Professional Documents

Culture Documents

Metric Tube - Parker

Uploaded by

Jenny Cecilia Ureña ZuriOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metric Tube - Parker

Uploaded by

Jenny Cecilia Ureña ZuriCopyright:

Available Formats

Click Here

Metric Tube

The Fitting Authority

Metric Tube

4300 Catalog

R2

Parker Hannin Corporation

Tube Fittings Division

Columbus, Ohio

http://www.parker.com/tfd

Metric Tube

4300 Catalog

Introduction

Applications

Recommended Bend Radius

Parker offers three types of seamless metric tubes for hydraulic,

pneumatic and instrumentation applications:

Steel seamless cold drawn tube, phosphate and oil

dipped for corrosion resistance

Steel seamless cold drawn tube, zinc Chromium-6 free

plating for corrosion resistance

Stainless steel cold drawn tube

A bend radius of 3 times the tube O.D. or greater is recommended

for cold bending of Parker tubes with hand, mechanical and

power bending equipment.

Use of Tube Supports

The use of VH tube supports for EO and EO-2 ttings is required

in certain thinner wall tubes to ensure proper assembly. Consult

the tube charts.

Conformance and Material Specications

Temperature Range

Parker steel (St. 37.4) metric seamless tube can be used

at the full rated working pressures without pressure rating reductions within the following temperature range:

-40C to +120C. Maximum allowable operating temperature of +250C.

Parker stainless steel (1.4571) metric seamless tube can

be used at full rated working pressures with-out pressure reductions within the following temperature ranges:

-200C to 350C (-60 to +20). Maximum allowable

operating temperature of +400C. Elevated temperature

pressure reductions are as listed in Table R2.

Tests and Certicates

All tubes are subjected to a non-destructive leak test and marked

accordingly. This marking is used in lieu of a works certicate

DIN 50 049-2-2. Test Class 1 DIN 17458 Table 7 applies for

tubes made of 1.4571 material.

Materials and Mechanical Properties

Steel Types, mechanical properties and conditions are listed

in Table R1.

Welding Suitability and Weldability:

Steel tubes of St. 37.4, R Series, are weldable according

to usual techniques.

Not recommended to weld St. 37.4, R-VZ series,

Zinc Chromium-6 Free plated tubes.

As Delivered Conditions:

Standard Tube Lengths: 6 meters (approx. 20 ft)

Surface Finish:

Steel (St. 37.4): Phosphated and oiled

I.D. dimensions 1.5 5 mm, outside and inside oiled

I.D. dimensions 6 mm and higher, outside and inside

phosphated and oiled

Steel (St. 37.4) R-VZ Series: Zinc Chromium-6 Free

Stainless steel tubes of 1.4571 are suitable for arc welding.

The welding ller should be selected in accordance with DIN

8556 part 1 taking into account the type of application and the

welding technique.

Assembly and Installation

Please refer to Section T for the assembly and installation instructions for Metric Tube ttings.

Parker

Series

R

Series

R-71

Series

Yield

%

Tensile

Material

Strength

Strength

Elongation

Condition

Seamless, cold drawn under inert

Steel, ne grain

340 N/mm2 min. 235 N/mm2 min.

quality (RR) St 37.4

25% min. gas, normal annealed, abbreviation

49,000 PSI

34,000 PSI

NBK DIN 2391C, Part 2

per DIN 1630

Seamless, cold drawn free of scale,

1.4571

500 N/mm2 min. 245 N/mm2 min.

35% min. heat treated in accordance with DIN

X6CrNiMoTi17122

72,500 PSI

35,500 PSI

17458 tab. 6

Table R1 Parker Steel tubes mechanical properties and conditions

Temperature

Material

-60 up to

+20 C

Pressure

reductions in %

1.45

50 C 100 C 200 C 300 C 400 C

4.5

11

20

29

33

Note: Interpolation is acceptable for intermediate temperautre level.

Table R2 Parker stainless tube elevated temperature derating factors

R3

Parker Hannin Corporation

Tube Fittings Division

Columbus, Ohio

http://www.parker.com/tfd

Metric Tube

4300 Catalog

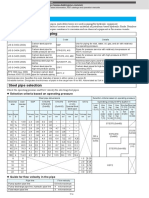

Seamless EO Steel Tubes

St. 37.4

Phosphated

& Oiled

Part No.

