Professional Documents

Culture Documents

0526 16 2004 07 en - en

Uploaded by

vtsusr fvOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0526 16 2004 07 en - en

Uploaded by

vtsusr fvCopyright:

Available Formats

EAM-0526-16:2004/07 (EN)

PED- Pressure Equipment Directive 97/23/EC

- European Approval for Materials This data sheet has been raised in accordance with the requirements of Article 11 of the Pressure Equipment Directive (97/23/EC).

The material described within is not included in a standard which has been harmonised to the afore mentioned directive.

EAM-0526-16:2004/07

Submitted by: Notified Body 0526

CETIM - BP. 80067 - 52 avenue Flix Louat

F-60304 SENLIS CEDEX France.

Tel. +33.344673479 Fax. +33.344673427

EAM 0526-16 -Rev 7 - EN

Date: 05 july 2004

e-mail chaieb.jarboui@cetim.fr

Designation

Type of material

1

Material

Designation

Standards to

which

consideration and

or reference has

been given.

EAM-NiCr21Mo14W

Nickel-chromium- Molybdenum alloy Flat products

1.1

Classification:

0526-16:2004/07

1.2

Name:

NiCr21Mo14W

1.3

Material Ref. No.:

2.4602 (Werkstoffnummer)

1.4

UNS Ref. No.:

N06022

1.5

ISO/TR 15608:2000

Group 43

This EAM incorporates by dated reference provisions from other publications. These

references are cited in the text and in the following list. Subsequent amendments to, or

revisions of any of these publications apply to this EAM only when incorporated in an

amendment or revision to this EAM.

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

VdTV 479 12/2003 (Origin) modified to reflect the actual material deliveries.

EN 10002-1:2001

EN 10002-5:19922.4

EN 10045-1:1990

EN 10204:1991

EN ISO 6508-1:1999

EN 910:1996

SEP 1877-II:1994.

Copyright: No copying without CETIM permission except as permitted by copyright law.

Original copies of this European Approval for Materials may be obtained from CETIM at the address detailed above, an administration charge of

20 is payable with the order. This EAM can also be downloaded free of charge from the Commission website

http://europa.eu.int/comm/enterprise/pressure_equipment/eam_published.htm.

This document has unrestricted use by public administration and other Notified Bodies within the context of PED 97/23/EC.

CETIM - Registered in France

Reg. No. Siren: 775629074

Reg. Office as above.

Page 1 of 6

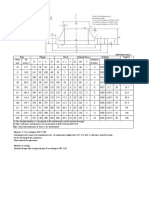

EAM-0526-16:2004/07 (EN)

Limiting

Dimensions

Form

Dimensions

Flat products

4

5

Melting Method

Thickness (mm)

Diameter (mm)

Up to and including 50 mm

4.1

Electric Arc Process and vacuum or argon process

4.2

Induction Furnace Process and vacuum or argon process

Production

Method /

Delivery

Condition

5.1

Hot Rolled

5.2

Cold Rolled

Application

Temperatures

6.1

-196 C to 400 C

6.2

The material is suitable for use down to 196 C. For use below 10 C, impact

energy values and verification procedures shall be agreed at the time of ordering.

Solution annealing (see section 10)

The products shall be free from surface and internal defects which might impair their

usability.

Chemical

Composition

% Composition by Weight

Ni

C*

Si

Mn

S*

P*

Fe

Cr

Mo

Co

Ladle and

Minimum

56.0

2.0

20.0

12.5

2.5

Product

Maximum

0.008

0.080

0.50

0.005

0.008

6.0

22.5

14.5

3.5

2.5

0.35

* modified to reflect the actual material deliveries.

Mechanical and

Technological

requirements

8.1

Tensile Properties at Room Temperature (20 C)

Rp0.2 min

Rp1.0 min

Rm min

A min (%)

(N/mm)

(N/mm)

(N/mm)

(both 5d and 5.65So)

310

335

690 - 950

45

Verification Test

Direction

8.2

Transverse (see section 9).

Tensile

Properties

8.3

Minimum proof strength values at Elevated Temperature (C)1)

100

200

300

400

Requirement N/mm

Rp1.0

290

245

215

195

Rp0.2

270

225

195

175

1) For design calculations no interpolation between stated values is permitted (unless the design code explicitly

provides for it). The values at the higher temperature shall be used.

These property values are taken from VdTV 479 12/2003.

