Professional Documents

Culture Documents

Application of Rock Mass Characterization For Det

Uploaded by

Hamza GeoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Rock Mass Characterization For Det

Uploaded by

Hamza GeoCopyright:

Available Formats

Application of Rock Mass Characterization for Determining the Mechanical Properti...

Page 1 sur 34

Rock Mechanics and Rock Engineering

Springer-Verlag 2009

10.1007/s00603-009-0048-y

Original Paper

Application of Rock Mass Characterization for

Determining the Mechanical Properties of Rock

Mass: a Comparative Study

Mahmoud Hashemi1

, Sh. Moghaddas2 and R. Ajalloeian3

(1) Department of Civil Engineering, Faculty of Engineering, The University of Isfahan, 8174473441 Isfahan, Iran

(2) Engineering Geology, Sabir Engineering Co., Tehran, Iran

(3) Department of Geology, Faculty of Science, The University of Isfahan, Isfahan, Iran

Mahmoud Hashemi

Email: m.hashemi@eng.ui.ac.ir

Received: 25 July 2008 Accepted: 23 March 2009 Published online: 16 April 2009

Abstract

The results of geotechnical explorations, engineering geological investigation (including

laboratory and in situ tests) and field observations have been used, along with borehole

logging charts, to obtain the rock mass geotechnical data. Based on the data, the rock mass

along the Sabzkuh water conveyance tunnel route was classified by rock mass rating (RMR),

Q-system (Q), rock mass index (RMi) and geological strength index (GSI) (3 methods). A

new series of correlations were established between the systems based on the data collected

from the study area. These relationships were then compared with those reported in the

literature, and two new relations were recommended. The classifications were utilized to

calculate mechanical properties (rock mass strength and deformation modulus) of the rock

mass along the tunnel according to available empirical relations, and to distinguish the upperbound and lower-bound relations.

Keywords Rock mass classification - RMR - Q - RMi - GSI - Mechanical properties Geotechnical explorations - Tunnel

1 Introduction

1.1 Background

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Properti... Page 2 sur 34

Rock mass classifications play an important role in estimating the strength and deformability

of rock masses and in assessing the stability of rock slopes. They also serve as an index to

rock rippability, dredgeability, excavibility, cuttability, and cavibility (Bieniawski 1989).

During the past 50 years, there have been numerous efforts around the world to create a

suitable engineering rock mass classification system so that the preliminary evaluation of

feasibility, development and stability/service of engineering structures/projects, would be

possible and fairly reliable. Terzaghis (1946) rock-load classification scheme could be

considered to be the first empirical classification system for rock mass. Subsequently, various

researchers proposed different rock mass classification systems, including Laufer (1958),

Deere et al. (1967), Wickham et al. (1972), Bieniawski (1973), Barton et al. (1974), Hoek

(1994), Hoek et al. (1995) and Palmstrm (1995). Many researchers have also tried to

correlate the various classification systems [mostly between rock mass rating (RMR) and Qsystem (Q)]. Some relations have been proposed by Bieniawski (1976), Rutledge and Preston

(1978), Moreno (1980), Cameron-Clarke and Budavari (1981), Abad et al. (1984), Kaiser and

Gale (1985), Al-Harthi (1993), Barton (1995), Turul (1998) and Kumar et al. (2004).

The construction of underground structures, such as powerhouses, gas and petroleum storage

systems, nuclear waste storage spaces, and water conveyance tunnels are of high importance.

The very first step for the design and stability analysis of such structures is to use numerical

and analytical modeling methods. The methods use the mechanical properties (deformation

modulus and strength) of the rock mass as input parameters.

Typically, a series of field tests, such as plate loading, jacking, flat jacking, or block shear

testing, are conducted to obtain the parameters. The tests are expensive and time-consuming,

especially when they are done in underground openings.

Therefore, the empirical (indirect) methods for estimating the parameters are the easiest,

quickest and simplest alternatives.

During years of developments in rock engineering, various empirical methods have been

proposed, where these use the classification systems as a base. To judge the relations, one

needs time to verify the relations by applying them at various sites with different types of

rocks and conditions for rock mass so that the advantages and disadvantages will be apparent

and the relations can be improved. Although none of the relations is absolutely the best, we

may find the best one under certain conditions by comparing them.

The estimation of uniaxial compressive strength of rock mass using classification systems is

important for correct evaluation of underground structure stability.

For this purpose, various relations have been suggested, including those by Yudbir et al.

(1983), Kalamaras and Bieniawski (1993), Singh (1993), Goel (1994), Bhasin and Grimstaad

(1996), Singh et al. (1997), Sheory (1997), Aydan and Dalgi (1998), Hoek et al. (2002),

Barton (2002), and Ramamurthy (2004).

A literature review of existing relations is presented by Edelbro et al. (2007). They

demonstrated that the results of the application of the relations vary significantly, even when

one system is used by different, qualified engineers. A comparison between the estimated rock

mass with in situ measured rock mass strength indicates the reliability of the various systems.

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Properti... Page 3 sur 34

To determine the engineering properties of rock mass for use in numerical analyses, the

evaluation of deformation modulus using the classification systems is essential. Bieniawski

(1978) estimated the modulus using the RMR value. Subsequently, various empirical relations

estimating the modulus based on the classification systems have been proposed, including

those by Serafim and Pereira (1983), Nicholson and Bieniawski (1990), Verman (1993),

Verman et al. (1997), Mitri et al. (1994), Singh (1997), Hoek and Brown (1997), Palmstrm

and Singh (2001), Barton (2002), Hoek et al. (2002), Kayabai et al. (2003), Gokeoglu et al.

(2003), Ramamurthy (2004), Sonmez et al. (2004), and Zhang and Einstein (2004).

It is important to note that the evaluation of all input data for the various above relations is

subjective; i.e., different input values are estimates by different people based on the same field

conditions. Therefore, different values are derived, even with the same relation.

1.2 The Study Area

The Sabzkuh water conveyance project (including the Sabzkuh diversion dam, open channel

and tunnel and Choghakhor dam rehabilitation) is designed to transfer 90 million m3 of water

annually from the Sabzkuh drainage basin to the Choghakhor dam reservoir. The project is

located about 109 km south of Shahr-e-Kord city and 90 km south west of Borujen city,

Chaharmahal-Bakhtyari province. The study area is situated on the north side of Zagros

mountain between 5050 to 5058 eastern longitude and 3145 to 3158 northern latitude.

The surface run-off along the Sabzkuh River may be kept by a diversion dam, which is a

4.5 km long open channel that runs to a main. The main is 8.574 km long, and the water is

finally carried to the Choghakhor dam reservoir (Fig. 1). The tunnel cross section has a

horseshoe shape with a diameter changing from 4.2 to 3.2 m.

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Properti... Page 4 sur 34

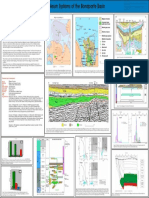

Fig. 1 Location map of the study area

2 Engineering Geological Assessment

The lithology of the tunnel route mainly consists of limestone, marly and dolomitic

limestones, dolostone, shale and variable sizes of alluvium. The lowest and the uppermost

lithologies belong to Camberian and Quaternary, respectively. The Sabzkuh syncline is the

main geologic structure at the project area. The axis of the syncline is extended in the NWSE

direction in which the Sabzkuh River flows. The Sabzkuh tunnel passes the north limb of the

syncline and is extended in the SWNE direction. From the viewpoint of structural geology,

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Properti... Page 5 sur 34

the stratification is regular along the tunnel route from the inlet section to the F11 fault.

Moving from the F11 fault towards the outlet, the stratigraphy of the area is disturbed due to

the active structural geology, intensive erosion and complex lithology of the area. The

morphology of the area mainly consists of high mountains and deep valleys with steep walls.

At the project area, there are karstic features and traces, including sinkholes, solution dolines,

lapies, poljes and shallow caves, which are locally observed in limestone. A total of six

boreholes have been drilled, with overall length of 1,646 m, using wireline and rotary core

boring methods along the tunnel route. The longest borehole is 522.1 m long. Currently,

approximately ten additional boreholes are being drilled, where these are concentrated in the

weak zones and critical areas. Since the overburden is high (around 1,200 m in the middle of

tunnel route), the borehole drilling has become very difficult and time- and money-consuming.

