Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weld

Uploaded by

hamidjoyiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weld

Uploaded by

hamidjoyiaCopyright:

Available Formats

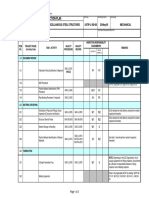

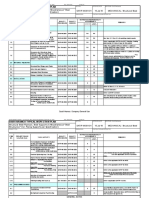

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of WPS & Process Control Procedure (Pipelines)

PROJECT TITLE

SAIC-W-2038

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

30-Jun-08

DATE APPROVED

QR NUMBER

WELDCONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

Instructions for Approval (Responsibilities) ... Quality Managers shall see Notes 1 & 2 at end of this checklist

A1

For shop and all field fabrication IK, NEW WPSs & PQRs are

prepared* and submitted using the correct SA Welding Forms:

A) Attachment 1 - SAES-W-011/012 WELDING PROCEDURE

SPECIFICATION (ATTACHMENT A, PAGES A1, A2, A3, A4, A5)

B) Attachment 2 - SAES-W-011/012 WELD & LINE DESCRIPTION

TABLE (ATTACHMENT B).

For New Procedures (Master Set), follow Attachment 3 rules.

C) If previous CSD-approved WPS is reused. See Section C.

SAES-W-012,

Para. 7.1.2

A2

All WPSs & PQRs shall conform to the latest edition of the relevant

Code (API STD 1104 or ASME SEC IX, as appropriate).

SAES-W-012,

Para. 7.2.1

A3

Complete Weld Table (Attachment B) listing all mat'ls, thicknesses, &

weld joint types for individual line designations, shall be submitted along

with the WPS & PQR documents for each job.

SAES-W-012,

Para. 7.1.3 & 4

A4

PQRs shall include certified copies/facsimiles of all test records for IK

qualification, (the TPI testing agency that issued the test record shall

certify the copies).

SAES-W-012,

Para. 7.1.10

A5

Originals of all test records, mill certificates, etc. including records from

independent test laboratory are available for review by SA.

SAES-W-012,

Para. 7.1.11

A6

Welding of qualification test coupons shall be monitored by either an

approved independent test laboratory or independent TPI. Monitoring

shall include verification of accuracy of the recorded parameters.

SAES-W-012,

Para. 7.2.5 a)

A7

PQR mechanical tests and examinations shall be performed by

approved independent test laboratory, unless Fabricator is specifically

approved by OID to perform their own tests.

SAES-W-012,

Para. 7.2.5 b)

A8

For all automatic welding & any process with pulsing, the WPS shall

include all applicable equipment and controller parameter settings.

SAES-W-012,

Para. 7.2.6

Procedure Variables to be checked in detail:

B1

Procedure Variables meet the detailed reqmts of SAES-W-012, Section

7.4 & 7.5. Use Attachment 5 as a thorough review aid.

SAES-W-012,

Section 7.4

B2

Welding Procedure Qualification Hardness testing is required (sour

service applications) with maximum allowable hardness VHN 250 per

SASD AB-036386. Use Attachment 5 as a review aid.

SAES-W-012,

Para. 7.5.1

Review & Submittal of Existing WPS (CSD Previously Approved) ... Quality Manager Checklist (Action & Review)

C1

After approval by CSD, the package of welding procedures,

qualification test records, & weld maps/tables may be approved for

additional jobs by Inspection Dept. Project assigned Inspector will

authorize the use of existing CSD-approved welding procedures if scope

& essential variables are acceptable for the new application. Follow

directions below for Existing WPS Package approval.

Page 1 of 4

SAES-W-012,

Para. 7.1.1

RE-INSP DATE

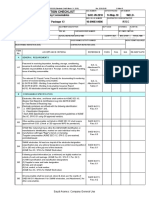

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Review of WPS & Process Control Procedure (Pipelines)

PROJECT TITLE

ITEM

No.

SAIC NUMBER

SAIC-W-2038

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

30-Jun-08

DATE APPROVED

QR NUMBER

5-Nov-08

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

Review & Submittal of Existing WPS (CSD Previously Approved) ... Quality Manager Checklist (Action & Review)

C2

CSD APPROVAL COVER SHEET LISTS APPROVAL STATUS &

CONDITIONS WITH ALL CSD COMMENTS. SUBMIT THIS COVER

SHEET ALONG WITH DETAILS OF THE INTENDED APPLICATION:

A) Complete Page A1, Request Welding Procedure Approval

It must be complete in entirety (Design Details) & Project Specific.

