Professional Documents

Culture Documents

Man44 Uk PDF

Uploaded by

khalidfarooq009Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Man44 Uk PDF

Uploaded by

khalidfarooq009Copyright:

Available Formats

KME ITALY

Handbook of electric cables MICO

FOURTH CHAPTER

JOINTS AND TERMINATIONS

63

KME ITALY

Handbook of electric cables MICO

64

KME ITALY

Handbook of electric cables MICO

This section, directly connected to the previous technical notes about the specific

arguments, intends to best explain the discussed topics and to complete the actual

information with additional suggestions we suppose to be useful for installers and

technicians.

Anyway instructions in actual section cannot substitute experience each Mineral Insulated

Cable installer must have.

In order to do this, KME ITALY workers and facilities are at anyone disposal for instruction

and qualification about MICO cable use.

TESTS

At the end of manufacturing cycle, 100 % of Mineral Insulated Cable coils, according to

product standard statement and "QUALITY SYSTEM MANUAL", drawn up in conformity

with UNI-ISO 9000, are subjected to the following approval tests:

conductors electrical resistance;

dielectric strength 2500 V x 30 for Heavy duty cables

2000 V x 30 for Light duty cables;

Insulation resistance ( 1000 M/km).

CABLE ENDS TEMPORARY SEALINGS

In order to preserve high insulation resistance as long as its possible, at the end of

manufacturing cycle, each cable coil end is temporary sealed, to prevent moisture to

penetrate inside the cable, from manufacturing to beginning using it.

Such sealing is made with waterproof and mechanical resistant plastic material.

If you expect to store mineral insulated cables for a long period, its better to temporary

seal both the ends, using one of the following ways:

wrapping self bonding tape around cable ends;

wrapping common tape around cable ends;

TERMINATIONS

Method of MICO layout is clearly different to traditional cables with organic insulation,

because the ends must be sealed using suitable terminations.

KME ITALY termination, according to European standard HD 586.2.S1/1994), is

composed by:

1. GLAND;

2. SEAL.

65

KME ITALY

Handbook of electric cables MICO

IP 67 WATERPROOF TERMINATION

Rubber ring

Earth tail seal

Compression ring

body

Locknut

EXPLOSIONPROOF TERMINATION

Earth tail seal

Compression ring

Body

Locknut

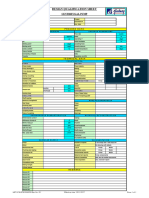

GLAND

Gland is used to connect Mineral Insulated Cable to junction box; following types of glands

are foreseen, according to particular kind of installation to achieve:

- " RN " glands for waterproof electrical installation

Such kind of glands allows an easy screwing of the cable to the waterproof junction box;

gland body, compression ring and locknut are made in brass and the outer thread is

cylindrical UNI ISO 228 (ex UNI 338) or isometric ISO 965; using a synthetic rubber ring

("OR" kind) gland assures IP 67 protection degree (CESI GR 015 certification enclosed).

In the table below, maximum diameter value is suggested, when you must drill a wall of a

junction box or electric board, to keep IP 67 protection degree.

Gland and cable type matching is shown in Mineral Insulated Cables technical data

table, in MICO brochure.

Rubber ring

"OR"

Gland locknut

L

Body

A (gland

thread)

1

1-

Maximum

L Thread

hole (mm) length (mm)

21,50

27,00

34,00

41,50

10,50

11,00

11,00

19,00

Compression

ring

D

Hexagon

size (mm)

24

30

38

46

- "RAD" glands for explosionproof electrical installation

Explosionproof glands for Mineral Insulated Cables are manufactured according to

following European standard:

EN 50.014 - 1993 (CEI 31-8 1978) general rules;

66

KME ITALY

Handbook of electric cables MICO

EN 50.018 - 1995 (CEI 31-1 1978) explosion proof boxes "d".

Since they passed all those tests described in above mentioned standards (CESI

certification NR. AD 86.125X, see enclosed), they are marked as:

EEx d IIC T6 T1

Also such kind of gland is composed by brass gland body, compression ring e locknut;

body outer thread, for junction box connection, is conical UNI 6125; gland and cable type

matching is shown in Mineral Insulated Cables technical data table, in MICO brochure; at

Customer request, they can be supplied with ISO or PG thread.

L

D

Body

Thread D

1

1-

Compression ring Locknut

Thread

length L

(mm)

15,40

15,40

19,70

19,70

SEALS KIT

The seal prevents moisture to penetrate into cable insulation (magnesium oxide); seals

parts are :

1.