Therefore, geophysical exploration is preferred for these sections of the tunnel route. In

addition, the pilot (probe) horizontal boreholes are planned ahead of main tunnel excavation

(Fig. 2).

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Properti... Page 6 sur 34

Fig. 2 The geological map and geotechnical longitudinal cross-section of the tunnel route

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Properti... Page 7 sur 34

For geotechnical evaluation and rock mass classification, the field observation, geophysical

exploration, borehole logging, the field tests and laboratory experiments have been used and

studied thoroughly. The studies show that the rocks in the area are slightly to moderately

weathered.

Regarding the joint conditions, the wall surfaces of the joints are mostly rough. The infillings

mainly consist of calcite, ferrous oxide and finely ground (clay to silt size) lithic particles.

The joint pattern along most parts of the tunnel consists of three sets (two joint sets and

bedding). In some areas, four joint series are observed (three joint sets and one bedding). The

results of laboratory tests that were mainly carried out on the borehole and some field samples

show that the uniaxial compressive strength of rocks varies from 10 to 125 MPa (Table 1).

Table 1 Summery of laboratory test results of boreholes and field samples

Value of

laboratory

tests

Tunnel section

Segment

no.

Lithology

From

1

2

3

5

6

7

8

10

To

0 + 000 0 + 043 Limestone

Marlstone

0 + 043 0 + 325

and marl

0 + 325 0 + 461 Limestone

Marly

limestone

0 + 461 0 + 679 and

calcareous

shale

0 + 679 1 + 247 Limestone

Limestone

1 + 247 12 + 150 and marly

limeston

2 + 150 2 + 770 Limestone

Dolostone

2 + 770 3 + 088 and dolomitic

limestone

Dolostone

3 + 088 3 + 868 and dolomitic

limestone

Dolostone

3 + 868 4 + 015 and marly

limestone

Limestone,

Max.

118

Modulus

of

elasticity

(GPa)

Min. Ave. Max.

Min. Ave.

68 85 33

27 31

28

12

15

21

15

15

105

63

85

32

28

30

74

42

55

25

21

23

95

52

60

32

26

29

75

25

38

28

23

24

110

53

65

30

27

31

118

50

67

33

29

32

112

50

62

33

28

31

98

48

58

29

23

26

Uniaxial

comprehensive

strength (MPa)

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Properti... Page 8 sur 34

11

12

13

14

15

16

17

18

19

20

21

22

23

dolostone

4 + 015 4 + 705 and dolomitic

limestone

Marly

4 + 705 4 + 715

limestone

4 + 715 5 + 120 Dolostone

5 + 120 5 + 745 Dolostone

Marly

5 + 745 5 + 871

limestone

Limestone,

dolostone

5 + 871 6 + 193

and dolomitic

limestone

Marly

6 + 193 6 + 352

limestone

6 + 352 6 + 442 Dolostone

Limestone,

dolostone

6 + 442 6 + 576

and dolomitic

limestone

Marly

6 + 576 6 + 823

limestone

Limestone,

dolostone

6 + 823 7 + 980

and dolomitic

limestone

Brecciated

7 + 980 8 + 059

limestone

Micaceous

8 + 059 8 + 231

shale

108

52

64

31

26

29

45

27

35

22

15

16

125

106

56

53

70

66

32

33

26

27

30

30

44

25

32

23

15

17

92

55

62

30

26

28

42

25

32

23

15

17

100

48

63

30

28

28

90

42

60

32

27

30

42

22

30

22

12

14

90

42

58

28

25

27

20

10

15

10

41

23

29

23

16

18

The RQD is mostly evaluated from the borehole cores, and in some cases, it is determined

using the Palmstrm (1982) method:

where J V is the volumetric joint count and is calculated as:

where s i is the average spacing of ith joint set.

Joint wall aperture is generally higher than 1 mm. In some stations, there are very high joint

apertures (more than 50 mm), which are mostly seen on the ground surface. Figure 3 shows

one of the cases in which a joint set is observed in a calcareous formation (DaryanFahlian

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Properti... Page 9 sur 34

Formation). The joint set wall spacing has been widened due to a secondary dissolution

process, so that the joint aperture is increased to 1540 cm. The joint has a dip/dip direction of

84/110 and is approximately parallel to the tunnel axis. The joint set wall condition is also

rough.

Fig. 3 One of the cases in which a joint set is observed in a calcareous formation (DaryanFahlian

Formation)

The geological features of the tunnel route are partially shown in Figs. 4, 5 and 6.

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 10 sur 34

Fig. 4 A shear zone is presented near the outlet between the CHT1 and CHT2 boreholes that are a

result of an active fault (F16)

Fig. 5 The joint sets in the Khanekat formation in a level higher than CHT3 borehole and in contact with

Neyriz formation. The joint wall condition is rough and dissoluble

Fig. 6 A dissolution and karstic cavity with dimensions of more than a meter in the SarvakIlam

formation near the ST202 borehole

A shear zone is also presented in Fig. 4, located near the outlet between the CHT1 and CHT2

boreholes; it is a result of an active fault (F16). The zone is extended to 100 m in width and

may affect the rock mass at the tunnel level. The zone consists of lithic pieces with diameters

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 11 sur 34

ranging from 1 to 100 cm that are connected by a matrix from the original formation. The

lithic pieces belong to the Khanekat formation, which consists mostly of limestone, dolostone

and dolomitized limestone.

The joint sets in the Khanekat formation at a higher level than the CHT3 borehole and in

contact with the Neyriz formation are shown in Fig. 5. The joint wall condition is rough and

dissoluble.

A dissolution and karstic cavity with dimensions more than a meter in the Sarvak-Ilam

formation near the ST202 borehole is also presented in Fig. 6. The cavity was made by the

karstic dissolution process, probably due to the presence of three joint sets. The joint sets

aperture measures more than 1 mm. The joint walls are mostly rough and rarely undulating

(Moghaddas 2004; Hashemi et al. 2004a, b; Ajalloeian et al. 2004).

3 Rock Mass Classification

3.1 Introduction

Over the past five decades, various rock mass classification systems have been proposed by

different researchers. All the systems tend to utilize the rock mass characteristics using either

quantitative or qualitative methods in rock engineering. The characteristics are undoubtedly

the essential requirements for empirical design and numerical modeling. However, none of the

systems could utilize all of the characteristics. This may be due to lack of homogenity and

isotropy in the material.

The characteristics of a particular rock mass could vary from one site to another site, perhaps

due to differences in engineering judgments and site conditions. This has led to the creation of

various classification systems instead of a single system.

The most well-known classification systems are briefly explained in the following sections.

3.1.1 The RMR System

Bieniawski (1973) proposed a geomechanical classification system (RMR). The system has

been revised many times, and the latest version was proposed in 1989. The system calculates

an index by summing the ratings for six main factors: the uniaxial compressive strength of the

rock material, the RQD value, spacing, condition and orientation of discontinuities, and

ground water conditions.

The system defines the rock mass as one of five classes based on structural geology and

strength characterization.

3.1.2 The Q-System

Barton et al. (1974) from NGI presented a tunneling quality index, called the Q-system. The

system is widely applied to various underground openings. Multiple revisions have been

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 12 sur 34

proposed for the system (Grimstaad and Barton 1993; Barton 2002), which classifies the rock

mass as one of nine classes. The index of the system ranges from 0.001 to 1000 on a

logarithmic scale and is calculated as:

(1)

RQD rock quality designation

Jn

the joint set number

Jr

roughness number of least favorable joint

Ja

alteration number of least favorable joint

Jw

the joint water reduction factor

SRF

stress reduction factor.

3.1.3 The RMi System

Palmstrm (1995) proposed the rock mass index (RMi) classification system. The RMi is a

volumetric parameter indicating the approximate uniaxial compressive strength of a rock mass

by combining c and a jointing parameter (JP). JP represents the block volume (V b) plus the

joint condition (jC). The joint condition can be estimated by joint roughness (jR), joint

alteration (jA) and joint size (jL).

The RMi system is similar to the Q-system. For instance, jA and jR in the RMi are

approximately similar to J r and J a in the Q-system, respectively.

The system evaluates the rock mass as one of seven classes. In addition, it has been recently

revised (Palmstrm 2000; Palmstrm and Singh 2001).