N.B. 1 N/mm2 = 1 MPa

CETIM - Registered in France

Reg. No. Siren: 775629074

Reg. Office as above.

Page 2 of 6

EAM-0526-16:2004/07 (EN)

Other

Properties

8.4

Minimum Impact Properties, Transverse direction (Charpy ISO - V)

EN 10045-1

8.5

at RT: KV min = 120 Joules,

at 196 C: KV min = 96 Joules.

Hardness Rockwell B - EN ISO 6508-1

HRB: 93 max

8.6

Modulus of Elasticity (kN/mm)

Temperature (C)

20

100

200

300

400

500

E-Modulus

206

203

197

191

185

180

8.7 Intergranular corrosion properties

SEP 1877 method II.

9

Testing

9.1

Type of Inspection and Test

Test / Inspection

Frequency

Reference

Cast Analysis

One per cast

Section 7

Product Analysis

One per cast (if required and agreed

at the time of ordering by the

purchaser).

Section 7

Positive Material

identification

All Items

Section 7

9.2

Tensile Test at RT

Product form

Plate

Frequency

< 10 mm

1 Transverse test

per cast, per heat treatment lot, per

size, per 10 sheets / plates minimum

or part thereof.

Plate

1 Transverse test per plate.

Reference

Section 8.1 and

EN 10002-1

10 mm

Coil Strip

4 mm

9.3

1 Transverse test at each end of the

coil, longitudinal for coil width < 200

mm.

Elevated Temperature Tensile Tests

Product Form

Frequency

Reference

All product forms for

operating temperatures

One test per cast from the product

with the largest thickness at the

design temperature (or 400 C if not

specified).

Section 8.3 and

> 50 C.

CETIM - Registered in France

Reg. No. Siren: 775629074

Reg. Office as above.

EN 10002-5

Page 3 of 6

EAM-0526-16:2004/07 (EN)

Testing

9.4

Impact Testing

Verification of impact properties is only required when specified

by the purchaser at the time of ordering.

The values stated in section 8.4 shall be the minimum average

of 3 specimens, with only one individual specimen value allowed

up to a maximum of 30 % lower.

9.5

Hardness Test

Reference

All

All Mechanical Test Samples / Coupons

Section 8.5

Product Form

Frequency

Reference

All

First finished worked product made from

the relevant cast

Section 8.7

Corrosion test

Visual Inspection1)

Product Form

Frequency

All

All items

9.8

Frequency

All

All items

Heat

Treatment

Reference

Dimensional Inspection1)

Product Form

1)

Joining

EN 10045-1

Frequency

9.7

11

Section 8.4 and

Product Form

9.6

10

Reference

Reference

100 % inspection of all products by the manufacturer. Dimensional tolerances for all product forms

shall be agreed between the manufacturer and purchaser at the time of ordering.

Method

Temperatures

(C)

Holding Time

(min)

Solution

Annealing

1105 to 1135

5 to 15

depending of thickness

Cooling

Water

For product thickness up to 1.5 mm,

rapid air cooling should be acceptable

11.1 Welding

This material has, historically, proven suitable for fusion welding by the TIG (141) and MIG

(131) welding process using the appropriate filler material, e.g. No. 2.4635*. The MMA (111)

welding process with coated electrodes using the appropriate filler material, e.g. material

No. 2.4638* may also be applied, but it is important to consult material manufacturer and

other interested parties to insure that appropriate precaution are implemented.

The use of submerged arc welding for this alloy is not recommended.

Information supplied by the consumable manufacturer on the filler wires suitability must be

considered, especially with regard to sulphur sensitivity and both low and elevated

temperature properties.

The material does not normally require preheat neither post-welded heat treatment. Stress

relief annealing is not required after welding.

Welding operations, however, must be carried out at a temperature of more than 5 C. The

temperature between passes must be kept relatively low i.e. less than 100 C.

Where cold forming exceeds 15 %, solution annealing shall be performed prior to welding.

Consultation with the material manufacturers technical department is recommended when

choosing a filler wire or welding process.

* Werkstoffnummer

11.2 Bend properties of welded joint: (on production test coupon)

Bending test at room temperature on welded joint shall be carried out on mandrel with

diameter, D = 3.a (a: specimen thickness) according to EN 910.

Bending angle: 180 .

CETIM - Registered in France

Reg. No. Siren: 775629074

Reg. Office as above.