R04x0.5

R04x0.75

R04x1

R05x1

R06x0.75

R06x1

R06x1.5

R06x2

R06x2.25

R08x1

R08x1.5

R08x2

R08x2.5

R10x1

R10x1.5

R10x2

R10x2.5

R10x3

R12x1

R12x1.5

R12x2

R12x2.5

R12x3

R12x3.5

R14x1

R14x1.5

R14x2

R14x2.5

R14x3

R14x3.5

R14x4

R15x1

R15x1.5

R15x2

R15x2.5

R15x3

R16x1

R16x1.5

R16x2

R16x2.5

R16x3

R18x1

R18x1.5

R18x2

R18x2.5

R18x3

Material St. 37.4

Design Pressure

St. 37.4

STANDARD

(bar)

Zinc Plated

FROM STOCK

& Chromium-6 End

Wall

Tube DIN 2413 DIN 2413 Burst

Free

I

III

Pressure Weight Phos &

Size Toler- Thickness I.D.

Part No.

(mm) ance

(mm)

(bar)

(kg/m)

Oil

CF

(mm) Static Dynamic

R04x0.5VZ

4

0.5

3

313

274

1160

0.047

R04x0.75VZ

4

0.1

0.75

2.5

409

393

1820

0.063

R04x1VZ

4

1

2

522

502

2850

0.074

R05x1VZ

5

0.1

1

3

432

416

2120

0.099

R06x0.75VZ

6

0.75*

4.5

333

289

1230

0.103

R06x1VZ

6

1

4

389

374

1680

0.123

R06x1.5VZ

6

0.1

1.5

3

549

528

3050

0.166

R06x2VZ

6

2

2

692

665

0.197

R06x2.25VZ

6

2.25

1.5

757

728

0.208

R08x1VZ

8

1

6

333

289

1190

0.172

R08x1.5VZ

8

0.1

1.5

5

431

414

1860

0.240

R08x2VZ

8

2

4

549

528

3020

0.296

R08x2.5VZ

8

2.5

3

658

632

0.339

R10x1VZ

10

1

8

282

249

870

0.222

R10x1.5VZ

10

1.5

7

373

358

1380

0.314

R10x2VZ

10 0.1

2

6

478

460

2100

0.395

R10x2.5VZ

10

2.5

5

576

553

3180

0.462

R10x3VZ

10

3

4

666

641

0.518

R12x1VZ

12

1

10

235

210

760

0.271

R12x1.5VZ

12

1.5

9

353

305

1150

0.388

R12x2VZ

12 0.08

2

8

409

393

1580

0.493

R12x2.5VZ

12

2.5

7

495

476

2600

0.586

R12x3VZ

12

3

6

576

553

3200

0.666

R12x3.5VZ

12

3.5

5

651

627

0.734

R14x1VZ

14

1*

12

201

182

620

0.321

R14x1.5VZ

14

1.5

11

302

265

940

0.462

R14x2VZ

14

2

10

403

343

1340

0.592

R14x2.5VZ

14 0.08

2.5

9

434

417

1760

0.709

R14x3VZ

14

3

8

507

487

2400

0.814

R14x3.5VZ

14

3.5

7

576

553

3220

0.906

R14x4VZ

14

4

6

641

616

0.986

R15x1VZ

15

1*

13

188

171

590

0.345

R15x1.5VZ

15

1.5

12

282

249

980

0.499

R15x2VZ

15 0.08

2

11

376

323

1250

0.641

R15x2.5VZ

15

2.5

10

409

393

1690

0.771

R15x3VZ

15

3

9

478

460

2120

0.888

R16x1VZ

16

1*

14

176

160

540

0.370

R16x1.5VZ

16

1.5

13

264

234

820

0.536

R16x2VZ

16 0.08

2

12

353

305

1170

0.691

R16x2.5VZ

16

2.5

11

386

372

1470

0.832

R16x3VZ

16

3

10

452

435

1920

0.962

R18x1VZ

18

1*

16

157

143

510

0.419

R18x1.5VZ

18

1.5

15

235

210

780

0.610

R18x2VZ

18 0.08

2

14

313

274

1040

0.789

R18x2.5VZ

18

2.5

13

392

335

1320

0.956

R18x3VZ

18

3

12

409

393

1830

1.111

Pressure Calculations:

Calculation pressures given

are according to DIN 2413

Part 1 for static stress

20 K s c (bar)

P=

S da

Material characteristic value

K=235 N/mm2

and

DIN 2413 part III for dynamic

stress

P=

20 K s c (bar)

S (da + s c)

Material characteristic value

K=226 N/mm2 (permanent

fatigue strength)

Safety correction value S=1.5

for static and dynamic stress.