2.

3.

4.

Brass pot;

Stub cap;

compound;

sleeving.

1 Brass pot

Its composed by a self-screwed brass hollow body, whose hole diameter is related to the

cable diameter, in order to be screwed on the outer copper sheath of the cable; 3 different

seal types are available:

standard: you need a suitable copper clip to connect the outer copper sheath (protection

conductor), with the earth bonding inside the junction box; earth bonding clamps for

1H300 e 1H400 are not available.

67

KME ITALY

Handbook of electric cables MICO

earth tailed: its provided with a suitable sized copper wire (as IEC60364 PT5 CH54

foresees), welded on its bottom, in order to lead the earth conductor (outer sheath)

directly inside the junction box; theyre not available for 70 mm to 400 mm single core

cables and for 12 to 19 conductors cables. We suggest to use these seals where

aesthetics is very important.

Both types of seals are divided into 4 classes (its better to define it, with the cable size,

when the order is emitted); the following table shows the right codes, dimensions and

pieces number inside each kit (every pack is completed by suitable stub caps)).

Seal type

Dimensions (mm)

Standard Earth tail

Height

G

J

K

M

GFT

JFT

KFT

MFT

15

21

32

34

17

25,5

32

34

kit

(Nr of

pieces)

10

2

2

2

Heat - shrinkable: basically used only for single core cables; its made by a 70 mm long

piece of heat-shrinkable sleeving; during the termination of the cable, this sleeving melts

under the heat effect, sealing the cable.

2 STUB CAP

Its made by a printed plastic polymer record; it keeps the right distance between the

conductors and, at the same type, avoids the compound exposure to environment; two

different types of stub caps are provided, depending upon outside temperature: a black

one in Moplen, up to 105 C, and a white PTFE one, up to 250 C.

68

KME ITALY

Handbook of electric cables MICO

STUB CAP

in Moplen

STUB CAP

in PTFE

3 - COMPOUND

Depending upon the installation requirement, 4 types can be used:

CS: standard compound in 100 g packs, it can be used up to 135 C;

HT: 2 components compound in 100 g packing, it can be used up to 185 C;

HT/W: silicon compound in 100 g packing, it can be used up to 185 C;

GF: glass fibre compound 100 g metallic pipes, it can be used up to 250 C.

Number of terminations that can be made with a 100 g packing of above mentioned

compounds is reported in the following table.

Seal type

G-GFT

J-JFT

K-KFT

M-MFT

NR of seals

With 100 g of

compound

36

12

6

2

4 - SLEEVING

They provide the insulation between the conductors coming out from the stub cap;

depending upon the installation requirement, 3 types can be used::

BT: firestop PVC sleeving (code BT/cable size), black coloured for all phase conductor

sizes but 300 e 400 mm, and yellow-green up to 25 mm for earth tail conductors; they

are supplied in 3 m coils and theyre recommended up to 105 C; sleeving pieces must

be slipped on the conductors and lightly pushed on the stub cap.

" B T " S L E E V IN G

HT: theyre made by PTFE (code HT/cable size) and theyre recommended when

temperature is higher than 105 C; ; they are suppl ied in coils 30 or 120 cm coils; this

kind of sleeving must be threaded in stub cap holes, then the edges must be lifted (as

following picture shows) to avoid them to come out, as further suggested.

G u a in a is o la n te " H T "

Heat shrinkable: are necessary for 1H300 e 1H400 conductors; their application method

is described in following pages.

Such kind of sleeving is used also as seal for the whole single core range of cables; its

made by a double layer heat shrinkable pipe, about 70 mm long; during the execution of

cable ends termination, internal layer melts under the heat effect, sealing the cable.

69

KME ITALY

Handbook of electric cables MICO

Following are the correct termination procedures for right execution of termination; the

operation sequence is simple, but it requires care by operators.

TERMINATION EXECUTION

STARTING CHECK OF INSULATION RESISTANCE

Each cable coil is controlled and sealed to keep unchanged in time the insulation

resistance; Before starting seal execution, its better to cut about 10 cm of cable from both

ends; after this, using a Megger with 500 Vcc voltage between conductors and sheath, the

insulation resistance value must be controlled to be more than 100 M.

Sometimes insulation resistance value could happen to be lower than 100 M (even 5

M); in this case termination execution can start anyway because, like its described

later, insulation resistance value will reach the required target after 510 minutes.

