Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Uploaded by

hamidjoyiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Uploaded by

hamidjoyiaCopyright:

Available Formats

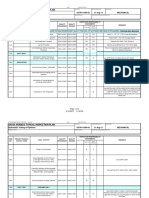

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2012)

Rev 6

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

31-Mar-12

DATE APPROVED

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

Note

1-5

A1

A2

A3

A4

A5

A6

A7

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

1. Contractor informs Company when a Subcontractor (or his own)

fabrication shop (facilities, equipment & associated storage areas) are

ready for Company approval. Notification is prior to start of any

production work per Sch. Q notification (2 weeks minimum).

2. Contractor

Quality uses this checklist & any of his own before Company Inspection

audits new shops for SA SHOP APPROVAL.

3.

"Shop" is an indoor/outddor fabrication facility approved by SA Inspection

(SAES-W-011, Sect 17.6) that follows standard industry fabrication

practice. 12-SAMSS-007 refers to AWS D1.1. See also standard practice

referenced as Piping Fab Institute (PFI) & others.

4.

Checklist identifies procedures, personnel, facilities, equipment & storage

including necessary controls for quality on SA Projects to assure

successful project start-up meeting quality reqmts.

5. SA can approve new shops in stages with controls in place.

As Listed

Special Process Procedures & Controls (For Shop Start-up)

Special Process Procedures were submitted 30 days prior to the start of

any work (operations) at fab shop as follows:

No

N/A

Comments

Use this guide

on interviewing

Project Quality

QA/QC Mgrs for

Prime

Contractor &

Subcontractor

for quality start

on major

projects

STAGE 1

Sch. Q, Att. V,

Special Process Procedure Revision Approval is received BEFORE

Sch. Q, Att. V,

starting production work (operations) at new shop.

Welding Engineer (Contractor) is available for WPS package

review/approval before "30 days Prior" submission deadline

SA Approved Engineer is at site (6-8 weeks before

SCH. Q, Att. VI,

shop kick-off)

Table 2

Engineer can expedite WPS revisions that

avoid work

start delay.

Welding

Procedures

Package (WPS) per SAES-W-011 Sect 7. A) Piping

WPS packages were submitted 30 days before work.

CSD has returned Status 1 or Status 2 cover sheets for all WPS

Complete list

of WPS is available in timely manner (no work delays)

Sch. Q, Att. V, &

B) Structural procedure package to Project Inspection early

IV

Use AWS

D1.1 Prequalified welding procedures

Maintain list of procedures/status at site

Welding Special Process Procedures & Controls are revised & approved

(Sch. Q, Att. V, BEFORE work starts):

A) Gap

Control for socket welds (meets code as revised)

B) Seal

welding threads (Meets SAES-L-110 & code as revised)

C) Weld Consummable Control (Store, Issue,

Reuse, Monitor)

D) Welder

Tracking (Qualification, WPS monitoring, retraining, etc)

Sch. Q, Att. V, &

E) Heat input measurement & WPS monitoring

IV

(pipe welding)

F) Pipe weld

repair (weld defect repair, buttering, base metals)

G) Pipe welding related (Bevelling, joint & surface

prep, preheat)

H) Repad

Installation, Bending & Forming (pipe bends, ovality)

i) Structural Welding related (splicing, weld

repair, prep, etc)

Welding Procedure Qualifications (for new shops):

A) Procedure Qualification Records (PQRs) are

prepared/submitted on SA Forms (Attachment A).

B) Weld and Line Designation Table

("Weld Table") is submitted along with PQR documents (Attachment B) &

provides a listing of materials, thickness, & weld joint types (individual

SCH. Q, Att. IV,

line designation).

C) Hardness Testing is per SASD AB036386 (mandatory)

D) Ferrite measurements per AWS

A4.2 (as applicable).

E) Weld maps & tables

are detailed & attached

F)

Originals of all test records, mill certs, etc., are available to SA.

Never assume CSD previously approved WPS are valid. Check Weld &

Line Description Table details:

A) Verify that service considerations are identical

B) ORIGINAL CSD Cover Sheet listing status/restrictions is

available

C) Groove Weld procedures do not cover socket

welds & fillets

Additional sketch or clear field

instruction notes for QC & welders is needed for socket & fillet welds

(size, # passes,etc)

Yes

SAES-W-011,

Section 7

Page 1 of 21

CSD has the

six-week policy

on WPS returns

As Applicable

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

A8

WPS Drawing Details (CSD common revisions):

A) Branch Connection Drawings are detailed to show

applications

B) Weld size & prep depth shown

(Drawings/Notes). Round up mm.

C) Single V-Groove

Drawings reflect the following Notes:

Maximum value for t

Maximum weld metal deposit value (GTAW, SMAW, etc)

D) Fillet Weld Notes provide clear instruction to

Sch. Q, Att. IV

welders & QC:

Minimum size (full fillet) or a min for seal welds/shims

Detail/note integral acute angle attachments (dummy leg, bracing)

E) Socket Weld Notes provide clear instruction to welders & QC:

Minimum number of passes (2), fillet size, shape, contour

F) Seal Weld Notes provide clear instruction to

welders & QC:

Process, sequence, shape, "no exposed threads" & NDT (MT/PT)

Ensure documents are not returned unapproved by CSD

A9

WPS Miscellaneous details (CSD common revisions):

A) SMAW & GTAW diameter limits

per SAES-W-011 are correct

B) Back purge rate

notes (O2 level below 1% verified by analyzer)

C) Galvanize welding

(sch. 80+) has special prep & test procedure.

D) Heat input limit

range calcs are closely checked & correct

E) ER70S6 is not utilized (GTAW). Use ER-70S-2, 3 (NACE matl's).

Sch. Q, Att IV

F) E-7018-1 (increased manganese) is specified for SMAW welds

when Low Temperature applications are required at the Fab Shop.

G) PQR Hardness Values do

not exceed 200 BHN (NACE WPS)

H) Travel speed RANGES

are specified. Maximum Oscillations (3 x wire diameter) are verified to be

within correct range (travel speed)

i) Preheat Tables provide

clear field instruction (SAES-W-011, etc)

A10

Check WPS Weld & Line Description Table for misc. details:

A) Identify lines that require Charpy

Impact, PHWT & BHT (values)

B) Cement lined

pipe welding requires special CSD considerations

C) Base

metal thickness range requires backing (butts below 1/8")

D) 100% PT & RT for GTAW butt welds below 1/8 or 3.2mm

E) A separate procedure requiring surface

preparation details and coating repair must be submitted for welding

galvanized piping.

F) Piping class

12LE0U1 (FBE-lined piping) requires similar treatment

A11

NDT/NDE Technique procedures have been Dhahran approved

Cover letter approval from NDTU Dhahran has been

received

Revision requests and changes

from NDTU Dhahran are complete

A12

A13

A14

Equipment & Set-up (See SAES-H-100 Checklists A,

B, C, D)

Location (Site) & Operations must be

approved by Saudi Aramco

Coating

crews (blaster, painter, & supervisor) have SA cards.

Heat Treatment Procedure & Equipment Package is CSD approved

(similar to Welding per SAES-W-011, Section 13):

Cover letter approval from CSD has been received

Revision request/changes from CSD have been

A15

No

N/A

Comments

SAES-W-011,

Section 7

Sch. Q, Att.IV,

NDT/NDE CONTROL procedures are issued and clear for all

NDT controls by prime contractor assure adequate

supervison

Critical elements in

Control procedure maintain NDT integrity

Guide

Sch. Q, Att. IV,

for PID Review (NDT CONTROLS)

Know the difference

between NDT "Technique" Procedure & and NDT "Control" Procedure.

