Professional Documents

Culture Documents

At Diagnosis

Uploaded by

vixentdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

At Diagnosis

Uploaded by

vixentdCopyright:

Available Formats

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

2003 AUTOMATIC TRANSMISSIONS

Allison LCT 1000 Diagnosis

APPLICATION

WARNING: Vehicle is equipped with Supplemental Inflatable Restraint (SIR) system.

When servicing vehicle, use care to avoid accidental air bag deployment.

SIR system-related components are located in various locations

throughout interior and exterior of vehicle, depending on application. Do

not use electrical test equipment on or near these circuits. If necessary,

deactivate SIR system before servicing components. See AIR BAG

DEACTIVATION PROCEDURES article in GENERAL INFORMATION.

TRANSMISSION APPLICATION

Application

Chevrolet Cab & Chassis Silverado 3500, Silverado 2500 HD & Silverado

3500 (6.6L & 8.1L)

GMC Cab & Chassis Sierra 3500, Sierra 2500 HD & Sierra 3500 (6.6L &

8.1L)

Transmission Model

(RPO)

LCT 1000 (M74)

LCT 1000 (M74)

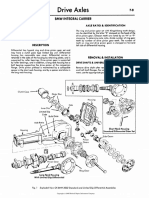

IDENTIFICATION

TRANSMISSION

Transmission is identified by metal identification plate attached to right side of transmission case. See Fig. 1 .

Helpmelearn

April-29-08 6:41:29

6:41:06 PM

Page 1

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 1: Locating Transmission Identification Plate

Courtesy of GENERAL MOTORS CORP.

DESCRIPTION & OPERATION

INTRODUCTION

Allison 1000 series transmissions are torque converter driven, fully automatic, transmission systems. The 1000

series transmissions have up to five forward speeds, Neutral, and Reverse. The 5th gear is an overdrive gear

ratio. The 1000 series incorporates a variety of standard and optional design features. These design features are:

z

z

z

z

z

z

z

z

z

Direct mount to engine block.

Flexplate drive.

Torque Converter with a Torque Converter Clutch (TCC) and integral vibration damper.

Three constant-mesh, planetary gear sets with helical gears.

Five multiple disk clutches, two rotating and three stationary.

Common hydraulic system for all transmission functions.

Two transmission fluid filtration systems.

Electro-hydraulic control valve assembly.

Electronically controlled automatic gear selection and clutch apply.

Helpmelearn

April-29-08 6:41:06 PM

Page 2

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

z

z

z

z

z

Provision for remote transmission fluid cooler.

Fill tube/dipstick provision on both sides of transmission.

Parking pawl.

Power Take Off (PTO) provision on both sides of transmission.

Variety of available output yokes or flanges.

TRANSMISSION COMPONENTS & SYSTEMS

Torque Converter

Several torque converters are available to match the transmissions to a wide variety of diesel and gasoline

engines. The torque converter is a single-stage, polyphase, and three-element unit, consisting of a pump, stator,

and turbine. At lower output speeds, the torque converter multiplies torque and provides a fluid coupling to the

engine. At higher speeds, the Torque Converter Clutch (TCC) is automatically engaged to provide direct drive

from the engine to the transmission. Hydraulic fluid for converter charging pressure comes from the sump and

is supplied by the input pump. The torque converter clutch is applied or released by changing direction of fluid

in the torque converter. An integral converter damper minimizes the need for additional engine vibration

control.

Gear Sets

The planetary gear train includes three constant-mesh planetary gear sets containing helical gears. By the

engagement of the clutches in various combinations, the planetary sets act independently or together to provide

five forward gear ranges, Neutral, and Reverse.

Clutches

Five clutches (two rotating and three stationary) direct the flow of torque through the transmission. All range

clutches are hydraulically actuated and spring-released, with automatic wear compensation. The transmission

fluid cools the clutches. The Transmission Control Module (TCM) signals solenoid valves to apply and release

clutches based on speed and power combinations and the gear range selected by the operator.

Hydraulic System

A common hydraulic system serves the torque converter and the transmission. Transmission fluid for all

hydraulic operations, lubrication, and cooling comes from the sump and is supplied by the charging pump.

Transmission Fluid Filtration

Fluid filtration is provided by two filter systems. A suction filter, located in the sump, provides general

protection to the entire hydraulic system by filtering large particulates. A spin-on filter provides full-time

protection for the control solenoids and multipass protection for the entire system. The spin-on filter is

externally located on the converter housing at the lower left front of the transmission.

Electro-Hydraulic Control Valve Assembly

Helpmelearn

April-29-08 6:41:06 PM

Page 3

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

The control valve assembly consists of two components. The main valve body contains the trim valves, the

TCC valve, the exhaust backfill valve, and the control main relief valve. The shift valve body contains the shift

valves, the control main pressure valve, and the manual selector valve. The control valve assembly attaches to

the bottom of the transmission and is enclosed by the oil pan.

Remote Oil Cooler Provision

Ports for remote-mount oil cooler lines are located on the right side of the converter housing near the converter

housing/main housing splitline. Remote oil-to-water coolers require plumbing for transmission fluid and

engine-cooling water. Remote oil-to-air coolers may also be used, and only transmission fluid lines need to be

provided. Heat is transferred from the transmission fluid to either water or air depending upon the cooler type

used.

Fill Tube/Dipstick Provision

All 1000 series transmissions have a fill tube/dipstick provision on both sides of the transmission. The fill tube

and dipstick are installed and adapted as specified by the vehicle manufacturer. A plug is installed in the unused

location.

Park Pawl

All 1000 series transmissions have a parking pawl. The internal parking pawl is engaged by selection of Park on

the gearshift lever.

PTO Provision

The 1000 series transmissions have a provision to mount and drive a PTO unit on the left and/or right side of

the transmission housing. The torque converter turbine drives the optional PTO drive gear. The PTO reflects

engine and torque converter characteristics. The vehicle manufacturer and/or body builder provides PTO units

and associated controls.

Output Yoke/Flange

A variety of output yokes or flanges are available to meet vehicle driveline requirements. Yokes or flanges are

installed and are adapted as specified by the vehicle manufacturer.

ADAPT FUNCTION

NOTE:

When replacing a failed transmission with a replacement unit, it is important to

reset the TCM to base calibration and fast adaptive for all shifts. This can be

done in one step with the scan tool. If this is not done, the TCM's adaptive

values will still be at the settings that it learned for the old transmission, and

will be in slow adaptive mode. Under these conditions, it would take an

unacceptably long time for the adaptive values to converge to levels suitable for

the new transmission.

The Transmission Control Module (TCM) produces excellent shift quality by applying closed loop control that

Helpmelearn

April-29-08 6:41:06 PM

Page 4

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

constantly adjusts shift characteristics for changes in operating conditions. These adjustments are based on

vehicle conditions such as grade, load, and engine power.

The learning process of comparing and adjusting shift parameters is referred to as adaptive control. Adaptive

control establishes initial conditions for shifts and makes adjustments during shifts. The TCM constantly

monitors operating conditions, such as battery voltage and transmission sump temperature, and adjusts shift

parameters accordingly. After a shift is completed, the TCM compares the shift to a target shift profile in the

TCM calibration and makes adjustments before the next shift of the same kind is made.

The Allison 1000 series transmission consists of five clutches labeled C1 to C5. A combination to two clutches

is required to be engaged to attain a torque path from the input to the output of the transmission. See CLUTCH

COMBINATIONS table to indicate the clutch combinations for each gear range.

CLUTCH COMBINATIONS

Application

Park/Neutral

Reverse

1st

2nd

3rd

4th

5th

C1

.....

.....

X

X

X

X

.....

C2

.....

.....

.....

.....

.....

X

X

C3

.....

X

.....

.....

X

.....

X

C4

.....

.....

.....

X

.....

.....

.....

C5

X

X

X

.....

.....

.....

.....

TCC

.....

.....

.....