SUITABLE TOOLS

The operation is divided into 3 parts, during which only 2 specific tools are required,

beyond the standard ones belonging to common operators tool-set:

Stripper

Its used to remove outer copper sheath to let the conductors free for following operations

and its suitable for Mineral Insulated Cables up to 185 mm size; its composed by 2

opposite V shape blocks, one of them is fixed (anyway it can be doubly oriented

according to the diameter of the cable) the other can be moved and height adjusted by a

screw: the second one is provided with the blade that must cut the copper sheath of the

cable.

A d ju s tm e n t

s c re w

B la d e

F re e "V "

F ix e d " V

Crimping tool for brass pot/stub cap calking

In order to joint stub cap and brass pot, you need this tool that, by a height adjustable

steel dish with 3 teeth placed at 120 degrees one from the others, allows to make 3 cut

on the brass pot edge, avoiding stub cap getting out; 3 different types of crimping tools are

available, according to seal size.

G and J/K type (see picture below)

70

KME ITALY

Handbook of electric cables MICO

Screw

3 teeth

steel dish

Brass pot slot

J/K crimping tool is provided with reduction cylinder (for brass pot slot) and calking steel

dish for J type seals

M type: for M seals

Screws

3 teeth steel

dish

Brass pot slot

CABLE ENDS PREPARATION

Using a little saw, cut about 1 cm of cable from the end you want to seal;

Set the stripper on the cable; the blade must rest on the edge of copper sheath and the

upper "V" block must be pressed on the cable by the suitable screw. Pressure must be

as strong to joint the tool to the cable but not to avoid the stripper rotation;

Start rotating the stripper clockwise, pushing it, at the same time, towards the cable

centre;

Do not allow the shaving to collect around the conductors, clasping it to the suitable

hook;

As the stripper removes enough copper sheath, place the pliers to stop stripper

advancing: it will cause the shaving cut, leaving perfectly smooth cable base and free

conductors.

71

KME ITALY

Handbook of electric cables MICO

SEAL EXECUTION

Clean conductors from Magnesium Oxide;

insert the brass pot on the cable;

remove eventual shavings;

start screwing with a pot wrench the brass pot on the cable, controlling it to be in axis;

the brass pot must be screwed until the cable edge is at the same level of the internal

hole;

NO

YES

YES

remove eventual magnesium oxide or metallic parts remaining inside the brass pot;

straighten the conductors with the pliers;

fill the pot with the compound, pushing it always from the same side, in order to prevent

air to remain inside the pot.

What above described is valid for CS, HT and HT/W compound; about GF compound,

the procedure foresees:

using a burner, heat seal and conductors up to 200250C degrees;

insert inside the seal the granulate up to 2 mm high and then lead it to the melting

point by the burner; during such operation, the granulate mustnt boil (lead could free

itself and this would be dangerous for insulation resistance);

repeat the operation until the brass pot is full;

slip the sleeving on the conductors, if using CS compound and BT sleeving with Moplen

stub cap, and press it with the suitable tool until 3 cuts are made on the pot.

When the other compound types are used (HT, HT/W and GF) with PTFE sleeving, the

sleeving edges must be lifted, as showed before, and then passed through the holes of

the stub cap; PTFE sleeving can be lifted using a warmed shroud, as showed in the

following picture;

72

KME ITALY

Handbook of electric cables MICO

Push the sleeving on

the warmed shroud, this way

then put the stub cap with the sleeving on the conductors and press it on the brass pot

by the suitable crimping tool.

remove the crimping tool and the compound coming out from the brass pot during the

pressing;

slip the sleeving on the conductors.

Conductors

Sleeving

Copper sheath of

Mineral Insulated Cable

Gland

Seal

Brass

lock nuts

Junction box

wall

INSULATION RESISTANCE CHECK

BEFORE THE INSTALLATION

After seal execution on both cable ends, insulation resistance check must be made; there

could be 2 reasons:

1) the seal is on a cable whose insulation resistance value is higher than 100 M; if the

sealing operation is in conformity with our procedure, the Megger will show an insulation

resistance value higher than 100 M .

2) the seal is on a cable whose insulation resistance value is lower than 100 M; in this

case the result of the control could point out an insulation resistance value lower than

100 M (even 15 M) but, if the termination is well executed, after 510 minutes the

insulation resistance value will become clearly higher than 100 M.