3.1.4 The GSI System

Hoek et al. proposed the geological strength index (GSI) to obtain reliable input data,

especially those related to rock mass properties required as inputs into numerical analysis

(Hoek 1994; Hoek et al. 1995; Hoek and Brown 1997). In the last decade, the index was

further developed and modified, particularly in poor and heterogeneous rock masses for

designing projects such as tunnels, slopes and foundations in rocks (Hoek et al. 1998, 2005;

Sonmez and Ulusay 1999, 2002; Marinos and Hoek 2000, 2001; Cai et al. 2004).

The GSI has been evaluated using three different methods that are described in the following

sections.

3.1.4.1 Evaluation of GSI Based on Field Observations

The GSI was first developed based on field observation: the experienced engineering geologist

evaluates the rock mass conditions from outcrops (overview and structural geology). Then, the

results are compared with the corresponding evaluation table (Hoek and Brown 1997). Finally,

the table yields the GSI.

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 13 sur 34

3.1.4.2 Evaluation of GSI Based on Other Rock Mass Classification

Systems

According to this method, the GSI is determined through other rock mass classification

systems, such as RMR (1976 and 1989) and Q (Hoek et al. 1995). The method is mostly

convenient for the sites in which the stratification outcrops and rock formations are not

present, but GSI estimation is required.

Based on RMR76 (Bieniawski 1976), the GSI is equal to the sum of the ratings for four

parameters: UCS, RQD, spacing and condition of discontinuities, but the rating for the

groundwater condition and joint orientation are set to ten and zero, respectively (Hoek et al.

1995):

(2)

For RMR76 < 18, a new parameter, Q is introduced:

(3)

For RMR89 (Bieniawski 1989), the formulation is similar to that of RMR76. The only

difference is that the groundwater condition rating is set to 15:

(4)

Again, for RMR89 < 23, Q has been used.

It should be mentioned that the minimum rating for RMR76 and RMR89 are 18 and 23,

respectively, according to the above conditions.

3.1.4.3 Evaluation of GSI Based on Block Volume and Joint Surface

Condition Factor

Cai et al. (2004) recently proposed a new approach based on the block size and condition,

block volume (V b) and joint condition factor (J C). The approach was intended to increase the

performance of GSI and to make it more quantitative. Block size is determined from the joint

spacing, joint orientation, number of joint sets and joint persistence. Compared to the variation

in joint spacing, the effect of the intersection angle between join sets is relatively small. Thus,

for practical purpose, the block volume for three or more joint sets can be approximated as

(5)

where S i is the spacing of each joint.

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 14 sur 34

The joint surface condition (J C), which is defined by the roughness, weathering, and infilling,

is similar to the factor used by Palmstrm (1995) to quantify the joint surface conditional and

is defined as:

(6)

where J W, J S and J A are the large-scale waviness, small-scale smoothness and joint

alteration factor, respectively.

The background of the chart provided by Cai et al. is the same as the chart produced by Hoek

and Brown (1997), but the HoekBrown chart has been precisely quantified by Cai et al. using

V b and J C.

3.1.5 The RCR and N

Goel et al. (1996) studied the various relationships between Q and RMR and found them to be

diverse and divergent. They noted that the UCS of intact rock ( c) indirectly presents the Q

formulation. In addition, the SRF is not present in the RMR calculation. Therefore, they

assumed that the UCS and joint orientation, and SRF may be dropped from the RMR and Q

formulations, respectively.

This led to the creation of two new concepts: rock condition rating (RCR) and rock mass

number (N). Based on the correlation between RCR and N values for the 63 case studies from

India, and other countries, they proposed the following relationships with a satisfactory

correlation coefficient of 0.92:

(7)

where RCR = RMR (rating for c and joint orientation) and N = Q (assuming SRF = 1).

3.2 Correlation Between the Rock Mass Classification

Systems

As the various engineering rock mass classification systems were being developed, a question

arose: if two classification systems are applied to two different sites, how can the rock masses

in the two sites be compared. The answer is to establish a correlation between the systems in

order to calculate one from another. Since some parameters may be used in one system but not

in the other, such correlations may be used as an approximate tool and not as an alternative for

routine calculation of another system.

Various researchers have tried to correlate the systems. If the systems are simultaneously

applied in various sites, the relations will become more convergent. Some of the relations are

listed in Table 2.

Table 2 Comparision of various correlations among the rock mass classifications

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 15 sur 34

Researcher(s)

Correlation (relation no.)

Estimated

parameter

Bieniawski (1976)

RMR from Q

Rutledge and Preston (1978)

RMR from Q

Moreno (1980)

RMR from Q

Cameron-Clarke and Budavari

(1981)

RMR from Q

Abad et al. (1984)

RMR from Q

Kaiser and Gale (1985)

RMR from Q

Al-Harthi (1993)

RMR from Q

Barton (1995)

RMR from Q

Turul (1998)

RMR from Q

RMR from Q

RMR from RMi

Kumar et al. (2004)

RMi from Q

RCR from N

3.3 Results and Discussion

3.3.1 Classification Systems

Each classification system contains various parameters with different ratings. One may find a

parameter common between the systems while the rating (dividing the boundaries and

assigned values) is different among the systems. Roughness, spacing, alteration, and infilling

are some of the parameters. Another difference is that the systems utilize the parameters in

different ways and ranges. For example, RQD has a maximum value of 15 in the RMR

system, whereas it is directly involved in Q evaluation and varies from 10 to 100. On the other

hand, the RQD is a way to calculate block volume (J v) in RMi system. Some parameters are

present in one system, but absent in another system. Some examples of such parameters are

the groundwater condition in the RMi system, the strike and dip of joints and uniaxial

compressive strength ( c) in the Q system, and the rock mass stress reduction factor (SRF) in

RMR and RMi systems. In addition, the RQD depends on the drilling method, and the effect

of the groundwater condition depends on the drainage conditions.

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 16 sur 34

Considering the range of the ratings, the Q and RMi systems are more sensitive than the RMR.

In RMR, a range is established, whereas in the other two methods (Q and RMi, and especially

Q), the parameters are individually and directly involved in formulas. Therefore, the main

disadvantage for the present systems is the different ranges for a particular parameter in

various systems due to their different logic and structure.

As another example, the rating sensitivity of the joint spacing in RMR is less than in RMi and

GSI (third method, Cai et al. 2004) because the parameter is very important in determining the

block volume, and therefore the final rating in RMi and GSI. Thus, the joint spacing rating for

RMi and GSI is more sensitive than RMR.

Finally, none of the systems as considered to be complete. This is also the reason that no

consistent relations can be found between the various systems.

The engineering rock mass classification has been done for 23 segments passing rock

formations using four systems: RMR89, Q, RMi and GSI (2 methods) (Fig. 7).

Fig. 7 The engineering rock mass classification for 23 segments passing rock formations using 4

systems: RMR89, Q, RMi and GSI (3 methods)

The GSI was determined for almost all the segments using the first method. There were two

lithological units (marly limestone of Khanekat Formation and dolostone of Dalan Formation)

whose outcrops were not available near the tunnel. Their GSI were evaluated based on the

available outcrops away from the tunnel route applying the geological conditions of the tunnel

route. The third GSI method (3.1.4.3) was also used for all the segments to compare it with the

other two methods of GSI. Figure 7 shows that there was no apparent difference between first

and third methods of GSI. Marinos et al. (2005) implied that the determination of GSI from

third method is not applicable for tectonically disturbed structures, such as segment 22. They

also recommended that where direct assessment of depth conditions is not possible, such as

segment 10 (Fig. 3), the GSI in depth can be evaluated by proper adjustment of the depth

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 17 sur 34

condition in their recommended GSI chart.

However, the first GSI method is mainly based on the real GSI characteristic (quick field

evaluation of rock mass strength). Both (first and third) methods are similar in the sense that

they evaluate the rock mass strength according to the exposed-in-surface (outcrop) conditions,

where the rock mass is determined by the number of joint sets, alteration, wall roughness,

degree of fracturing (blocky structure) in rock mass. Therefore, GSI does not consider the

underground (depth) conditions, such as groundwater, dip and strike of discontinuities (with

respect to excavation direction) and in situ stress characteristics.

It is also evident that the third method is similar to the RMi system in the sense that it involves

the block volume measurement and joint condition factor. Perhaps, the only difference

between the GSI and RMi systems is that GSI does not consider the UCS ( c) of intact rock.

