Professional Documents

Culture Documents

10 Steps To ISO 9001 Certification

Uploaded by

Tanzeel Liaqat0 ratings0% found this document useful (0 votes)

119 views2 pages10 Steps to ISO 9001 Certification

Original Title

10 Steps to ISO 9001 Certification

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document10 Steps to ISO 9001 Certification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

119 views2 pages10 Steps To ISO 9001 Certification

Uploaded by

Tanzeel Liaqat10 Steps to ISO 9001 Certification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

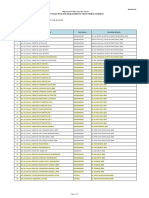

10 STEPS TO

ISO 9001

CERTIFICATION

Regardless of the product or service your organization provides,

ISO 9001 focuses on the effectiveness of your processes and

delivery of your services.

DNV offers 10 simple steps to certification:

1. Identify your key drivers

We recommend that you formally review, at a senior

management level, your key drivers for implementing

a Quality Management System.

Such drivers should include improved awareness of the

performance of your key processes and the need for

continual improvement, as well as any specific customer

requirements.

2. Obtain the standard

Purchase a copy of the standard. Search the web for links

to ISO 9001 relating to your particular sector. Make sure

you know the facts from the myths. For example, ISO 9001

is applicable to any organization in any industry, not just

the manufacturing sector.

3. Define your strategy

To successfully implement a Quality Management System,

commitment is required from senior management on

defining the strategy.

Start to formally document a quality policy and objectives

following the requirements given in ISO 9001. Ensure the

requirements of the quality policy are measureable to be

able to demonstrate continuous improvements.

4. Planning provides resources for developing the

quality management system

The required resources need to be made available and

realistic timelines allocated ensuring that responsibilities

are shared within the organization and not just allocated

to the Quality Manager. In itself, a formal implementation

project plan is not a requirement of ISO 9001 but is

a sensible way of identifying needs and progressing

implementation.

As the system is developed, this plan should be

reviewed by senior management and kept updated.

The responsibility for the Quality Management System

and the Quality Management representative should be

clearly identified. In addition, you may wish to employ a

consultant to help develop the system. Take care that the

consultant knows and understands your business and any

advice covers your whole business.

5. Know your processes

IS0 9001 requires you to formally describe the interaction

between the processes within the management system.

This can be achieved by a simple process map specific to

your organization.

The map should identify the key processes and also

indicate the resources, controls, documentation and

records needed to meet your customers requirements.

Ensure this process map is validated throughout your

business to ensure no areas or interactions are missed. As

the system is developed this process map should be used,

reviewed and updated for its eventual inclusion in the

Quality Manual.

6. Determine training needs

ISO 9001 requires proper identification of competence

requirements for employees coming within the scope

of the Quality Management System. Team leaders,

employees and internal auditors will all need to meet

the requirements of competence, sometimes requiring

external training.

A range of courses, workshops and seminars are available

to meet these needs. Make sure to define how you will

demonstrate the effectiveness of training.

7. Develop management system documentation

8. Implement your Quality Management System

Proper implementation of the requirements of your Quality

Management System should be measured and recorded

by internal audits. A management review must also be

conducted to ensure the systems continuing suitability,

adequacy and effectiveness.

The main review is a key driver to demonstrate the

effective implementation of the Quality Management

System. Any corrective and preventive actions should be

identified, progressed and recorded.

9. Consider a pre-assessment audit

A pre-assessment audit or gap analysis by your intended

certification body will help you identify any gaps that

exist between the requirements of the standard and your

organizations existing processes.

This audit can be carried out at any stage and is

independent of the certification process - it will not

constitute consultancy help.

ISO 9001 requires controlled documentation of a policy,

manual and procedures as well as certain records. Whilst

certification requires documented procedures,

over-detailed documents are not the goal.

10. Go for certification

There are six documented procedures specifically required

by ISO 9001 as well as those needed and identified by the

organization. The required procedures should be drafted

and developed in conjunction with the personnel who will

be involved.

The stage 1 process is an on-site document and readiness

review at your head office. You will be awarded a UKAS

accredited certificate on successful completion of the stage

2 audit. Forward planning and early dialogue with your

chosen certification body is important.

Only use a nationally accredited certification body:

http://www.ukas.com/. DNV has a very wide range of

accreditation. Initial certification is a two-stage process.