INSULATION RESISTANCE CHECK AFTER THE INSTALLATION

73

KME ITALY

Handbook of electric cables MICO

Rarely happens, during installation final testing, to check low insulation resistance due to a

bad execution of a seal; in this case, you can proceed this way:

recognise the defective seal;

remove the seal;

remove compound residual, stripping 23 mm of copper sheath with suitable tool;

restore insulation resistance as suggested before;

start again with seal execution like previously described.

SEAL EXECUTION ON MICO CABLE

WITH LSF OUTER COVERING

Operation described in previous chapter deal with seal execution on bare Mineral

Insulated Cables; but, in particular environments where its necessary to install MICO

cable with LSF outer serving, you cant help using a PVC shroud.

It must restore the additional protection (before the junction box) on the cable part that

becomes free from the covering when seal execution operation are made.

In this case the procedure foresees:

remove LSF additional serving for a length "L" suitable for the execution of the operation;

we suggest on the following page the values of the length "L" (including the length of the

conductors to strip, which is about 150 mm) according to different sizes of the

termination:

- " glands : mm 250;

- " glands : mm 250;

- 1" glands : mm 260;

- 1-" glands : mm 300;

cut the end of the protection shroud, as shown in following picture;

PVC protection shroud

cut

LSF additional serving

Bare MICO

Insert the cut shroud on the cable and repeat the operations described in previous

section.

LSF covered MICO cable

Bare MICO cable

Junction box wall

PVC protection shroud

4 sizes of PVC shrouds are available, according to seals sizes:

74

KME ITALY

- CO1 code: for glands

- CO2 code: for glands

- CO3 code: " 1 glands

- CO4 code: " 1- glands

Handbook of electric cables MICO

(10 pieces packs);

(2 pieces packs);

(2 pieces packs);

(2 pieces packs).

THERMO-SHRINKABLE SEAL EXECUTION

As previously stated, such kind of seal is used for 1H300 and 1H400 cables, but can be

used also for all the others single core cables; it doesnt require stripper and crimping tool

to be executed, but only a ringer and cutting nippers.

Operations to follow are:

cut the copper sheath to easily remove the shaving; its important to cut the copper

sheath for half of its thickness.

Remove the copper sheath by helical movement of the cutting nippers;

Check the insulation resistance as previously described procedure;

Clean the stripped conductor with emery cloth;

Remove any eventual impurity from unsealed insulation, to minimise any risk of

decreasing dielectric strength;

Place the heat shrinkable double layer pipe, 70 mm long, on the cable and, with a

burner, make it stick on the cable, taking care of the melting of seal internal layer; in

order to be sure about it, its better to previously warm the copper sheath and

conductor;

Insert the double layer heat shrinkable sleeving around the conductor and, using a

burner, make it stick on the conductor itself and on the previously placed seal.

ACCESSORIES

EARTH BONDING CLAMPS

When earth tail seals are not used, its necessary to use a suitable copper clamp to

connect the copper sheath, acting as protection conductor, to the earth bonding of the

junction box.

In MICO general catalogue, correspondence between cable types and earth bonding

clamps codes is shown; each clamps pack is composed by 10 pieces.

75

KME ITALY

Handbook of electric cables MICO

COPPER CLIPS AND FIXING STRIP

Each type of cable is equipped with copper clips to fix at sight one or two cables with the

same diameter; both types of clips can be supplied bare or LSF covered, in 50 pieces

packs.

Fixing clips for 2 cables

Fixing clips for a single cable

When you need to fix different diameter cables or more than 2 cables, 3 metres long

annealed copper strips are available. Such strips, 12 mm wide and 0,8 mm thick, is prepunched with 4 mm diameter and 10 mm stepped holes: CUM3 code).

BRASS LOCK NUTS

If the holes of the junction boxes arent threaded, you need a brass lock nut inside the

junction box itself, in order to joint the gland; the following table shows GAS and ISO

thread lock nut codes and pieces number in each pack.

Lock nut

codes

C1

C2

C3

C4

Thread

diameter

1

1-

Pieces NR in

each pack

10

2

2

2

Lock nut

codes

C1-20

C2-25

C3-32

C4-40

Thread

diameter

M20x1,5

M25x1,5

M32x1,5

M40x2

Pieces NR in

each pack

10

2

2

2

WATERPROOF JOINTS

If you need to joint 2 lengths of the same kind of cable and you cannot use a waterproof

junction box, because its size is too large, a waterproof joint can be installed.

For such requirements, our Sales/Technical Office is at your disposal to supply specific

documentation.