For the rock masses along the tunnel route, the GSI varies in the ranges of 2260 and 2556,

for the first (Hoek et al. 1995) and third (Cai et al. 2004) methods, respectively.

Moreover, based on the surface field evaluation, and considering the shear zones due to faults

activities, the rock mass along the tunnel lies in the Disintegrated-Blocky class, as per the

GSI system.

The other systems such as RMR89, Q and RMi evaluate the rock mass as very poor and fair,

exceptionally poor and poor, and low and high quality, respectively.

Overall, based on the qualitative description of rock mass, the Q is the most conservative

method (considering the weakest description for rock mass), whereas the RMi gives the

radical (strongest) description for rock mass.

Along segment 1: as compared to other segments, RMR and Q present high values and

evaluate the rock mass similarly to the RMi description, probably due to low overburden,

reasonable strength of intact rock (leading to SRF 1) and dry conditions for groundwater in

this segment. In addition, the rock mass is mostly blocky, leading to higher values of RMi and

GSI (Fig. 7).

Along segments 8 and 9: the RMi yields higher values than Q because of the thick bedding,

high values of Jv or the block volume formed by discontinuities, high RQD and the uniaxial

compressive strength of intact rock, whereas these parameters are not involved in the Q

calculations, except RQD and ci (indirectly). The high SRF due to high overburden and

groundwater condition are the other reasons for the low Q values. In this segment of the

tunnel, the RMR and GSI values are also high due to the above reasons.

Along segment 21: due to a relatively low overburden, and therefore, low SRF, the Q value is

increased even more than that for RMi. In addition, the RMR and GSI values are relatively

low and high, respectively, due to groundwater conditions and other effective factors.

Along segment 22: there is a likely intersection of a shear zone and the tunnel in depth.

Therefore, the rock mass classification calculations are very difficult for almost all the

systems. Due to the high crushing effect, the block volume value is very low, leading to

minimum values for RMi and GSI. The Q values are also low, due to an important factor

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 18 sur 34

(SRF). The RMR evaluation is also low due to various factors, such as very low strength and

groundwater conditions.

These were the most effective parameters, whereas the other parameters could be effective as

well.

In segments 12, 15, 17 and 20: the values of all the systems are low and almost similar. This

may be due to the intersection of the tunnel with a deep low-strength layer that belongs to the

base of the Khanekat formation, which consists of marlstone, marly limestone, and siltstone.

3.3.2 Proposed Correlations Between the Systems

In the earlier studies, a series of correlations have been established, and various relations were

proposed which are mostly between the Q and RMR (Table 2).

Correlated data from the Sabzkuh tunnel, along with the other correlations available in

literature (10 cases), are presented in Fig. 8.

Fig. 8 Correlated data from the Sabzkuh tunnel, along with the other correlations available in the

literature (10 cases)

It is shown that the closest relation to the Sabzkuh tunnel data is the one proposed by Rutledge

and Preston (1978).

The recommended relation for the Sabzkuh tunnel data is

(22)

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 19 sur 34

Figure 9 shows the correlation between RMi and RMR values for the Sabzkuh tunnel route

(23)

Fig. 9 Correlation between RMi and RMR values for the current case and comparing with relation by

Kumar et al. (2004)

It is observed that there is no similarity between the above relation and the available literature

(Kumar et al. 2004).

Figure 10 presents the correlation between Q and RMi for the Sabzkuh tunnel data

(24)

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 20 sur 34

Fig. 10 Correlation between Q and RMi in this case and available literature (Kumar et al. 2004)

A comparison of the above relation with available literature (relation 20, Table 2, Kumar et al.

2004) shows that the relations match well, especially for low values of Q (Q < 0.35).

However, relation (20) by Kumar et al. 2004 did not show good agreement with the Sabzkuh

data for high values of Q (Q > 0.35).

Figure 11 presents correlation between N and RCR for the Sabzkuh tunnel data as:

(25)

Fig. 11 Correlation between N and RCR in this case and available literature (Goel et al. 1996 and

Kumar et al. 2004)

Comparison of the recommended relation and available literature (Goel et al. 1996; Kumar et

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 21 sur 34

al. 2004) shows that the proposed relation in the current study lays between the two relations

in available literature.

Figure 12 shows the correlation between RMR and GSI (Hoek et al. 1995) in the current study

as:

(26)

Fig. 12 Correlation between RMR and GSI (Hoek et al. 1995) in the current study

This relation is calculated based on the first method of GSI (Hoek et al. 1995) and RMR89.

Figure 13 shows the correlation between the first method of GSI (Hoek et al. 1995) and the

third method of GSI (Cai et al. 2004) in the current study with a strong correlation coefficient:

(27)

Fig. 13 Correlation between first method of GSI (Hoek et al. 1995) and third method of GSI (Cai et al.

2004) in the current study

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 22 sur 34

It is evident that there is little difference between the two methods.

4 Determination of Mechanical Properties for

Rock Masses

4.1 Uniaxial Compressive Strength of Rock Mass

4.1.1 Background

Various parameters have been used as input for different empirical relations to get the UCS of

rock mass. The parameters are mostly related to classification systems and the rock mass

constants. However, the uniaxial compressive strength of intact rock is used in the majority of

the relations. Some of the relations are presented in Table 3.

Table 3 Various relations for estimation of rock mass strength

Researchers

Yudbir et al.

(1983)

Kalamaras and

Bieniawski

(1993)

Equation (in terms of MPa) (relation no.)

Limitation

Singh (1993)

(kN/m3)

Goel (1994)

N = Q (with

SRF = 1)

B = tunnel width

(m)

Bhasin and

Grimstaad (1996)

Sheory, 1997

Aydan and

Dalgi 1998

Hoek et al.

(2002)

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

s = exp

[(GSI 100)/

(9 3D)]

a = 1/2 + (1/6)

(eGSI/15

e20/3)

Q c = Q 0 ci/100

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 23 sur 34

Barton (2002)

Q 0 = Q (with

RQD0)

Ramamurthy

(2004)

The following points are interesting regarding the relations presented in Table 3. First, Yudbir

et al. modified the original intact rock criterion (Bieniawski 1973) for rock mass. In addition,

Singh et al. (1997) evaluated the relation given by Bhasin and Grimstaad (1996). They

concluded that the relation is convenient for good classes of rock mass (Q > 10,

ci > 100 MPa). They also evaluated the relation given by Singh (1993) and concluded that the

relation can be properly used for weak classes of rock mass (Q < 10, ci > 2 MPa).

Ramamurthy (2004) found the following relation for rock mass:

(38)

where Jf is the joint factor and is set to 0 and 500 for intact rock and rock mass, respectively,

in site conditions. In addition, Ramamurthy (2001) found the following relation as:

(39)

Substituting (38) into (39), the relation is obtained as given by Ramamurthy (2004), which is

very similar to the relation proposed by Kalamaras and Bieniawski (1993) (Table 3).

In addition, the RQD0 is the oriented RQD in the loading or measurement direction (in the

TBM model, it is in the tunneling direction).

4.1.2 Results and Discussion

The rock mass strength estimated using the above relations shows a wide range (Fig. 14).

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 24 sur 34

Fig. 14 The rock mass strength estimated using relations available in literature

The relations proposed by Goel (1994) and Singh (1993) estimate high values (upper bound)

for cm, whereas the relation proposed by Barton (2002) and Yudbir et al. (1983) yields low

values (lower bound).

Some relations, such as those proposed by Aydan and Dalgi (1998) and Kalamaras and

Bieniawski (1993), give average (medium) values. It seems that the relation given by Hoek et

al. (2002) that is widely used in geotechnical softwares is somewhat conservative. As

explained earlier, the relations given by Kalamaras and Bieniawski (1993) and Ramamurthy

(2004) give similar results.

The cm parameter decreases as the stability and strength condition of the rock mass becomes

weaker, due to the direct effect of ci and the values given by the classification systems.

Interestingly, none of the relations directly consider the tunnel dimension (diameter) as a

parameter, except the relation given by Goel (1994).

For the upper bound relations, the variation of cm is much higher, whereas the input

parameter of the relations (such as intact rock strength) varies in a small range (for example

for segments 1 and 2 with strong and weak rock masses, respectively) (Fig. 14).