B) Complete Attachment B, Weld & Line Description Table

Service description & line class information details are provided.

Note 1: New Application is compared against CSD-approved docs.

Note 2: If the CSD approval cover sheet is not available, the WPS

cannot* be approved by PID. Request a copy from CSD providing the

CSD Log Number on all requests. * CSD Notes are mandatory .

C) All existing WPS, PQR, Attachments (A1, B) are submitted as one

package (Incl. NEW Attachment A1, B) for approval.

SAES-W-012,

Para. 7.1.1

C3

Each Weld and Line Description Table (Att. B) must be complete and

show line designations (service), materials, joints, & WPS used for

the NEW APPLICATION.

SAES-W-012,

Para. 7.1.4

RE-INSP DATE

Note: CSD HAS IDENTIFIED 6 SELECTED VARIABLES FOR CLOSE REVIEW OF WPS (MOST COMMON CAUSE OF WPS REJECTION)

C4

Check Material requirements (compare old & new application), using

ASME IX, WPS (QW-403) for P-No, Group No., Spec & Grade

SAES-W-012,

Para. 7.1.1

C5

Per QW 403 & 450, Check Thickness range, comparing the old and new

application.

SAES-W-012,

Para. 7.1.1

C6

Per QW 403, Check Pipe Diameter range, comparing the old and new

application.

SAES-W-012,

Para. 7.1.1

C7

Per QW 407 & Service Application (Form Page A1), Check PWHT,

comparing the old and new application.

SAES-W-012,

Para. 7.1.1

C8

Check Service & Materials (scope) for Hardness Reqmts, comparing the

old and new application.

SAES-W-012,

Para. 7.1.1

C9

Check for Charpy Impact requirements, comparing old and new

applications, carefully checking test temperature and impact test values ...

Ranges often vary & require requalification.

SAES-W-012,

Para. 7.1.1

Note: The following revisions apply to all existing WPS. QA/QC Mgrs. shall take immediate action for revision as needed.

C10

Existing P-No. 1 WPS (GTAW/SMAW) without Heat Input reqmt:

Revise without requalification of procedure, follow request below:

A)

Specify in WPS Technique Section (QW 410), under Maximum weave

width, the following: 3 x electrode diameter.

Note 1: Revisions are legibly handwritten or typed, signed & dated.

Note 2: Bead widths over 5 x electrode diam. (excess weave width) can

adversely affect weld quality (poor technique). Instruct welders to follow 3

x electrode diameter, & never exceed 5 x electrode dia.

Note 3:

If Heat Input measurement is req'd , Heat Input reqmts will control

weave width (technique). Ensure that travel speeds are closely monitored

along with proper bead width for good HI values. Note 4: Weave widths

exceeding 5 x dia. result in quite significant reduction in notch toughness

test results. (This is unacceptable).

As referenced,

Contact CSD on

any welding

technical

questions

SAES-W-012,

Para. 7.1.1

C11

NOTICE: ERRORS EXIST IN SAES-W-012 PREHEAT TABLES.

NEW & EXISTING WPS SHALL BE REVISED PER ATTACHMENT 6.

Background: The 28 February 1998 edition was revised and the following

"copy and paste error" was made in welding standards. Preheat Values of

Table 4A/4B (Vertical Down SMAW Butt Welds) are identical to Table

3A/3B (Vertical Up SMAW Butt Welds).This is incorrect as higher preheat

is needed for vertical down position.

Utilize

February 1998 Table 4A/4B immediately on project .

See Attachment 3 of this Checklist for correct table values.

This will result in higher preheats. Train welders accordingly.

As referenced,

Attachment 3,

Contact CSD as

needed to verify

SAES-W-012,

Para. 7.1.1

Page 2 of 4

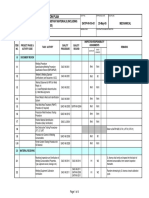

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Review of WPS & Process Control Procedure (Pipelines)

PROJECT TITLE

SAIC NUMBER

SAIC-W-2038

WBS / BI / JO NUMBER

C12

This exists for every type welding joint covered by a WPS.

A) See SAIC-W-2037 for socket welding requirements.

B) See SAIC-L-2015, SAIC-W-2037 for seal welded thread jts

C) See SAIC-L-2013 for welding of branch connections.

