Professional Documents

Culture Documents

08 FluidStructureInteraction 113

Uploaded by

Jasmine RaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08 FluidStructureInteraction 113

Uploaded by

Jasmine RaiCopyright:

Available Formats

13th International LS-DYNA Users Conference

Session: Fluid Structure Interaction

Interaction Methods for the SPH Parts

(Multiphase Flows, Solid Bodies) in LS-DYNA

Jingxiao Xu, Jason Wang

Livermore Software Technology Corporation

Abstract

The interesting and complex behaviour of fluids emerges mainly from interaction processes.

Smooth particles hydrodynamics is a meshfree, Lagrangian particle method and a simple, yet

flexible method for modeling fluid flows and solid bodies in a robust way. It has been applied

extensively to the multiphase flows, heat conduction, high explosive problems and so on. In this

paper, different interaction methods available in the LS-DYNA for SPH parts which have wide

range of density and material properties are studied and compared. Node to node contacts fit

well for the interaction between two SPH parts with high density ratio, the standard SPH

interpolation method has better accuracy around the interfaces when two SPH parts have

similar density and material properties. Different interaction approaches can be combined

together in one model to reach the best results. Also the interactions between Lagrangian

elements with SPH particles are discussed. Some examples are presented to show how to use

different approaches with different combination of LS-DYNA keywords.

Introduction

SPH is a Lagrangian method for solving partial differential equations. Essentially, the domain is

discretized by approximating it by a series of roughly equi-spaced particles. They move and

change their properties (such as temperature) in accordance with a set of ordinary differential

equations derived from the original governing PDEs. SPH was first applied by Lucy (1977) to

astrophysical problems, and was extended by Gingold (1982). Cloutman (1991) used SPH to

model hypervelocity impacts. Libersky and Petschk have shown that SPH can be used to model

materials with strength. In recent years it has been developed as a method for incompressible

isothermal enclosed flows by Monaghan (1994).

As a Lagrangian method, the interaction between SPH particles and FEM elements can be easily

handled by a normal node to surface contact in LS-DYNA. Because of its ability to handle large

distortions by avoiding the need for intensive FEM remeshing, its reasonable precision and

stability compared with classical methods FEM, SPH is a competitive approach compared to

finite elements (FE) and is increasingly being used in some fast-transient dynamics problems.

Several authors have proposed to couple FE and SPH which seems a reasonable approach in

order to benefit from the advantages of both formulations. In LS-DYNA, hybrid elements that

enable coupling effects between SPH particles and FEM solid are implemented. In this method,

hybrid elements are configured to facilitate coupling effect of solid element and smoothed

particle hydrodynamics (SPH). This method can be used to adaptively transform a Lagrangian

solid Part or Part Set to SPH particles. Also hybrid elements are defined in a computer aided

engineering (CAE) grid model as a buffer or interface between the SPH particles and FEM solids

1-1

13th International LS-DYNA Users Conference

Session: Fluid Structure Interaction

When simulating fluids, it is important to capture interaction effects accurately in order to

reproduce real world behavior. Smoothed Particle Hydrodynamics has shown to be a simple, yet

flexible method to cope with many fluid simulation problems in a robust way. Unfortunately, the

results obtained when using SPH to simulate miscible fluids are severely affected, especially if

density ratios become large. In SPH, particles have a spatial distance covered by smooth length

over which their properties are smoothed by a kernel function. Problems arise when rest densities

and masses of neighboring particles vary within the smoothing length, as in such cases the

smoothed quantities of a particle show falsified values. The undesirable effects reach from

unphysical density and pressure variations to spurious and unnatural interface tensions, as well as

severe numerical instabilities. A node to node penalty based contact was introduced to avoid

those interface effects in LS-DYNA.