X

X

X

X

This transmission utilizes clutch-to-clutch shift control to achieve gear range changes. In every case, except

shifts to or from Neutral, one clutch is exhausted and another applied to make a range shift. The handoff

between exhausting and applying clutches is very precisely controlled by use of two Pressure Proportional to

Current (PPC) solenoids. These solenoids are labeled "A" and "B" in the transmission, and are referred to as

trim solenoids. For example, to make a 1-2 shift, solenoid "A" is used to trim pressure off C5 clutch, and

solenoid "B" is used to trim pressure on C4 clutch. The TCM modulates the current to both "A" and "B"

solenoids, which translates to a proportional level of pressure to the clutch. To make a shift, the TCM uses

software and calibration settings of several program parameters to determine the level of current sent to the

respective trim solenoids. These parameters are referred to as adaptive values. With a new transmission and

TCM calibration, the adaptive values are set to base calibration level. The transmission uses the base calibration

to perform the first of each type of shift. However, once it has performed a shift, the TCM evaluates the actual

shift and compares it to an ideal shift in the TCM's memory. Based on that comparison, the TCM changes the

settings of the adaptive values to a level that it believes will result in a shift closer to the ideal shift the next time

it makes that type of shift. This is referred to as adaptive shifting. When the TCM calibration is new, the TCM

is in fast adaptive mode. In other words, the TCM is allowed to make relatively large changes in the adaptive

values after each shift. Once the TCM determines that a given shift is close to its ideal level, it switches to slow

adaptive mode. In slow adaptive, the TCM is still evaluating shifts and changing adaptive values, but is only

allowed to do so in smaller increments. When a shift switches from fast to slow adaptive mode, it is described

as converged. The TCM is programmed to try to switch from fast to slow adaptive mode in as many as 15 to 20

shifts. It is important to understand that there are many different distinct shifts recognized by the TCM, and

each of these shifts has its own adaptive values. For example, there are upshifts and downshifts to and from

each range, as well as unique adaptive values for several different throttle regions for each upshift and

downshift. The point is, it may take a significant amount of time before most of the shifts converge from fast to

Helpmelearn

April-29-08 6:41:07 PM

Page 5

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

slow adaptive, and thus it is not unusual to experience somewhat harsh or unpleasant shift quality until these

shifts are adapted.

TCC engagement is accomplished by a separate Pulse Width Modulated (PWM) solenoid labeled "F" in the

transmission. There are adaptive values for this as well, and thus it will also require some driving for TCC

engagement to converge.

If you are experiencing harsh shifts, it is important to verify whether the particular shift is converged. Use the

scan tool to determine if the problem shift is converged.

z

If it is not, the TCM is still learning how to adapt that shift, and simply needs to be driven a bit more with

the intention of performing more of the particular type of shift.

If a particular shift is converged, but still objectionable, it's good trouble shooting practice to reset the

adaptive values for that shift back to base calibration level. This will automatically reset the TCM to fast

adaptive mode. The vehicle should then be driven to allow the TCM to re-learn the shift. Many times this

will correct the problem. It is possible to reset individual shifts without affecting the other shifts.

TRANSMISSION INDICATORS & MESSAGES

Normal Inhibits Which Result In Blinking PRNDL

Inhibits which result in a blinking PRNDL are as follows:

z

z

z

High engine speed Neutral to gear range shifts when a Neutral to Drive or Neutral to Reverse shift is

made when engine RPM is too high, the shift will be inhibited to Neutral. The TCM has torque

management capability and will attempt to slow the engine to a point where it will make the requested

shift.

High throttle or torque direction change shifts from Reverse to Drive, Drive to Reverse, Neutral to Drive,

and Neutral to Reverse shifts where throttle position is greater then 25 percent transmission will be

inhibited to Neutral. The TCM has torque management capability, and will attempt to slow the engine to

a point where it will make the requested shift.

If the 4-wheel drive transfer case is shifted into Neutral while the transmission is in Drive or Reverse, the

transmission will continue to command the gear range until output speed is low, at which point Neutral is

commanded. If the driver attempts to shift the transmission from Neutral to Drive or Neutral to Reverse

with the transfer case in Neutral, the PRNDL display will blink immediately.

High output speed direction change shifts Reverse to Drive, Drive to Reverse, and Neutral to Reverse

shifts initiated above 300 RPM output speed will be inhibited to Neutral.

Insufficient transmission fluid and lack of initial pump prime caused by refilling the transmission.

Extremely low transmission fluid temperature. A shift out of Neutral when ATF temperature is below 49F (-45C) may be inhibited.

Blinking PRNDL

Malfunctions which may cause a blinking PRNDL are as follows:

z

Failure to detect turbine speed pull-down during a shift. This may occur, for example, when a clutch is

Helpmelearn

April-29-08 6:41:07 PM

Page 6

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

z

z

z

z

z

failed and the transmission cannot attain the requested range.

Invalid gear ratio.

Misadjusted PNP switch or gearshift lever linkage.

Solenoid "A" or "B" failure.

Turbine or output speed sensor failure.

Lack of pressure at start-up.

Blank PRNDL

Conditions which may cause a blank PRNDL are as follows:

z

The PRNDL display may be blank due to failure of PNP switch circuits "A", "B", "C", or "P", or when

the PNP switch is out-of-adjustment or damaged.

The transmission will command the most appropriate gear range based on Reverse pressure switch and

the remaining PNP switch inputs.

ELECTRONIC COMPONENT DESCRIPTION

Transmission Control Module

A microcomputer controls the transmission by receiving and processing signals from various switches and

sensors. The microcomputer determines shift sequences, shift timing, and clutch apply and release

characteristics. The microcomputer is an independent controller and is referred to as the Transmission Control

Module (TCM). See Fig. 2 . TCMs are available in 12-volt configurations to match the configuration of the

vehicle electrical system. The pressure switch manifold and Park/Neutral Position (PNP) switch provide

operator input to the TCM. Other data sent to the TCM include throttle position; engine, turbine, and output

speeds; and sump temperature. Any active special function, such as anti-lock brakes or power takeoff, is also an

input to the TCM. The TCM processes this data to determine proper shift points, to monitor the current gear

range, to perform ratio tests, and to compile diagnostic data. The TCM is programmed to protect the

transmission and other vehicle driveline components by inhibiting actions such as full-throttle shifts from

Neutral and high-speed direction changes. The TCM determines if a system malfunction exists and stores

Diagnostic Trouble Codes (DTC) related to the malfunction. The codes, accessed by the service technician, are

used in diagnosing persistent or intermittent trouble in the system.

Helpmelearn

April-29-08 6:41:07 PM

Page 7

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 2: Identifying Transmission Control Module

Courtesy of GENERAL MOTORS CORP.

Throttle Position/Torque Management

The TCM receives input on throttle position/torque management from a signal transmitted by the engine

electronic controls.

The engine electronic controls communicate directly to the transmission electronic controls over an SAE J1850

or J1939 Serial Communication Interface (SCI) data link. The transmission TCM must be calibrated to receive

these signals.

Speed Sensors

CAUTION: Do not rotate the sensor in its retaining bracket. Changing the

sensor/bracket orientation may cause improper operation.

There are three speed sensors typically required for use: the engine speed sensor, the turbine speed sensor, and

the output speed sensor. The speed sensors provide RPM information to the TCM. The speed ratios between the

various sensors allow the TCM to determine the transmission operating range. Speed sensor information is also

used to control the timing of clutch apply pressures, resulting in the best possible shift quality. Hydraulic

problems are detected by comparing the speed sensor information for the current gear range to that range's

speed sensor information stored in the TCM memory. The speed sensors are variable reluctance devices that

Helpmelearn

April-29-08 6:41:07 PM

Page 8

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

convert mechanical motion to an AC voltage. Each sensor consists of a wire coil wrapped around a pole piece

that is adjacent to a permanent magnet. These elements are contained in a housing that is mounted adjacent to a

rotating ferrous member. See Fig. 3 .