D) See SAIC-L-2144 for Pipeline repair sleeve applications.

1) Instructions are available at all sites where welding is done.

2) Instructions can be written in or attached to WPS or may be in a

Welding Process Control Procedure covering all welding activity.

3) Those responsible for implementation are adequately trained.

As referenced,

Attachment 3,

Contact CSD as

needed to verify

SAES-W-012,

Para. 7.1.1

C13

WPS using ER70S-6 filler mat'l (GTAW, GMAW Process) are

revised without WPS requalification (unless impact tests are req'd) as

directed below (CSD has approved this direction):

A) Substitute ER70S-2 for ER70S-6 (GTAW Process)

B) Substitute ER70S-3 for ER70S-6 (GMAW Process)

See Attachment 4.

As referenced,

Attachment 4,

Contact CSD as

needed to verify

SAES-W-012,

Para. 7.1.1

C14

WPS using Internal & External Field applied FBE Coatings shall be

CSD approved. The process shall be GMAW STT or GTAW to assure the

following criteria: All weld joints including adjacent areas to be FBE coated

either Internal or External shall be ground smooth and free from burrs,

weld spatter, sharp edges. Weld toes shall be merged smoothly and

rounded with no sharp undercuts. Weld cap or internal root protrusion

shall not be more than 1.5 mm. WPS provides adequate field

instruction.

SAES-H-201,

Para. 7.2.2

C15

CSD approved WPS with essential variables that include the restriction

of electrodes (Per Attachment 5) are "noted":

A) G Designated Electrodes are restricted to the exact brand & type

specified on the PQR & WPS.

B)

WPS & PQR with Impact Toughness Reqmts use the same brand name

& type GMAW electrode, SAW flux & FCAW electrode.

C)

Change in filler metal or deposit chemistry from A-No. 1 to A-No. 2

(ASME SECT IX) Note: Requalify Sour Service Procedures

WPS Notes shall specify that substitutions are not allowed and exact

brand name and type consumable shall be used.

Plan Consumable substitution approvals by CSD. Do not wait until

designated & required consumables are gone.

SAES-W-012,

Section 7

30-Jun-08

DATE APPROVED

QR NUMBER

5-Nov-08

WELD-

CONTRACTOR / SUBCONTRACTOR

WELDING PROCESS CONTROL PROCEDURE (COVERS ALL WELDING RELATED ACTIVITY OTHER THAN THE WPS)

D1

Welding related activities other than the actual WPS are identified and

controlled (Special Construction Process) by Procedure. Option exists for

a single procedure (Welding Process Control) or multiple procedures

covering the remaining elements in Section D below.

A single Procedure is recommended for efficiency . All SAIC are

referenced in this procedure. Use the specific checklists.

SAEP-1160 Weld ID & Tracking System (Database) required.

D2

WPS & PQR (Review) for Welding Master Sets

SAIC-W-2038

D3

Review of Welder & Welding Operator Certs (Pipelines) & Review of

welder performance. See SAIC-W-2039 Att. 2

SAIC-W-2039

D4

Weld Repair Procedure (Including WPS)

SAIC-W-2040

D5

Weld Joint ID & Database (Status, Reporting) per SAEP-1160*

SATR-W-2008, SATR-W-2013, SATR-W-2018, SATR-W-2019 can be

eliminated if Database gives an acceptable report format

SAIC-W-2008

D6

Welding Machine Calibration per BS7500 for Pipelines

SAIC-W-2045,

SATR-W-2011

D7

Welding Consumable Control (Pipelines)

A) Receiving Inspection (SAIC-W-2044) (SATR-W-2020)

B) Storage & Handling (SAIC-W-2046)

C) Consumable Issuance & Control (SAIC-W-2055) (SATR-W-2010)

D) Calibration of Electrode Oven, Baking & Portable (SAIC-W-2055)

Note: Use SATR-W-2009 for Report Form (Calibration)

E) GTAW Tungsten Electrode use, care, restoration (SAIC-W-2049)

F) GTAW Purging Consumables (Gas, Purge Dams) (SAIC-W-2049)

SAIC-W-2049 Attachment 1 covers GTAW Consumables

SAIC-W-2055

D8

Procedure for Buttering and/or Weld Buildup

SAIC-W-2047

D9

Pre-Welding & Fit-Up Inspection (& How WPS is monitored)

Disposition for Repairs - Alignment Tolerances. See Note 3.