Control is mandated by Q.

PMI procedures & Equipment (Package) is CSD approved

Equipment for testing is at site or readily available

Material

receiving checks & system of testing identification known

Coating Package (application/procedures) has been approved

Yes

Sch. Q, Att. IV,

Sch. Q, Att. IV,

Sch. Q, Att. IV,

addressed

CSD has returned Status 1 or Status 2

cover sheets for WPS

Page 2 of 21

Attachment 1

Guide for

approval of NDT

control

Procedures

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

Heat Treatment (associated process) requirements:

A) Prior to work (2 wks), contractor or

fabricator prepares a table listing each joint or component for heat

treatment (to SA Inspection)

B) Table (each

joint or component) has location, dwg number, size, wall thickness,

material, heating rate, cooling rate, soak temp/time.

A16

C) Brinnell Hardness Test procedure is NACE RP 0472,

App. A

Brinnell

Equipment Kit is available at site for testing

Contractor has good supply of "Certified" test bars (194, 200+)

Contractor has certificates available for hardness testing

bars.

B

Welder Qualification Testing

(Welding Equipment Set-up & Welding Consummables)

B1

Prior to welder qualifications, Shop Controls are established for welder

WPS monitoring (heat input measurement & hardness tests),

consumables, documentation & test materials.

B2

B4

N/A

Comments

STAGE 2

Welder Testing (Procedures & Controls) are approved:

A) An independent 3rd party (SA approved)

has been selected

B) Company is notified prior to any

testing.

C) Test

Facilities are available at the Shop (to be approved).

D) Equipment meets SA standard requirements (CS, alloy & SS)

Sch. Q, Att. IV,

SAES-W-011,

Section 7

Machine spacing & clearances (layout) is adequate and safe.

Routing of cables & controls does not present safety

Contract Based

hazards.

Ventillation & air supply is adequate

Safety

for testing/training.

Requirement

Grounding tests (equipment is well grounded) are performed

Schedule A, B,

Electrical system & controls have been tested & are

et al

properly rated

Training/Testing

areas have proper test stands and work support

Covers (to prevent arc flash) are in

place for personnel protection

Welders are considered competent, qualified through practice & trained

in WPS & SA requirements by QC in place before testing by approved

3rd Party. (Identify experienced welders with JCC cards)

SAES-W-011,

Section 7.2.5 a

Welding Procedure Controls for Low Temp Applications:

Initial welding (first ten, etc) is monitored

(calibrated tong testers).

Best welders selected (Consistently meet Heat Input & Hardness)

B5

No

SAES-W-011,

Section 13 & 14

Welder Testing Facility is first approved (Safety, Electrical):

B3

Yes

Sch. Q, Att. IV

Contractor use of E7018-1 (SMAW fill & cap) is strictly

assured.

PMI can distinguish higher

manganese content in E-7018-1

Welders with

marginal heat input results are reassigned.

B6

Welding on NACE material is performed as follows:

A) Welders are NACE experienced & familiar with NACE WPS

B) Welders meet NACE WPS

NACE Standard

Heat Input & hardness values.

MR0175

C) NACE welders are listed on a roster & on SA JCCs.

D) CS Welders demonstrate NACE ability through

Section 5.3

daily monitoring.

E) Shops start early monitoring of Heat

Input during training & testing to qualify any welders for NACE welding &

Low Temp applications.

B7

Work stations for each welder are checked as follows:

A) There are a sufficient number of uncrowded work stations.

B) Stations are level & capably support

fabricated components.

C) Sufficient

shielding protection exists for welder work stations.

ANSI Z49.1,

Annex J

B8

Welder training & testing areas are segregated or in a separate area

where approved welders with JCCs perform shop work.

SAEP-323,

Section 6

B9

Welding machines for each work station have current calibration

B10

Welding power supplies were calibrated per British Standard 7570 when

impact toughness tests are required (SA, spec or code)

Sch. Q,

Section 3

SAES-W-011,

Section 19

Page 3 of 21

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

B11

Welding machines (singular or banked) have sufficient spacing and

ventilation to dissipate heat.

ANSI Z49.1,

Annex J

B12

Welding machine leads are in good condition & are fed to each work

location as follows:

A) Organized & safely secured (tie wraps) overhead routing exist

B) Laid out & properly

covered in walkways for access/egress

C) Method of lay out is an orderly fashion that prevents tripping.

D) Lead routing through heavy equipment (forklift,

crane, etc) area is between 2x4's or under inverted channels to prevent

damage.

ANSI Z49.1,

Annex J

B13

Gas cylinders at welder stations are properly secured with quality hoses

and fittings rated for use in GTAW set-ups (rigs).

ANSI Z49.1,

Annex J

B14

Each welder is supplied with the following at his work station.

Weld rigs (leak tested & good), Standard, Gas Lens, Mini Rig, etc...

Gloves, Helmet, Vest

Proper weld lenses, (shaded, clear,& cheaters)

Portable weld rod oven (calibrated)

Weld gages or gages are available

Grinder, File, Chipping Hammer / Hammer

Vise or Vises (work station)

Level, T square, Measuring Tape

Adequate lighting (fixed, portable, mini-lights for root pass check)

O2 detector is available for TIG welders

Calibrated Digital Pyrometer is available

Supports, guides or stands as needed for pipe or structural item.

ANSI Z87.1 &

ANSI Z49.1,

Annex J

B15

Welding Facilities (Environmental Shielding) provides adequate

protection from elements of wind, sand & rain:

A) Condition of the roof is good (no holes, missing panels, etc)

B) Doors for closure are available

and function properly

C) Partitions

are installed & properly oriented for environment.

D)

Wind Shields or tents are available in adequate numbers

SAES-W-011,

Section 11.2

B16

Welding equipment set-up & testing is complete:

A)

Maintenance, testing & monitoring records are available.

B) Machines have a unique ID number

C) Machines have leads and

connections secured (as calibrated). D) Machines are properly grounded

(tested & passed per results)

E) Current Calibration sticker (checked with calibrated tong tester)

F) Machine

Controls function properly & current values are legible

G) Special GTAW equipment is available (Corrosion-Resistant Mat'l) H)

Electrical supply & outlets are adequate & safely installed.

Sch. Q, Att. IV,

Section 4

B17

Welding Electrode & Consummable Storage:

A) Climate controlled storage area is clean & free of dust & moisture

B) Area is secured and has counters to control access

C) Consummable Control

personnel (issue) are available & trained

SAES-W-011,

Attachment 1 & 2

B18

Drying, Storage & Portable ovens are operable with calibrated controls

(temperature gauge) per SAES-W-001 Table 1 Ranges. SAES-W-011,

Table 1 requirements are posted near ovens.

SAES-W-011,

Attachment 1 & 2

B19

Calibrated weld rod holding ovens are set up & controlled:

Initial baking

Re-conditioning

Weld rod oven interior map indicates weld rod type & location

Weld rod oven interior map indicates weld rod

status (final issue).

Logs, issue slips, rod receipt

records, bake records, etc, exist.

SAES-W-011,

Attachment 1 & 2

B20

Pressurized gas cylinder (consumable) storage:

A) Designated area exists for storage of cylinders

B) Segregation (marking & identification) exists in

storage area.

C) Warning signage exists for this

area (No smoking, cautions, etc)

D) Storage area is on level

concrete surface with bottles upright.

E) Storage

area can be locked & secured to prevent access.

F)

Locks & chains are available for cylinder storage areas.