You might also like

- 10 STEPS TO ISO 9001 CERTIFICATION - tcm12-52346 PDFDocument2 pages10 STEPS TO ISO 9001 CERTIFICATION - tcm12-52346 PDFRajanNo ratings yet

- Guia Implementacion Iso 9001 2008Document8 pagesGuia Implementacion Iso 9001 2008Fernando Medina ValeraNo ratings yet

- Iso 9001Document11 pagesIso 9001Thiyaga RajanNo ratings yet

- Tips For Internal Auditing of ISO 9001 QMSDocument12 pagesTips For Internal Auditing of ISO 9001 QMSabdul qudoosNo ratings yet

- Iso 9001 2015Document21 pagesIso 9001 2015Sapan Kansara100% (1)

- Iso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailFrom EverandIso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailRating: 5 out of 5 stars5/5 (3)

- Internal Audit Guidance ExampleDocument2 pagesInternal Audit Guidance Examplesunderrajan100% (1)

- ISO 9001 2015 Internal Audit Checklist SampleDocument7 pagesISO 9001 2015 Internal Audit Checklist SampleNaeem Iqbal33% (3)

- Summary of Iso 90091Document3 pagesSummary of Iso 90091Ihuhwa Marta TauNo ratings yet

- Internal Audit Checklist Q1 - IsO 2015 - Final FormatDocument30 pagesInternal Audit Checklist Q1 - IsO 2015 - Final FormatThee BouyyNo ratings yet

- Documented InformationDocument5 pagesDocumented InformationripacNo ratings yet

- Project Proposal For ISO9001 2015 Implementation enDocument5 pagesProject Proposal For ISO9001 2015 Implementation enNeftali Lopez ElizondoNo ratings yet

- SO 90012015 Clause by ClauseDocument12 pagesSO 90012015 Clause by ClauseVitelariu Leonard100% (1)

- Iso 9001 2015 Gap QuestionsDocument6 pagesIso 9001 2015 Gap QuestionsL100% (5)

- ISO 9001-2015 ChecklistDocument28 pagesISO 9001-2015 Checklisthesham_tm3658100% (3)

- Certified ISO 9001 Lead Auditor - Two Page BrochureDocument2 pagesCertified ISO 9001 Lead Auditor - Two Page BrochurePECBCERTIFICATIONNo ratings yet

- ISO 9001 Requirements ExplainedDocument18 pagesISO 9001 Requirements ExplaineddesurkarbNo ratings yet

- What Is Iso CertificationDocument4 pagesWhat Is Iso CertificationShailesh GuptaNo ratings yet

- ISO 9001-2015 Presentation PDFDocument92 pagesISO 9001-2015 Presentation PDFDaniel Tan100% (3)

- Internal Audit Guidance Assessing ISO 90Document13 pagesInternal Audit Guidance Assessing ISO 90Srinivas Yanamandra100% (1)

- Checklist ISO 9001-2015Document37 pagesChecklist ISO 9001-2015indri100% (2)

- PR018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Document9 pagesPR018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2uks444100% (1)

- Internal Audit ChecklistDocument74 pagesInternal Audit Checklistinternationalindustrialsprings100% (1)

- ISO 9001 Gap Analysis ChecklistDocument4 pagesISO 9001 Gap Analysis ChecklistmukundisoNo ratings yet

- ISO 9001 2015 - Internal AuditDocument124 pagesISO 9001 2015 - Internal AuditAngel Gorospe100% (1)

- Iso 9001-2015 Gap AnalysisDocument30 pagesIso 9001-2015 Gap Analysisjamilvora100% (4)

- ISO 9001 QuizDocument4 pagesISO 9001 QuizGVS Rao0% (1)

- Gap Analysis ISO-9001 2015Document84 pagesGap Analysis ISO-9001 2015Dian Razak BastianNo ratings yet

- ISO 9001 2015 Transition Checklist C 01 Rev ADocument4 pagesISO 9001 2015 Transition Checklist C 01 Rev APlant Head PrasadNo ratings yet

- Understanding QMS 9001 2015 PDFDocument108 pagesUnderstanding QMS 9001 2015 PDFLeoncio Lumaban100% (2)

- ISO 9001 2015 GAP Analysis ReviewDocument58 pagesISO 9001 2015 GAP Analysis ReviewabcNo ratings yet

- Iso 9001:2008 Audit Checklist: Yes No If Any? No. Clause/Doc. No CommentsDocument14 pagesIso 9001:2008 Audit Checklist: Yes No If Any? No. Clause/Doc. No CommentsMeijin SenjinNo ratings yet

