Professional Documents

Culture Documents

Pin Bikkasandra Biomass Briquetting Unit PDF

Uploaded by

Sandeep Rao D0 ratings0% found this document useful (0 votes)

16 views3 pagesThe project would result in annual production of 16,000 MT of Biomass Briquettes. Briquettes could displace firing of coal in Industrial Boilers. The project makes contributions to rural community development.

Original Description:

Original Title

pin-bikkasandra-biomass-briquetting-unit.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe project would result in annual production of 16,000 MT of Biomass Briquettes. Briquettes could displace firing of coal in Industrial Boilers. The project makes contributions to rural community development.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views3 pagesPin Bikkasandra Biomass Briquetting Unit PDF

Uploaded by

Sandeep Rao DThe project would result in annual production of 16,000 MT of Biomass Briquettes. Briquettes could displace firing of coal in Industrial Boilers. The project makes contributions to rural community development.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

PROJECT INFORMATION NOTE (PIN) - 009

1.

Project Title

Biomass Briquetting Unit

2.

Project Location

Bikkasandra Village, K R Pet Taluka, Mandya District, Karnataka

3.

Project Mission

To provide assured quality of Biomass Briquettes as Cooking Fuel or as

replacement to Coal (being fired in Industrial Boilers), produced from

sustainably available, local bio resources.

4.

Project Brief Description

(A) The project would result in annual production of 16,000 MT of

Biomass Briquettes

(B) The project objectives are as follows

(i) Provide monetary value to agricultural residues which currently

have no commercial applications (eg. Cane trash, Coconut

fronds, etc.) & simultaneously mitigate environment pollution.

(ii) To produce assured quality (NCV of > 4000 Kcal/Kg) Biomass

Briquettes with appropriate blend of agriculture/forest residues

viz.

50% cane trash/coconut fronds

25% press mud/coffee husk

25% corn cobs/saw dust/toppings of plantation wood

(C) The project comprises following components/works

(i) Site development of around 1.75 acres, including site grading,

fencing, gate/security chamber, roads, water harvesting and

drainage systems, sewerage systems, raw water systems, area

lighting, etc.)

(ii) Components of Briquetting line (drum shredder, dryer,

pulverizer, mixer, briquetting press, cooling/cutting line,

bagging system, etc.)

(iii) Mechanical Auxiliary Systems (weigh bridge, fire alarm &

protection system, etc.)

(v) Electrical Auxiliary Systems (power receiving

station/transformer, distribution boards, cabling, earthing/

lightning protection, illumination systems, communication

systems, etc.

5.

Project Contributions to Sustainable Development

The project makes following contributions to rural community development :

a) Socio-economic

JOB CREATION : 36 Nos. direct jobs within Briquetting Unit + 100

Nos. indirect jobs in Biomass Supply Chain

RELIABLE ENERGY : The briquettes could displace use of

LPG/Kerosene in Community Cooking applications

The briquettes could displace firing of coal in industrial boilers (in

particular Cogeneration Plant of Chamundeshwari Sugar Mills)

6.

b) Environmental

Prevents burning of cane trash on sugarcane fields causing

environmental pollution through particulate emissions as well as

ground water contamination through leaching.

c) Ecological

Coconut fronds if allowed to decay releases GHG emissions

Key Indicators for

Performance Monitoring

PRIMARY :

(i) Number of community stoves supported and quantity of briquettes

supplied.

(ii) Number of industrial boilers supported and quantity of briquettes

supplied.

SECONDARY:

(iii) Kg of LPG and/or litres of Kerosene displaced.

(iv) Quantity of coal displaced

(v) Number of jobs created in the supply chain

7.

Project Cost

Rs. 40 million

8.

Project Financing

Proposed as follows:

40% of project cost as equity/grants (with 5% of project cost being

contribution of local entrepreneur).

60% of project cost as Bank debt/Soft loans.

9.

Project Developer(s)

CREWA, a not for profit organization with a mission to improve

energy and potable water access in rural areas supported by another

not for Profit organization Grameena Abhivrudhi Mandali (refer

website: www.gam-rd.co.in) will undertake Project Development on

behalf of overseas Indian, who would like to promote such project

10.

Project Schedule

Land acquisition completed and key permits obtained

Financial closure targeted for March 2012

Project commissioning targeted for December 2012

You might also like

- Bio Coal EstimateDocument1 pageBio Coal EstimateDhananjay KulkarniNo ratings yet

- Regional Wood Energy Development Programme in Asia GCP/RAS/154/NETDocument193 pagesRegional Wood Energy Development Programme in Asia GCP/RAS/154/NETSandeep Rao DNo ratings yet

- Biomass Price Analysis Report - Main ReportDocument41 pagesBiomass Price Analysis Report - Main ReportSandeep Rao DNo ratings yet

- Bio Coal EstimateDocument1 pageBio Coal EstimateDhananjay KulkarniNo ratings yet

- Biomass Price Analysis Report - Main ReportDocument41 pagesBiomass Price Analysis Report - Main ReportSandeep Rao DNo ratings yet

- Bio Coal EstimateDocument1 pageBio Coal EstimateDhananjay KulkarniNo ratings yet