Factor c for consideration of

wall thickness divergence for

static and dynamic stress

=0.8 for tube o.d. 4 and 5;

0.85 for tube o.d. 6 and 8; 0.9

for larger tube o.d.

da = Tube O.D. in mm

s = Wall thickness in mm

Standard Tube Length:

6 m (19.7 ft.)

Conversion Factors:

Bar x 14.5 = psig

kg/m x 0.672 = lbs/ft

N/mm2 x 145 = lb/in2

See Remarks on page R5.

* Tubes which need a support sleeve (VH) for assembly in EO and EO-2 ttings.

Table R3 Seamless EO steel tubes

Dimensions and pressures for reference only, subject to change.

R4

Parker Hannin Corporation

Tube Fittings Division

Columbus, Ohio

http://www.parker.com/tfd

Metric Tube

4300 Catalog

Seamless EO Steel Tubes (contd.)

St. 37.4

Phosphated

& Oiled

Part No.

R20x1.5

R20x2

R20x2.5

R20x3

R20x3.5

R20x4

R22x1.5

R22x2

R22x2.5

R22x3

R25x2

R25x2.5

R25x3

R25x4

R25x4.5

R25x5

R28x1.5

R28x2

R28x2.5

R28x3

R28x4

R28x5

R30x2

R30x2.5

R30x3

R30x4

R30x5

R35x2

R35x2.5

R35x3

R35x4

R35x5

R35x6

R38x2.5

R38x3

R38x4

R38x5

R38x6

R38x7

R42x2

R42x3

R42x4

R50x6

R50x9

R65x8

R80x10

Design Pressure

St. 37.4

STANDARD

(bar)

Zinc Plated

FROM STOCK

& Chromium-6 End

Wall

Tube DIN 2413 DIN 2413 Burst

Size Toler- Thickness I.D.

Free

I

III

Pressure Weight Phos

(mm) ance

(mm)

(mm) Static Dynamic (bar)

(kg/m) & Oil

CF

Part No.