G) Tags (certs) are attached to cylinders (from approved

sources)

H) Records of receipt & documentation (log)

kept on all cylinders

AWS Z49.1,

Annex J

Page 4 of 21

Yes

No

N/A

Comments

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

B21

Shop has welding equipment (& tool) maintenance & repair ability.

Alternately, Maintenance company performs repairs.

AWS Z49.1,

Annex J

B22

Shop has a Tungsten grinder (diamond cutting/grinding/shaping) &

follows quality GTAW equipment & consumable handling practices.

Procedures cover specific practice ... See Also SAIC-W-2006

AWS C5.5,

Section 6

Yes

No

N/A

Comments

Manpower Reqmts (Quantity & Qualifications) Note: Task all inspectors with reqd reading (SATIPs). Tests after required

reading are given by discipline with a goal for Process Improvement (SA System Training/Orientation)

C1

Construction Manpower Forecast (start-up & peak) showing total

numbers (welders, fitters, helpers, etc) is available.

Schedule Q,

Sec- VI Table 2

C2

QC MANPOWER FORECAST (start-up & peak) showing total number of

inspectors, engineers & supervisors is available.

Schedule Q,

Sec- VI Table 2

QC Manpower meets Construction manpower ratios.

Schedule Q,

Sec- VI Table 2

C4

CV-approved Quality personnel arrive early* (10-days before work) for

job training & any testing requested by Saudi Aramco.

Schedule Q,

Sec- VI Table 2

C5

Quality Personnel experience minimum requirements (Contractors or

subcontractors that perform the work) per Sch. Q:

A) Have 10 years of industrial experience minimum (Age 27)

B) Have 6 years experience in a given

inspection specialty

C) Have 4 years

(of 6 years) in Oil & Gas (petrochemical) industry

D) High School graduate, or equivalent

E) Fully conversant with

applicable Industry Standards & Specs

F) Can perform inspection functions with minimal supervision.

G) Can pass a SA interview

& testing when requested by Company

SCH. Q, Att. I,

Qualification

Requirements

C6

Welding/Mechanical Inspectors:

A) Certified as a CWI, CSWIP Certified Welding

Inspector.

B)

Knows codes (ASME B31.3, 31.4 & 31.8, ASME V and IX, API 620 & 650,

AWS D1.1, required for the execution of the WORK.

C) Can monitor NDT work & results

D) Qualified ASNT Level II (relevant methods) when

performing, viewing, ensuring or auditing NDT specific method(s).

E) Pass interview & test given to welding QC

(knows workmanship, code undercut, WPS, socket weld specific reqmts

& references, understands service implications and RELATED

SPECIFICATIONS)

SCH. Q, Att- I

HAVE ALL

WELDING QC

TAKE TEST

C7

Heat Treatment Inspector:

A) Five years work experience (heat treatment tech or

supervisor) B) Knows heat treatment methods/equipment used on

projects

C) Knows requirements of

ASME B31.3 code & passes SA test

SCH. Q, Att- I

HAVE ALL

PWHT QC

TAKE TEST

C8

Coating Inspector: Inspector demonstrates a thorough working

knowledge & proven ability in critical coating applications/methods &

recognized industry standards. Inspector is qualified to NACE Level II

Critical Coatings Certification, CSWIP Level I, or equivalent.

INSPECTOR DEMONSTRATES ORGANIZATION & PROFICIENCY IN

SAES-H-100 ATTACHMENTS A, B, C, D for SA INSPECTION

SCH. Q, Att- I

HAVE ALL

COATING QC

TAKE TEST

C9

All IK CONTRACTOR & subcontractor NDT personnel performing NDT

operations, or interpreting, reviewing, ensuring or auditing NDT

operations meet SA requirements of SAEP-1142 & hold current NDT

certifications. Also, RTFI Personnel must be certified by SA.

NDT Personnel are monitored at start of work (Issue RFI).

SCH. Q, Att- I

NDT TECHS

Demonstrate

Competency in

the field

MONITOR initial

work closely

SCH. Q, Att- I

Dedicated solely

for QA Mgr

duties & Quality

Concerns

C3

Quality Assurance Manager is approved:

A) Has demonstrated knowledge & training (ISO9000 int'l stds)

B) Has a university

degree or equivalent

C) Has a minimum of 10 years of direct experience in QA system

activities in the oil, gas and petrochemical industries.

D) Is willing to address Quality & Continuing Process

C10

Improvements as required by approved Quality Plan to SA customer

satisfaction

E) Understands the entire workscope for

which he is responsible

F) Passes day-long

interview & test (as needed) for new QA Mgr. Note: Interview of Prime QA

Mgr & Subcontractor QC Managers together recommended to see how

they interact as a team and respond to SA expectations. Utilize this

checklist on interview/test.

Page 5 of 21

STAGE 2

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

REQUESTED INSPECTION DATE

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

C11

Quality Control Manager is approved:

A) Has demonstrated knowledge & training in the use

of measuring and test equipment routinely used in conducting

inspections.

B) Has university degree &

7 years inspection experience OR

C) Has HS diploma with 10 years inspection experience

related to supervision of construction activities (Oil, gas & petrochemical)

SCH. Q, Att- I

Other Duties do

not conflict with

QC Mgr duties

SCH. Q, Att VI,

HAVE ALL PMI

TECHS

TESTED

SCH. Q, Att- I

HAVE ALL

CRANE

INSPECTORS

TASKED TO

READ

PMI technician & PMI procedures are available.

A) PMI technician is qualified & certified as an ASNT

RT Level I

B) Has at least one year

experience in using PMI instruments.

C) Has passed a SA demonstration test with an approved PMI

C12

instrument on an alloy sample with 100% correct assessment.

D) PMI Technician works to an approved written procedure.

E) PMI technician has documented training (instrument &

procedure)

Approved by COMPANY (demonstration test performance)

Crane Inspector (demonstrates thorough working knowledge of

codes such as ANSI-A17.1 & 17.2, ANSI-B30.1 through B30.16) for

certification of cranes in newly constructed shops as follows:

A)

C13 Concrete structural foundation inspections are performed

B) Calculations for foundation & anchoring are

available to SA

C) Certs documenting Crane

capacity & construction are required

Crane

Inspectors are available for work & tasked to read

C14

Adequate supervision is available for the quantity of shop workers for all

shifts.

No

N/A

Comments

Schedule Q,

Sec- VI Table 2

Schedule Q,

Sec- VI Table 2

C15 Adequate QC works Full Time while work is in progress.

C16

Yes

No Conflicts of Interest exist regarding personnel, NDT Companies, Third

Schedule A,

Party Inspection agency personnel & Contracted Inspection personnel

Section 20

performing the work.

& Sch. Q

Personnel from other projects have approval/release letter.

Shop Layout & Location of Facilities

STAGE 2

D1

Shop/Yard Layout Map is available during walkdown & review.

PFI-ES-43,

Section 1

Environmental

controls

D2

Shop/Yard Layout is based on quality engineering controls & considers

prevailing winds, dust movement & contamination.

PFI-ES-43,

Section 1

Environmental

controls

D3

Segregated & enclosed area installations are complete.

PFI-ES-43,

Section 1

Environmental

controls

D4

Valve Testing Facility is upwind of CS dust & contaminants, enclosed &

shielded from the elements (fouling & contamination).

PFI-ES-43,

Section 1

Environmental

controls

SS & alloy work areas are located upwind of all CS work areas.

PFI-ES-43,

Section 3.6

Environmental

controls

Coating operation is downwind or isolated, enclosed & shielded.