- 01 ISO 9001-2015 Transition Checklist C 01 Rev ADocument4 pages01 ISO 9001-2015 Transition Checklist C 01 Rev Avikkas vermaNo ratings yet

- Internal AuditsDocument9 pagesInternal Audits李哲祥100% (1)

- Sample - Management Review MeetingDocument9 pagesSample - Management Review MeetingClaire TanNo ratings yet

- ISO 9001:2015 IN BriefDocument4 pagesISO 9001:2015 IN BriefGiritharan Sankaralingam100% (1)

- ISO 9001 Internal Audit ChecklistDocument22 pagesISO 9001 Internal Audit ChecklistPCNo ratings yet

- ISO 9001 2015 OverviewDocument72 pagesISO 9001 2015 OverviewGilang Cakra D100% (1)

- ISO 9001 - 2015 Overview and ExpectationsDocument59 pagesISO 9001 - 2015 Overview and ExpectationsAnonymous DP6iO3DfQ88% (8)

- ISO 9001-2015 Client-Transition-Checklist - Add Your Co NameDocument11 pagesISO 9001-2015 Client-Transition-Checklist - Add Your Co NameTomBerendsenNo ratings yet

- Main Difference Between 2008 & 2015Document3 pagesMain Difference Between 2008 & 2015santhoshneo02@gmail.comNo ratings yet

- QM 9001-2015 TemplateDocument32 pagesQM 9001-2015 TemplateBobby IM Sibarani100% (12)

- ISO 9001 2015 Transition Gap Analysis ChecklistDocument49 pagesISO 9001 2015 Transition Gap Analysis ChecklistSagar PandaNo ratings yet

- ISO 9001 2015 Management BriefingDocument23 pagesISO 9001 2015 Management BriefingSeni Oke100% (1)

- Cracking the Case of ISO 9001:2015 for Manufacturing: A Simple Guide to Implementing Quality Management in ManufacturingFrom EverandCracking the Case of ISO 9001:2015 for Manufacturing: A Simple Guide to Implementing Quality Management in ManufacturingNo ratings yet

- QMS 3Document11 pagesQMS 3Ram MohanNo ratings yet

- Project Checklist of ISO 9001Document2 pagesProject Checklist of ISO 9001Rajat Jain100% (1)

- ISO Awareness SurveyDocument2 pagesISO Awareness SurveyJepoi Clemente100% (3)

- Preview - Iso9001-2015.checklist For ISO 9001-2015Document6 pagesPreview - Iso9001-2015.checklist For ISO 9001-2015Jones RNo ratings yet

- ISO 9001-2015 Supplier Audit ChecklistDocument23 pagesISO 9001-2015 Supplier Audit ChecklistFadhel Audia YusranNo ratings yet

- ISO 9001 2015 Implementation Process Diagram enDocument1 pageISO 9001 2015 Implementation Process Diagram enStrahinja Stojanovic100% (3)

- Pecb Iso 9001 Lead Auditorexam Preparation GuideDocument15 pagesPecb Iso 9001 Lead Auditorexam Preparation GuideDian Abiyoga50% (2)

- ISO 9001 Lead Auditor Course Training - IRCA ApprovedDocument4 pagesISO 9001 Lead Auditor Course Training - IRCA ApprovedintertekmoodyNo ratings yet

- ISO 9001 Lead Auditor Course ChartsDocument8 pagesISO 9001 Lead Auditor Course ChartsPili Colorada100% (2)

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- Honda CityDocument8 pagesHonda CityTanzeel LiaqatNo ratings yet

- Industry Research Production and Linkages With Academia: Evidence From Uk Science ParksDocument18 pagesIndustry Research Production and Linkages With Academia: Evidence From Uk Science ParksTanzeel LiaqatNo ratings yet

- CERC (2014 Edition)Document462 pagesCERC (2014 Edition)Jason Simpson100% (1)

- The Contract Management Process Post AwardDocument11 pagesThe Contract Management Process Post AwardTanzeel LiaqatNo ratings yet

- Introduction To Feasibility Studies 97Document32 pagesIntroduction To Feasibility Studies 97Tanzeel LiaqatNo ratings yet

- Retail Invoice: Iworld Business Soluon PV T. LTDDocument3 pagesRetail Invoice: Iworld Business Soluon PV T. LTDВиктор РакушкинNo ratings yet