We have couples of keyword options available in LS-DYNA for the interactions between SPH

parts also the interactions between SPH part and Solid part: Standard SPH interpolation method

(normal

way);

Node

to

node

penalty

based

contact

through

keyword

*DEFINE_SPH_TO_SPH_COUPLING; Combination of both method through keyword

*SECTION_SPH_INTERACTION; Node to surface contact between SPH part and Solid part;

Coupling

between

SPH

parts

and

solid

parts

through

keyword

*DEFINE_ADAPTIVE_SOLID_TO_SPH; Coupling between SPH particles with ALE elements

through keyword *ALE_COUPLING_NODAL_PENALTY. Different interaction approaches

can be combined together in one model to reach the best results. Some examples are

demonstrated to show how to use different approaches with different combination of LS-DYNA

keywords.

Standard SPH formulation

Fundamentals of the SPH method

Particles methods are based on quadrature formulas on moving particles ( xi (t ), wi (t ))i P , P is

the set of the particles. xi (t ) is the location of particle i and wi (t ) is the weight of the particle i.

The quadrature formulation for a function can be written as:

f ( x)dx w (t ) f ( x

jP

(t ))

(1)

The quadrature formulation (1) together with the definition of smoothing kernel leads to the

definition of the particle approximation of a function. The interpolated value of a function:

u ( X ) at position X

using the SPH method is:

h (u ( xi )) w j (t )u ( x j )W ( xi x j , h)

(2)

Where the sum is over all particles inside and within a radius 2h , W is a spline based

interpolation kernel of radius 2h. It mimics the shape of a delta function but without the infinite

tails. It is a C 2 function. The kernel function is defined as following:

1 x xj

W ( xi x j , h) i

h h ( x, y )

1-2

(3)

13th International LS-DYNA Users Conference

Session: Fluid Structure Interaction

W ( xi x j , h) when h 0 , is Dirac function, h is a function of xi and x j and is

the so-called smoothing length of the kernel.

And the cubic B-spline function is defined:

3 2 3 3

d d

1

2

4

1

(d ) C (2 d )3

4

0

The gradient of the function u ( X )

smoothing length:

when 0 d 1

when 1 d 2

(4)

elsewhere

is given by applying the operator of derivation on the

h (u ( xi ) w j u ( x j )W ( xi x j , h)

j

(5)

Evaluating an interpolated product of two functions is given by the product of their interpolated

values.

Fig 1. Support size of 2d kennel function

Continuity equation and Momentum equation

The particle approximation of continuity equation is defined as:

m

d i

i j v i v j Wij '

dt

j j

(6)

1-3

13th International LS-DYNA Users Conference

Session: Fluid Structure Interaction

It is Galilean invariant due to that the positions and velocities appear only as differences, and has

good numerical conservation properties. v i is the velocity component at particle i.

The discretized form of the SPH momentum equation is developed as:

m

dvi

j ( i

j )Wij ,

dt

j i j

(7)

The above formulation ensures that stress is automatically continuous across material interfaces.

Different types of SPH momentum equations can be achieved through applying the identity

equations into the normal SPH momentum equation. Symmetric formulation of SPH momentum

equation can reduce the errors arising from particle inconsistency problem.

From equation (7), the following particle body forces were derived:

Fi pressure m j

pi p j

Fi vis cos ity m j

vi v j

2 j

2 j

W ( rij , h)

2W (rij , h)

(8)

Where rij xi x j , is the viscosity coefficient of the fluid. The pressure pi are computed via

the constitutive equation:

pi k ( i 0 )

(9)

where k is the stiffness of the fluid and 0 is its initial density.

Finally, for the acceleration of a particle i, we have:

a i 1 / i ( Fi pressure Fi vis cos ity Fi external )

(10)

Where Fi external are external forces such as body forces or forces due to contacts.

Multiple Fluids and Solid bodies

The above equations (1)--(10) were designed to handle single phase fluid and can be easily

extended in order to handle multiple fluids and Solid bodies with different rest density. Cares

must be taken to avoid the interface instability due to the large density ratio across the interfaces.