PFI-ES-43,

Section 3.6

Environmental

controls

SAES-W-011,

Section 13

Environmental

controls

SAEP-1141,

Section 1

Environmental

controls

D5

D6

D7

PWHT facility or area is segregated, barricaded, accessible, well

ventillated, with adequate supports & weather protection for work.

D8

Radiography set-up per SAEP-1141 (Industrial Radiation Safety):

A) Shop is prepared for NDT Unit Dhahran SAEP-1141

Safety Audit

B) Copy of Radiation Safety

Manual (SAEP-1141) is available

C)

Radiography location is isolated (2mr boundaries, barricades).

D) Equipment storage areas are approved, locked

and secured

E) Transportation &

Handling Safety measures are known

D9

Storage yard is of adequate size to accommodate the types of materials

expected to be received during the course of the project.

Sch. Q, Att. IV,

D10

Storage yard organization allows easy material access & flow (for proper

movement & handling) during the course of the project.

Sch. Q, Att. IV,

D11

Preservation & Special Storage requirements are known and adequate

space exists with carefully planned material organization.

Sch. Q, Att. IV,

D12

Quarantine Areas are established (includes a tagging system) for reject

materials. Fence or other marked boundary is in place.

Sch. Q, Att. IV,

Page 6 of 21

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

D13

E

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

OFFICE SPACE clearly designated for Company & Contractor is

available. Facilities for SA work access are per the contract.

Electrical Inspection & Safety (Access/Egress & Equipment)

Contract Safety

Requirement

E2

Shop has sufficient electrical outlets (support for workstations).

Contract Safety

Requirement

E3

Electrical outlets & extension cords have GFIs & dust covers.

Contract Safety

Requirement

E4

Electrical power feeds (j-boxes, power, lighting, etc) are installed.

Contract Safety

Requirement

E5

Terminals for weld leads & power cables are shielded from contact by

personnel or by metal objects (vehicles, cranes, etc).

ANSI Z49.1,

Annex J

E6

Welding Connections between welding leads & power supples are

guarded by one of the following methods:

A) Dead front construction and receptacles for plug

connections

B) Terminals located in a cover

C) Insulating sleeves

D) Other

equivalent mechanical means.

ANSI Z49.1,

Annex J

Welding Grounds are inspected/tested & in good condition.

ANSI Z49.1,

Annex J

The workpiece being welded & the frame or chassis of all electrically

powered machines is connected to a good ground.

ANSI Z49.1,

Annex J

E9

Grounding is done by locating the workpiece or machine on a grounded

metal floor or platen, or by connecting it to a properly grounded building

frame or other satisfactory ground.

ANSI Z49.1,

Annex J

E10

Chains, wire ropes, cranes, hoists, etc are not be used as grounding

connectors or to carry welding current.

ANSI Z49.1,

Annex J

E11

The workpiece lead is not the grounding lead. The workpiece lead

connects the work terminal on the power source to the workpiece.

ANSI Z49.1,

Annex J

E12

A separate lead is required to ground the workpiece or power source

work terminal.

ANSI Z49.1,

Annex J

E13

The welding current magnitude is safely carried by the grounding

conductor (not overloaded, hot).

ANSI Z49.1,

Annex J

E14

Areas are clear of tripping hazards. Lay out of production areas

for gas hoses, cables, mechanical assemblies, and other equipment do

not cross walkways or interfere with routine tasks.

AWS Z49.1,

Annex J

E15

Work above ground or floor level has safety rails or lines to prevent falls.

Safety lines & harnesses are available for fall protection.

AWS Z49.1,

Annex J

E16

Fire and explosion escape routes are identified and kept clear so that

orderly, rapid, and safe evacuation of an area can take place.

AWS Z49.1,

Annex J

E17

Equipment, machines, cables, hoses & other apparatus are placed to

prevent hazards to personnel in passageways. (ladders, stairs).

AWS Z49.1,

Annex J

E18

Warning signs are posted to designate welding areas & they specify that

eye protection must be worn.

AWS Z49.1,

Annex J

E19

E20

N/A

Comments

Identify Hazards

Shop has adequate lighting (fixed overhead & portable lights).

E8

No

Sch. Q, Att. IV,

E1

E7

Yes

Protective screens exist for persons in areas adjacen to welding & cutting

operations to protect them from radiant energy & hot spatter:

A) Flame-resistant screens or shields

B) Suitable eye and face protection and protective

clothing.

C) Appropriate radiation protective

semi-transparent materials

Combustible control in welding areas is handled as follows:

A) Combustibles are stored away or

shielded from welding/cutting.

B)

Combustible floors, roofs, partitions are not found in weld areas.

C) Building contents

including trash, wood, paper, textiles, plastics and chemicals are kept

away from welding areas

D)

Flammable gases and liquids are kept away from welding areas.

E) Outdoors, dry grass & brush are kept away from

welding areas.

AWS Z49.1,

Annex J

AWS Z49.1,

Annex J

Page 7 of 21

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

E21

Excessive noise, particularly continuous noise at high levels that can

damage hearing is identified & warning signs/zones exist.

AWS Z49.1,

Annex J

E22

Machinery Guards are available to protect welders & other workers from

injury by machinery & equipment being operated.

A) Moving components & drive belts are covered by guards to

prevent physical contact. (especially grinders)

B) Workers are protected against

accidental entry into the working envelope of all machinery and robotic

equipment.

C) Because welding

helmets and dark filter lenses restrict visibility of welders, special

attention is required for these hazards.

AWS Z49.1,

Annex J

E23

Persons do not consume food in work areas where toxic fumes are

generated to avoid ingestion of contaminants. Lunch areas are

designated and wash stations are readily available.

AWS Z49.1,

Annex J

E24

E25

Equipment is installed in clean, dry areas and adequately protected from

dirt and moisture.

EQUIPMENT for use is adequate for the scope of work required.

A) Structural support fabrication areas & equipment

are adequate

B) Structural steel (jigs and cutting

machines) are in good condition.

C) Pipe

rolling method exists for thick segments

D)

Air Compressors are adequate for supply at peak of work.

AWS Z49.1,

Annex J

AWS Z49.1,

Annex J

E26

Shop floors are level, clean and stable for ongoing work.

Contract Safety

Requirement

E27

Shop has adequate ventilation and air movers.

Contract Safety

Requirement

E28

Fire Extinguishers are stationed throughout the work areas

Contract Safety

Requirement

E29

Overhead cranes (existing shops) for lifting have current certification, are

properly rated, & are found in good condition.

Contract Safety

Requirement

E30

CRANE CERTIFICATION for smaller cranes in newly constructed shops

must be documented as follows prior to shop approval:

A)

Concrete structural foundation inspections are performed

B) Calculations for foundation & anchoring are

available to SA

C) Certs documenting Crane

capacity & construction are required

Contract Safety

Requirement

E31

Portable hoist & fork-lifts are rated & in good working condition.

Contract Safety

Requirement

E32

Access & egress pathways for fork-lifts & hoists are sufficient.

Contract Safety

Requirement

E33

Sufficient passage ways exist for personnel exit in an emergency

Contract Safety

Requirement

E34

Lifting components (slings, shackles, wire ropes, etc) are good.

Contract Safety

Requirement

E35

Overhead crane installations have been inspected & load tested.