Page 4 of 6

EAM-0526-16:2004/07 (EN)

12

Forming

12.1 Hot and Cold forming

This material is suitable for both hot and cold forming subject to the following provisions:

1)

Hot forming shall occur at between 1080 C to 900 C followed by solution

annealing (see section 10).

2)

Where cold forming deformation exceeds 15 % a solution annealing shall be

performed (see section 10).

3)

The material is sensitive to sulphur above 400 C, therefore the surface should

be carefully cleaned before heating: hot forming, welding or heat treatment.

4)

It is important that furnace atmospheres for processing are sulphur free.

13

Marking

Material shall be marked with the following information:

1) Manufacturers Identification Mark

2) Cast/Melt Number

3) Test or Manufacturing Batch Number

4) Material Grade

5) EAM Reference No.

Markings shall normally be by permanent ink marking or vibro-etching.

14

Inspection

documents

14.1 Document type

1) Material manufacturers shall supply documentation affirming compliance with this EAM.

This documentation shall normally be in the form of an inspection certificate in

accordance with EN 10204 - 3.1.B.

Note: Where a material manufacturer has an appropriate quality assurance system, certified by a

competent body, established within the community and having undergone a specific assessment for

materials, certificates issued by the manufacturer are presumed to certify conformity with the

requirements of section 4.3 of Annex I of the PED.

2) If an inspection document in accordance with EN 10204 - 3.1.C or 3.2 is specified, the

purchaser shall notify the manufacturer of the name and address of the organisation or

person who is to carry out the inspection and produce the inspection document. In the

case of the inspection report 3.2 it shall be agreed which party shall issue the certificate.

Note: The affirmation of the compliance of the delivery with this EAM is not a mandatory

requirement of EN 10204. Such affirmation as it is required by PED, 97/23/EC, in Annex I

4.3 first paragraph can be added into the text of the inspection certificate, when it is

signed by the manufacturer. It could also be provided in a separate document. In the case

the inspection certificate is signed by a third party, the affirmation shall be contained in a

document which is (also) signed by the manufacturer.

CETIM - Registered in France

Reg. No. Siren: 775629074

Reg. Office as above.

Page 5 of 6

EAM-0526-16:2004/07 (EN)

14

Inspection

documents

14.2 Content of inspection documents

CETIM - Registered in France

1)

Details of the manufacturer

2)

Details of the purchaser (if required)

3)

Description and dimensions of the Product

4)

Supply conditions

5)

Ladle Analysis

6)

Product Analysis (if required)

7)

Results from mechanical verification tests

8)

Heat treatment applied

9)

Results from other applicable Tests (e.g. PMI)

10)

Marking and identification

11)

Affirmation of compliance with this EAM

12)

Declaration of the Status of the Manufacturers Quality System (including the

name of the competent body having certified the Quality System, if applicable).

Reg. No. Siren: 775629074

Reg. Office as above.

Page 6 of 6

You might also like

- 21Document6 pages21Dannis AnantoNo ratings yet

- Ped Eam-0526-24-1-2006-03Document6 pagesPed Eam-0526-24-1-2006-03nathachaiNo ratings yet

- Mechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesDocument4 pagesMechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesJarek CieslakNo ratings yet

- Aluminium en AW 6082Document3 pagesAluminium en AW 6082doshi78No ratings yet

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- Material Data Sheet en Aw 6082 Almgsi1Document1 pageMaterial Data Sheet en Aw 6082 Almgsi1pankajrs.mechengineer4502No ratings yet

- 1.4404 enDocument5 pages1.4404 enyraju88No ratings yet

- Jis G3458Document14 pagesJis G3458riky nurgiantoroNo ratings yet

- 010 Sa29 Sa29mDocument26 pages010 Sa29 Sa29mWeniton OliveiraNo ratings yet

- BS en 00287-6-2010Document26 pagesBS en 00287-6-2010Shan Sandaruwan AbeywardeneNo ratings yet

- BS en 1708-3-12Document22 pagesBS en 1708-3-12gaso99No ratings yet

- GuidanceNotes EN131 Version2Document10 pagesGuidanceNotes EN131 Version2Javier Quintero SaavedraNo ratings yet

- BS 3799 (74) Specification For Steel Pipe Fittings, Screwed and Socket-Welding For The Petroleum Industry PDFDocument32 pagesBS 3799 (74) Specification For Steel Pipe Fittings, Screwed and Socket-Welding For The Petroleum Industry PDFjodasi300% (1)

- Bs 3293Document18 pagesBs 3293nguyenmainam0% (1)