Interaction through standard SPH interpolation

As shown in Fig 2, the standard way to handle the interactions between different SPH parts is

through the SPH interpolation functions (i.e treated as one part for multiple SPH fluids) and no

1-4

13th International LS-DYNA Users Conference

Session: Fluid Structure Interaction

contact treatments are needed on the interfaces of the different SPH parts. In SPH, particles have

a spatial distance (smoothing length) over which their properties are smoothed by a kernel

function (such as density, pressure). Smoothed quantities of a particles show falsified values

when densities and masses of neighboring particles vary largely within the smoothing length. As

shown in Muller et al (2005), miscible fluids with a density ratio larger than 10 cannot be

realistically simulated if the standard SPH density summation is used. The reason is that in SPH,

the macroscopic flow is mainly governed by the density computation. Over or underestimating

the density leads to erroneous pressure values, which might result in unnatural acceleration

caused by erroneously introduce pressure ratio (Ihmsen et al 2011). Also lead to a spurious

interface tension and a large gap between the fluids. The erroneous quantities lead to undesirable

effects, reaching from unphysical density and pressure variations to spurious and unnatural

interface tensions, and even to severe numerical instabilities

Another issue with the interaction through standard SPH interpolation is that different SPH fluid

parts may stick together after the interaction due to the SPH function interpolations. To activate

this option, CONT parameter in *CONTROL_SPH has to be set as 0, and no contacts are

allowed between those SPH parts.

PartI

2

PartII

Fig 2. Interaction through SPH interpolation (treated as one part and no contact is needed)

Interaction through node to node contacts

A penalty based node to node contact model is introduced on the interfaces of the different SPH

parts. As shown in Fig 3, all the SPH interpolations (density, pressure and so on) are carried out

inside the local domains of each SPH part. No spurious interface tension or interfaces instability

happened in this model. The contact forces on the interfaces will be applied to the external forces

as in equation (10).

1-5

Session: Fluid Structure Interaction

13th International LS-DYNA Users Conference

Fig 3. Interaction through node to node contacts

In this system, the repulsive contact force acting on particle due to contact

proportional to the displacement or overlap between particles :

, is directly

(11)

is the linear-spring constant or stiffness. If the contact is modeled

where d 2h and

using only this linear-spring, no energy will be consumed and the contact will be ferfectly

elastic. In reality, some kinetic energy is dissipated in plastic deformation, and/or converted to

heat or sound energy. To account for those energy losses, a contact damping force based on a

dashpot model is also included:

(12)

The contact damping force is proportional to the relative velocity of the contacting particles,

where the constant of proportionality

is known as the damping coefficient,

v v1 v2

A *DEFINE_SPH_TO_SPH_COUPLING keyword is needed between any two SPH parts for

the contact interaction, also parameter CONT in *CONTROL_SPH need to be set as 1 to

deactivate the interaction through standard interpolation.

Interaction through both normal interpolation method and node to node contact method in

one model

Combine the CONT=1 option in *CONTROL_SPH keyword with keyword

*SECTION_SPH_INTERACTION to support the partial interactions between SPH parts through

normal interpolation option and partial interaction between SPH parts through node to node

contacts

in

one

model.

All

the

SPH

parts

that

are

defined

with

*SECTION_SPH_INTERACTION keyword will integrate with each other through normal

interpolation method automatically, and node to node contacts are needed for the interactions

between SPH parts defined with *SECTION_SPH_INTERACTION keyword and other SPH

1-6

13th International LS-DYNA Users Conference

Session: Fluid Structure Interaction

parts, also for the interactions between any other SPH parts that not defined through

*SECTION_SPH_INTERACTION keyword.

Normally, interaction through the standard interpolation method produces more consistent results

across the interface when SPH parts interacted have similar densities and material properties,

however the smoothed quantities of a particles show falsified values when densities and masses

of neighbouring particles vary largely within the smoothing length. The erroneous quantities lead

to undesirable effects, reaching from unphysical density and pressure variations to spurious and

unnatural interface tensions, and even to severe numerical instabilities. Interaction through node

to node contact allow the users to select the desired amount of contact force between two SPH

parts by choosing the desired penalty scale factors according to the simulation problem at hand

and it help to avoid the instabilities due to large density ratios at the interfaces. Also for any two

SPH parts with total Lagrangian formulation definition, only node to node contact can be used as

interaction method, since the neighbouring lists are only updated at beginning for SPH particles

with total Lagrangian formulation definition. With *SECTION_SPH_INTERACTON keyword,

users can take advantage of both interaction methods in one model based on the SPH parts

properties as shown in Fig 4.