JUNCTION BOXES

When electric installation must be executed in artistic or historical environments, its

necessary to limit the unpleasant esthetical impact of the common junction boxes; In order

to do this, as accessories for Mineral Insulated Cables, are available 2 different types of

junction boxes, whose main characteristics are:

Brass body;

Brass cap;

Sand-blasting of the whole external surface;

76

KME ITALY

Handbook of electric cables MICO

Neoprene membrane;

IP 67 protection degree against dust or fluid penetration, according to CESI

93/0226610 certification (enclosed); this certification is valid for CA 1 type;

Great mechanical strength;

pleasant esthetical impact;

chance to insert supports for switches or plugs, by 2 openings on CA1 cap.

GR-

Such junction boxes are manufactured according 3 different types:

CA1

CA1/2F (if 2 openings on CA1 cap are made)

CA2

Above mentioned junction boxes are supplied in a pack including also the screws for fixing

the cap on the body and the screw for the earth bonding inside the junction box.

CA1 and CA1/2F size is suitable for MICO terminations with glands up to or ISO 25

and for 6 mm maximum conductor size.

B

CA1

and

CA2

type

Y

CA 1 IP 67

EUROPA METALLI

X

CA1/2F

Y

type

CA 1

EUROPA METALLI

X

Junction

box type

X

(mm)

CA1- CA1/2F

CA2

117

191

Y

H

(mm) (mm)

83

132

63

72

IP 67 water proof

gland type

gas UNI ISO 228

gas UNI ISO 228

77

A

max.

(mm)

22

27

B

(mm)

33

41

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Q1 Welfare AdministrationDocument3 pagesQ1 Welfare Administrationkhalidfarooq009No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Headline Title: This Is Hole Scralw AND Nice LookingDocument4 pagesHeadline Title: This Is Hole Scralw AND Nice Lookingkhalidfarooq009No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Human Development and Learning (EDU302) : Assignment 1 (Spring 2020) Total Marks: 20 Lecture: 1-3Document1 pageHuman Development and Learning (EDU302) : Assignment 1 (Spring 2020) Total Marks: 20 Lecture: 1-3khalidfarooq009No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Curriculum Vitae: Sajid FarooqDocument2 pagesCurriculum Vitae: Sajid Farooqkhalidfarooq009No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Human Development and Learning (EDU302) : Assignment No.1Document4 pagesHuman Development and Learning (EDU302) : Assignment No.1khalidfarooq009No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Assignment No. 02 Cyber Law - CS204 Name Khalid Farooq Roll No BC190410864Document6 pagesAssignment No. 02 Cyber Law - CS204 Name Khalid Farooq Roll No BC190410864khalidfarooq009No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Assignment No. 01 Cyber Law - CS204 Name Khalid Farooq Roll No BC190410864Document2 pagesAssignment No. 01 Cyber Law - CS204 Name Khalid Farooq Roll No BC190410864khalidfarooq009No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- GIS Thermografie Audits PDFDocument2 pagesGIS Thermografie Audits PDFkhalidfarooq009No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- After Reading The ScenarioDocument8 pagesAfter Reading The Scenariokhalidfarooq009No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Assignment No.2 Semester: Spring2020 CS408 - Human Computer Interaction Khalid Farooq BC190410864 Question No 1Document2 pagesAssignment No.2 Semester: Spring2020 CS408 - Human Computer Interaction Khalid Farooq BC190410864 Question No 1khalidfarooq009No ratings yet

- 11.1 General.: Section - 11 Telephone SystemDocument2 pages11.1 General.: Section - 11 Telephone Systemkhalidfarooq009No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Do Not Write More Than 5 To 6 Lines For Your Answer - Each Question Carries 1.25 MarksDocument1 pageDo Not Write More Than 5 To 6 Lines For Your Answer - Each Question Carries 1.25 Markskhalidfarooq009No ratings yet

- D13 800 PDFDocument2 pagesD13 800 PDFkhalidfarooq009No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Auto Synchronizing and Auto Load SharingDocument24 pagesAuto Synchronizing and Auto Load Sharingravi_kumar_100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Auto Synchronizing and Auto Load Sharing: in The Name of Allah, The Beneficent, The MercifulDocument26 pagesAuto Synchronizing and Auto Load Sharing: in The Name of Allah, The Beneficent, The Mercifulkhalidfarooq009No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Series: Pumping Unit Technical DataDocument2 pagesSeries: Pumping Unit Technical DataRolandas GaudėšiusNo ratings yet