Fig. 3: Identifying Speed Sensor

Courtesy of GENERAL MOTORS CORP.

Gear Selection

The vehicle is equipped with a column-type gearshift lever. In addition to the column gearshift lever provided

for the operator, another component associated with shift selection is the Park/Neutral Position (PNP) switch

mounted on the selector shaft. See Fig. 4 . The PNP switch transmits selector position information to the TCM.

The PNP switch mounts directly onto the transmission housing from the outside, and detects the angular

position of the shift selector shaft. This position is communicated to the TCM so that certain vehicle control

Helpmelearn

April-29-08 6:41:07 PM

Page 9

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

functions can be coordinated with the position of the shift controls. The PNP switch has redundant circuitry to

alert the TCM in the event of a single wire or switch failure. The Neutral signal output of the PNP switch is

typically used as confirmation that the transmission is in Neutral before the engine starter is engaged. The PNP

switch is interfaced to the starter circuit with weatherproof electrical connectors. The Reverse signal provision

may be used to activate vehicle back-up lights and/or Reverse warning devices.

The operator chooses the transmission gear range by moving the gearshift lever to the appropriate gate position.

When properly adjusted, the shifter gates prevent inadvertent shifting between gear ranges, and correspond to

the internal transmission detent positions. A positive detent is provided in the transmission to maintain the

selector shaft in the selected position.

The TCM shift calibration determines the available forward gear ranges for each gearshift lever position.

Although specific installations vary, typical gearshift lever positions for the 1000 series are:

Park (P) - The parking pawl is engaged. The transmission is in Neutral. This position is not available on

all shift selectors. When available, may be used when starting the engine and for stationary operations.

Reverse (R) - Selected to move vehicle backward.

Neutral (N) - May be used when starting the engine and for stationary operations. The TCM disables the

starter switch if a range other than Neutral or Park is selected before starting the vehicle.

Drive (D) - The highest forward range, and is used for normal driving. The transmission shifts to 1st gear

for starting, and then automatically upshifts through the gear ranges (as operating conditions permit) until

the highest gear range is attained.

Forward Range 4, (3), 2, 1 - There are four forward gear range selector positions. The first position after

N (Neutral) is D (Drive), where all five forward gear ranges are available. Another position is first range

hold. There are three choices for the next two positions. These choices are 1-4, 1-3, and 1-2, which

describe the gear ranges available in that position. The vehicle manufacturer chooses the two positions

that best fit the vocation for which the vehicle is intended.

Helpmelearn

April-29-08 6:41:07 PM

Page 10

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 4: Identifying PNP Switch

Courtesy of GENERAL MOTORS CORP.

Solenoids

The control valve body contains both normally closed and normally open solenoids. A normally closed solenoid

remains closed until a signal from the TCM energizes the solenoid. A normally open solenoid remains open

until the TCM energizes the solenoid. When a solenoid valve is in the closed position, the valve blocks the

flow. When a solenoid valve is in the open position, flow is permitted through the valve. The pulse width

modulated solenoid "F" (1) and the ON/OFF shift valve solenoids "C", "D", and "E" (4), (2) and (3)

respectively, are normally closed. Both solenoid types have an orifice, electrical windings, an iron core, and a

steel check ball. See Fig. 5 .

The solenoids used differ in their ability to control flow or fluid pressure. The solenoids may operate in the

open or closed state with no modulation capability (solenoids "C", "D", and "E"), an intermediate flow and

resultant pressure based on duty cycle (solenoid "F") or produce pressure proportional to current (solenoids "A"

and "B").

Shift solenoids "C", "D", and "E" provide the necessary logic to distribute fluid to the correct clutches. The shift

Helpmelearn

April-29-08 6:41:07 PM

Page 11

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

solenoids provide either full control main pressure or exhaust to the head of each of the corresponding shift

valves "C", "D", and "E". Since the valve states (stroked or unstroked) are critical to providing the correct

transmission gear range, each shift valve has a pressure switch (located in the pressure switch manifold) which

provides feedback to the computer as to the valve's position.

Trim solenoids "A" and "B" (6) and (5) respectively, are used to control oncoming, off-going, and holding

pressure to the five clutches. These solenoids are referred to as Pressure Proportional to Current (PPC)

solenoids, since the output hydraulic pressure supplied by these solenoids is proportional to the controlled

current command.

Fig. 5: Identifying Shift Solenoids

Courtesy of GENERAL MOTORS CORP.

Pressure Switch Manifold

The pressure switch manifold is a multiple-switch assembly made up of three normally open pressure switches

and one normally closed switch. See Fig. 6 . Normally open switches (4), (3) and (2) correspond to shift valves

Helpmelearn

April-29-08 6:41:07 PM

Page 12

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

"C", "D" and "E". Fluid pressures are fed from shift valves "C", "D", and "E" and the manual selector valve to

the switches based on the positions of the valves and shift selector. The shift valve fluid pressures reflect the

logic condition at the corresponding solenoids. This logic indicates the current transmission operating range to

the TCM.

The three fluid pressure switches corresponding to the shift valves are normally open (contacts not touching)

when no fluid pressure is present, so that electrical current is stopped at the switch. When fluid pressure is

routed to the switch, it moves the diaphragm and upper contact so that the contact element touches both the

positive and ground contacts. This closes the circuit and allows current to flow from the positive contact and

through the switch.

The pressure switch (1) corresponding to Reverse is normally closed, since fluid pressure is always present

unless the selector valve is moved to Reverse. The pressure switch manifold also contains a temperature sensor

thermistor (5) for sump temperature. Changes in sump fluid temperature are indicated by changes in sensor

resistance (for example, increasing temperature causes decreased sensor resistance). The resistance value is then

relayed to the TCM as an input for shift control.

Fig. 6: Identifying Pressure Switch Manifold

Helpmelearn

April-29-08 6:41:07 PM

Page 13

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Courtesy of GENERAL MOTORS CORP.

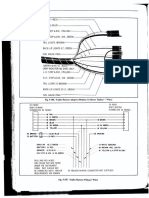

Internal Wiring Harness

The internal wiring harness has connectors (7), (3) and (4) for the shift solenoids "C", "D" and "E". Connectors

(6) and (5) go to clutch trim solenoids "A" and "B". Connector (2) goes to the torque converter clutch solenoid

"F". There is also a connector (1) for the pressure switch manifold. All of these connectors go to the

transmission in-line 20-way connector (8). See Fig. 7 . The transmission in-line 20-way connector transports

signals from these connectors to the TCM via the external harness.

Fig. 7: Identifying Transmission Internal Wiring Harness

Courtesy of GENERAL MOTORS CORP.

ELECTRONIC CONTROL SYSTEM

Helpmelearn

April-29-08 6:41:07 PM

Page 14

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

NOTE:

The 6.6L diesel models use an Electronic Control Module (ECM), and 8.1L

gasoline models use a Powertrain Control Module (PCM). For the purpose of

this article, PCM will be used throughout to indicate all engine control modules.

A separate Transmission Control Module (TCM) is also used on models using

the Allison transmission.

The PCM constantly monitors the information from various sensors, and controls the systems that affect vehicle

performance and emissions. The PCM also performs the diagnostic functions for those systems. The PCM can

recognize operational problems and alert the driver through the Malfunction Indicator Lamp (MIL) when a

malfunction has occurred. When a malfunction is detected, the PCM stores a Diagnostic Trouble Code (DTC)

which helps to identify problem areas. This is done to aid the technician in making repairs.

SHIFT INTERLOCK SYSTEM

NOTE:

For system description and repair information, see appropriate SHIFT

INTERLOCK SYSTEMS article.