SAIC-W-2048

SATR-W-2006

Page 3 of 4

Schedule Q,

Attachment VI,

Special Process

Tables

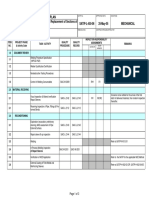

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of WPS & Process Control Procedure (Pipelines)

PROJECT TITLE

30-Jun-08

DATE APPROVED

QR NUMBER

SAIC-W-2038

5-Nov-08

WBS / BI / JO NUMBER

D10

In-Process Welding Inspection (Heat Input Measurement)

SAIC-W-2049

D11

Post-Welding Visual Inspection

SAIC-W-2050

SATR-W-2007

D12

Inspection of Weld Repairs (Repair Verification)

SAIC-W-2051

D13

Production Weld & Welder Repair Rate Assessment

SAIC-W-2056

D14

Temperature Tie-In Welding

SAIC-W-2057,

SATR-W-2014

WELD-

CONTRACTOR / SUBCONTRACTOR

Remarks:

NOTES: 1) See Section "C" regarding Existing WPS (whether approved or not). Follow all specifics. Contact CSD on any technical matter

related to Welding. Contact your Project Inspection Representative on any checklist question for Welding. QA/QC Mgr. Action Required!

2) QA/QC Mgr shall ensure a detailed Welding Process Control Procedure per Section D is established. See item D1.

Certain procedure elements (heat input, wps monitoring, associated forms, etc) are also provided as applicable to scope.

3) Alignment Tolerances & Disposition of Repairs shall be addressed during Pipe Stringing. See SAIC-W-2048.

4) Structural steel welding (AWS D1.1 related) on Pipelines shall utilize SAIC-M-2012. See SAIC-M-2012.

ATTACHMENTS: 1 - SAES-W-011/012 WELDING PROCEDURE SPECIFICATION (ATTACHMENT A, PAGES A1, A2, A3, A4, A5)

Attachment 2 - SAES-W-011/012 WELD & LINE DESCRIPTION TABLE (ATTACHMENT B)

Attachment 3 - SAEP-352 Welding Master Set Preparation & Approval (Instructions)

Attachment 4 - NACE RP-0472 Table 2: Process/Filler Material Combinations Exempt from Weld Deposit Hardness Testing

Attachment 5 - WPS PROCEDURE VARIABLES (SAES-W-012, Section 7.4)

Attachment 6 - SAES-W-012 TABLE 4A/4B - PREHEAT TEMPS. VERTICAL DOWN SMAW BUTT WELDS (NOTICE OF ERROR IN SA STDS)

REFERENCE DOCUMENTS: 1. SAES-W-012, Welding Requirements for Pipelines, (31 December 2002)

2. SAEP-352, Welding Procedures Review and Approval, (31 May, 2003)

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 4 of 4

N = NO F = FAILED

You might also like

- Saic W 2003Document14 pagesSaic W 2003Mohammed IlliasuddinNo ratings yet

- SAIC-W-2015 Rev 7 (NDE Selection)Document17 pagesSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Satip Nde LPT 01Document3 pagesSatip Nde LPT 01Durga Jagan PuppalaNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- 1 SATIP-L-350-08 Shop Fab - Piping and Steel Structures-Rev1Document2 pages1 SATIP-L-350-08 Shop Fab - Piping and Steel Structures-Rev1skychurch100% (2)

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldDocument2 pagesWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289No ratings yet

- Saep-352, 01.01.2018 PDFDocument15 pagesSaep-352, 01.01.2018 PDFRami ELLOUMI100% (2)

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SAIC-H-2010 Rev 7Document1 pageSAIC-H-2010 Rev 7Satheesh Rama SamyNo ratings yet

- SatipDocument5 pagesSatipMuhammad Abdul Kadher100% (3)

- Saudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldDocument13 pagesSaudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldAnonymous S9qBDVky100% (1)

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- 1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1Document4 pages1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1JithuJohnNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Satr H 1003Document2 pagesSatr H 1003Thouseef MaNo ratings yet

- Saes L 650Document14 pagesSaes L 650Shawn LeoNo ratings yet

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Document2 pagesSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyNo ratings yet