The other case studies by Edelbro et al. (2007) revealed that the N, Yudhbir-RMR76, RMi, Q-,

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 25 sur 34

and HoekBrown-GSI methods appeared to yield reasonable agreement with the measured

strengths. These methods are thus considered the best candidates for realistic strength

estimation, provided that care is taken when choosing values for each of the included

parameters in each method. This study has also clearly shown the limits of the presently

available strength estimation methods for rock masses, and further work is required to develop

more precise, practical, and easy-to-use methods for determining the rock mass strength

(Edelbro et al. 2007).

4.2 Deformation Modulus of Rock Mass

4.2.1 Background

The deformation modulus of a rock mass is apparently different from that of intact rock. To

obtain the modulus of a rock mass, there are direct (in situ) methods, which require extensive

and costly field operations, similar to those needed to obtain cm.

Therefore, indirect empirical relations were proposed to calculate the E m based on a particular

classification system for rock mass. Some of the relations are listed in Table 4.

Table 4 Various relations for estimation of rock mass deformation modulus

Researchers Equation (relation no.)

Bieniawski

(1978)

Serafim and

Pereira

(1983)

Nicholson

and

Bieniawski

(1990)

Verman

(1993),

Verman et al.

(1997)

Mitri et al.

(1994)

Limitation

Singh (1997)

Q < 10

Palmstrm

and Singh

(2001)

1 > RMi > 0.1

1 < RMi < 30

ci < 100 MPa

Barton (2002)

Qc=Q

(ci/100)

Hoek et al.

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

RMR > 50

RMR 50

H > 50 m

ci 100 Mpa

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 26 sur 34

(2002)

ci > 100 Mpa

Kayabai et

al. (2003)

Gokeoglu et

al. (2003)

Ramamurthy

(2004)

Sonmez et al.

(2004)

Zhang and

Einstein

(2004)

Hoek and

Diederichs

(2006)

a

= 0.160.35, (0.16 for hard rocks and 0.35 for weak rock)

D is the disturbance factor or the effect of blast damaged stress relaxation (D = 01)

cWD

is the weathering degree (14)

E i and E m are in GPa, ci in MPa and H is overburden in meter

In addition, values of deformation modulus of intact rock (belonging to various lithologies)

from laboratory tests are given in Table 1.

Regarding the relation proposed by Verman (1993) and Verman et al. (1997), it is assumed

that the deformation modulus of the rock mass increases with RMR and tunnel depth. This

depth dependency of the deformation modulus is likely to be more pronounced in weaker rock

masses and is almost absent in strong, brittle rock masses, due to the effect of the confining

pressure (Verman et al. 1997).

The relation given by Ramamurthy (2004) was also derived by substituting relation (38) in the

following (Ramamurthy 2001):

(40)

4.2.2 Results and Discussion

The above relations were used to estimate the E m along the tunnel route (Fig. 15). It seems

that the convergence of the results calculated by the E m relations is greater than the results

given by the cm relations.

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 27 sur 34

Fig. 15 Estimated Em by various relations available in literature along the tunnel route

It can be concluded from Fig. 15 that the relation provided by Ramamurthy (2004) gives the

lowest value of E m. Therefore, it is the most conservative relation when compared to the other

relations. The relation by Singh (1997) gives the second lowest values. The other two

relations, provided by Mitri et al. (1994) and Gokeoglu et al. (2003) yield the highest values

of E m.

It seems that the relation by Hoek and Diederichs (2006) is more sensitive than that of Hoek et

al. (2002) to the variation of D values. By increasing the D parameter from 0 to 1, the relation

by Hoek and Diederichs (2006) shows more reduction than the relation by Hoek et al. (2002).

In addition, the modulus values generated by the Hoek and Diederichs (2006) relation are

close to that given by the relation proposed by Singh (1997) in weak lithologies.

The other relations provided by Bieniawski (1978), Serafim and Pereira (1983), and Hoek et

al. (2002) generate medium values for E m. The relations proposed by Palmstrm and Singh

(2001) present medium E m values, but these are not applicable for RMi > 30 and RMi < 0.1,

which is the case for segment 22.

The relation provided by Kayabai et al. (2003) seems to be illogical and, when compared to

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 28 sur 34

the other relations, it is basically a different relation.

Of course, the relation provided by Kayabai et al. (2003) has been modified by Gokeoglu et

al. (2003). The latter also yields results totally different from the other relations, probably due

to a decrease in ci values.

The two relations given by Verman (1993), Verman et al. (1997), and Singh (1997) consider

the overburden as a parameter, which is a crucial factor, especially at high overburden values.

These two relations overall give reasonable values of E m.

As the overburden increases, the E m values also become higher according to both relations.

It should be recalled that determination of the deformation modulus in loading and unloading

cases shall be differentiated.

5 Conclusions

The rock mass along the Sabzkuh tunnel has been divided into 23 segments and classified

using RMR, Q, RMi and GSI (2 methods). The GSI varies in the ranges of 2260

(Disintegrated-Blocky) and 2556, for the first and third methods, respectively. Please note

that the quantification of GSI (Cai et al. 2004) is not applied in tectonically disturbed rock

masses in which the structural fabric has been destroyed, such as segment 22. In such rock

masses, the application of the original qualitative approach (Hoek et al. 1995) based on careful

visual observations is recommended (Marinos et al. 2005).

The other systems, such as RMR and Q and RMi, evaluate the rock mass as very poor and fair,

exceptionally poor and poor and low and high quality, respectively. Overall, the Q and RMi

yield the most conservative and radical descriptions of rock mass, respectively.

Based on Sabzkuh tunnel data, the following relations are proposed (Table 5). The relations in

the lower two rows of Table 5 are introduced for the first time in the available literature. Note

the RMR value was obtained by summing the rating of all influence factors (six parameters).

However, these relations may not be taken to be unique because they are related to a certain

rock mass type. Moreover, the effects of anisotropy, dissolution and karstification are not

considered in these relations.

Table 5 The recommended relations based on the Sabzkuh tunnel data

Equation (relation no.)

RMR = 5.37 ln Q + 40.48 (22)

RMR = 7.5 ln RMi + 36.8 (23)

r

Fig. no.

0.73 8

0.69 9

RMi = 1.082Q 0.4945 (24)

RCR = 6 ln N + 33.84 (25)

GSI (Hoek et al. 1995 ) = 0.692 RMR89 + 22.32 (26)

0.73 10

0.59 11

0.86 12

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 29 sur 34

GSI(Hoek et al. 1995) = 0.917 GSI(Cai et al. 2004) + 3.18 (27) 0.9 13

The closest QRMR correlation to the Sabzkuh tunnel data is the Rutledge and Preston

(1978).

The relations proposed by Goel (1994) and Singh (1993) estimate high values (upper bound)

for cm, whereas the relations proposed by Barton (2002) and Yudbir et al. (1983) yield low

values (lower bound); this shows a wide range for cm. For the upper bound relations, the

variation of cm is very sensitive to variation in the input parameter.

The Ramamurthy (2004) relation gives the lowest (lower bound) value of E m, whereas the

Mitri et al. (1994) and Gokeoglu et al. (2003) relations yield the highest (upper bound) values

of E m.

The tunnel overburden is involved directly in E m calculations only by Verman (1993),

Verman et al. (1997) and Singh (1997) relations. As the overburden increases, the E m values

also become higher according to both the relations.

The relation by Hoek and Diederichs (2006) is more sensitive than Hoek et al. (2002) to the

variation of D values. Moreover, the modulus values by the Hoek and Diederichs (2006)

relation are similar to those generated by the Singh (1997) relation in weak lithologies.

Acknowledgments Thanks are expressed to the Mahab-Ghods Consulting Engineers

Company, especially R. Banihashemi and A. Ahangaran for providing a site visit. We also

thank professor Hoek, professor Palmstrm and professor Gokeoglu for providing useful

points while writing this paper.

References

Abad J, Caleda B, Chacon E, Gutierrez V, Hidlgo E (1984) Application of geomechanical classification

to predict the convergence of coal mine galleries and to design their supports. In: 5th Inter. Cong.