PROGRAMMING

FAST LEARN PROCEDURE

Overview

In general, Fast Learn is a procedure for Allison 1000 Series transmissions in which a series of tests are run to

allow the Transmission Control Module (TCM) to "learn" individual clutch characteristics. Once the clutch data

is learned, Fast Learn translates it to the adaptive data cells, which the TCM uses for clutch control during range

shifts. Fast Learn is used at GM assembly plants and allows the vehicle to be driven out of the assembly plant in

a near-fully-adapted state so as to minimize any customer shift complaints. The scan tool version of Fast Learn

is intended to provide the same benefit following transmission repair or replacement at GM Dealerships.

Fast Learn must be used when one of the following repairs have been made to the vehicle:

z

z

z

z

z

Transmission replacement or internal service/overhaul.

Valve body repair or replacement, including replacement of "A" or "B" solenoids.

Transmission control module replacement.

TCM software/calibration update.

Any service in response to a shift quality complaint.

The scan tool is used to initiate Fast Learn by selecting the following commands:

z

z

z

F3: Special Functions.

F1: Transmission Output Controls.

Fast Learn.

Helpmelearn

April-29-08 6:41:07 PM

Page 15

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

When performing Fast Learn, the following conditions must be met:

z

z

z

z

z

z

Block drive wheels.

Apply parking brake.

Apply service brake during Drive and Reverse mode.

0% throttle, engine at idle RPM.

Transmission sump temperature at 40-100C (Reference temperature bar graph on scan tool screen).

If equipped, 4WD transfer case in 2WD.

If at any time during the procedure, required conditions are not met, Fast Learn may abort and the process will

need to be re-started from the beginning.

Description

Four steps are required to successfully complete the Fast Learn procedure:

1.

2.

3.

4.

Park Mode

Drive Mode

Reverse Mode

C2 Learn Mode

Park Mode

While the transmission is in Park with the engine idling, Fast Learn will cycle through a series of tests where C3

and C4 clutches are repeatedly applied to learn their clutch characteristics. During the C3 and C4 clutch

apply/release procedure, Fast Learn is able to characterize the "A" and "B" solenoid pressures corresponding to

clutch return springs, and also is able to learn the volumes for C3 and C4 clutch packs. In addition, C5 clutch is

repeatedly applied and released in Park to purge out air for later learning of its clutch volume.

Drive Mode

CAUTION: While in Drive, if the scan tool loses communication, or becomes

disconnected, the vehicle may remain in Drive and could move forward if

the wheels have not been securely blocked.

Once all of the Park test data have converged, the scan tool instructs the driver to select Drive. Once Drive is

selected, the TCM engages C1 clutch to obtain Drive and learn C1 clutch volume. The TCM repeats this test

until the volume learned for C1 clutch has converged.

Reverse Mode

CAUTION: While in Reverse, if the scan tool loses communication, or becomes

disconnected, the vehicle may remain in Reverse and could move

backward if the wheels have not been securely blocked.

Helpmelearn

April-29-08 6:41:07 PM

Page 16

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Next the scan tool instructs the driver to select Reverse. Once Reverse is selected, the TCM engages C5 clutch

to obtain Reverse and learn C5 clutch volume. The TCM repeats this test until the volume learned for C5 clutch

has converged.

After learning C1 and C5 clutch volume, Fast Learn updates the adaptive volume data for all shifts with either

C1 or C5 on-coming clutch. This completes the "stationary modes" of Fast learn.

NOTE:

All shifts will be left in "fast" adaptive mode at this point.

C2 Learn Mode

Following the Reverse Mode step, the scan tool exits Fast Learn and the only adaptive cells that remain to be

learned are the adaptive volume data for C2 clutch. The vehicle must be driven in order to make at least three 34 upshifts on the same ignition cycle and at steady throttle position. This data is learned by the TCM

intentionally overfilling C2 clutch. Once this overfill is corrected, C2 clutch volume is learned and all special

Fast Learn actions are completely disabled.

NOTE:

The technician should verify that transmission shift quality for all types of shifts

is acceptable prior to releasing the vehicle to the customer.

Trouble Shooting

If Fast Learn will not run and the above-stated conditions have been met, ensure the following:

z

z

z

z

z

z

z

Transmission fluid temperature at 40-100C.

Closed throttle and engine at warm-idle RPM.

No active DTCs.

All speed sensors are connected and functioning properly.

NSBU switch properly adjusted and functioning.

Main pressure within specification.

TCC slip speed less than 100 RPM at idle in park/neutral.

TROUBLE SHOOTING

NOTE:

Any diagnosis should begin with confirming the customer's complaint. If

possible, road test vehicle first, and note transmission performance for future

reference during diagnosis.

PRELIMINARY INSPECTION

Transmission malfunctions may be caused by poor engine performance, improper adjustments or failure of

hydraulic, mechanical or electronic components. Prior to diagnosing transmission concerns, always begin by

checking fluid level, fluid condition and shift cable adjustment. Ensure engine starts with gearshift lever in Park

and Neutral to ensure proper adjustment of park/neutral position switch. Ensure all system-related fuses are

Helpmelearn

April-29-08 6:41:07 PM

Page 17

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

okay. Check wire harnesses for proper routing. Verify all harness and component connections are clean and

tight. See WIRING DIAGRAMS . If area of fault cannot be located or repaired during preliminary inspection,

check self-diagnostic system. See SELF-DIAGNOSTIC SYSTEM . Repair as necessary.

Perform road test to determine if problem has been corrected. See ROAD TEST under PERFORMANCE

TESTS. If problem still exists, diagnose by symptom. See SYMPTOM DIAGNOSIS .

SYMPTOM DIAGNOSIS

NOTE:

Perform PRELIMINARY INSPECTION prior to diagnosing by symptom.

NOTE:

Use the following symptoms to aid in preliminary diagnosis. See Fig. 8 -Fig. 27 .

If a listed symptom matches the customer's concern, check the applicable

items for possible cause.

Fig. 8: Excessive Slippage & Clutch Chatter

Courtesy of GENERAL MOTORS CORP.

Helpmelearn

April-29-08 6:41:07 PM

Page 18

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 9: Fluid Leaks From Fluid Fill Tube & Vent

Courtesy of GENERAL MOTORS CORP.

Fig. 10: Fluid Leaks From Transmission Input

Courtesy of GENERAL MOTORS CORP.

Fig. 11: Fluid Leaks From Transmission Output

Courtesy of GENERAL MOTORS CORP.

Helpmelearn

April-29-08 6:41:07 PM

Page 19

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 12: Intermittent Buzzing Noise

Courtesy of GENERAL MOTORS CORP.

Fig. 13: Low Main Line Pressure In All Gear Ranges (1 Of 2)

Courtesy of GENERAL MOTORS CORP.

Fig. 14: Low Main Line Pressure In All Gear Ranges (2 Of 2)

Courtesy of GENERAL MOTORS CORP.

Fig. 15: Low Main Line Pressure In Specific Gear Ranges, Normal In All Other Gear Ranges

Courtesy of GENERAL MOTORS CORP.

Helpmelearn

April-29-08 6:41:07 PM

Page 20

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 16: Low Lubrication Pressure

Courtesy of GENERAL MOTORS CORP.

Fig. 17: Contaminated Transmission Fluid

Courtesy of GENERAL MOTORS CORP.

Fig. 18: Excessive Flare - Engine Overspeed On Wide-Open Throttle (1 Of 2)

Courtesy of GENERAL MOTORS CORP.

Helpmelearn

April-29-08 6:41:07 PM

Page 21

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 19: Excessive Flare - Engine Overspeed On Wide-Open Throttle (2 Of 2)

Courtesy of GENERAL MOTORS CORP.

Fig. 20: High Stall Speeds (Stall In Ranges 1-5)

Courtesy of GENERAL MOTORS CORP.

Fig. 21: Low Stall Speeds (Stall In Ranges 1-5)

Courtesy of GENERAL MOTORS CORP.

Fig. 22: Transmission Will Not Make A Specific Shift

Courtesy of GENERAL MOTORS CORP.

Helpmelearn

April-29-08 6:41:07 PM

Page 22

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 23: Transmission Will Not Stay In Forward Or Reverse

Courtesy of GENERAL MOTORS CORP.