Contract Safety

Requirement

E36

Storage racks & shelves are level & sufficiently supported

Contract Safety

Requirement

E37

Safety Lanes (for access/egress) are marked in saftey colors such as

yellow & black, etc to identify hazards

Contract Safety

Requirement

E38

Safety Signage & Markings identify hazards (posts, doorways, etc)

Contract Safety

Requirement

E39

Disposal bins (trash cans, metal refuse, plastics, etc) are marked to

identify contents allowed inside them (fire hazard warnings).

Contract Safety

Requirement

E40

Overall housekeeping of the shop is sufficient to prevent a fire.

Contract Safety

Requirement

E41

E42

Paints, coatings & NDT supplies are stored per manufacturer's

recommendations in climate controlled areas out of direct sun.

Cleaning materials & chemical storage as follows:

A) Flammable material storage is away from heat/electrical sources

Storage is per manufacturer's (warning label) data sheet

(MSDS)

B) Cloths & Rags are stored & issued

by Consummable Control

Cloth & rag storage bins have covers that are kept closed.

Used (refuse) Cloth & rag disposal bins are available.

Contract Based

Requirement

Contract Based

Requirement

Page 8 of 21

Yes

No

N/A

Comments

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

E43

Supervisors & workers know protocol in case of emergency

Contract Safety

Requirement

E44

Emergency services (ambulance) is available.

Contract Safety

Requirement

E45

Precautionary labels on consumables & equipment concerning the safe

use of the products are available for reading & guidance.

Contract Safety

Requirement

Austenitic Stainless Steel & Nickel Alloy Shops

PID Guide

F1

Stainless Steel & Nickel Alloy Shops address material Handling &

Storage, Fabrication & Shipping per Piping Fabrication Institute (PFI)

Standard ES-43.

PFI-ES-43,

Section 1

F2

Stainless Steel & Nickel Alloy Shops are safely & properly ventillated

(ANSI Z49.1). Adequate air movers lift toxic fumes.

PFI-ES-43,

Section 1

F3

Handle Austenitic stainless steel & nickel alloys with nylon slings or

equipment protected with a non-contaminating buffer mat'l.

PFI-ES-43,

Section 2.1

F4

Receive these alloys and conduct a visual exam of both internal &

external surfaces to detect existing contamination or gouges caused by

contact with contaminating material.

PFI-ES-43,

Section 2.2

F5

Fittings are stored on pallets or shelving that is constructed of noncontaminating material.

PFI-ES-43,

Section 2.3

F6

Storage areas for these materials are separate from the areas where

carbon steel material is stored.

PFI-ES-43,

Section 2.4

F7

SS material stored outdoors is covered with water repellent sheet.

PFI-ES-43,

Section 2.5

F8

Carbon steel strapping is used if a durable, non-contaminating material

(clean wood, cardboard, cloth, paper & SS buffer) isolates the strapping

from contact with the stainless steel or nickel alloy.

Gray duct tape (high chlorides) is absolutely prohibited

PFI-ES-43,

Section 2.6

F9

Walking on austenitic SS or nickel alloy material is not allowed.

PFI-ES-43,

Section 2.7

F10

Fabrication requirements (austenitic stainless steel or nickel alloy): A)

Contact surfaces of tools & equipment containing CS, zinc, copper or

their alloys are covered in a noncontaminating material.

PFI-ES-43,

Section 3.1

F11

Tools such as grinding wheels & wire brushes previously used on carbon

steel are not used on stainless steel or nickel alloys.

PFI-ES-43,

Section 3.2

F12

Grinding discs, abrasive discs & belts are made of resin-bonded alumina,

silicon carbide or zirconium carbide. (No Sulphurized items)

PFI-ES-43,

Section 3.3

F13

Only 300 series SS brushes are used on austenitic & nickel alloys.

PFI-ES-43,

Section 3.4

F14

All material removal & cleaning tools are marked to identify that they are

to be used on austenitic & nickel alloy materials only.

Marking is visible while a tool is in use. (Purple color code)

PFI-ES-43,

Section 3.5

F15

Austenitic & nickel alloy material fabrication areas are separated from CS

areas (upwind to prevent cross contamination).

PFI-ES-43,

Section 3.6

F16

Suitable methods prevent cross contamination by CS shavings, grinding

dust, & zinc dust from coating operations as follows:

A) Enclosure, separation & location of work areas is adequate

B) Engineering controls & ventillation

assure cleanliness & safety

PFI-ES-43,

Section 3.6

F17

Where tape is used for back purging, the tape uses an adhesive with a

water soluble chloride content not exceeding 50 ppm.

PFI-ES-43,

Section 3.7

F18

Pressure-sensitive & adhesive-backed tapes removed (along with any

residual adhesive) utilize a suitable solvent or abrasive.

PFI-ES-43,

Section 3.8

F19

Cutting fluids or oils are low halogen, low sulphur & are completely

removed from all surfaces prior to any welding or forming.

PFI-ES-43,

Section 3.9

F20

Shipping of materials utilizes new packing materials & shipping protectors

such as PVC caps, plugs, & new adhesive tapes. No harmful substances

are utilized in shipping.

PFI-ES-43,

Section 4.1

F21

Certified chloride-free marking or color coding has a water soluble

chloride content below 50 ppm (measured after drying).

PFI-ES-43,

Section 4.2

Page 9 of 21

Yes

No

N/A

Comments

Approve SS

Shop

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

F22

Identification tags & Attachment devices used are made of

noncontaminating materials.

PFI-ES-43,

Section 4.3

F23

Austenitic stainless steel & nickel alloys are shipped in a manner that will

minimize the risk of the material becoming contaminated.

PFI-ES-43,

Section 4.4

F24

Shipping alloys on same load as CS material ensures segregation

through use of wood bracing or other non-contaminating material.

PFI-ES-43,

Section 4.4

Yes

No

N/A

Comments

Equipment for Corrosion-resistant Material Welding such as austenitic

stainless steel (excluding types 304/304L/316/316L), or nickel-based

alloys meets these specific requirements:

F25

G1

A) All manual GTAW uses a high frequency start & post-purge gas flow

for the torch.

B) A remote contractor & current control (pedal or

torch mounted).

C) Pre-set

power source current start/rise and decay/stop controls triggered by a

foot switch or torch mounted control is an acceptable alternative for the

remote control.

D) O2

Analyzers & proprietary dissolvable (water soluble) dams

SAES-W-016,

Section 6

NACE & NACE Low-Temp Material Shops

NACE Material Fabrication shops are segregated from other CS.

NACE MR0175,

Section 1

G2

G3

G4

NACE Material Fabrication for NACE varieties are segregated from each

other (NACE CS, NACE Low Temp CS, NACE alloy & SS).

NACE MR0175,

Section 1

NACE Material ID is by low stress stamp & unique color-code. Segments NACE MR0175,

are stamped before cutting.

Section 1

NACE Material storage is segregated by color code. (NACE CS, NACE

Low Temp CS, etc). NACE varieties are not mixed together.

NACE MR0175,

Section 1

G5

Careful Handling of NACE materials does not create susceptibility to

Stress Corrosion Cracking in finished welds as follows:

A) Heavy

hammering is never allowed on NACE materials.

B) Identification

stamps use low-stress stamps.

NACE MR0175,

Section 1

Field & Yard Welding (Outside of a Shop)

H1

SA Inspection approves indoor facilities (shops). Welding outdoors at a

Shop facility in a yard is considered Field welding, & subject to increased

NDE extent per SAES-W-011 as applicable:

A)

Low Temp (-18C MDT) applications outdoors receive 100% NDE

B) Alloy steel (P-No. 4 & above), stainless, &

nonferrous materials (all services except Cat. D fluids) welded outdoors

are 100% NDE.