- Sandy Vs IVYDocument4 pagesSandy Vs IVYSandeep Rao DNo ratings yet

- Fortigate-SSLVPN's FortiOS Handbook 4.0 MR1aDocument106 pagesFortigate-SSLVPN's FortiOS Handbook 4.0 MR1awbrcoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Interbus A Group 2: Arnetta Siagian (19018057) Muhammad Ilham Gunawan (19018192) Safira Khoirunnisa (19018047)Document7 pagesInterbus A Group 2: Arnetta Siagian (19018057) Muhammad Ilham Gunawan (19018192) Safira Khoirunnisa (19018047)Safira KhoirunnisaNo ratings yet

- ANALISIS LAMA WAKTU PANGKAL BATANG TEBU (Saccharum Officinarum L.) Tertinggal Di Lahan Terhadap Nilai RendemenDocument5 pagesANALISIS LAMA WAKTU PANGKAL BATANG TEBU (Saccharum Officinarum L.) Tertinggal Di Lahan Terhadap Nilai RendemenelenaNo ratings yet

- Carbonized Rice Hull: Ronnie O. NaagDocument18 pagesCarbonized Rice Hull: Ronnie O. NaagRonnie NaagNo ratings yet

- IHS 6th CIVIL Chapter 1 NotesDocument9 pagesIHS 6th CIVIL Chapter 1 NotesTanvir Rajib 191-47-234No ratings yet

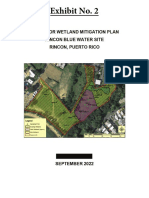

- Exhibit 2 - Wetland Mitigation Plan - Calrincon Corp Vs EPADocument13 pagesExhibit 2 - Wetland Mitigation Plan - Calrincon Corp Vs EPALa Isla OesteNo ratings yet

- Unit Lecture - Freshwater Systems and Resources - DLDocument82 pagesUnit Lecture - Freshwater Systems and Resources - DLana lamiquizNo ratings yet

- Causes of Climate ChangeDocument6 pagesCauses of Climate ChangeAkhilesh AjayanNo ratings yet

- WorkDocument8 pagesWorkOdumboni TopeNo ratings yet

- Water Desalination Using Renewable Energy - Technology Brief معلومات اخري عن الطاقة المتجددة ستجدها هنا https://sites.google.com/site/e4poor/Document28 pagesWater Desalination Using Renewable Energy - Technology Brief معلومات اخري عن الطاقة المتجددة ستجدها هنا https://sites.google.com/site/e4poor/Hassan EbeidNo ratings yet

- Golden Triangle Report March2016Document12 pagesGolden Triangle Report March2016Yash ladkeNo ratings yet

- Keyline Plowing ResearchDocument16 pagesKeyline Plowing ResearchPermacultura Strambeni100% (1)

- EVS CO-5 AssessmentsDocument5 pagesEVS CO-5 Assessments33 .Snehal GhadgeNo ratings yet

- IUCN Habitats Classification SchemeDocument14 pagesIUCN Habitats Classification SchemeElenora GitaNo ratings yet

- BD NR 05 en PDFDocument147 pagesBD NR 05 en PDFMazharul SajeebNo ratings yet

- Implementation of Reporting Code Guidelines For Mineral Resources and Mineral Reserves Using A General Mine Planning PackageDocument6 pagesImplementation of Reporting Code Guidelines For Mineral Resources and Mineral Reserves Using A General Mine Planning PackageIoannis KapageridisNo ratings yet

- Constructed Wetlands CompleteDocument219 pagesConstructed Wetlands CompleteNguyen Cong ThanhNo ratings yet

- Lesson 6.1 Running WaterDocument29 pagesLesson 6.1 Running Waterazzamomar2018No ratings yet

- Cost Benefit Analysis Outline ECDocument5 pagesCost Benefit Analysis Outline ECmelenyo tuqueroNo ratings yet

- Carbon Neutral Fuel Presentation For Indonesia - Final - JAMADocument22 pagesCarbon Neutral Fuel Presentation For Indonesia - Final - JAMAMohamad BachtiarNo ratings yet

- 1512629888channel Morphology Final (1Document12 pages1512629888channel Morphology Final (1KASHIF QUAMARNo ratings yet

- BP 220 DenDocument5 pagesBP 220 DenGeraldine F. CalubNo ratings yet

- Kimberlitic Tubes Underquarry ReservesDocument4 pagesKimberlitic Tubes Underquarry ReservesManuel AragonNo ratings yet

- The Role of Technology in AgricultureDocument35 pagesThe Role of Technology in AgricultureDivyesh ThumarNo ratings yet

- 2014 Bookmatter TheSoilsOfThePhilippinesDocument39 pages2014 Bookmatter TheSoilsOfThePhilippinesRemer JalbunaNo ratings yet

- Mining Methods-Part IV-Solution Mining: February 2010Document50 pagesMining Methods-Part IV-Solution Mining: February 2010DewaDewi BussinessNo ratings yet

- Running WaterDocument24 pagesRunning WaterpicefeatiNo ratings yet

- Water-Sewage Investigation Haninge Municipality 201404Document49 pagesWater-Sewage Investigation Haninge Municipality 201404ErSoravNo ratings yet

- Urea Granular 46-0-0Document20 pagesUrea Granular 46-0-0DAPUREAGRO FertilizersNo ratings yet

- J.N. Patnaik-BhanjapaliDocument8 pagesJ.N. Patnaik-Bhanjapalivaibhavtanwar2810No ratings yet

- Proposal For Integrated Planning and Development of The Sabarmati River Front by MRDocument1 pageProposal For Integrated Planning and Development of The Sabarmati River Front by MRShrila MitraNo ratings yet