Fig. 24: Transmission Will Not Shift To Forward Or Reverse

Courtesy of GENERAL MOTORS CORP.

Fig. 25: Transmission Overheats

Courtesy of GENERAL MOTORS CORP.

Helpmelearn

April-29-08 6:41:07 PM

Page 23

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 26: Transmission Does Not Shift Properly

Courtesy of GENERAL MOTORS CORP.

Fig. 27: Abnormal Activities Or Responses

Courtesy of GENERAL MOTORS CORP.

CLUTCH APPLICATIONS

Helpmelearn

April-29-08 6:41:07 PM

Page 24

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 28: Clutch & Solenoid Chart (1 Of 2)

Courtesy of GENERAL MOTORS CORP.

Helpmelearn

April-29-08 6:41:07 PM

Page 25

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 29: Clutch & Solenoid Chart (2 Of 2)

Courtesy of GENERAL MOTORS CORP.

PERFORMANCE TESTS

ROAD TEST

CAUTION: Complete the test in the sequence given. Incomplete testing cannot

guarantee an accurate evaluation.

The following test provides a method of evaluating the condition of the automatic transmission. The test is

structured so that most driving conditions would be achieved. The test is divided into the following parts:

z

z

z

Electrical Function Check

Upshift Control and TCC Apply

Part Throttle Detent Downshifts

Helpmelearn

April-29-08 6:41:07 PM

Page 26

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

z

z

z

z

Full Throttle Detent Downshifts

Manual Downshifts

Coasting Downshifts

Manual Gear Range Selection

Before the road test, ensure the following:

z

z

z

The engine is performing properly.

Transmission fluid level is correct.

Tire pressure is correct.

During the road test:

z

z

z

z

Perform the test only when traffic conditions permit.

Operate the vehicle in a controlled, safe manner.

Observe all traffic regulations.

View the scan tool data while conducting this test. Take along qualified help in order to operate the

vehicle safely.

Observe any unusual sounds or smells.

After the road test, check the following:

z

z

z

Transmission fluid level.

DTCs that may have set during the testing. Refer to the applicable DTC.

Scan tool data for any abnormal readings or data.

Electrical Function Check

Perform this check first, to ensure the electronic transmission components are connected and functioning

properly. If these components are not checked, a simple electrical condition could be mis-diagnosed.

1.

2.

3.

4.

Connect the scan tool.

Ensure the gearshift lever is in Park and set the parking brake.

Start the engine.

Verify that the following scan tool data can be obtained and is functioning properly. Data that is

questionable may indicate a concern.

z Engine Speed

z Transmission Input Speed

z Transmission Output Speed

z Vehicle Speed

z "C", "D", "E" & Reverse Pressure Switch States

Helpmelearn

April-29-08 6:41:07 PM

Page 27

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Transmission Range

z 4WD Low

z Commanded Gear

z "A" & "B" Solenoid Reference Current

z "A" & "B" Solenoid Actual Current

z "A" & "B" Solenoid Duty Cycle

z Brake Switch

z Engine Coolant Temperature

z Transmission Fluid Temperature

z Throttle Angle

z Ignition Voltage

z Shift Solenoid "C" On/Off

z Shift Solenoid "D" On/Off

z Shift Solenoid "E" On/Off

z TCC Solenoid Duty Cycle

z TCC Slip Speed

5. Monitor the brake switch signal while depressing and releasing the brake pedal. The scan tool should

display:

z CLOSED when the brake pedal is released.

z OPEN when the brake pedal is depressed.

z

NOTE:

Harsh engagement may be caused by high idle speed, commanded low PC

solenoid current or a default condition caused by certain DTCs that result

in maximum line pressure to prevent slippage.

NOTE:

Soft or delayed engagement may be caused by low idle speed, low fluid

level, commanded high PC solenoid current or cold transmission fluid.

6. Check the garage shifts in the following order:

A. Apply the brake pedal and ensure the parking brake is set.

B. Move the gearshift lever through the following ranges: Park to Reverse, Reverse to Neutral and

Neutral to Drive.

C. Pause 2-3 seconds in each gear position.

D. Verify the gear engagements are immediate and not harsh.

7. Monitor transmission gear range on the scan tool engine list while performing the following:

A. Apply the brake pedal and ensure the parking brake is set.

B. Move the gearshift lever through all gear ranges.

C. Pause 2-3 seconds in each gear range.

D. Return gearshift lever to Park.

Helpmelearn

April-29-08 6:41:07 PM

Page 28

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

E. Verify that all gearshift lever positions match the scan tool display.

8. Check throttle angle input in the following order:

A. Apply the brake pedal and ensure the parking brake is set.

B. Ensure the gearshift lever is in Park.

C. Monitor throttle angle while increasing and decreasing engine speed with the throttle pedal. The

scan tool throttle angle should increase and decrease with engine speed.

If any of the above checks do not perform properly, record the result for reference after completion of the road

test.

Upshift Control & Torque Converter Clutch Apply

The TCM calculates the upshift points based on throttle angle and the engine, turbine and output speed. When

the TCM determines that conditions are met for a shift to occur, the TCM commands the shift and controls

solenoid "A" and "B" current to properly control clutch pressures during the shift.

1. Choose a throttle angle of 10, 25 or 50 percent. All throttle angles shown should be tested to cover the

normal driving range.

2. Monitor the following scan tool parameters:

z Throttle Angle

z Vehicle Speed

z Engine Speed

z Output Shaft Speed

z Commanded Gear

z Slip Speed

z Solenoid States

3. Place the gearshift lever in the Drive position.

4. Accelerate the vehicle using the chosen throttle angle. Hold the throttle steady.

5. As the transmission upshifts, note the vehicle speed when the shift occurs for each gear change. There

should be a noticeable shift feel or engine speed change within 1-2 seconds of the commanded gear

change.

6. Compare the shift speeds to the shift speed chart. Shift speeds may vary slightly due to transmission fluid

temperature or hydraulic delays in responding to electronic controls. Note any harsh, soft or delayed

shifts or slipping. Note any noise or vibration.

7. Repeat steps 1 -6 to complete all throttle angles.

8. Check for TCC apply in 2nd, 3rd, 4th and 5th gear. Note the TCC apply point. When the TCC applies,

there should be a noticeable drop in engine speed and a drop in slip speed to below 100 RPM. If the TCC

apply can not be detected, check for DTCs. Lightly tap and release the brake pedal. The TCC will release.

Part Throttle Detent Downshift

1. Place the gearshift lever in the Drive position.

Helpmelearn

April-29-08 6:41:07 PM

Page 29

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

2. Accelerate the vehicle to a speed just above the 4th to 5th gear shift point using less than 50 percent

throttle.

3. Quickly increase throttle angle to greater than 63 percent.

4. Verify the TCC releases and transmission downshifts immediately to 4th gear.

Manual Downshifts

The shift solenoid valves do not control manual downshifts. All manual downshifts are hydraulic. The solenoid

states will change during, or shortly after, a manual downshift is selected.

Manual 5-3 Downshift

1.

2.

3.

4.

Place the gearshift lever in the Drive position.

Accelerate the vehicle to obtain 5th gear.

Release the throttle while moving the gearshift lever to 3rd.

Verify the transmission downshifts immediately to 3rd gear and the engine slows the vehicle.

Manual 5-2 Downshift

1.

2.

3.

4.

Place the gearshift lever in the Drive position.

Accelerate the vehicle to obtain 5th gear.

Release the throttle while moving the gearshift lever to 2nd.

Verify the TCC releases, the transmission downshifts immediately to 2nd gear and the engine slows the

vehicle.

Manual 2-1 Downshift

1.

2.

3.

4.

5.

Place the gearshift lever in the Drive position.

Accelerate the vehicle until the 1-2 shift occurs.

Go to 5 MPH above the 1-2 shift point.