C) Severe Cycle (Cat. M) shall be

identified (100% NDE, 0 undercut)

Follow SAES-W-011

Guideline carefully based on NDT Specs

Create SPECCHECK as a field surveillance & review tool

SAES-W-011,

Section 17.5

H2

Work stations located outside of a Shop in a Yard:

A) The areas for work are properly identified as work stations.

B) Stations are level & capably support

fabricated components.

C) Sufficient

shielding & weather protection exists for stations.

D) Adequate power & remote welding controls exist for stations.

Additional NDE is required for Yard Welding

Operations.

SAES-W-011,

Section 17.5

H3

Remote Current Control use (field welding) is available for welding more

than 30 meters from power source (remote locations)

SAES-W-011,

Section 19

Procedures, Documentation & Records

Quality Plan &

Sch Q reqmt

Control of Work

I1

Approved procedures (required by Sch. Q) are available and understood

by the workers and QC.

QP

Provide

Instructions

I2

Approved WPS are posted in multiple conspicuous work areas.

QP

Provide

Instructions

Page 10 of 21

Develop &

Utilize SpecCheck ASAP on

Projects

Attachment 2

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

Yes

No

N/A

Comments

I3

Current AFC/ IFC drawings are issued & available for work

QP

Provide

Instructions

I4

Controlled record storage, i.e. offices, file cabinets, etc, is adequate

QP

Document

Quality

I5

Computer availability for record storage and back-up is adequate.

QP

Document

Quality

I6

Contractor has a filing system for the following:

Calibration records

Material receipt records, CMTRs, Mill certs, valve reports, etc

Consumables & records

Welder certs

Drawing register

Construction forms & records (spools, materials, coating, etc)

QP

Document

Quality

I7

Database per SAEP-1160 & SAIC-W-2008 for tracking and status

Weld ID system (Full Pen Butt welds, socket/groove & fillet)

Track weld special process until completion (PWHT, HT, PMI, etc)

Track welder performance

Track modifications (repairs) after

completion

Track Pressure

Tests (SAIC-A-2001 & Procedure detail steps)

SAEP-1160

Document

Quality

Valve Testing Shop

J1

Valve Testing at new shops is approved by SA Proponent as a desirable

location for any field testing prior to line installation.

J2

Proper segregation exists for CS, NACE & SS valve materials.

J3

J4

See Other

Checklist

SAES-L-108,

Section 4 4.7.1

SAES-L-108,

Section 4

An adequate water supply (treated or demin water) exists & meets SA

SAES-A-007 requirements for testing and purity.

Test Equipment is available as follows and does not promote fouling &

contamination of alloy components:

A) Pressure Test manifold rated for work per SAES-A004 reqmts.

B) Pressure hoses rated for the work

C) Water tanks, mixing

apparatus & filling hoses

SAES-L-108,

Section 4

SAES-L-108,

Section 4

SAES-L-108,

Section 4

J5

Procedure for Field Testing of Valves is approved.

J6

Personnel including QC dedicated to Valve receiving inspection & field

testing have experience with valves and have been approved.

SAES-L-108,

Section 4

J7

List of valves to be tested is available before the start of work & meets

SA standards and approved testing procedure.

SAES-L-108,

Section 4

J8

Records, QC form & unique ID numbers will exist for every valve tested.

Valves are traceable to their unique test reports.

SAES-L-108,

Section 4

See other

checklist

Coating Facility

Coating Works QC Set-up meets SAES-H-100 as follows:

A) QC Equipment Kit (SAES-H-100 Attachment A Checklist Items)

K1

B)

QC Equipment Check Sheet (SAES-H-100, Att B) available

C) In-Process Inspection Sheet (SAES-H-100, Att

C) available

D) Paints/Coatings &

Equipment Log (SAES-H-100, Att. D) available

SAES-H-100,

Section 9

K2

Ground is blacktop or marl base that will not allow dust from grade to rise

& stick to wet paint.

SAES-H-100,

Section 9

K3

Protection from the elements (sun, wind blown sand & dust, moisture) is

adequate for coating applications.

SAES-H-100,

Section 8

K4

Overspray protection (within the facility) is adequate & does not affect

other ongoing fabrication work.

PFI-ES-43,

Section 3.6

K5

Coating material storage areas meets SA & manufacturer data sheet

environmental condition requirements.

SAES-H-100,

Section 6

Page 11 of 21

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

K6

SA Inspection approved initial set-up, Qualification report & the field

demonstration & issued JCC cards to applicators.

SAEP-316,

Attachment A, B

K7

Coating Inspector qualification report & Inspector clearance card has

been issued after successful inspection during demonstration.

SAEP-316,

Attachment C, D

L1

L2

Material Handling and Storage

Pipe handling procedure including equipment used for handling is

Company approved and good practice is in effect as follows:

A) Material is not rolled/dropped

off trucks during unloading.

B) Material is stacked

properly to protect pipe and coatings.

C) Slings are nylon or

similar and wire rope slings are not used.

D) Metal hooks are padded to prevent contact damage to

coating

E) Internally coated fittings are handled on the OD only.

F) Bevel protectors

Components

from coatings.

mechanical damage with welding ends

remain intact are

andprotected

don't damage

protected with suitable wood, plastic, or metal covers and all fittings

packaged in steel-banded wooden crates or secured to skids in staging

areas for field use as follows:

A) All fittings (02-SAMSS-005, Section 10)

B) All flanges (02-SAMSS011, Section 10)

Yes

No

N/A

Comments

See other

checklist

SAES-L-450

Section 8

02-SAMSS-005

Section 10

L3

Field facilities for storage/preservation of materials are approved prior to

the start of piping installation as outlined in SAES-L-350 Section 7 and as

follows:

A) On-Plot Material Warehouse and Storage Facilities

B) Field Welding Consumable

Sch Q Attachment

Storage Facilities

IV,

C) Yard Welding Areas/Shops (CS, alloy and SS areas)

D) Spool

Storage areas, Lay Down Yards and staging areas

E) Site Valve Testing Facility, Site

Instrumentation/Testing facility

L4

The minimum amount of temporary support is available and spools are

not laying on the ground. They are supported on wooden cribbing in

approved staging areas. Fittings and valves are covered and stored in

shipping crates or on racks off the ground.

SAES-L-350

Section 7

L5

Stainless steel spools, components and other materials are kept covered

during storage in lay down yards and staging areas.

SAES-L-350

Section 7

System for Plate, Piping & Material Receipt Inspection, Material

Management & Storage

Matl Id &

Traceability

Item in QP or

Procedure

M1

A "System" used for documentation regarding ID & Traceability for spools

& structural assemblies (traceability to CMTRs) exists.

Sch Q, Att - IV

Item in QP or

Procedure

M2

CS Shop Storage areas (inside the shop) are adequate in size for large &

small materials, well marked, organized & segregated.

Sch Q, Att - IV

Item in QP or

Procedure

M3

Storage bins for cut items are marked & organized.

Sch Q, Att - IV

Item in QP or

Procedure

M4

Shop has segregated areas for reject & unusable scrap materials.

Sch Q, Att - IV

Item in QP or

Procedure

M5

Storage areas (inside the shop) are off the ground & adequate wood

(dunnage) or other supporting materials exist.

Sch Q, Att - IV

Item in QP or

Procedure

M6

Quarantine "Tagging System" used to segregate & store reject material

does not invite use of unauthorized/rejected items.

Sch Q, Att - IV

Item in QP or

Procedure

M7

Quarantine "System" Disposal Rules are in effect & disposal schedules

are available (Sch. G rules apply here also).