- Lab Manual Switchgear and Protection SapDocument46 pagesLab Manual Switchgear and Protection SapYash MaheshwariNo ratings yet

- Fronius IG Plus PDFDocument6 pagesFronius IG Plus PDFKirsten HernandezNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Man Rec Severing ToolDocument10 pagesMan Rec Severing ToolNgoc NguyenNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Deep Sea Ro-Ro ShippingDocument14 pagesDeep Sea Ro-Ro Shippingmayuresh100% (1)

- Tucson 2022 CatalogDocument8 pagesTucson 2022 CatalogHyundai CambodiaNo ratings yet

- Report GSM Based Remote Monitoring of 3 Parameters On TransformersDocument16 pagesReport GSM Based Remote Monitoring of 3 Parameters On TransformersJilly ArasuNo ratings yet

- Maspric ATS - M V02 LowresDocument25 pagesMaspric ATS - M V02 LowresvenkatNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Mine Venting DuctDocument28 pagesMine Venting DuctSergej SchlegelNo ratings yet

- BC-5800 Auto Hematology Analyzer Engineer Maintenance ManualDocument20 pagesBC-5800 Auto Hematology Analyzer Engineer Maintenance ManualJaime EspinosaNo ratings yet

- Low Distortion Audio Range ..Document2 pagesLow Distortion Audio Range ..ztmpztmpNo ratings yet

- Generator Honda EP2500CX1Document50 pagesGenerator Honda EP2500CX1Syamsul Bahry HarahapNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- HerramientasDocument2 pagesHerramientasJose FavaNo ratings yet

- FADZXcv SXDocument1 pageFADZXcv SXMohamed SelimNo ratings yet

- Underground Drilling Common / Boomer DCS: System Knowledge and Troubleshooting Training 10. MaintenanceDocument42 pagesUnderground Drilling Common / Boomer DCS: System Knowledge and Troubleshooting Training 10. Maintenancefranco avilaNo ratings yet

- Product Bulletin Fisher Vee Ball v150 v200 v300 Rotary Control Valves en 122994Document28 pagesProduct Bulletin Fisher Vee Ball v150 v200 v300 Rotary Control Valves en 122994Swastik MahapatraNo ratings yet

- Sew EurodriveDocument232 pagesSew EurodrivetujiohNo ratings yet

- Upmo, Ovcpd Uplb: The Electrical Services SectionDocument24 pagesUpmo, Ovcpd Uplb: The Electrical Services SectionMickiee OracionNo ratings yet

- Schedule of Loads: Electrical NotesDocument1 pageSchedule of Loads: Electrical NotesKenneth RicafrancaNo ratings yet

- Datasheet tl494Document6 pagesDatasheet tl494london335No ratings yet

- Drs00750 Rig Bom 1.0Document4 pagesDrs00750 Rig Bom 1.0sertecs polNo ratings yet

- Stepper MotorDocument16 pagesStepper MotoranaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- EE308 Electric DrivesDocument2 pagesEE308 Electric DrivesMerin MariamNo ratings yet

- Rail Injector Girs12: FeaturesDocument2 pagesRail Injector Girs12: FeaturesAndrea VaccariNo ratings yet

- Telehandlers: Parts AccessoriesDocument36 pagesTelehandlers: Parts AccessoriesWilliam Gonzalez EscobarNo ratings yet

- CSS10 - Teacher - Made - Home - Task - MELC 1.2 Computer Hardware IdentificationDocument7 pagesCSS10 - Teacher - Made - Home - Task - MELC 1.2 Computer Hardware IdentificationFaye LouraneNo ratings yet

- Pure Vent User Manual Rev 9Document64 pagesPure Vent User Manual Rev 9Sandro SammoriNo ratings yet

- WEG CFW11 70x Rs232 01 Rs485 01 Can 01 Can Rs485 01 Profibusdp 01 and Ethercat Communication Modules 0899.5486 Installation Guide enDocument2 pagesWEG CFW11 70x Rs232 01 Rs485 01 Can 01 Can Rs485 01 Profibusdp 01 and Ethercat Communication Modules 0899.5486 Installation Guide envromikoNo ratings yet

- Airless TireDocument12 pagesAirless TireLaxmipriya SenapatiNo ratings yet

- Productos Western Digital02032023Document1 pageProductos Western Digital02032023Maldi RamirezNo ratings yet