R20x1.5VZ

20

1.5*

17

212

191

570

0.684

R20x2VZ

20

2

16

282

249

920

0.888

R20x2.5VZ

20 0.08

2.5

15

353

305

1220

1.079

R20x3VZ

20

3

14

373

358

1450

1.258

R20x3.5VZ

20

3.5

13

426

410

1720

1.424

R20x4VZ

20

4

12

478

460

2080

1.578

R22x1.5VZ

22

1.5

19

192

174

590

0.758

R22x2VZ

22 0.08

2

18

256

228

850

0.986

R22x2.5VZ

22

2.5

17

320

280

1040

1.202

R22x3VZ

22

3

16

385

329

1.406

R25x2VZ

25

2

21

226

202

670

1.134

R25x2.5VZ

25

2.5

20

282

249

920

1.387

R25x3VZ

25 0.08

3

19

338

294

1050

1.628

R25x4VZ

25

4

17

394

379

1520

2.072

R25x4.5VZ

25

4.5

16

437

420

1780

2.275

R25x5VZ

25

5

15

478

460

2120

2.466

R28x1.5VZ

28

1.5

25

151

139

450

0.980

R28x2VZ

28

2

24

201

182

620

1.282

R28x2.5VZ

28 0.08

2.5

23

252

224

770

1.572

R28x3VZ

28

3

22

302

265

920

1.850

R28x4VZ

28

4

20

403

343

2.368

R28x5VZ

28

5

18

434

417

2.836

R30x2VZ

30

2*

26

188

171

620

1.381

R30x2.5VZ

30

2.5

25

235

210

770

1.695

R30x3VZ

30 0.08

3

24

282

249

920

1.998

R30x4VZ

30

4

22

376

323

1250

2.565

R30x5VZ

30

5

20

409

393

1580

3.083

R35x2VZ

35

2

31

161

147

470

1.628

R35x2.5VZ

35

2.5

30

201

182

620

2.004

R35x3VZ

35 0.15

3

29

242

216

720

2.367

R35x4VZ

35

4

27

322

281

960

3.058

R35x5VZ

35

5

25

403

343

3.699

R35x6VZ

35

6

23

419

403

4.291

R38x2.5VZ

38

2.5*

33

186

168

550

2.189

R38x3VZ

38

3

32

223

200

660

2.589

R38x4VZ

38 0.15

4

30

297

261

970

3.354

R38x5VZ

38

5

28

371

319

1350

4.069

R38x6VZ

38

6

26

390

375

4.735

R38x7VZ

38

7

24

446

429

5.352

R42x2VZ

42

2*

38

134

124

390

1.973

R42x3VZ

42 0.2

3

36

201

182

580

2.885

R42x4VZ

42

4

34

269

238

850

3.749

R50x6VZ

50 0.2

6

38

338

6.511

R50x9VZ

50

9

32

437

9.100

R65x8VZ

65 0.3

8

49

347

11.246

R80x10VZ

80 0.35

10

60

353

17.263

Material St. 37.4

Remarks:

Corrosion Additional

allowances are not considered for the calaculation of

pressures

da (bar)

di max.

1.35

are calculated for static stress

in accordance with DIN 2413

Part III, but with K = 235

N/mm2

When a specic factor of

safety is required, calculations should be based upon

the burst pressures shown in

the above tables.

Temperature range: -40C

up to 120C without pressure

reductions.

Surface nish:

Tubes with I.D. 1.5 to 5 mm:

outside and inside oiled.

Tubes from 6 mm I.D. and

above: outside and inside

phosphated and oiled.

* Tubes which need a support sleeve (VH) for assembly in EO and EO-2 ttings.

Table R3 Seamless EO steel tubes (contd.)

Dimensions and pressures for reference only, subject to change.

R5

Parker Hannin Corporation

Tube Fittings Division

Columbus, Ohio

http://www.parker.com/tfd

Metric Tube

4300 Catalog

Seamless EO Stainless Steel Tubes

Part No.

R6x171

R8x171

R8x1.571

R10x171

R10x1.571

R10x271

R12x171

R12x1.571

R12x271

R14x1.571

R14x271

R14x2.571

R15x171

R15x1.571

R15x271

R16x271

R16x2.571

R16x371

R18x1.571

R18x271

R20x271

R20x2.571

R20x371

R22x1.571

R22x271

R25x2.571

R25x371

R28x1.571

R28x271

R30x371

R30x471

R35x271

R38x471

R38x571

R42x271

R42x371

End

Size

(mm)

6

8

8

10

10

10

12

12

12

14

14

14

15

15

15

16

16

16

18

18

20

20

20

22

22

25

25

28

28

30

30

35

38

38

42

42

Wall

Toler- Thickness

ance

(mm)

0.1

1

0.1

1

1.5

1

0.1

1.5

2

1

0.08

1.5

2

1.5

0.08

2

2.5

1*

0.08

1.5

2

2

0.08

2.5

3

0.08

1.5

2

2

0.08

2.5

3

0.08

1.5

2

0.08

2.5

3

0.08

1.5

2

0.08

3

4

0.15

2

0.15

4

5

0.2

2*

3

Tube

I.D.

(mm)

4

6

5

8

7

6

10

9

8

11

10

9

13

12

11

12

11

10

15

14

16

15

14

19

18

20

19

25

24

24

22

31

30

28

38

36

1.4571

Design Pressure

Burst

(bar)

DIN 2413-1 DIN 2413-1 Pressure

Static

Dynamic

(bar)

426

330

2340

368

256

1660

472

366

2800

294

209

1290

389

301

1930

498

386

3100

245

177

1220

368

256

1580

426

330

2380

315

223

1550

420

289

2180

452

351

2800

196

143

860

294

209

1140

392

271

1750

368

256

1800

403

312

2120

472

366

2800

245

177

1050

327

230

1520

294

209

1250

368

256

1550

389

301

1960

200

146

720

267

192

1020

294

209

1190

353

247

1520

158

117

620

210

153

880

294

209

1140

392

271

1650

168

124

670

309

219

1240

387

268

1680

140

104

520

210

153

860

Material-No.: 1.4571

STANDARD

FROM STOCK

Stainless

Steel

Weight

(71)