Sch Q, Att - IV

Item in QP or

Procedure

Matl Id &

Traceability

Item in QP or

Procedure

System for documentation (Spool ID & Traceability)

N1

COMPLETE TRACEABILITY is easily demonstrated for all components

of pipe spools & structural assemblies

Sch Q, Att - IV

Item in QP or

Procedure

N2

Traceability to CMTRs (system) is documented & well organized.

Sch Q, Att - IV

Item in QP or

Procedure

N3

Drawings & Revision Control system in place are organized.

Sch Q, Att - IV

Item in QP or

Procedure

N4

Report Records (sytem) is available for spool ID & traceability

Sch Q, Att - IV

Item in QP or

Procedure

Page 12 of 21

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

Yes

No

N/A

Comments

Sch Q, Att - IV

Item in QP or

Procedure

Data Report Contents provide adequate tracking & information. SAIC-W2008 (DATABASE) & SAIC-A-2001 (PRESSURE TESTS)

SAEP-1160

Item in QP or

Procedure

System for Identification Transfer after cutting

Matl Id &

Traceability

Item in QP or

Procedure

N5

QC forms exist for spool ID & traceability.

N6

O

O1

System (procedure) for transfer of ID BEFORE cutting exists

Sch Q, Att - IV

Item in QP or

Procedure

O2

System for transfer contains Unique Identification Numbers or UINs

Sch Q, Att - IV

Item in QP or

Procedure

O3

System can be followed by those who do not speak or write in English.

Example: Manoj is cutting two small diameter pipe lengths (different

grade CS). Small pieces can easily be mixed, misplaced, dropped or

placed in bins with other materials. Safeguards in place prevent this

occurrence. Identification methods are effective.

Sch Q, Att - IV

Item in QP or

Procedure

O4

Material markings for identification are permanent marks that remain

intact & legible on the material until recorded into QC records.

Sch Q, Att - IV

Item in QP or

Procedure

O5

Color code remains intact after cutting of pieces. System to disposition

missing & faded color coded segments exists.

Sch Q, Att - IV

Item in QP or

Procedure

Matl Id &

Traceability

Item in QP or

Procedure

Sch Q, Att - IV

Items in QP or

Procedure

Sch Q, Att - IV

Items in QP or

Procedure

Sch Q, Att - IV

Items in QP or

Procedure

Sch Q, Att - IV

Items in QP or

Procedure

P

P1

P2

P3

P4

Color Coding Verification Upon Receipt

Disposition rules for missing & faded (unidentifiable or questionable

grade) color coded piping & materials exist.

Quality Control (verification) is always performed upon receipt.

Only Quality Personnel may approve repainting after the following:

Materials have been verified (CMTR & UIN) for distinct color code.

Quality Control documentation & issuance of

NCR against Vendor

Notification

& approval from Saudi Aramco is received

Positive Material Identification verifies composition (alloy, SS

items)

Material Receiving Inspection personnel (quality) are adequately trained

and can identify missing, faded and improper (mixed) color coded items

that arrive on site.

P5

Repainting is done with correct RAL paint per applicable SAMSS

requirement (length & size of striping).

Sch Q, Att - IV

Items in QP or

Procedure

P6

Positive Material Identification (PMI) is witnessed.

Sch Q, Att - IV

Items in QP or

Procedure

System Identification (Pipe Spools, Pipe Lengths, etc)

After Sandblasting & Coating

Matl Id &

Traceability

Item in QP or

Procedure

Q1

System for Identification after sandblasting/coating exists

Sch Q, Att - IV

Items in QP or

Procedure

Q2

System prevents sandblasting removal of UINs (Unique Identification

Numbers) & resulting loss of traceability

Protective tape covering stamp identifcation

adjacent to weld

Marking inside spools with permanent marker (systematic marking)

Application of wire & stamped tags showing spool or segment UIN

Sch Q, Att - IV

Items in QP or

Procedure

Q3

System protects UINs after coating

Remarking restrictions (QC notified) are identified

Stamped tag identification method is employed

Verification of UIN is performed by QC

Sch Q, Att - IV

Items in QP or

Procedure

System Controls for Special Process (NDE, PMI, PWHT, etc)

R1

System of checks & control is in place for materials requiring special

processes (NDE, PMI, PWHT, BHT, etc). Spool Clearance!!!

Sch Q, Att - IV

Items in QP or

Procedure

R2

Personnel are trained & understand this system of control

Sch Q, Att - IV

Items in QP or

Procedure

R3

Identification status through special flagging & marking systems can

physically identify spools & materials:

A) Requiring a special process

B) Completed and accepted special

process

C) Completed and

rejected special process

Sch Q, Att - IV

Items in QP or

Procedure

Page 13 of 21

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

REQUESTED INSPECTION DATE

ITEM

ACCEPTANCE CRITERIA

No. System Documentation & Tracking Records are in place to identify all

material special processes required before fabrication:

A) Spool tracking & clearance Sheets

B) NDE

R4 Clearance (RT Trackers, RT Backlog Control, etc)

C) Coatings

Application Tracking

Isolation rules & methods are employed for special processes:

A)

Segregation employed is effective

B) Signs & barricade warning tape exist (segregated areas)

RT pending Laydown & Staging

R5

Areas

PWHT pending Laydown & Staging Areas

Coating Pending Laydown & Staging

Areas

REFERENCE

Yes

No

N/A

Comments

Schedule Q &

SAEP-1160

Database

Reqmts

Items in QP or

Procedure

Sch Q, Att - IV

Items in QP or

Procedure

R6

Hold status (tagging, etc) system exists & is understood to prevent

shipments of materials & spools not accepted by Quality.

Sch Q, Att - IV

Items in QP or

Procedure

R7

Completed Spool Staging Area(s) (Ready to ship, etc) exist.

Sch Q, Att - IV

Items in QP or

Procedure

Piping spools (assemblies) are checked, cross referenced & clearly

marked after in-process verification of dimensional requirements.

Schedule Q &

Fit-up OK, Inspector initial & date,

SAEP-1160

etc

Database

Visual weld (VT) OK, Inspector initial & date

Reqmts

Final Dimensional check (Final) OK,

Inspector initial & date

Items in QP or

Procedure

S1

T1

T2

T3

T4

T5

System Controls for In-Process Spools

In-progress Radiographic Testing & Reporting Controls

RT selection process has the highest integrity possible

Subcontractor QC does not exclusively select welds to be RT'd.

Contractors maintain tight control over selection of Random RT.

Subcontractor &

Contractor QC work together in selection & invite Company QA personnel

into the process in a spirit of Teamwork.

RT Selection Process is closely watched & monitored

RT shooting lists are available & system is monitored as follows:

Daily RT Shoot List is always

available to Contractor & Company

RT Shoot List Results (previous day) are checked every day.

Tracking of Reject welds &

reshoots are carefully monitored

Penalty

shot selection is carefully monitored

Defect location marking is carefully performed & monitored

Daily RT shooting lists with Reshoots (film & weld quality) identify shots

as follows:

The cause of

the Reshoot is identified (in writing) on the Shoot list.

Penalty shots are identified on the list.

Repair attempts (R1or R2) are identified on the

Shoot list.

RT Clearance (Repaired welds, reshoots, penalty shots) are closely

monitored by Contractor

Poor welder performance is identified very early in the

process.

Poor RT technique &

performance is identifed & corrected early.

RT Clearance is verified by SA Level III at the earliest opportunity.

RT Backlog is closely monitored by Contractor & Subcontractor.

Backlog goals

are set & maintained early in the project.