- BS en 1412-2016Document12 pagesBS en 1412-2016S TNo ratings yet

- Metric DIN 434 Square Taper Washers Technical Specifications and StandardsDocument4 pagesMetric DIN 434 Square Taper Washers Technical Specifications and StandardsRodrigoNo ratings yet

- En1564-1 2017Document4 pagesEn1564-1 2017Dan PopaNo ratings yet

- En 764-4-2002Document44 pagesEn 764-4-2002Marija IvanovskaNo ratings yet

- Submerged arc welding consumablesDocument7 pagesSubmerged arc welding consumablesMuhammed SulfeekNo ratings yet

- Whitworth Tapered Pipe Thread DIN EN 10226-1, DIN EN 10226-2 Formerly Known As DIN 2999 BSPT (British Standard Tapered Pipe)Document1 pageWhitworth Tapered Pipe Thread DIN EN 10226-1, DIN EN 10226-2 Formerly Known As DIN 2999 BSPT (British Standard Tapered Pipe)LucianNechiforNo ratings yet

- Iso DTR 20172Document66 pagesIso DTR 20172weldnoteNo ratings yet

- BS EN 13480-2-2012 + A1-2013. - MaterialsDocument86 pagesBS EN 13480-2-2012 + A1-2013. - MaterialsJosé CarvalhoNo ratings yet

- European Standards For Metallic MaterialsDocument16 pagesEuropean Standards For Metallic MaterialsClaudia Mms0% (1)

- File - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Document8 pagesFile - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Corey DodsonNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- 13480-3 p5Document2 pages13480-3 p5Arjun NegiNo ratings yet

- 21 CR Mo V511Document1 page21 CR Mo V511uksrajNo ratings yet

- ISO 15510 - Part 1Document5 pagesISO 15510 - Part 1Zdenko MahacekNo ratings yet

- SB - 622 PDFDocument10 pagesSB - 622 PDFSamir ChaudharyNo ratings yet

- VagogyuruDocument856 pagesVagogyurupsnmyNo ratings yet

- En 12451 1999Document24 pagesEn 12451 1999victoraghiNo ratings yet

- Spe 76-222 Dec 2012Document10 pagesSpe 76-222 Dec 2012akashdruva892No ratings yet

- Astm A 494Document7 pagesAstm A 494Rodrigo BarrosNo ratings yet

- Metric Heavy Hex Nut DimensionsDocument3 pagesMetric Heavy Hex Nut DimensionsSenthillkumar BalasubramaniamNo ratings yet

- ASTM A686 T72301 W1A 9.5 Steel GuideDocument2 pagesASTM A686 T72301 W1A 9.5 Steel GuideBernice JohnsonNo ratings yet

- BF-PPS As Dismantling Joints - EngDocument3 pagesBF-PPS As Dismantling Joints - EngbikarexpansionjointsNo ratings yet

- En 10164-2005 PDFDocument15 pagesEn 10164-2005 PDFUmut HızırNo ratings yet

- BS 5276-3-1979Document10 pagesBS 5276-3-1979anoopkumarNo ratings yet

- Hexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)Document15 pagesHexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)kumar QANo ratings yet

- Din 6915 PDFDocument3 pagesDin 6915 PDFa.tabkhi1980100% (3)

- Dimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardDocument77 pagesDimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardPankaj PatilNo ratings yet

- Chemical Composition of Stainless Steels To BS EN 10088-2Document41 pagesChemical Composition of Stainless Steels To BS EN 10088-2amit_91340% (1)

- Dinen 10079 - 200706 - enDocument46 pagesDinen 10079 - 200706 - enAnonymous dvrhf5No ratings yet

- PI Tectyl-506 TE031-01Document2 pagesPI Tectyl-506 TE031-01nicusebpNo ratings yet

- Iso 9606 4 Qualification Testing of Welders NickelDocument26 pagesIso 9606 4 Qualification Testing of Welders NickelPeterDoner100% (1)

- ErmetoDocument14 pagesErmetoJavier VespaNo ratings yet

- Standard GB - T1804-m & ISO 2768-1 - 2 - Advanced CeramicsDocument5 pagesStandard GB - T1804-m & ISO 2768-1 - 2 - Advanced CeramicsMohd DanishNo ratings yet

- ASME Section 1 and Pressure Equipment DirectiveDocument5 pagesASME Section 1 and Pressure Equipment DirectivealextentwentyNo ratings yet