Fig 4. Interaction through both standard interpolation methods and contact methods

SPH coupling with Solid elements

For the normal interaction between SPH particles and FEA elements (Solids and Shells), node to

surface contacts in LS-DYNA can be used, since both methods are based on the Lagrangian

description. When modelling SPH particles as fluids flow and FEA elements as structure in the

models, the Fluid Structure Interaction problems can be easily handled by the node to surface

contact.

Keyword *DEFINE_ADAPTIVE_SOLID_TO_SPH is used to adaptively transform a

Lagrangian solid Part or Part Set to SPH particles, when the Lagrangian solid elements

comprising those parts fail (Shown in Fig 5). One or more SPH particles (elements) will be

1-7

Session: Fluid Structure Interaction

13th International LS-DYNA Users Conference

generated for each failed element. The SPH particles replacing the failed element inherit all of

the properties of the failed solid element, e.g. mass, kinematic variables, and constitutive

properties.

Fig 5. Transform Solid elements into SPH particles

With ICPL=0, this keyword is used for debris simulation, no coupling happens between newly

generated SPH particles and solid elements, user need to define node to surface contact for the

interaction between those two parts. When ICPL=1 and IOPT=1, the newly generated SPH

particles are bonded with solid elements as one part through the coupling (Hybrid elements).

With ICPL=1 and IOPT=0, this keyword is used as Hybrid Element coupling SPH with Solid (as

shown in Fig 6).

Hybrid elements

SPH Particles

Solid elements

Fig 6. Example of Hybrid elements a stransit layers between SPH particles and Solid elements

In this hybrid elements method, we have the SPH formulation which can endure quite large

deformation and at the same time we have the Solid meshes which clearly describe the material

interfaces. Solid elements constrain SPH nodal locations. SPH elements provide penalty force

against solid nodal motions. Hybrid elements are used as transit layers between SPH elements

and Solid elements, for a portion of grid model comprises SPH particles because the likelihood

of enduring large deformation, while the rest of the model comprises FEM solid elements, hybrid

elements are placed between the solids and the particles, each hybrid element comprises two

layers: solid layer and particle layer.

1-8

13th International LS-DYNA Users Conference

Session: Fluid Structure Interaction

SPH coupling with ALE, DEM methods

Keyword *ALE_COUPLING_NODAL_PENALTY provides a penalty base contact interaction

between SPH particles and ALE materials (master segments). Also keyword

*DEFINE_SPH_DE_COUPLING defines a penalty based contact between SPH particles and

DEM particles. This option uses the node to node contacts to couple SPH solver with discrete

element sphere (DES) solver.

Examples

Water, air impacting with rigid ring

3D tank with fluids which has the dimension of 1.0X0.8X0.01 (Fig. 7) was calculated to validate

the node to node contact in LS-DYNA for multiple SPH parts with high density ratio across the

interfaces. The fluids in the tank were water and air with air on the top, the density ratio between

those two fluids is more than 1000. Both water and air were model with SPH particles. A rigid

ring modeled with cylinder shell impacted the fluids in the tank with the speed of 50 in Y

direction. The results from the SPH particles were compared with the results from the ALE

method with the same dimension and parameters (see Fig.9 and Fig.10).

In the model, automatic_ node_ to_surface contacts were used for the interaction between air,

water particles and rigid shells, a node to node contact was used for the interaction between air

particles and water particles. The contact between two SPH particles from different parts was

detected when the distance of two particles is less than SRAD*(sum of smooth lengths from two

particles)/2.0. SRAD is parameter ranged from 0 to 1.0 and is used to adjust the detecting criteria

due to initial penetration.