System of tracking reports RT Backlog numbers regularly (weekly)

Backlogs exceeding 100 joints receive

immediate attention to clear

Sch Q, Att - IV

Guide for

approval of NDT

control

Procedures

Sch Q, Att - IV

Guide for

approval of NDT

control

Procedures

Sch Q, Att - IV

Guide for

approval of NDT

control

Procedures

Sch Q, Att - IV

Guide for

approval of NDT

control

Procedures

Sch Q, Att - IV

Guide for

approval of NDT

control

Procedures

System Controls

U1

Tracking System for organization of material & storage is in place

(Demonstrate how a piece of pipe and fittings become a spool)

Sch Q, Att - IV

U2

Signs in Segregated Areas exist (materials, warnings, etc)

Sch Q, Att - IV

U3

Segregation Area rules exist and are followed.

Sch Q, Att - IV

U4

Material Receiving Personnel are of adequate number & are properly

trained and available.

Sch Q, Att - IV

Page 14 of 21

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

WBS/BI/JO NUMBER

DISCIPLINE

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

U5

QC Inspection Personnel are adequate in number per Sch. Q & are

properly trained & approved by Company prior to start of work.

Sch Q, Att - IV

U6

Tracking system for spools is available (QC tracking lists, etc)

Sch Q, Att - IV

U7

Color Coding system is approved (PFI-ES-22 & SAES-A-206)

Sch Q, Att - IV

U8

Material Storage Yard is level and properly compacted or asphalted

Sch Q, Att - IV

U9

Pipe racks or supports (metal, wood) are adequate to provide full support

to new piping (3 to 4 sets) with no bowing or sagging

Sch Q, Att - IV

U10

Material Receiving Yard is of adequate size for significant quantities of

piping to be received

Sch Q, Att - IV

U11

Safety Signs (access/egress/overhead crane/etc) exist

Sch Q, Att - IV

U12 Overhead crane construction is complete and approved by SA.

Sch Q, Att - IV

U13 Overhead crane certification is available to SA Safety & Insp.

Sch Q, Att - IV

V1

V2

W1

Yes

No

N/A

Comments

System Controls for Handling Materials

The System used for handling all types of materials meets minimum

industry requirements and good practice

Equipment is properly outfitted to handle a variety of materials:

Stainless & alloy materials are not

directly handled with CS

Coated materials & spools employ equipment protection

coverings

Sch Q, Att - IV

Sch Q, Att - IV

Material Warehouse & Controlled Climate Storage

5 M + E (Coating Consumables, Welding Electrodes, etc)

Sch Q, Att - IV

Equipment Check Points

X1

Proper cleaning equipment (tools) for all diameter piping fabrication is

available at the shop in adequate numbers as follows:

A) Variety of grinders (internal, external

prep of metal surfaces)

B) Attachments (grinding wheels, cones, stones, flappers, etc)

C) Slag hammers, chipping tools, brushes

(Each worker)

D) Adequate

rags, cleaning solvents (Storage Room Control)

X2

Demineralized water (treated water) supply exists for SS shops

X3

Drills (various size) & presses are adequate in their number & condition

for small diameter pipe openings. (No torches allowed)

X4

Internal machining tools (beveling, preparation) provide a quality surface PFI-ES-21,

finsih & allow fit-up of GTAW process butt welds

Section (All)

X5

Bending equipment is available & in good condition.

X6

Procedure for pipe bending methods is approved (by CSD).

A) Hot bending methods (Furnace, Incremental, & Induction

bending)

PFI-ES-24,

B) Cold bending methods (Rotary draw, ram & roll bending)

Section (All)

C) Bends are examined, protrusions repaired (VT, MT/PT,

UT) & gauging internals is performed (deformation, 97.5% nominal id)

X7

Pipe ovality repair tools (jacks, crescents*) for repairs to 3% out.

PFI-ES-24,

* SMYS values are not exceeded. A 30-ton jack

Section (All)

for CS (maximum)

X8

Pipe ovality repair procedure is approved & details equipment.

PFI-ES-5,

Section (All)

PFI-ES-05,

Section 4

PFI-ES-21,

Section (All)

PFI-ES-24,

Section (All)

Sch Q, Att - IV

Page 15 of 21

Manufacturer

recommended

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review & Approve Piping Fabrication Shop

(Guide - Assure Successful Project Start-up)

DATE APPROVED

SAIC- L-2031

PROJECT TITLE

DISCIPLINE

30-Apr-13

WBS/BI/JO NUMBER

CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER

EQUIPMENT DESCRIPTION

EQPT CODE

SYSTEM

LAYOUT DRAWING NUMBER

REV. NO.

S/U SYSTEM

FACILITY

K. Raja Roa

RFI No.

ITEM

No.

REQUESTED INSPECTION DATE

ACCEPTANCE CRITERIA

REFERENCE

X9

Demineralized/Treated water supply (tank) exists for SS shop.

X10

Flapper wheels to obtain ID cleanliness needed. Solvents for degreasing

PFI-ES-5,

and cleaning piping after cutting operations needed.

Section (All)

See PFI ES-5

X11

Bevel machines are in good condition. Means to meet groove weld

parameters is acceptable to Company & gauges are available

Y1

Y2

Yes

No

QP

N/A

Comments

scope of work

QP

scope of work

QP

Items in QP or

Procedure

QP

Items in QP or

Procedure

Measuring & Test Equipment (M&TE) for Welding

Adequate quantities of the following M&TE exist:

A) Hygrometers

B) Digital pyrometers

C) O2 Analyzers

D) Calibrated tong testers

E) Weld gauges

(fillet, VWAC, Hi-Lo, etc)

F)

Calipers, tapes & levels

Record log (certs, calibrations, etc) exists for all M&TE

AUDITS for main shops for Carbon steel should be performed with

attention to the elements listed in Piping Fabrication Institute ES-05, 21,

22, 24, 26, 27, 31, 37 and 41. Company will give close attention to

systematic material and consumable control. Conduct shop audit well

before offering the shop for Company approval.

REMARKS: PASS ALONG THIS CHECKLIST AT TIME OF INTERVIEW OF SUBCONTRACTOR &

PRIME CONTRACTOR QA/QC MGR INTERVIEW TO TASK THEM TO ASSURE A SMOOTH

QUALITY START ON PROJECTS

REFERENCE DOCUMENTS:

Contract Schedule Q (Date Variable) Quality Assurance and Control, Inspection and Testing

01-SAMSS-010 - Fabricated Carbon Steel Piping (25 May 2011)

02-SAMSS-005 - Butt Welding Pipe Fittings (20-Feb. 2012)

012-SAMSS-008 - Erection of Structural and Miscellaneous Steel (9-May 2011)

SAEP-1141 - Industrial Radiation Safety (8-Dec-2010)

SAEP-323 - Performance Qualification Testing of Contract Welders and Brazers (01 July, 2008)

SAES-A-206 - Positive Material Identification (30-April 2011)

SAES-H-200 - Storage, Handling and Installation of Externally Coated Pipe (24 Oct 2011)

SAES-L-310 - Design of Plant Piping (29 April, 2007)

SAES-L-350 - Construction of Plant Piping (22 April 2009)

SAES-W-011 - Welding Requirements for On-Plot Piping (4-Oct. 2009)

ANSI/AWS Z49.1 - Safety in Welding, Cutting & Allied Processes (January 2004 Edition)

ANSI/AWS D1.1-96 - Structural Steel Welding Code (2004 Edition)

ASME B31.3 - Process Piping (2010 Edition)