Rock Mech., Melbourne, pp 1519

Ajalloeian R, Hashemi M, Mogshaddas Sh (2004) The Engineering Geology Assessment of Sabzkuh

Water Conveyance Tunnel Route, Central Iran, In: Viana da Fonseca & Mayne (eds) Proc. Int. Conf.

on Site Characterization (ISC-2), Porto, Portugal, pp 13971402

Al-Harthi AA (1993) Application of CSIR and NGI classification systems along tunnel no. 3 at Al-Dela

Descant, Asir Province, Saudi Arabia. In: Cripps JC, Coulthard JM, Culshaw MG, Forster A, Hencher

SR, Moon CF (eds) The Engineering geology of weak rock. Balkema, Rotterdam, pp 323328

Aydan , Dalgi S (1998) Prediction of deformation behaviour of 3-lanes Bolu tunnels through

squeezing rocks of North Anatolian Fault Zone (NAFZ). Regional symposium on sedimentary rock

engineering, Taipei, pp 228233

Barton N (1995) The influence of joint properties in modelling jointed rock masses. Keynote Lecture.

In: 8th Cong. ISRM, Tokyo

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 30 sur 34

Barton N (2002) Some new Q value correlations to assist in site characterization and tunnel design.

Int J Rock Mech Min Sci 39:185216

Barton N, Lien NR, Lunde J (1974) Engineering classification of rock masses for the design of tunnel

support. Rock Mech 6(4):189236

Bhasin R, Grimstaad E (1996) The use of stressstrength relationship in the assessment of tunnel

stability. Tunnel Under Space Tech 11(1):9398

Bieniawski ZT (1973) Engineering classification of jointed rock masses. Trans S Afr Inst Civil Eng 15

(12):335344

Bieniawski ZT (1976) Rock mass classification in rock engineering. In: Proc. Symp. On Expl. For Rock

Eng. Johannesburg, South Africa, Balkema, Rotterdam, pp 97106

Bieniawski ZT (1978) Determining rock mass deformability: experience from case histories. Inter J

Rock Mech Min Sci Geomech Abstr 15:237247

Bieniawski ZT (1989) Engineering rock mass classifications. Wiley, New York, p 251

Cai M, Kaiser PK, Uno H, Tasaka Y, Minami M (2004) Estimation of rock mass deformation modulus

and strength of jointed hard rock masses using the GSI method. Inter J Rock Mech Min Sci 41:319

Cameron-Clarke IS, Budavari S (1981) Correlation of rock mass classification parameters obtained

from borecore and in situ observations. Eng Geol 17:1953

Deere DU, Henderson AJ, Patton FD, Cording EJ (1967) Design of Surface and near surface

construction in rock. In: Proc. 8th US Symp. Rock Mech., AIME, New York, pp 237302

Edelbro C, Sjberg J, Nordlund E (2007) A quantitative comparison of strength criteria for hard rock

masses. Tunnel Under Space Tech 22(1):5768

Goel RK (1994) Correlations for predicting support pressures and closures in tunnels. Ph.D. Thesis,

Nagpur University, Nagpur, India, 154

Goel RK, Jethwa JL, Paithakar AG (1996) Correlation between Bartons Q and Bieniawskis RMR: a

new approach. Int J Rock Mech Min Sci Geomech Abstr 33(2):179181

Gokeoglu C, Sonmez H, Kayabai A (2003) Predicting the deformation moduli of rock masses. Int J

Rock Mech Min Sci 40:701710

Grimstaad E, Barton N (1993) Updating the Q-system for NMT, Int. Sym. Sprayed Concrete,

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 31 sur 34

Fagernes, Norway, Norwegian Concrete Association, Oslo, Norway, pp 2028

Hashemi M, Ajalloeian R, Moghaddas Sh (2004a) Rock Mass stability analysis for underground

excavation support system, the Sabzkuh water conveyance Tunnel, Iran, In: Ahmadi M (ed) 2nd edn.

Iranain Rock Mechanics Conf. (IRMC2004), Tehran, IRAN

Hashemi M, Ajalloeian R, Moghaddas Sh (2004b) Rock mass characterization for underground

excavation support system, the Sabzkuh water conveyance tunnel, Iran. Int J Rock Mech Min Sci 41

(3):532533

Hoek E (1994) Strength of rock and rock masses. News J ISRM 2(2):416

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34

(8):11651186

Hoek E, Diederichs MS (2006) Empirical estimation of rock mass modulus. Int J Rock Mech Min Sci

Vol 43:203215

Hoek E, Kaiser PK, Bawden WF (1995) Support of underground excavation in hard rock, A.A.

Balkema, Rotterdam, p 215

Hoek E, Marinos PG, Benissi M (1998) Applicability of the geological strength index (GSI)

classification for weak and sheared rock massesthe case of the Athens schist formation. Bull Eng

Geol Env 57(2):151160

Hoek E, Carranza-Torres CT, Corkum B (2002) Hoek-Brown failure criterion-2002 edition, In: Bawden

HRW, Curran J, Telsenicki M (eds) Proceedings of the fifth North American rock mechanics Society

(NARMS-TAC 2002) symposium, Mining Innovation and Technology, Toronto, Canada, pp 267273

Hoek E, Marinos PG, Marinos VP (2005) Characterization and engineering properties of tectonically

undisturbed but lithologically varied sedimentary rock masses. Int J Rock Mech Min Sci 42(2):277

285

Kaiser TK, Gale AD (1985) Evaluation of Cost and Emprical Support Design at B.C. Rail Tumbler

Ridge Tunnels. Canadian Tunnelling, Tunnelling Association of Canada, Wiley, New York, pp 77106

Kalamaras GS, Bieniawski ZT (1993) A rock mass strength concept for coal seams, In: Peng SS (ed)

12th Conf. Ground Control in Mining, Morgantown, pp 274283

Kayabai A, Gokeoglu C, Ercanoglu M (2003) Estimating the deformation modulus of rock masses: a

comparative study. Int J Rock Mech Min Sci 40:5563

Kumar N, Samadhiya NK, Anbalagan R (2004) Application of rock mass classification system for

tunneling in Himalaya, India Paper 3B 14, SINOROCK2004 Symposium. Int J Rock Mech Min Sci 41

(3):531

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 32 sur 34

Laufer H (1958) Classification for tunnel construction (in German). Geologie und Bauwesen 24(1):46

51

Marinos P, Hoek E (2000) GSI: a geologically friendly tool for rock mass strength estimation. In:

Proceeding of the GeoEng 2000. The international conference on geotechnical and geological

engineering, Melbourne, Technomic publishers, Lancaster, pp 14221446

Marinos P, Hoek E (2001) Estimating the geotechnical properties of heterogeneous rock masses such

as flysch. Bull Eng Geol Env 60:8292

Marinos V, Marinos P, Hoek E (2005) The geological strength indexapplications and limitations. Bull

Eng Geol Environ 64:5565

Mitri HS, Edrissi R, Henning J (1994) Finite element modelling of cable-bolted stopes in hardrock

groundmines. In: SME Annual Meeting. Albuquerque. New Mexico, pp 94116

Moghaddas Sh (2004) Evaluation of engineering geology characteristics of rock mass along the

Sabzkuh water conveyance tunnel, M.Sc. thesis, Engineering Geology group, Department of

Geology, Faculty of Science, The University of Isfahan (UI), Isfahan, IRAN, p 124

Moreno TE (1980) Application de las c1assificaciones geomechnicas a los tuneles de parjares. 11

Cursode Sostenimientos Activosen Galeriasy Tunnels. Foundation Gomez Parto, Madrid

Nicholson GA, Bieniawski ZT (1990) A nonlinear deformation modulus based on rock mass

classification. Int J Min Geol Eng 8:181202

Palmstrm A (1982) The volumetric joint counta useful and simple measure of the degree of

jointing, In: Proc. IV Inter. Congress of IAEG, New Delhi, 1982, pp 221228

Palmstrm A (1995) RMi: a rock mass classification system for rock engineering purposes. Ph. D.

Thesis. The University of Oslo, 400

Palmstrm A (2000) Recent development in rock support estimates by the RMi. J Rock Mech Tunn

Tech 6(1):119

Palmstrm A, Singh R (2001) The deformation modulus of rock masses- comparisons between in situ

tests and indirect estimates tunnelling. Underground Space Tech 16:115131

Ramamurthy T (2001) Shear strength response of some geological materials in triaxial compression.

Int J Rock Mech Min Sci 38:683697

Ramamurthy T (2004) A geo-engineering classification for rocks and rock masses. Int J Rock Mech

Min Sci 41:89101

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 33 sur 34

Rutledge JC, Preston RL (1978) Experience with engineering classifications of rock. In: Proc. Int.