The standard interaction through SPH interpolation will not work for this case. A proper penalty

scale factor has to be used for better performance. As show in Fig. 8, a double value of penalty

scale factor will cause more noises around the interface of the two SPH fluids. The final

deformed shape of water was comparable with the results from ALE elements (Fig. 9). The

velocity historys for the rigid ring from both SPH model and ALE model were plotted and

compared in Fig. 10, two results were close.

1-9

Session: Fluid Structure Interaction

13th International LS-DYNA Users Conference

Fig 7. Problem set up of water impact

t=2.7 ms

t=2.7 ms

1-10

t=5.0 ms

t=5.0 ms

13th International LS-DYNA Users Conference

Session: Fluid Structure Interaction

Fig 8. Upper: deformation shape for air and water model

Lower: deformation shape with double value of penalty scale factor

Fig 9. Final deformation shape from SPH model (left) compared to ALE model (right)

Fig 10. Impact velocity from SPH model (B) compared to velocity from ALE model (A)

Summary

We present couples of keyword options available in LS-DYNA for the interactions between SPH

parts also the interactions between SPH part and Solid part: Standard SPH interpolation method

(normal

way);

Node

to

node

penalty

based

contact

through

keyword

*DEFINE_SPH_TO_SPH_COUPLING; Combination of both method through keyword

*SECTION_SPH_INTERACTION; Node to suface contact between SPH part and Solid part;

Coupling

between

SPH

parts

and

solid

parts

through

keyword

*DEFINE_ADAPTIVE_SOLID_TO_SPH; Coupling between SPH particles with ALE elements

through keyword *ALE_COUPLING_NODAL_PENALTY. Different interaction approaches

can be combined together in one model to reach the best results. Some examples are

1-11

Session: Fluid Structure Interaction

13th International LS-DYNA Users Conference

demonstrated to show how to use different approaches with different combination of LS-DYNA

keywords.

References

Jingxiao Xu, Jason Wang, Node to node contacts for SPH applied to multiple fluids with large

density ratio, 9th European LS-DYNA Conference 2013.

L.B. Lucy, A numerical approach to the testing of the fission hypothesis, Astron. J. 82 (12)

(1977) 1013.

L.D. Cloutman, SPH simulations of hypervelocity impacts, Lawrence Livermore National

Laboratory, Rep. UCRL-ID-105520, 1991.

R.A. Gingold and J.J. Monaghan, Kernel estimates as a basis for general particle methods in

hydrodynamics, J. Comput. Phys. 46 (1982) 429-453.

L.D. Libersky and A.G. Petschek, Smooth particle hydrodynamics with strength of materials,

New Mexico Institute of Mining and Technology, Socorro, NM.

J.J. Monaghan, Simulating free surface flows with SPH, J. Comp. Phys. 110 (1994) 399-406.

Paul W. Cleary, Modelling confined multi-material heat and mass flows using SPH, Applied

Mathematical Modelling, Volume 22, Issue 12, December 1998, Pages 981993.

F. OTT and E. SCHNETTER, A modified SPH approach for fluids with large density

differences, 2003.

X. Y. Hu and N. A. ADAMS, A multi-phase sph method for macroscopic and mesoscopic flows,

Comput. Phys. 213, 2 (2006), 844-861.

B. Solenthaler and R. Pajarola, Density contrast SPH Interfaces, Eurographics/ACM

SIGGRAPH symposium on Computer Animation, 2008.

Matthias Muller, Barbara Solenthaler, Richard Keiser and Markus Gross, Particle-Based Fluidfluid Interaction, Eurographics/ACM SIGGRAPH symposium on Computer Animation (2005),

pp. 237-244. 1, 2, 4, 6.

Markus Ihmsen, Julian Bader, Gizem Akinci and Mathias Teschner, Animation of air bubbles

with SPH, International Conference on Computer Graphics Theory and Application, 2011.

P. A. Cundall and O. D. L. Strack, A discrete numerical model for granular assemblies (1979),

Geotechnique, 29(1), 47-65.