Release the throttle while moving the gearshift lever to 1st.

Verify the TCC releases, the transmission immediately downshifts to 1st gear and the engine slows the

vehicle.

Coasting Downshifts

1.

2.

3.

4.

Place the gearshift lever in the Drive position.

Accelerate the vehicle to 5th gear with the TCC applied.

Release the throttle and lightly apply the brakes.

Verify the TCC releases, and downshifts occur in normal sequence and the transmission returns to 1st

gear before the vehicle comes to a stop.

Manual Gear Range Selection

Helpmelearn

April-29-08 6:41:08 PM

Page 30

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

The shift solenoids control the upshifts in the manual gear ranges.

NOTE:

Perform the following tests using 10 percent to 15 percent throttle angle.

Reverse

1. With the vehicle stopped, move the gearshift lever to Reverse.

2. Slowly accelerate the vehicle.

3. Verify that there is no noticeable slip, noise or vibration.

Manual First

1. With the vehicle stopped, move the gearshift lever to 1st.

2. Accelerate the vehicle to 20 MPH.

3. Verify no upshifts occur, the TCC does not apply and there is no noticeable slip, noise, or vibration.

Manual Second

1. With the vehicle stopped, move the gearshift lever to 2nd.

2. Accelerate the vehicle to 35 MPH.

3. Verify the 1-2 shift occurs, the 2-3 shift does not occur and there is no noticeable slip, noise or vibration.

Manual Third

1. With the vehicle stopped, move the gearshift lever to 3rd.

2. Accelerate the vehicle to 40 MPH.

3. Verify the 1-2 shift occurs, the 2-3 shift occurs and there is no noticeable slip, noise or vibration.

SHIFT SPEED SPECIFICATIONS

Fig. 30: 1-2 & 2-3 Shift Speed Specifications

Courtesy of GENERAL MOTORS CORP.

Helpmelearn

April-29-08 6:41:08 PM

Page 31

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 31: 3-4 & 4-5 Shift Speed Specifications

Courtesy of GENERAL MOTORS CORP.

TORQUE CONVERTER DIAGNOSIS

The Torque Converter Clutch (TCC) is applied by fluid pressure, which is controlled by a PWM solenoid valve.

This solenoid valve is located inside of the automatic transmission assembly. The solenoid valve is controlled

through a combination of computer controlled switches and sensors.

Torque Converter Stator

The torque converter stator roller clutch can have two different malfunctions.

z

z

The stator assembly freewheels in both directions.

The stator assembly remains locked up at all times.

Poor Acceleration At Low Speed

If the stator is freewheeling at all times, the vehicle tends to have poor acceleration from a standstill. At speeds

above 30-35 MPH, the vehicle may act normally. For poor acceleration, you should first determine that the

exhaust system is not blocked, and the transmission is in 1st gear when starting out.

If the engine freely accelerates to high RPM in Neutral, you can assume that the engine and the exhaust system

are normal. Check for poor performance in Drive and Reverse to help determine if the stator is freewheeling at

all times.

Poor Acceleration At High Speed

If the stator is locked up at all times, performance is normal when accelerating from a standstill. Engine RPM

and vehicle speed are limited or restricted at high speeds. Visual examination of the converter may reveal a blue

color from overheating.

If the converter has been removed, you can inspect the stator roller clutch by inserting a finger into the splined

Helpmelearn

April-29-08 6:41:08 PM

Page 32

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

inner race of the roller clutch and trying to turn the race in both directions. You should be able to freely turn the

inner race clockwise, but you should have difficulty in moving the inner race counterclockwise or you may be

unable to move the race at all.

Whine Noise

NOTE:

Do not confuse this noise with pump whine noise, which is usually noticeable in

Park, Neutral and all other gear ranges. Pump whine will vary with line pressure.

You may notice a torque converter whine when the vehicle is stopped and the transmission is in Drive or

Reverse. This noise will increase as you increase the engine RPM. The noise will stop when the vehicle is

moving or when you apply the torque converter clutch, because both halves of the converter are turning at the

same speed.

Perform a stall test to make sure the noise is actually coming from the converter:

1. Place your foot on the brake.

2. Place the gearshift lever in the Drive position.

CAUTION: You may damage the transmission if you depress the accelerator for

more than 6 seconds.

3. Depress the accelerator to approximately 1200 RPM for no more than 6 seconds. Listen for torque

converter noise. A torque converter noise will increase under this load.

Torque Converter Clutch Shudder

The key to diagnosing Torque Converter Clutch (TCC) shudder is to note when it happens and under what

conditions.

TCC shudder which is caused by the transmission should only occur during the apply or the release of the

converter clutch. Shudder should never occur after the TCC plate is fully applied.

If the shudder occurs while the TCC is applying, the problem can be within the transmission or the torque

converter. Something is causing one of the following conditions to occur:

z

z

z

Something is not allowing the clutch to become fully engaged.

Something is not allowing the clutch to release.

The clutch is releasing and applying at the same time.

One of the following conditions may be causing the condition to occur:

z

z

Leaking turbine shaft seals.

A restricted release orifice.

Helpmelearn

April-29-08 6:41:08 PM

Page 33

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Defective friction material on the TCC piston.

If Shudder Occurs After TCC Has Applied

If shudder occurs after the TCC has applied, most of the time there is nothing wrong with the transmission.

As mentioned above, the TCC is not likely to slip after the TCC has been applied. Engine problems may go

unnoticed under light throttle and load, but they become noticeable after the TCC apply when going up a hill or

accelerating. This is due to the mechanical coupling between the engine and the transmission.

Once TCC is applied, there is no torque converter, fluid coupling, assistance. Engine or driveline vibrations

could be unnoticeable before TCC engagement.

Inspect the following components to avoid misdiagnosis of TCC shudder. An inspection will also avoid the

unnecessary disassembly of a transmission or the unnecessary replacement of a torque converter.

Spark Plugs - Inspect for cracks, high resistance or a broken insulator.

Plug Wires - Look in each end. If there is red dust (ozone) or a black substance (carbon) present, the

wires are bad. Also look for a white discoloration of the wire. This indicates arcing during hard

acceleration.

Coil - Look for a black discoloration on the bottom of the coil. This indicates arcing while the engine is

misfiring.

Fuel Injector - The filter may be plugged.

Vacuum Leak - The engine will not get a correct amount of fuel. The mixture may run rich or lean

depending on where the leak occurs.

EGR Valve - The valve may let in too much or too little unburnable exhaust gas, and could cause the

engine to run rich or lean.

MAP/MAF Sensor - Like a vacuum leak, the engine will not get the correct amount of fuel for proper

engine operation.

Carbon On Intake Valves - Carbon restricts the proper flow of air/fuel mixture into the cylinders.

Flat Cam - Valves do not open enough to let the proper fuel/air mixture into the cylinders.

Oxygen Sensor - This sensor may command the engine too rich or too lean for too long.

Fuel Pressure - This may be too low.

Engine Mounts - Vibration of the mounts can be multiplied by TCC engagement.

Axle Joints - Check for vibration.

TP Sensor - The TCC apply and release depends on the TP sensor in many engines. If the TP sensor is

out of specification, TCC may remain applied during initial engine loading.

Cylinder Balance - Bad piston rings or poorly sealing valves can cause low power in a cylinder.

Fuel Contamination - This causes poor engine performance.

HYDRAULIC PRESSURE TESTS

Line Pressure

Helpmelearn

April-29-08 6:41:08 PM

Page 34

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

WARNING: Keep the brakes applied at all times to prevent unexpected vehicle

motion. Personal injury may result if the vehicle moves unexpectedly.

Checking main line pressure helps to determine if a transmission malfunction is due to a mechanical or an

electrical problem. Properly making these pressure checks requires transmission and vehicle preparation,

recording of data, and comparing recorded data against specifications provided.

1. Remove the oil pressure tap plug. Install Pressure Test Adapter Fitting (J-45056) prior to connecting the

oil pressure gauge. See Fig. 32 .