Tunnelling Symp. Tokyo, A3.lA3.7

Serafim JL, Pereira JP (1983) Considerations of the geomechanics classification of Bieniawski. In:

Proc. of Int. Symp. Eng. Geol. Underground Construction., LNEC. Lisbon. 1, II. 33II. 42

Sheory PR (1997) Empirical rock failure criterion. Oxford IBH Publishing co. and A.A. Balkema,

Rotterdam, Netherlands, p 176

Singh B (1993) Workshop on Norvegian method of tunneling. CSMRS, New Delhi, India

Singh S (1997) Time-dependent deformation modulus of rocks in tunnels. M. E. Thesis, Civil

Engineering Department, University of Roorkee, India, p 180

Singh B, Viladkar MN, Samadhiya NK, Mehrotra VK (1997) Rock mass strength parameters

mobalized in tunnels. Tunn Under Tech 12(1):4754

Sonmez H, Ulusay R (1999) Modifcations to the geological strength index (GSI) and their applicability

to stability of slopes. Int J Rock Mech Min Sci 36:743760

Sonmez H, Ulusay R (2002) A discussion on the HoekBrown failure criterion and suggested

modification to the criterion verified by slope stability case studies, Yerbilmleri. Earth Sci 26:7799

Sonmez H, Gokeoglu C, Ulusay R (2004) Indirect determination of the modulus of deformation of

rock masses based on the GSI system. Int J Rock Mech Min Sci 41(5):849857

Terzaghi K (1946) Rock defects and loads on tunnel support. In: Proctor RV, White T (eds) Rock

tunnelling with steel supports. Commercial Shearing co., Youngstown, pp 1599

Turul A (1998) The application of rock mass classification systems to underground excavation in

weak limestone, Ataturk dam. Turkey Eng Geol 50:337345

Verman M (1993) Rock masstunnel support interaction analysis, Ph.D. Thesis, University of

Roorkee, Roorkee, India, p 267

Verman M, Singh B, Viladkar MN, Jeyhwa JL (1997) Effect of tunnel depth on modulus of deformation

of rock mass. Rock Mech Rock Eng 30(3):121127

Wickham GE, Tiedman HR, Skinner EH (1972) Support determination based on geologic predictions,

In: Proc. Rapid Exc. Tunneling Conf., AIME, New York, pp 4364

Yudbir F, Lemanza W, Prinzel F (1983) An empirical failure criterion for rock masses. In: Proc. 5th Int.

Cong. ISRM, Melbourne, vol 1. Balkema, Rotterdam, pp 131138

Zhang L, Einstein HH (2004) Using RQD to estimate the deformation modulus of rock masses. Int J

Rock Mech Min Sci 41(2):337341

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

Application of Rock Mass Characterization for Determining the Mechanical Prope... Page 34 sur 34

file://F:\geo\Application of Rock Mass Characterization for Determining.htm

28/03/2012

You might also like

- Study On Design and Stability of Tunnels by Using Rock Mass Classification Systems at Neelum Jhelum Hydro-Power Plant Project in Azad KashmirDocument7 pagesStudy On Design and Stability of Tunnels by Using Rock Mass Classification Systems at Neelum Jhelum Hydro-Power Plant Project in Azad Kashmirzia ahmadNo ratings yet

- Rock Mechanics and Engineering: Prediction and Control of Landslides and Geological DisastersFrom EverandRock Mechanics and Engineering: Prediction and Control of Landslides and Geological DisastersNo ratings yet

- Stochastic Estimation of The Hoek-Brown Strength Parameters Using Spreadsheet ModelsDocument12 pagesStochastic Estimation of The Hoek-Brown Strength Parameters Using Spreadsheet ModelsCamilo LilloNo ratings yet

- 16 BrownDocument20 pages16 BrownY.I. JangNo ratings yet

- Q SystematBakhtiarydamDocument8 pagesQ SystematBakhtiarydamManish Kumar SinghNo ratings yet

- Sabatakakis 2008-Index Properties and Strength Variation Controlled by Microstructure For Sedimentary RocksDocument11 pagesSabatakakis 2008-Index Properties and Strength Variation Controlled by Microstructure For Sedimentary RocksMiguel RegaladoNo ratings yet

- The Geological Strength Index - Applications and LimitationsDocument11 pagesThe Geological Strength Index - Applications and LimitationsRodrigo MarinNo ratings yet

- Stability Analysis of Cut Slopes Using Empirical, Kinematical, Numerical and Limit Equilibrium MethodsDocument27 pagesStability Analysis of Cut Slopes Using Empirical, Kinematical, Numerical and Limit Equilibrium MethodsBYRON BRAVONo ratings yet

- Strength TestsDocument12 pagesStrength TestsZanele MbathaNo ratings yet

- Abstract Estimation of Rock Mass Strength and Deformation Modulus of Jointed Hard Rock Masses Using The GSI SystemDocument2 pagesAbstract Estimation of Rock Mass Strength and Deformation Modulus of Jointed Hard Rock Masses Using The GSI SystemAzeNo ratings yet

- Mechanical Behavior of Bimrocks Having High Rock Block ProportionDocument9 pagesMechanical Behavior of Bimrocks Having High Rock Block ProportionRaul PozoNo ratings yet

- Tunneling in Weak Rock Mass - An Evaluation On Stability Condition of Headrace Tunnel of Setikhola Hydropower Project, 22MWDocument9 pagesTunneling in Weak Rock Mass - An Evaluation On Stability Condition of Headrace Tunnel of Setikhola Hydropower Project, 22MWInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 1 s2.0 S0886779819303359 Main PDFDocument18 pages1 s2.0 S0886779819303359 Main PDFCristian RincónNo ratings yet

- Stress Characterization and Support Measures EstimDocument8 pagesStress Characterization and Support Measures Estimaecom2009No ratings yet

- Liu2021 Article Geostatistics-block-basedCharaDocument18 pagesLiu2021 Article Geostatistics-block-basedCharaRico KabesNo ratings yet

- A Modified Rock Mass Classification System For Preliminary Design of Rock SlopesDocument9 pagesA Modified Rock Mass Classification System For Preliminary Design of Rock SlopeskrainajackaNo ratings yet

- Q-System at Bakhtiary DamDocument8 pagesQ-System at Bakhtiary DamMuhammadImranShahzadNo ratings yet

- Iraqi Geological Journal: Predicting TBM Performance For Pila Spi Formation in Qara Dagh Anticline, NE IraqDocument9 pagesIraqi Geological Journal: Predicting TBM Performance For Pila Spi Formation in Qara Dagh Anticline, NE IraqBurkan YayçıNo ratings yet

- Drilling and Penetration RatioDocument6 pagesDrilling and Penetration RatioCristian CabreraNo ratings yet

- Challenges in Modelling Geomechanical Heterogeneity of Rock Masses Using Geostatistical ApproachesDocument12 pagesChallenges in Modelling Geomechanical Heterogeneity of Rock Masses Using Geostatistical ApproachesEduardoSebastianCondoriVelasquezNo ratings yet

- 270367.interactive Design For deDocument6 pages270367.interactive Design For deIkke Landupa MessiNo ratings yet

- Analysis of The Deformation Characteristics of TheDocument28 pagesAnalysis of The Deformation Characteristics of TheBal Krishna ShresthaNo ratings yet

- Rostami Et Al. 2008 - Impact of Rocj Mass Characteristics On Hard Rock TBM PerformanceDocument9 pagesRostami Et Al. 2008 - Impact of Rocj Mass Characteristics On Hard Rock TBM PerformanceFederico MalteseNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Mohammad Mohammadi, Mohammad Farouq HossainiDocument6 pagesJournal of Rock Mechanics and Geotechnical Engineering: Mohammad Mohammadi, Mohammad Farouq HossainiPaul MatshonaNo ratings yet

- A Parametric Study Using Numerical Modelling To Assess TH - 2017 - Procedia EngiDocument10 pagesA Parametric Study Using Numerical Modelling To Assess TH - 2017 - Procedia EngiGustavo MariduenaNo ratings yet

- Application of Geological Strength Index (GSI) For The Tunnel in Crocker Formation: A Case Study in Tenom, Sabah, MalaysiaDocument5 pagesApplication of Geological Strength Index (GSI) For The Tunnel in Crocker Formation: A Case Study in Tenom, Sabah, Malaysiasatriowibowo16-1No ratings yet