(kg/m)

0.125

0.175

0.244

0.225

0.319

0.401

0.275

0.394

0.501

0.469

0.601

0.720

0.351

0.507

0.651

0.701

0.845

0.977

0.620

0.801

0.901

1.095

1.277

0.770

1.002

1.408

1.653

0.995

1.302

2.028

2.605

1.653

3.405

4.131

2.003

2.930

Pressure Calculation:

Pressure calculation given

are according to DIN 2413

part I for static stress

P=

20 K s c (bar)

S da

Material characteristic

value K=235 N/mm2 (1.4571),

K=235 N/mm2 (1.4571)

(1% proof stress)

Safety factor S = 1.5

Factor c for consideration of

wall thickness divergence: 0.9

da = Tube O.D. in mm

s = Wall thickness in mm

Remarks:

Corrosion Additional allowances are not considered

for the calculation of pressures.

Tubes with a diameter ratio

da/di 1.35 are calculated

according to DIN 2413 part

III (formula see page R4) with

above characteristic K value.

Conversion Factors:

Bar x 14.5 = psig

kg/m x 0.672 = lbs/ft

N/mm2 x 145 = lb/in2

* Tubes which need a support sleeve (VH) for assembly in EO and EO-2 ttings.

Table R4 Seamless EO stainless steel tubes

Dimensions and pressures for reference only, subject to change.

R6

Parker Hannin Corporation

Tube Fittings Division

Columbus, Ohio

http://www.parker.com/tfd

You might also like

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Metric TubeDocument6 pagesMetric TubePartsGopher.comNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Material Selection 1Document21 pagesMaterial Selection 1yulianus_srNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Metric Seamless TubeDocument4 pagesMetric Seamless Tuberaghu_mnNo ratings yet

- PIpingDocument32 pagesPIpingbalumagesh1979100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Piping Guide BookDocument15 pagesPiping Guide BookJagankumar100% (1)

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Critical PipingDocument7 pagesCritical PipingFRAN0026No ratings yet

- Hydraulic PipingDocument1 pageHydraulic Pipingpandunugraha04No ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- Inosindt Seamless Tubes 22Document40 pagesInosindt Seamless Tubes 22Pimen AjjahNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- 5026-PS-001 - 0 Supply of Piping MaterialsDocument17 pages5026-PS-001 - 0 Supply of Piping MaterialsCARLOS OLIVEROSNo ratings yet

- Elbow Component For Piping Direction ChangeDocument16 pagesElbow Component For Piping Direction ChangeKyaw Kyaw AungNo ratings yet

- Codes Standards For YANBU ProjectDocument7 pagesCodes Standards For YANBU ProjectBehçet Serdal CanbazNo ratings yet

- Din 1615Document5 pagesDin 1615David FonsecaNo ratings yet

- Buttweld FittingsDocument4 pagesButtweld Fittingskamal_mdNo ratings yet

- 3D & 5D Pipe Bend For PipelineDocument6 pages3D & 5D Pipe Bend For PipelinemohammadazraiNo ratings yet

- Ihara Fittings For High PressureDocument45 pagesIhara Fittings For High PressureQuang Thanh NguyenNo ratings yet

- Metal Hose With Braiding Catalogue ArsenflexDocument16 pagesMetal Hose With Braiding Catalogue ArsenflexcecotheoneNo ratings yet

- Astm A 106 Seamless Pressure PipeDocument2 pagesAstm A 106 Seamless Pressure Pipegkdora574No ratings yet

- Catálogo Equipo para Conducciones Ford Meter BoxDocument36 pagesCatálogo Equipo para Conducciones Ford Meter BoxeduarshNo ratings yet

- Introducción Tubería PittingDocument26 pagesIntroducción Tubería PittingOscar SarmientoNo ratings yet

- Valves Pipe Fittings DimensionsDocument37 pagesValves Pipe Fittings DimensionstsoheilNo ratings yet