2. Check the transmission fluid level. See SERVICING - "C" & "K" SERIES (ALLISON) article. All

transmission fluid level and pressure checks must be made at normal operating temperatures of 160-200

F (71-93C).

3. Connect a 0-300 psi (0-21.1 kg/cm2 ) oil pressure gauge to the pressure test adapter fitting. Use the scan

tool to check the engine RPM. See Fig. 33 .

4. With the brakes applied, record the line pressure values at 600 RPM in Neutral and Reverse. The

transmission will be in converter mode (torque converter clutch not applied).

5. With the brakes applied, record the line pressure values with the engine running at 2100 RPM in Neutral.

The transmission will be in converter mode (torque converter clutch not applied).

6. With the brakes applied, use the following scan tool settings to check pressures in 1st through 5th gear

ranges at 600 RPM. The transmission will be in converter mode (torque converter clutch not applied) at

600 RPM.

A. Select - F0: Diagnostics and press ENTER.

B. Select - Model Year.

C. Select - LDTrk, MPV, Incomplete.

D. Select - F0: Powertrain, press ENTER.

E. Select - Engine size, press ENTER.

F. Select - 5 Speed Automatic, press ENTER.

G. Select - F2: Special Functions, press ENTER.

H. Select - F1: Transmission Output Controls.

I. Select - Shift transmission. This will allow the technician to shift the transmission and check line

pressure in each forward gear range.

7. Compare the data recorded to the line pressure specifications. See Fig. 33 .

8. Disconnect the oil pressure gauge and remove the pressure test adapter fitting.

9. Reinstall the oil pressure tap plug using NEW "O" ring. Tighten the plug to 106 INCH lbs. (12 N.m).

Helpmelearn

April-29-08 6:41:08 PM

Page 35

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Fig. 32: Checking Line Pressure

Courtesy of GENERAL MOTORS CORP.

Fig. 33: Line Pressure Specifications

Courtesy of GENERAL MOTORS CORP.

CLUTCH TEST

Introduction

Helpmelearn

April-29-08 6:41:08 PM

Page 36

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Clutch test allows the technician to manually select each of the five forward gear ranges with the vehicle

stopped. The intent of this procedure is to verify the ability of all five clutches to transmit torque without

slipping. See CLUTCH & SOLENOID APPLICATIONS under TROUBLE SHOOTING.

Test Procedure

Use the scan tool to perform the clutch test. Select the following information when setting up the scan tool for

running the test. Use the shift transmission feature on the scan tool to complete the clutch test.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Select - F0: Diagnostics and press ENTER.

Select - Model Year (i.e., 1 = 2001).

Select - LDTrk, MPV, Incomplete.

Select - F0: Powertrain, press ENTER.

Select - Engine size, press ENTER.

Select - 5 Speed Automatic, press ENTER.

Select - F2: Special Functions, press ENTER.

Select - F1: Transmission Output Controls.

Select - Shift transmission. This will allow the technician to shift the transmission and check the integrity

of each clutch in the transmission.

Attach the transmission pressure gauge as described in line pressure check procedure. See HYDRAULIC

PRESSURE TESTS . Apply parking brake and hold service brakes and increase engine speed to 1400 RPM.

Using scan tool, select UPSHIFT and shift transmission from 1st gear range sequentially to 5th gear range,

while observing turbine speed. Turbine speed should increase momentarily and then drop to zero RPM when

each gear range is attained. Line pressure should drop momentarily then regain pressure when each gear range

is attained.

Maintain 1400 RPM, select the DOWNSHIFT soft key and downshift transmission from 5th gear range

sequentially to 1st gear range while observing turbine speed. Turbine speed should increase momentarily and

then drop to zero RPM when each gear range is attained.

To further investigate a suspected leak in a clutch circuit, the clutch test should be repeated keeping engine at

idle speed. While performing clutch test at 600 RPM, main pressure should drop momentarily, then regain

pressure when each gear range is attained. If main pressure remains low, suspect damaged seal in that gear

range. If low pressure is in 1st gear range only, suspect C5 piston seal damage.

SELF-DIAGNOSTIC SYSTEM

DIAGNOSTIC SYSTEM CHECK

Circuit Description

The diagnostic system check is an organized approach to identify a condition created by the automatic

transmission. The diagnostic system check is the diagnostic starting point for a automatic transmission

complaint. The diagnostic system check directs you to the next logical step for diagnosing a transmission

Helpmelearn

April-29-08 6:41:08 PM

Page 37

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

concern. Perform this check only if there is a driveability complaint or if you have been directed here from

another service information section.

Test Description

The numbers listed below refer to step numbers in the diagnostic procedure:

1 - This step determines if the scan tool is receiving power through the DLC connector.

2 - The MIL should illuminate whenever the ignition is on and the engine is not running.

3 - This step determines if the TCM is transmitting class 2 serial data to the DLC and that the class 2 data

circuit is not open or shorted.

4 - This step determines if a DTC is current or stored in history.

Diagnostic Procedure

NOTE:

Check for applicable service bulletins before proceeding with this test. Perform

this test only if there is a driveability complaint or if you have been directed to

this table from another section in the service information.

NOTE:

Do not turn the ignition off when performing this diagnostic procedure. Do not

clear the DTCs unless instructed by this diagnostic procedure.

1. Turn ignition on, engine off. Does the scan tool turn on? If so, go to next step. If not, diagnose scan tool

concern. See appropriate BODY CONTROL MODULES article in ACCESSORIES & EQUIPMENT.

2. Is the MIL on? If so, go to next step. If not, diagnose MIL concern. See appropriate SELFDIAGNOSTICS article in ENGINE PERFORMANCE.

3. Attempt to establish communication with the TCM. Does the scan tool communicate with the TCM? If

so, go to next step. If not, diagnose scan tool concern. See appropriate BODY CONTROL MODULES

article in ACCESSORIES & EQUIPMENT.

NOTE:

Diagnostic Trouble Codes (DTC), engine performance, and transmission

default actions can greatly affect the transmission performance. Ensure

that these items are not the cause of a transmission concern.

4. Use the scan tool CAPTURE INFO function to save or capture (store information) any DTC information.

Are there any DTCs present? If so, see DIAGNOSTIC TROUBLE CODE DEFINITIONS . If not, see

SYMPTOM DIAGNOSIS under TROUBLE SHOOTING.

Diagnostic Aids

NOTE:

DO NOT clear the DTC unless directed by a diagnostic procedure. Clearing the

DTCs will erase all freeze frame and failure records stored in PCM memory.

NOTE:

Poor engine performance can sometimes be diagnosed as a transmission

Helpmelearn

April-29-08 6:41:08 PM

Page 38

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

driveability condition. To avoid mis-diagnosis of the automatic transmission,

always perform powertrain diagnostic system check. See appropriate SELFDIAGNOSTICS article in ENGINE PERFORMANCE.

z

z

z

Use a scan tool that is known to function correctly. If necessary, test the scan tool on another vehicle.

Ensure the scan tool contains the most current file available.

The scan tool will display a loss of communication error message under the following conditions:

TCM power is interrupted.

The ignition is turned off.

The battery voltage level is very low.

A poor connection at the Diagnostic Link Connector (DLC).

DIAGNOSTIC TROUBLE CODE DEFINITIONS

NOTE:

Only transmission-related DTCs are listed. For engine-related DTC definitions,

see appropriate SELF-DIAGNOSTICS article in ENGINE PERFORMANCE. These

DTCs pertain to engine performance and must be repaired first, as engine

performance and related component signals will affect transaxle operation and

diagnosis.