- Waste Dump ChinaDocument20 pagesWaste Dump ChinaBikis MisganNo ratings yet

- Rock Mass ClassificationDocument8 pagesRock Mass ClassificationM JaffaNo ratings yet

- Prediction of Strength and Deformability of An Interlocked Blocky Rock Mass Using UDEC - Y M AlshkaneDocument12 pagesPrediction of Strength and Deformability of An Interlocked Blocky Rock Mass Using UDEC - Y M AlshkaneemrahNo ratings yet

- Application of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionDocument17 pagesApplication of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionAmit Kumar GautamNo ratings yet

- A Method For Determining The Mechanical Parameters of Solution Pore and Crevice Limestone Based On Porosity-Zheng Hu 2021Document14 pagesA Method For Determining The Mechanical Parameters of Solution Pore and Crevice Limestone Based On Porosity-Zheng Hu 2021GeotecoNo ratings yet

- GSI: A GEOLOGICALLY FRIENDLY TOOL FOR ROCK MASS STRENGTH ESTIMATION - Marinos & HoekDocument12 pagesGSI: A GEOLOGICALLY FRIENDLY TOOL FOR ROCK MASS STRENGTH ESTIMATION - Marinos & HoekJohan Van StaverenNo ratings yet

- Sostenimiento TúnelesDocument22 pagesSostenimiento TúnelesAleNo ratings yet

- Power Variation With External Load in Vertical Vibration Based Electret-Cantilever Micro-Power GenerationDocument5 pagesPower Variation With External Load in Vertical Vibration Based Electret-Cantilever Micro-Power GenerationInnovative Research PublicationsNo ratings yet

- A.c.mclean C.d.gribble - Geology For Civil Engineers (2005)Document18 pagesA.c.mclean C.d.gribble - Geology For Civil Engineers (2005)Soeryawan GilangNo ratings yet

- Predicting Squeeze - Hoek - MarinosDocument22 pagesPredicting Squeeze - Hoek - MarinosGrenierNo ratings yet

- Journal of Rock Mechanics and Geotechnical EngineeringDocument9 pagesJournal of Rock Mechanics and Geotechnical EngineeringTeguh HanapiNo ratings yet

- An Empirical Correlation of Uniaxial Compressive Strength With P-Wave Velocity and Point Load Strength Index On Marly Rocks Using Statistical MethodDocument11 pagesAn Empirical Correlation of Uniaxial Compressive Strength With P-Wave Velocity and Point Load Strength Index On Marly Rocks Using Statistical MethodHüseyin EkiciNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Manchao HeDocument15 pagesJournal of Rock Mechanics and Geotechnical Engineering: Manchao HeMilton TeranNo ratings yet

- Numerical Verification of Empirically Designed SupDocument13 pagesNumerical Verification of Empirically Designed SupBal Krishna ShresthaNo ratings yet

- Experimental and Statistical Investigation of The Mechanical Properties of Limestone Rocks in LebanonDocument6 pagesExperimental and Statistical Investigation of The Mechanical Properties of Limestone Rocks in LebanonRodrigo Souza FreitasNo ratings yet

- Mechanical Properties of Precast Reinforced Concrete Slab Tracks On Non-Ballasted FoundationsDocument7 pagesMechanical Properties of Precast Reinforced Concrete Slab Tracks On Non-Ballasted FoundationsRohan ReddyNo ratings yet

- Mechanical Response of Surrounding Rock of Tunnels Constructed With The TBM and Drill-Blasting MethodDocument12 pagesMechanical Response of Surrounding Rock of Tunnels Constructed With The TBM and Drill-Blasting MethodPatricio CisternasNo ratings yet

- Index Properties and Observations For Design of Chambers in RockDocument30 pagesIndex Properties and Observations For Design of Chambers in RockOlivinNo ratings yet

- 1-S2.0-S1674775514000390-Main Geology RecordDocument13 pages1-S2.0-S1674775514000390-Main Geology RecordSanjeev Kr. ThakurNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Shahé Shnorhokian, Bryce Macneil, Hani S. MitriDocument12 pagesJournal of Rock Mechanics and Geotechnical Engineering: Shahé Shnorhokian, Bryce Macneil, Hani S. Mitrialejandra rojasNo ratings yet

- The Geological Strength Index: Applications and LimitationsDocument11 pagesThe Geological Strength Index: Applications and LimitationsJinChongNo ratings yet

- E3sconf Icst2021 01014Document7 pagesE3sconf Icst2021 01014sharathNo ratings yet

- Charact of Phyllites For TunnellingDocument6 pagesCharact of Phyllites For TunnellingNadim527No ratings yet

- Icsmge 2022-132Document7 pagesIcsmge 2022-132fraztyaNo ratings yet

- An Investigation of Geological Parameters To Estimate Support Resistance by Smart System of Powered Support Longwall System in IndiaDocument16 pagesAn Investigation of Geological Parameters To Estimate Support Resistance by Smart System of Powered Support Longwall System in Indiaaveek mangalNo ratings yet

- Stability Analysis of Large Scale Stope Using S 2015 Journal of Rock MechanicDocument8 pagesStability Analysis of Large Scale Stope Using S 2015 Journal of Rock MechanicevensNo ratings yet

- The Geological Strength Index GSI A CharacterizatiDocument9 pagesThe Geological Strength Index GSI A CharacterizatitariqNo ratings yet

- Analytical Approach For The Design of Active Grouted Rockbolts in Tunnel Stability Based On Convergence-Confinement MethodDocument13 pagesAnalytical Approach For The Design of Active Grouted Rockbolts in Tunnel Stability Based On Convergence-Confinement MethodManoj BaralNo ratings yet

- An Investigation of Mechanisms Involved in Backfill-Rock Mass Behaviour in Narrow Vein MiningDocument10 pagesAn Investigation of Mechanisms Involved in Backfill-Rock Mass Behaviour in Narrow Vein MiningJesus SalamancaNo ratings yet

- Numerical Investigation of The Horseshoe Tunnels Structural BehaviorDocument16 pagesNumerical Investigation of The Horseshoe Tunnels Structural BehaviorsCoRPion_trNo ratings yet

- Tunnel Blasting TechniquesDocument25 pagesTunnel Blasting TechniquesBaga Yoice100% (1)

- 1245695019use of Rock PropertiesDocument21 pages1245695019use of Rock PropertiesJoel Cabrera LauraNo ratings yet

- Hencher - Interpretation of Direct Shear Tests On Rock JointsDocument8 pagesHencher - Interpretation of Direct Shear Tests On Rock JointsMark2123100% (1)

- Practical Considerations in The Use of Rock Mass Classification in MiningDocument6 pagesPractical Considerations in The Use of Rock Mass Classification in MiningHamza GeoNo ratings yet

- Ductile Shear ZoneDocument7 pagesDuctile Shear ZoneGoldy BanerjeeNo ratings yet

- Variogramtutorial PDFDocument23 pagesVariogramtutorial PDFYo GoldNo ratings yet

- RMR Q RMi - v2 1Document27 pagesRMR Q RMi - v2 1Hamza GeoNo ratings yet

- EXPLORATION and ULTILATION ENERGY GEOTHERMAL As Development Efforts Renewable Energy 2023Document1 pageEXPLORATION and ULTILATION ENERGY GEOTHERMAL As Development Efforts Renewable Energy 2023muhrizkyalfian15No ratings yet

- Undiscovered Resource Assessment Methodologies and Application To The Bonaparte Basin PDFDocument1 pageUndiscovered Resource Assessment Methodologies and Application To The Bonaparte Basin PDFMaurin PuspitasariNo ratings yet

- 5 Module V Volcanic Hazards1Document14 pages5 Module V Volcanic Hazards1Gom-o Eugenio JrNo ratings yet

- Chapter 3 Intrusive Igneous RocksDocument39 pagesChapter 3 Intrusive Igneous Rocksroziel A.mabitasan100% (1)

- Sinkhole 3Document7 pagesSinkhole 3Lenoj OlarNo ratings yet

- Civil S1 AggregatesDocument29 pagesCivil S1 AggregatesNoushad Bin JamalNo ratings yet

- AKPAH, Fabian Apeh 08 35407Document86 pagesAKPAH, Fabian Apeh 08 35407Ikponmwonsa Olotu100% (1)

- Popocatépetl - Wikipedia PDFDocument31 pagesPopocatépetl - Wikipedia PDFPorfirio DiazNo ratings yet