- SAIC-L-2035 Rev 6Document2 pagesSAIC-L-2035 Rev 6biplabpal2009No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- SAIC-D-2005 Rev 2Document4 pagesSAIC-D-2005 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-A-2003 Rev 0Document3 pagesSAIC-A-2003 Rev 0bluelions_19No ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- SATIP-Q-006-01rev4 (Asphalt Paving - Batch Plant & 3rd Party Lab) PDFDocument3 pagesSATIP-Q-006-01rev4 (Asphalt Paving - Batch Plant & 3rd Party Lab) PDFRamziAhmedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection Checklistabdulgafoor54100% (2)

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument5 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNo ratings yet

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- SAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Document3 pagesSAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Anonymous S9qBDVkyNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- Schedule QDocument36 pagesSchedule QPrabu Baskaran100% (1)

- SAIC-W-2084 Buttering or Build-Up of JointsDocument1 pageSAIC-W-2084 Buttering or Build-Up of Jointskarioke mohaNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument11 pagesSaudi Aramco Typical Inspection PlanAhdal NoushadNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinNo ratings yet

- 1044 Plant Inspection Career Poster March 2015 PDFDocument1 page1044 Plant Inspection Career Poster March 2015 PDFHoque Anamul100% (1)

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection Plankarthi51289No ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Test Report Temperature Tie-In Welding ReportDocument2 pagesSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- SAEP-385 - Oct 2017 PDFDocument66 pagesSAEP-385 - Oct 2017 PDFAllan Lindo0% (1)

- Saep 1160Document13 pagesSaep 1160Durga Jagan Puppala100% (1)

- SAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionDocument10 pagesSAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionAbdul HannanNo ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalNo ratings yet

- Typical Inspection Plan (TIP) Title: ElectricalDocument2 pagesTypical Inspection Plan (TIP) Title: ElectricalBhaskar PitchikaNo ratings yet

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- Saudi Aramco Inspection ChecklistDocument21 pagesSaudi Aramco Inspection ChecklisthamidjoyiaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Selecting Elastomeric Linings For Storage TanksDocument4 pagesSelecting Elastomeric Linings For Storage TankshamidjoyiaNo ratings yet

- Remittance Results (Receipt) - Money Express: User Name: Hamid ALI AliDocument1 pageRemittance Results (Receipt) - Money Express: User Name: Hamid ALI AlihamidjoyiaNo ratings yet

- API Individual Certification Programs: Hamid AliDocument1 pageAPI Individual Certification Programs: Hamid AlihamidjoyiaNo ratings yet

- SCR: A Practical Method For Requirements SpecificationDocument5 pagesSCR: A Practical Method For Requirements SpecificationhamidjoyiaNo ratings yet

- RWP - SievertDocument2 pagesRWP - SieverthamidjoyiaNo ratings yet

- Tag Grinder AngleDocument1 pageTag Grinder AnglehamidjoyiaNo ratings yet

- Information Regarding Equivalence of Deeni AsnadDocument2 pagesInformation Regarding Equivalence of Deeni AsnadhamidjoyiaNo ratings yet

- Agriculture ChemistryDocument53 pagesAgriculture ChemistryhamidjoyiaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument21 pagesSaudi Aramco Inspection ChecklisthamidjoyiaNo ratings yet

- B. Tech. Regulations: (Applicable For Batches Joined in 2004 and Onwards)Document12 pagesB. Tech. Regulations: (Applicable For Batches Joined in 2004 and Onwards)hamidjoyiaNo ratings yet

- API 510 Exam CDocument14 pagesAPI 510 Exam ChamidjoyiaNo ratings yet

- API 510 Pressure Vessel Inspector Preparatory Course Final Exam - Open Book Answer SheetDocument1 pageAPI 510 Pressure Vessel Inspector Preparatory Course Final Exam - Open Book Answer SheethamidjoyiaNo ratings yet

- Mce Gulf Contracting Co. Welder Performance QualificationDocument2 pagesMce Gulf Contracting Co. Welder Performance QualificationhamidjoyiaNo ratings yet

- Mce Gulf Contracting Co. Welder Performance QualificationDocument2 pagesMce Gulf Contracting Co. Welder Performance QualificationhamidjoyiaNo ratings yet

- API 510 Pressure Vessel Inspector Preparatory Course Final Exam - Closed Book Answer SheetDocument1 pageAPI 510 Pressure Vessel Inspector Preparatory Course Final Exam - Closed Book Answer SheethamidjoyiaNo ratings yet

- Mce Gulf Contracting Co. Welder Performance QualificationDocument2 pagesMce Gulf Contracting Co. Welder Performance QualificationhamidjoyiaNo ratings yet