- Operations Management - Amit Anil KulkarniDocument87 pagesOperations Management - Amit Anil KulkarniSudhir KumarNo ratings yet

- Evaluating The Social Media For Marketers Conference and Providing Recommendations For The Next ConDocument11 pagesEvaluating The Social Media For Marketers Conference and Providing Recommendations For The Next ConAnoofa AhmedNo ratings yet

- XS - MW PATTERNsDocument17 pagesXS - MW PATTERNsimma coverNo ratings yet

- What Is A SWOT AnalysisDocument23 pagesWhat Is A SWOT AnalysisvssNo ratings yet

- Project Report: Recruitment and SelectionDocument34 pagesProject Report: Recruitment and SelectionGurusaran SinghNo ratings yet

- Key Strategy ToolsDocument2 pagesKey Strategy Toolsscribd2learn100% (2)

- Production/Operations ManagementDocument97 pagesProduction/Operations Managementdinesh0014No ratings yet

- trắc nghiệm quản trị kênh phân phốiDocument14 pagestrắc nghiệm quản trị kênh phân phốiVinh HuỳnhNo ratings yet

- Assistant Labour Officer 126 - 2018Document14 pagesAssistant Labour Officer 126 - 2018ARUNNo ratings yet

- Statement of Cash Flows: Kimmel Weygandt Kieso Accounting, Sixth EditionDocument43 pagesStatement of Cash Flows: Kimmel Weygandt Kieso Accounting, Sixth EditionJoonasNo ratings yet

- OD328636244353646100Document3 pagesOD328636244353646100ankit ojhaNo ratings yet

- Waste Management in PDO Ahmed Al-Sabahi - CSM/25 Corporate Environmental AdvisorDocument22 pagesWaste Management in PDO Ahmed Al-Sabahi - CSM/25 Corporate Environmental AdvisorMojtaba TahaNo ratings yet

- Unit 9 - Perfect CompetetionDocument101 pagesUnit 9 - Perfect CompetetionRavi GargNo ratings yet

- List of Vacant Posts (Civil Wing) Available For Choice Filling by CandidatesDocument5 pagesList of Vacant Posts (Civil Wing) Available For Choice Filling by CandidatesPreetam SundarayNo ratings yet

- InventoryDocument18 pagesInventoryAdam Cuenca100% (1)

- GovREVIEWER in FINALS (Compilatioin of Assignmenst and Exercises)Document74 pagesGovREVIEWER in FINALS (Compilatioin of Assignmenst and Exercises)Hazel Morada100% (1)

- Marketing PlanDocument26 pagesMarketing PlanKrysten BelistaNo ratings yet

- Factor Markets and Income Distribution: Presented By: Sbac-1CDocument45 pagesFactor Markets and Income Distribution: Presented By: Sbac-1CHartin StylesNo ratings yet

- De Boer-Hekkert-and-Woolthuis PDFDocument40 pagesDe Boer-Hekkert-and-Woolthuis PDFAdriana BernalNo ratings yet

- Conviser Company: Joint Cost Product C Product L Product T TotalDocument6 pagesConviser Company: Joint Cost Product C Product L Product T TotalKiyo KoNo ratings yet

- MCQs - Chapters 4 - 6Document12 pagesMCQs - Chapters 4 - 6Lâm Tú HânNo ratings yet

- ALL GOLD OFFERS June 2021-1-1Document15 pagesALL GOLD OFFERS June 2021-1-1Lin Chris100% (1)

- Entrepreneurship Assignment 2Document5 pagesEntrepreneurship Assignment 2Musa MasoodNo ratings yet

- PBO - Lecture 01 - Introduction To Business OperationsDocument5 pagesPBO - Lecture 01 - Introduction To Business OperationskevorkNo ratings yet

- Indian Institute of Management, Udaipur: FMCG Industry Group No. 14Document5 pagesIndian Institute of Management, Udaipur: FMCG Industry Group No. 14Chirag JainNo ratings yet

- Chavi Marodia LLM D Literature ReviewDocument11 pagesChavi Marodia LLM D Literature ReviewChavi MarodiaNo ratings yet

- Minutes of Organizational Meeting of BODDocument2 pagesMinutes of Organizational Meeting of BODCourtney TirolNo ratings yet

- Management Principle and Application Unit 1 IntroDocument54 pagesManagement Principle and Application Unit 1 IntroAiwiwNo ratings yet

- ACCT230 Ch7Document60 pagesACCT230 Ch7Said MohamedNo ratings yet