- Astm A31 (1995)Document4 pagesAstm A31 (1995)gsb2100% (1)

- Iso-15667Document7 pagesIso-15667Chichi Julian FlekerNo ratings yet

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- Nfa 49 310 Grade Tu 52 B Tubes PDFDocument1 pageNfa 49 310 Grade Tu 52 B Tubes PDFMitul MehtaNo ratings yet

- A 1016 - A 1016M - 04 Qtewmtyvqtewmtzn PDFDocument11 pagesA 1016 - A 1016M - 04 Qtewmtyvqtewmtzn PDFfekihassan100% (1)

- BS en 10025-3Document28 pagesBS en 10025-3yasser awadallhNo ratings yet

- Sa 325 PDFDocument12 pagesSa 325 PDFMo'men Abu-SmaihaNo ratings yet

- Importing Nozzle Loads From Autopipe Into Autopipe NozzleDocument3 pagesImporting Nozzle Loads From Autopipe Into Autopipe NozzlegchammaNo ratings yet

- Uni 663 Grade Fe55 1 Tubes PDFDocument1 pageUni 663 Grade Fe55 1 Tubes PDFMitul MehtaNo ratings yet

- How To Draw A Square PlateDocument2 pagesHow To Draw A Square Platevtsusr fvNo ratings yet

- ValveDesign speCIFICATIONS PDFDocument1 pageValveDesign speCIFICATIONS PDFvtsusr fvNo ratings yet

- Keyfiles NewfilesDocument1 pageKeyfiles Newfilesvtsusr fvNo ratings yet

- API Spec q1 9th EditionDocument3 pagesAPI Spec q1 9th Editionvtsusr fv80% (5)

- Types of Valves and Their UsesDocument1 pageTypes of Valves and Their Usesvtsusr fvNo ratings yet

- Keyfiles Newfiles PDFDocument1 pageKeyfiles Newfiles PDFvtsusr fvNo ratings yet

- Astm d6677Document1 pageAstm d6677vtsusr fvNo ratings yet

- Astm B733-04 (2014)Document5 pagesAstm B733-04 (2014)vtsusr fvNo ratings yet

- Valve Fire Safe-Api607Document1 pageValve Fire Safe-Api607vtsusr fvNo ratings yet

- Mesc 76-210Document3 pagesMesc 76-210vtsusr fv100% (1)

- Check Valves Logo2Document1 pageCheck Valves Logo2vtsusr fvNo ratings yet

- Types of Valves and Their UsesDocument1 pageTypes of Valves and Their Usesvtsusr fvNo ratings yet

- ASME Section VIII Division3Document1 pageASME Section VIII Division3vtsusr fvNo ratings yet

- Astm A489Document7 pagesAstm A489vtsusr fvNo ratings yet

- HT 625Document2 pagesHT 625vtsusr fvNo ratings yet

- Custom PCDocument1 pageCustom PCvtsusr fvNo ratings yet

- Astm A29Document5 pagesAstm A29vtsusr fvNo ratings yet

- Nomograph Valve SizingDocument1 pageNomograph Valve Sizingvtsusr fvNo ratings yet

- ASME B1.20 Preview - New LatestDocument2 pagesASME B1.20 Preview - New Latestvtsusr fvNo ratings yet

- Same AsmeDocument1 pageSame Asmevtsusr fvNo ratings yet

- Isa 75Document4 pagesIsa 75vtsusr fvNo ratings yet

- Nozzle Check Valve SpringDocument5 pagesNozzle Check Valve Springvtsusr fvNo ratings yet

- IEC 60534-1 Industrial Process Control Valves - Terminology & General ConsiderationsDocument1 pageIEC 60534-1 Industrial Process Control Valves - Terminology & General Considerationsvtsusr fv50% (2)

- ASME B1.30M PreviewDocument2 pagesASME B1.30M Previewvtsusr fvNo ratings yet

- Dresser Valve Sizing HandbookDocument2 pagesDresser Valve Sizing Handbookvtsusr fvNo ratings yet

- Circlip Sizes IS 3075Document5 pagesCirclip Sizes IS 3075vtsusr fvNo ratings yet

- Fundamentals Handbook Materials Vol 10 PDFDocument2 pagesFundamentals Handbook Materials Vol 10 PDFvtsusr fvNo ratings yet

- IBM - X Servers Offers For X3650, X3400, X3200 & X3550 Servers - Server Upgrades - IndiaDocument4 pagesIBM - X Servers Offers For X3650, X3400, X3200 & X3550 Servers - Server Upgrades - Indiavtsusr fvNo ratings yet