DIAGNOSTIC TROUBLE CODE DEFINITIONS (1)

DTC (2)

P0218

P0500

P0561

P0562

P0563

P0700

P0701

P0703

P0708

P0711

P0712

P0713

P0716

P0717

P0721

P0722

P0726

P0727

P0731

Description

Transmission Fluid Over Temperature

Vehicle Speed Sensor Circuit

Unrealistic Variations In Vehicle System Voltage

System Voltage Low

System Voltage High

MIL Illumination Requested

Transmission Control System Performance

Brake Switch Circuit

Transmission Range Sensor Circuit High Input

Transmission Fluid Temperature Sensor Circuit - Performance

Transmission Fluid Temperature Sensor Circuit - Low Input (High Temperature)

Transmission Fluid Temperature Sensor Circuit - High Input (Low Temperature)

Turbine Speed Sensor Circuit - Performance

Turbine Speed Sensor Circuit - No Signal

Output Speed Sensor Circuit - Performance

Output Speed Sensor Circuit - No Signal

Engine Speed Sensor Circuit - Performance

Engine Speed Sensor Circuit - No Signal

Incorrect 1st Gear Ratio

Helpmelearn

April-29-08 6:41:08 PM

Page 39

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

P0732

P0733

P0734

P0735

P0736

P0741

P0742

P0743

P0746

P0747

P0748

P0763

P0768

P0773

P0776

P0777

P0778

P0836

P0840

P0841

P0842

P0843

P0845

P0846

P0847

P0848

P0870

P0871

P0872

P0873

P0875

P0876

P0880

P1571

P1688

P1779

U2105

(1) Some DTCs are model specific.

(2)

Incorrect 2nd Gear Ratio

Incorrect 3rd Gear Ratio

Incorrect 4th Gear Ratio

Incorrect 5th Gear Ratio

Incorrect Reverse Ratio

Torque Converter Clutch System Stuck Off

Torque Converter Clutch System Stuck On

Torque Converter Clutch - Electrical

Solenoid "A" Controlled Clutch Stuck Off

Solenoid "A" Controlled Clutch Stuck On

Pressure Control Solenoid "A" Electrical

Shift Solenoid "C" Electrical

Shift Solenoid "D" Electrical

Shift Solenoid "E" Electrical

Solenoid "B" Controlled Clutch Stuck Off

Solenoid "B" Controlled Clutch Stuck On

Pressure Control Solenoid "B" Electrical

4-Wheel Drive Low Switch Circuit Malfunction

Pressure Switch Solenoid "C" Circuit Malfunction

Pressure Switch Solenoid "C" Circuit Stuck Open

Pressure Switch Solenoid "C" Circuit Stuck Closed

Pressure Switch Solenoid "C" Circuit High

Pressure Switch Solenoid "D" Circuit Malfunction

Pressure Switch Solenoid "D" Circuit Stuck Open

Pressure Switch Solenoid "D" Circuit Stuck Closed

Pressure Switch Solenoid "D" Circuit High

Pressure Switch "E" Circuit Malfunction

Pressure Switch Solenoid "E" Circuit Stuck Open

Pressure Switch Solenoid "E" Circuit Stuck Closed

Pressure Switch Solenoid "E" Circuit High

Reverse Pressure Switch Circuit Malfunction

Reverse Pressure Switch Circuit Stuck Open

TCM Power Input Signal

TCS PWM Circuit No Frequency

Unmanaged Engine Torque Delivered To TCM

Engine Torque Delivered To TCM

CAN Bus PCM Error

For DTC diagnostic procedures, see DIAGNOSTIC TESTS .

Helpmelearn

April-29-08 6:41:08 PM

Page 40

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

CLEARING DIAGNOSTIC TROUBLE CODES

Using scan tool, clear DTCs following scan tool manufacturer's instructions. Do not clear DTCs unless

instructed to do so.

SUMMARY

NOTE:

Always clear DTCs once repairs are complete. See CLEARING DIAGNOSTIC

TROUBLE CODES . Road test vehicle and retrieve DTCs to determine if

complaint or DTC is repaired.

If no hard DTCs are present, and driveability symptoms or intermittent DTCs exist, attempt diagnosis by

symptom, or by testing individual components related to system fault. See TROUBLE SHOOTING . If no

problem is found, verify proper electronic control system circuit operation.

DIAGNOSTIC TESTS

DTC P0218: TRANSMISSION FLUID OVER TEMPERATURE

NOTE:

For circuit identification, see CONNECTOR IDENTIFICATION and WIRING

DIAGRAMS .

Circuit Description

The Transmission Fluid Temperature (TFT) sensor is a part of the transmission pressure switch manifold

assembly. The TFT sensor is a thermistor which changes its value based on temperature. The Transmission

Control Module (TCM) supplies a 5-volt reference signal to the TFT sensor. When the transmission fluid is

cold, the sensor resistance is high and the TCM detects a high signal voltage. As transmission fluid temperature

increases, the resistance becomes less, and the signal voltage decreases.

This is a type "C" DTC.

Conditions For Running The DTC

DTC will run under the following condition:

z

z

The components are powered, and ignition voltage is greater than 9 volts and less than 18 volts.

Engine speed is greater than 200 RPM and less than 7500 RPM for 5 seconds.

Conditions For Setting The DTC

DTC will set under the following condition:

z

DTC sets when the TCM detects a transmission fluid temperature greater than 259F (126C) for 10

seconds.

Helpmelearn

April-29-08 6:41:08 PM

Page 41

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

Action Taken When The DTC Sets

TCM performs the following actions if DTC is set:

z

z

z

DTC is stored in the TCM history.

The TCM freezes shift adapts.

The TCM inhibits TCC engagement.

Conditions For Clearing The DTC

DTC will clear under the following conditions:

z

z

A scan tool can clear the DTC from the TCM history.

The TCM automatically clears the DTC from the TCM history if the vehicle completes 40 warm-up

cycles without failure.

Test Description

The numbers listed below refer to step numbers in the diagnostic procedure:

4 - This step tests for ignition voltage.

5 - This step tests for unrealistic changes in transmission fluid temperature.

6 - This step tests the internal wiring harness.

7 - This step checks the wiring harness for opens or shorts.

9 - This step tests the resistance of the TFT sensor.

Diagnostic Procedure

1. Did you perform the diagnostic system check? If so, go to next step. If not, see DIAGNOSTIC

SYSTEM CHECK under SELF-DIAGNOSTIC SYSTEM.

2. Inspect the engine cooling system for air flow restrictions, air flow blockage or debris. Inspect the

transmission cooling system for air flow restrictions, air flow blockage, damaged cooler lines or hoses,

and low transmission fluid cooler flow. Did you perform the inspection and correct the conditions if

necessary? If so, go to next step. If not, see SERVICING - "C" & "K" SERIES (ALLISON) article.

3. Check the transmission fluid level. Is the transmission fluid level correct? If so, go to next step. If not, see

SERVICING - "C" & "K" SERIES (ALLISON) article.

4. Install the scan tool. Turn ignition on, engine off. Record DTC and failure records. Start the engine.

Using the scan tool, check ignition voltage. Is the voltage 9-18 volts? If so, go to next step. If not, see

DTC P0562: SYSTEM VOLTAGE LOW or DTC P0563: SYSTEM VOLTAGE HIGH .

5. Turn the ignition on, engine off. Using scan tool, monitor transmission fluid temperature. Start the engine

and drive the vehicle under normal operating conditions or in the specific operating mode when the

overtemperature condition occurred if known. Do the transmission fluid temperature readings appear

inconsistent or exceed 250F (121C)? If so, go to next step. If not, see DIAGNOSTIC AIDS .

6. Disconnect transmission in-line 20-way connector. Using a DVOM, measure the resistance of the TFT

Helpmelearn

April-29-08 6:41:08 PM

Page 42

2005 Mitchell Repair Information Company, LLC.

2003 Chevrolet Silverado 1500

2003 AUTOMATIC TRANSMISSIONS Allison LCT 1000 Diagnosis

7.

8.

9.

10.

11.

12.

sensor between transmission in-line 20-way connector terminals "G" and "H". Is the resistance within the

specified range? See COMPONENT RESISTANCE under ELECTRONIC COMPONENT