- Coating Format SABICDocument1 pageCoating Format SABIChamidjoyiaNo ratings yet

- CFRD 05 - BayardoDocument23 pagesCFRD 05 - BayardodiegofernandodiazsepNo ratings yet

- 02 February 1990Document108 pages02 February 1990Monitoring TimesNo ratings yet

- KinematicsDocument33 pagesKinematicsErik MagnoNo ratings yet

- Carrier SelectionDocument13 pagesCarrier SelectionRanesh SinglaNo ratings yet

- AdClient SDK For Android 4.3.0 PDFDocument48 pagesAdClient SDK For Android 4.3.0 PDFOscarGomezNo ratings yet

- Fertilizer Industry Wastewater TreatmentDocument1 pageFertilizer Industry Wastewater TreatmentAnmol UpadhyayNo ratings yet

- Topobase Performance and ScalabilityDocument16 pagesTopobase Performance and ScalabilityFernandoKNo ratings yet

- SRI FireFighting Equipments 2012 PDFDocument46 pagesSRI FireFighting Equipments 2012 PDFsullamsNo ratings yet

- BX 3010 (0C)Document362 pagesBX 3010 (0C)Lâm Hồ Ngọc HãnNo ratings yet

- Digital Document Processing and ManagementDocument312 pagesDigital Document Processing and ManagementJuanNo ratings yet

- NSX Battle Card - FinalDocument2 pagesNSX Battle Card - FinalElias Bezulle100% (1)

- Water Filtration System - Method StatementDocument7 pagesWater Filtration System - Method Statementsunil_v575% (4)

- Affidavit of Undertaking - TransferDocument2 pagesAffidavit of Undertaking - TransferGracelyn Enriquez Bellingan100% (2)

- Sony Walkman GuideDocument39 pagesSony Walkman Guideapi-3797085No ratings yet

- Python LAB Exercises: Sample OutputDocument2 pagesPython LAB Exercises: Sample OutputMadhu Priya Guthi100% (1)

- Modeling Complex Zo For Op AmpsDocument28 pagesModeling Complex Zo For Op Ampswalid OUNISNo ratings yet

- TSC 247 PrinterDocument2 pagesTSC 247 Printerr4zorxNo ratings yet

- 11460145-PIB Rev. 01-重型散热器升级包Document5 pages11460145-PIB Rev. 01-重型散热器升级包xlzyydf2015No ratings yet

- References:: 111 Richard Valantine, "Motor Control Electronics Handbook", 1998, ISBN 0-07-066810-8Document30 pagesReferences:: 111 Richard Valantine, "Motor Control Electronics Handbook", 1998, ISBN 0-07-066810-8rajeevNo ratings yet

- 2018 2019 - Seafirst CatalogDocument40 pages2018 2019 - Seafirst CatalogЯрослав БогдановNo ratings yet

- Quectel MC60 at Commands Manual V1.2Document262 pagesQuectel MC60 at Commands Manual V1.2Adimaro MontoyaNo ratings yet

- Difference Between Dictionary Managed Tablespace (DMT) and Locally Managed Tablespace (LMT)Document2 pagesDifference Between Dictionary Managed Tablespace (DMT) and Locally Managed Tablespace (LMT)Rose MaNo ratings yet

- High Voltage Engineering MCQsDocument6 pagesHigh Voltage Engineering MCQsSubrahmanyam Adda50% (2)

- Impact Sprinkler Troubleshooting GuideDocument11 pagesImpact Sprinkler Troubleshooting GuidemuthuvelaaNo ratings yet

- Doosan IR Light SourceDocument2 pagesDoosan IR Light SourceMolie1979No ratings yet

- Quadrature Amplitude ModulationDocument10 pagesQuadrature Amplitude ModulationSafirinaFebryantiNo ratings yet

- Mahila Pay and ParkDocument113 pagesMahila Pay and ParkSaurabh PednekarNo ratings yet

- Exact Solution Tank DrainageDocument8 pagesExact Solution Tank DrainageFelipe CastNo ratings yet

- Outline Spesifikasi BPKPDocument44 pagesOutline Spesifikasi BPKPnadyaNo ratings yet

- Hydrostatic Force On Plane Surfaces: Experiment No. 03Document2 pagesHydrostatic Force On Plane Surfaces: Experiment No. 03ChristopherHiladoNo ratings yet