1-12

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FULL REPORT ConsolidationDocument29 pagesFULL REPORT ConsolidationFatin Nabihah86% (21)

- FLOCALC Calc DetailsDocument15 pagesFLOCALC Calc DetailsLuanLTNo ratings yet

- Generalized Correlations For GasesDocument3 pagesGeneralized Correlations For GasesAllen DimayugaNo ratings yet

- QuizDocument2 pagesQuizJasmine RaiNo ratings yet

- Role of Stress Triaxiality in Elastoplastic Characterization and Ductile Failure PredictionDocument19 pagesRole of Stress Triaxiality in Elastoplastic Characterization and Ductile Failure PredictionJasmine RaiNo ratings yet

- Fundametals of University Teaching Spring 2015 Workshop ScheduleDocument3 pagesFundametals of University Teaching Spring 2015 Workshop ScheduleJasmine RaiNo ratings yet

- Elastic Solids Vol.1 MathDocument214 pagesElastic Solids Vol.1 MathMohamed FaragNo ratings yet

- QuizDocument2 pagesQuizJasmine RaiNo ratings yet

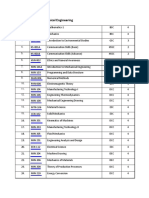

- ME 631-Lectures ContentDocument1 pageME 631-Lectures ContentJasmine RaiNo ratings yet

- Maindemo KDocument4 pagesMaindemo KJasmine RaiNo ratings yet

- SpringDocument2 pagesSpringJasmine RaiNo ratings yet

- Large Density RatioDocument11 pagesLarge Density RatioJasmine RaiNo ratings yet

- Taylor Bar TestDocument20 pagesTaylor Bar TestJasmine RaiNo ratings yet

- 5 3 4Document10 pages5 3 4Jasmine RaiNo ratings yet

- 11 IjaersDocument4 pages11 IjaersJasmine RaiNo ratings yet

- 08 FluidStructureInteraction 113Document12 pages08 FluidStructureInteraction 113Jasmine RaiNo ratings yet

- Maindemo KDocument4 pagesMaindemo KJasmine RaiNo ratings yet

- AFEM 03 Rep BaoDocument48 pagesAFEM 03 Rep BaoJasmine RaiNo ratings yet

- 06 2Document14 pages06 2Jasmine RaiNo ratings yet

- P 339Document4 pagesP 339Jasmine RaiNo ratings yet

- Hyper Mesh 11 Install InstructionsDocument1 pageHyper Mesh 11 Install InstructionsJasmine RaiNo ratings yet

- ReadmeDocument1 pageReadmeOsman OmerovićNo ratings yet

- FVMDocument4 pagesFVMJasmine RaiNo ratings yet

- FEA of Nonlinear Problems 2011 IvancoDocument62 pagesFEA of Nonlinear Problems 2011 IvancohazemismaeelradhiNo ratings yet

- FEM Conststrain HoleplateDocument9 pagesFEM Conststrain HoleplateBac Nam VuNo ratings yet

- Vectors AlgebraDocument19 pagesVectors AlgebraJose Maria Hazel TadlasNo ratings yet

- Lattice Theory of Threedimensional Cracks: 129.97.21.43 On: Tue, 03 Feb 2015 18:48:53Document9 pagesLattice Theory of Threedimensional Cracks: 129.97.21.43 On: Tue, 03 Feb 2015 18:48:53Jasmine RaiNo ratings yet

- Scan of Aside For Rate of Volume ElementDocument4 pagesScan of Aside For Rate of Volume ElementJasmine RaiNo ratings yet

- CH 12 Homework SolutionsDocument16 pagesCH 12 Homework SolutionsJasmine RaiNo ratings yet

- Formulae Involving Vector Identities With Proofs: Nabla Formulae For Vector AnalysisDocument8 pagesFormulae Involving Vector Identities With Proofs: Nabla Formulae For Vector AnalysisMarcho HbrNo ratings yet

- All Checks PointsDocument1 pageAll Checks PointsJasmine RaiNo ratings yet

- Worksheet Fluxdiv SolnDocument3 pagesWorksheet Fluxdiv SolnJasmine RaiNo ratings yet