- STP CatalogueDocument37 pagesSTP CataloguemmkattaNo ratings yet

- Pipe DesignDocument6 pagesPipe DesignmaneeshmsanjagiriNo ratings yet

- ErmetoDocument14 pagesErmetoJavier VespaNo ratings yet

- Avances en Soldadura para Diseños Sanitario Apuntes AWS D18.1 18.2 18.3Document27 pagesAvances en Soldadura para Diseños Sanitario Apuntes AWS D18.1 18.2 18.3hernando gelvesNo ratings yet

- S-0000-1360-0005 - TECHNICAL SPECIFICATION FOR PipesDocument22 pagesS-0000-1360-0005 - TECHNICAL SPECIFICATION FOR PipesPaul NieNo ratings yet

- Piping System: Amj Engineering Consultants Co.,LtdDocument18 pagesPiping System: Amj Engineering Consultants Co.,Ltdprashantms1481No ratings yet

- 7a. Steel Pipeline FittingDocument37 pages7a. Steel Pipeline Fittingamaliabdulkader100% (1)

- Pipe FittingsDocument40 pagesPipe FittingsLucky Jaswal100% (1)

- Advances in Welding For Sanitary DesignsDocument34 pagesAdvances in Welding For Sanitary Designskart_rlNo ratings yet

- Technical Catalogue: Pipes Tubes Fittings FlangesDocument121 pagesTechnical Catalogue: Pipes Tubes Fittings FlangesDANIELVENZUELAANo ratings yet

- Astm f1548 1994Document6 pagesAstm f1548 1994dharlanuctcomNo ratings yet

- 13 BushingsDocument25 pages13 BushingsRolffoTelloNo ratings yet

- 6606 Ebaa 3800 Series: Restrained CouplingDocument1 page6606 Ebaa 3800 Series: Restrained CouplingDGWNo ratings yet

- Standard For Mechanical: I.PipingDocument4 pagesStandard For Mechanical: I.PipingHiếu Nguyên0% (1)

- M PL 033Document19 pagesM PL 033Ali ClubistNo ratings yet

- Piping System: Presented byDocument28 pagesPiping System: Presented byReymond IgayaNo ratings yet

- Hottappingrequirement1 160722152313 PDFDocument94 pagesHottappingrequirement1 160722152313 PDFadel100% (1)

- PTSC MC-Piping Design Training-Basic Piping-LATESTDocument31 pagesPTSC MC-Piping Design Training-Basic Piping-LATESTNguyen Anh Tung50% (2)

- Hottappingrequirement1 160722152313Document94 pagesHottappingrequirement1 160722152313ansherina2No ratings yet

- Conexao de Dupla Anilha RotarexDocument68 pagesConexao de Dupla Anilha RotarexElias Barros de FigueiredoNo ratings yet

- Astm f1155 1998Document25 pagesAstm f1155 1998nerissaloveNo ratings yet

- 32 - Seamless EO Steel Tubes Material E235N (St. 37.4)Document6 pages32 - Seamless EO Steel Tubes Material E235N (St. 37.4)samohaomer001No ratings yet

- Astm f1155 1998Document25 pagesAstm f1155 1998ttplan800No ratings yet

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- Flangemanagementpresentation 160911122834Document83 pagesFlangemanagementpresentation 160911122834Yusuf Alfathony100% (2)

- Project Standard Specification: Pipe Expansion Fittings and Loops 15121 - Page 1/5Document5 pagesProject Standard Specification: Pipe Expansion Fittings and Loops 15121 - Page 1/5adel rihanaNo ratings yet

- PROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01Document7 pagesPROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01mihahudeaNo ratings yet

- Aterial Specification & All Thickness CalculationDocument35 pagesAterial Specification & All Thickness CalculationPanjiUte100% (1)

- 03 ComponentsDocument61 pages03 ComponentsEhab AbowardaNo ratings yet

- Design of Vertical Lift GATESDocument31 pagesDesign of Vertical Lift GATESDheeraj Verma90% (39)

- The Basic System The Basic SystemDocument26 pagesThe Basic System The Basic SystemJenny Cecilia Ureña Zuri100% (1)

- Machine Installation - Shaft AlignmentDocument17 pagesMachine Installation - Shaft AlignmentD.b. Tampubolon100% (1)