- ASTM A313 TYPE SS316 Stainless Steel 316 - Alloy Wire InternationalDocument2 pagesASTM A313 TYPE SS316 Stainless Steel 316 - Alloy Wire Internationalvtsusr fvNo ratings yet

- Gauge in Decimals of An InchDocument2 pagesGauge in Decimals of An InchHina MuslimNo ratings yet

- Determination of Heavy Metals in TextilesDocument9 pagesDetermination of Heavy Metals in TextilesCristhian MendezNo ratings yet

- Is 1239 - (2004) Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specification Steel TubeDocument14 pagesIs 1239 - (2004) Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specification Steel TubevetrikamalNo ratings yet

- Parts Catalog: Dadf-P2Document46 pagesParts Catalog: Dadf-P2luis1984bolNo ratings yet

- Topic 3. Metal Industry (Part 1)Document16 pagesTopic 3. Metal Industry (Part 1)Kate BladeNo ratings yet

- TECHNILDocument40 pagesTECHNILCaptIsqanNo ratings yet

- Forming Tap Hole - PrestoDocument16 pagesForming Tap Hole - Prestocluk4No ratings yet

- Domestic Water Piping Systems GuideDocument15 pagesDomestic Water Piping Systems Guideroinbanerji100% (1)

- Incoloy Alloy 825 UNS N08825 Welding Rod Manufacturer in IndiaDocument2 pagesIncoloy Alloy 825 UNS N08825 Welding Rod Manufacturer in IndiaOZAIRTRADELINKNo ratings yet

- Properties of Matter and Materials IntroductionDocument6 pagesProperties of Matter and Materials IntroductionShabana ShagulNo ratings yet

- TIG Bohler S ER70S G ER70S GDocument1 pageTIG Bohler S ER70S G ER70S GwahyuufoNo ratings yet

- 01 Samss 017Document13 pages01 Samss 017Alin Tomozei100% (1)

- 5 Mine Operating Costs and The Potential Impacts of Energy and Grinding (2) - 11Document11 pages5 Mine Operating Costs and The Potential Impacts of Energy and Grinding (2) - 11wunjonatxoNo ratings yet

- Uk Steel CatalogueDocument46 pagesUk Steel CatalogueMusa AliNo ratings yet

- Sandvik Materials Handling Idler CatalogueDocument28 pagesSandvik Materials Handling Idler CatalogueEd Ace100% (1)

- ASTM A853 Alambre RecocidoDocument3 pagesASTM A853 Alambre RecocidoRober Moises Chumbe SoveroNo ratings yet

- Edm NotesDocument98 pagesEdm NotesDeepankumar AthiyannanNo ratings yet

- India's Iron & Steel Industry: A Brief HistoryDocument17 pagesIndia's Iron & Steel Industry: A Brief HistoryEMJAY100% (1)

- Zoeller x292Document2 pagesZoeller x2922009tamerNo ratings yet

- H53015302 TRQ XXXDocument2 pagesH53015302 TRQ XXXTuTuy AnNo ratings yet

- Compare ASME and material specsDocument2 pagesCompare ASME and material specsg_sanchetiNo ratings yet

- MTC Catalog 2009 ENGLISCHDocument196 pagesMTC Catalog 2009 ENGLISCHAsif JalgaonkarNo ratings yet

- EnclosurecatalogueDocument153 pagesEnclosurecatalogueTomuta StefanNo ratings yet

- Saw Storage HandlingDocument1 pageSaw Storage HandlingDave MulvihillNo ratings yet

- BS en 439-94 PDFDocument12 pagesBS en 439-94 PDFAhmet Memiş100% (2)

- ASTM International - Volume 01.01 Steel - Piping, Tubing, FittingsDocument3 pagesASTM International - Volume 01.01 Steel - Piping, Tubing, Fittingsamitkumar8946No ratings yet

- Is 4049 Part 1Document7 pagesIs 4049 Part 1Otavio123No ratings yet

- Minfc930 Astm A322 Grade 4140Document3 pagesMinfc930 Astm A322 Grade 4140Muthazhagan SaravananNo ratings yet

- ChemistryDocument7 pagesChemistryVic Rizenn Isidore BobilesNo ratings yet

- Kyocera Turning CatalogDocument593 pagesKyocera Turning CatalogthyskieNo ratings yet