- Platform Screen DoorDocument2 pagesPlatform Screen DoorethjetjetNo ratings yet

- Photon Interaction With MatterDocument16 pagesPhoton Interaction With MatterShafuan WanNo ratings yet

- E103 - Moment of InertiaDocument5 pagesE103 - Moment of InertiaStephh LouisNo ratings yet

- Aristotle and Galileo On MotionDocument46 pagesAristotle and Galileo On MotionMaria TheresaNo ratings yet

- The High Strength Friction GripDocument10 pagesThe High Strength Friction GripfiarNo ratings yet

- 2012 Elsevier MaterialsScienceandEngineeringA Aminallahp3 Vol.538pages2027Document9 pages2012 Elsevier MaterialsScienceandEngineeringA Aminallahp3 Vol.538pages2027Israel AliagaNo ratings yet

- Introduction To Creep Mechanics PDFDocument13 pagesIntroduction To Creep Mechanics PDFFaizanNo ratings yet

- Handouts PPE Day 1Document7 pagesHandouts PPE Day 1Raziel SalasibarNo ratings yet

- 2 Conduction Heat TransferDocument52 pages2 Conduction Heat Transferbirhanu kefieNo ratings yet

- Compresor CentrifugoDocument16 pagesCompresor CentrifugoIgnacio SotoNo ratings yet

- Commensurability, Comparability, Communicability Thomas KuhnDocument21 pagesCommensurability, Comparability, Communicability Thomas KuhnPablo MelognoNo ratings yet

- Annel Saavedra - S.PHY1.Q1.W7.AAS35-36 PDFDocument4 pagesAnnel Saavedra - S.PHY1.Q1.W7.AAS35-36 PDFTerius KimNo ratings yet

- Pp07 - Asep - NSCP 2015 Update On Ch4 Structural Concrete Part 2Document23 pagesPp07 - Asep - NSCP 2015 Update On Ch4 Structural Concrete Part 2Carlo Joseph100% (4)

- Laporan Tugas 3: Wellbore Performance: Mata Kuliah: Teknik Produksi (PE3103)Document6 pagesLaporan Tugas 3: Wellbore Performance: Mata Kuliah: Teknik Produksi (PE3103)Vini Nandi RahmaNo ratings yet

- M7500 Ultra HPHT Rheometer BrochureDocument1 pageM7500 Ultra HPHT Rheometer Brochuremega87_2000No ratings yet

- GKR GKS GSS Gearboxes With MD MH AC Motors - v1-0 - ENDocument460 pagesGKR GKS GSS Gearboxes With MD MH AC Motors - v1-0 - ENIndahNo ratings yet

- P11 Practice 7 SolnsDocument7 pagesP11 Practice 7 SolnsajjagottuNo ratings yet

- CCB 2092 Experiment 3 - Fluid StaticsDocument6 pagesCCB 2092 Experiment 3 - Fluid StaticsFahmi EsaNo ratings yet

- Me PDFDocument340 pagesMe PDFShyam ChoudharyNo ratings yet

- AI MI Catalogue - A4 PDFDocument26 pagesAI MI Catalogue - A4 PDFAbhishek SinhaNo ratings yet

- Physics Paper 1 M:J 2009Document5 pagesPhysics Paper 1 M:J 2009Faisal Iqbal KhanNo ratings yet

- B Tech Mechanical Engineering Syllabus For Batch 2013-14Document30 pagesB Tech Mechanical Engineering Syllabus For Batch 2013-14ra44993541No ratings yet

- Training CourseDocument44 pagesTraining CourseTugay ArıçNo ratings yet

- MC MomentumDocument33 pagesMC MomentumPuntos de periciaNo ratings yet

- Non - Rectangular Components: Prepared By: D.M.ODocument2 pagesNon - Rectangular Components: Prepared By: D.M.OCiero John MarkNo ratings yet

- Fresnel BiprismDocument6 pagesFresnel BiprismRahul SrivastavaNo ratings yet

- Ultrasonic PhysicsDocument16 pagesUltrasonic PhysicsCarlos AlviarezNo ratings yet