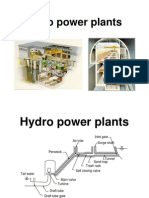

- 5 - Hydro Power PlantsDocument73 pages5 - Hydro Power Plants2003_335100% (1)

- GEA31236Final HydroTestInspectConditionAssessmentService PDFDocument6 pagesGEA31236Final HydroTestInspectConditionAssessmentService PDFJenny Cecilia Ureña ZuriNo ratings yet

- Engineering Design Handbook - Hydraulic FluidsDocument289 pagesEngineering Design Handbook - Hydraulic FluidsDonald BrittinNo ratings yet

- OpenStax Physics-Student Solution ManualDocument240 pagesOpenStax Physics-Student Solution ManualJackKingsman79% (14)

- Alignment of Vertical Shaft HydrounitsDocument50 pagesAlignment of Vertical Shaft HydrounitsAlexander Gotte100% (3)

- Shaft Precision Alignment FundamentalsDocument9 pagesShaft Precision Alignment FundamentalsJenny Cecilia Ureña ZuriNo ratings yet

- Ludeca-A Practical Guide To Shaft Alignment PDFDocument0 pagesLudeca-A Practical Guide To Shaft Alignment PDFDelfinsh100% (1)

- Acoples FLOWSERVE - Instalación PDFDocument12 pagesAcoples FLOWSERVE - Instalación PDFJenny Cecilia Ureña ZuriNo ratings yet

- Mesauring Hydro TurbinesDocument8 pagesMesauring Hydro TurbinesJenny Cecilia Ureña ZuriNo ratings yet

- Mechanical Engineering - WikipediaDocument453 pagesMechanical Engineering - WikipediaJenny Cecilia Ureña Zuri100% (2)

- Hydro Power Workshop at Kathmandu Afganistan Janak KoiralaDocument70 pagesHydro Power Workshop at Kathmandu Afganistan Janak KoiralaJenny Cecilia Ureña ZuriNo ratings yet

- Fundamental of Heat Exchanger DesignDocument972 pagesFundamental of Heat Exchanger Designabiy12791% (44)

- Bearing Electro PittingDocument19 pagesBearing Electro PittinglyanagustNo ratings yet

- Feedback Control and Time-Optimal Control About Overhead Crane by Visual Servo and These Combination ControlDocument17 pagesFeedback Control and Time-Optimal Control About Overhead Crane by Visual Servo and These Combination ControlJenny Cecilia Ureña ZuriNo ratings yet

- Welding Process and TechnologyDocument63 pagesWelding Process and TechnologySuresh KumarNo ratings yet

- Welding Process and TechnologyDocument63 pagesWelding Process and TechnologySuresh KumarNo ratings yet

- Ido 10107 Vol.1 pt2Document212 pagesIdo 10107 Vol.1 pt2Vanu VamalaiNo ratings yet

- Siteselectionfinaltalaga 130716070855 Phpapp02Document28 pagesSiteselectionfinaltalaga 130716070855 Phpapp02Jenny Cecilia Ureña ZuriNo ratings yet

- Hydrology Site Selection of HydropowerplantDocument25 pagesHydrology Site Selection of HydropowerplantJenny Cecilia Ureña ZuriNo ratings yet

- Process Heat Group Major ChallengesDocument29 pagesProcess Heat Group Major ChallengesKhloud MadihNo ratings yet

- PR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and CertificationDocument113 pagesPR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and Certificationmac1677No ratings yet

- Voith Hypower 2013Document29 pagesVoith Hypower 2013Jenny Cecilia Ureña ZuriNo ratings yet

- 31394Document33 pages31394Jenny Cecilia Ureña ZuriNo ratings yet

- Sealing For Hydropower EquipmentDocument28 pagesSealing For Hydropower EquipmentJenny Cecilia Ureña ZuriNo ratings yet

- TurbinesDocument19 pagesTurbinesSamarakoon BandaNo ratings yet

- Anchor Bolt Design Per ACI-318-11 Crane Beam DesignDocument3 pagesAnchor Bolt Design Per ACI-318-11 Crane Beam DesignJenny Cecilia Ureña ZuriNo ratings yet

