagesSoil Settlement ElasticityAnonymous aZrC1EZNo ratings yet

- Laser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsDocument6 pagesLaser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsK. JayarajanNo ratings yet

- Free Electron Theory 2015-16 (VTU) PDFDocument14 pagesFree Electron Theory 2015-16 (VTU) PDFU and me SNo ratings yet

- Lucia 1995 Rock-FabricPetrophysical Classification of Carbonate Pore SpaceDocument26 pagesLucia 1995 Rock-FabricPetrophysical Classification of Carbonate Pore SpaceMarcos Antonio Romero Arteaga100% (1)

- Refraction Through Spherical Surfaces and LensesDocument2 pagesRefraction Through Spherical Surfaces and LensesOrbit MBBS PreparationNo ratings yet

- Role of Infill WallDocument16 pagesRole of Infill WallGaurav MallaNo ratings yet

- PMM WordDocument3 pagesPMM WordShrey R DhanawadkarNo ratings yet

- Reka Bentuk, Pembinaan Dan Pentadbiran UjianDocument9 pagesReka Bentuk, Pembinaan Dan Pentadbiran UjianAiman HazimNo ratings yet

- SKEM 3742 Electro Hydraulic LabsheetDocument6 pagesSKEM 3742 Electro Hydraulic Labsheetcikgu_relaNo ratings yet

- Measuring Instruments Practice QuestionsDocument6 pagesMeasuring Instruments Practice QuestionsAsif Ayaz100% (2)

- History of Buckling of ColumnDocument10 pagesHistory of Buckling of ColumnSorin Viorel CrainicNo ratings yet

- Harald J. W. Muller-Kirsten-Electromagnetic Field Theory-World Scientific Publishing Company (2004) PDFDocument203 pagesHarald J. W. Muller-Kirsten-Electromagnetic Field Theory-World Scientific Publishing Company (2004) PDFMonã Hegel BenettiNo ratings yet

- Refrigerant R22 Properties TableDocument4 pagesRefrigerant R22 Properties TableKiki Indra HNo ratings yet

- TMTL2400KDocument4 pagesTMTL2400KRushit ShahNo ratings yet

- Luo Shu Ancient Chinese Magic Square On Linear AlgDocument12 pagesLuo Shu Ancient Chinese Magic Square On Linear AlgAJAY KUMAR JAINNo ratings yet

- MCAT Formula SheetDocument3 pagesMCAT Formula SheetYank AzharNo ratings yet

- OAT Bootcamp Physics Equation Sheet PDFDocument11 pagesOAT Bootcamp Physics Equation Sheet PDFjon100% (2)

- IEEE Paper For Image ProcessingDocument32 pagesIEEE Paper For Image Processingsaravanan_dijucsNo ratings yet

- Chemistry Test 1 July 2019 BatchDocument3 pagesChemistry Test 1 July 2019 BatchDaNo ratings yet

- (Architecture Ebook) Alvar Aalto, Alvar Aalto and The Bio-ArchitectureDocument5 pages(Architecture Ebook) Alvar Aalto, Alvar Aalto and The Bio-Architecturepooh86poohNo ratings yet

- Math II Tutorial 1Document2 pagesMath II Tutorial 1devang_siNo ratings yet

- A AjouterDocument3 pagesA Ajouter00JoNo ratings yet

- Tuned Liquid Dampers for Efficient Tall Building DesignDocument9 pagesTuned Liquid Dampers for Efficient Tall Building Designsukanya12345No ratings yet

- ASTM TablesDocument185 pagesASTM Tableslahiru198367% (3)

- Grade 9: Coordinate GeometryDocument5 pagesGrade 9: Coordinate GeometryEduGainNo ratings yet

- Mock C4 Paper Key ConceptsDocument4 pagesMock C4 Paper Key ConceptsWojtek BażantNo ratings yet

- Pore Structure of Air-Entrained Hardened Cement PasteDocument9 pagesPore Structure of Air-Entrained Hardened Cement Paste1mattelliottNo ratings yet

- Static Studies of Magneto-Electro-Elastic 3-D Beam Using ANSYS - FINALDocument8 pagesStatic Studies of Magneto-Electro-Elastic 3-D Beam Using ANSYS - FINALjssrikantamurthyNo ratings yet

- Balloon and Travoltage AnswersDocument4 pagesBalloon and Travoltage Answersosama47% (17)