- Biocleaner Presentation SewageDocument10 pagesBiocleaner Presentation SewageLTE002No ratings yet

- SonnyDocument16 pagesSonnyEmme Ya100% (13)

- Chapter 2 Advances in Concrete Properties and Concrete Making MaterialsDocument77 pagesChapter 2 Advances in Concrete Properties and Concrete Making MaterialsMosisa ShelemaNo ratings yet

- Sublimation Heat Press Settings - Quick Reference GuideDocument1 pageSublimation Heat Press Settings - Quick Reference GuidecherNo ratings yet

- NYYHYDocument1 pageNYYHYCiwa DoankNo ratings yet

- Experiment 3: Extraction Prelab Questions (Week 2) Due Upon Entering LabDocument1 pageExperiment 3: Extraction Prelab Questions (Week 2) Due Upon Entering LabTor JanssonNo ratings yet

- CF CM HE 4206a enDocument60 pagesCF CM HE 4206a enNius Pahala NainggolanNo ratings yet

- Galvalok INGLESDocument8 pagesGalvalok INGLESsanvel1815No ratings yet

- SRSDocument7 pagesSRSCLC 18C4No ratings yet

- CI2400ENG Bondstrand 2400 Product DataDocument6 pagesCI2400ENG Bondstrand 2400 Product DatachabibNo ratings yet

- DSMTS-0095.3 NiCrAlMo CompositeDocument3 pagesDSMTS-0095.3 NiCrAlMo Compositeivanis_davorNo ratings yet

- VS1 (ZN63A) - 12 Indoor AC High Voltage Vacuum Circuit BreakerDocument2 pagesVS1 (ZN63A) - 12 Indoor AC High Voltage Vacuum Circuit BreakerVinod KumarNo ratings yet

- Vibration Analysis of An Alstom Typhoon Gas Turbine Power Plant Related To Iran Oil IndustryDocument8 pagesVibration Analysis of An Alstom Typhoon Gas Turbine Power Plant Related To Iran Oil IndustryFajar HidayatNo ratings yet

- Ishrae - 365 - 2009Document16 pagesIshrae - 365 - 2009babudevanandNo ratings yet

- Samsung DVM Chiller InstallationManualDocument56 pagesSamsung DVM Chiller InstallationManualjlmoleroNo ratings yet

- Catalogue Centrifugal Pumps 2Document54 pagesCatalogue Centrifugal Pumps 2Velez SantanderNo ratings yet

- Retrofit Assessment ChecklistDocument8 pagesRetrofit Assessment ChecklistPrakash SIngh RawalNo ratings yet

- Hot PlateDocument2 pagesHot PlateGiniung AugieNo ratings yet

- CAM Question Paper AktuDocument2 pagesCAM Question Paper AktuAshutosh KumarNo ratings yet

- Api and British Standard Trim DesignationsDocument1 pageApi and British Standard Trim DesignationsPOTDARNo ratings yet

- PFI HFB High Flow Pleated Bag Filter CartridgeDocument2 pagesPFI HFB High Flow Pleated Bag Filter Cartridgebennypartono407No ratings yet

- Automotive Transmission - Lecture Notes CompleteDocument156 pagesAutomotive Transmission - Lecture Notes CompleteAkshay PundeNo ratings yet

- Hydrogen Gas Dryer - AspxDocument2 pagesHydrogen Gas Dryer - AspxtpplantNo ratings yet

- Machine FoundationDocument4 pagesMachine Foundationp kishorNo ratings yet

- Technical Data Sheet: High Performance Rail Grease With GraphiteDocument1 pageTechnical Data Sheet: High Performance Rail Grease With GraphiteDon HowardNo ratings yet

- UK P3 VEN 0153 201409 02 Vent Silencer CatalogueDocument9 pagesUK P3 VEN 0153 201409 02 Vent Silencer Cataloguetiffanyyy00No ratings yet

- ConclusionDocument2 pagesConclusionRohit Kumar75% (4)

- BMSDocument70 pagesBMSbilal almelegy100% (1)

- Plastic Bottle For Children's EducationDocument9 pagesPlastic Bottle For Children's EducationHeHe HaHaNo ratings yet

- Curing 4Document588 pagesCuring 4santoruno lupinottiNo ratings yet

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)