Professional Documents

Culture Documents

Drives Miniproject

Uploaded by

FaroukBoukhettaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drives Miniproject

Uploaded by

FaroukBoukhettaCopyright:

Available Formats

CONTROLLINGDC MOTOR

CONTENTS

PAGES

INTRODUCTION. . .

..

. . . . . . . ..2

DC MOTORS3

THEORY OF OPERATION3

Mathematical model.4

Feedback Control Principles ...6

PERFORMANCE CRITERIA.6

PROPORTIONAL + INTEGRAL CONTROLER..7

Analog PI Controller...8

CONTROLLING WITH OPEN LOOP SYSTEM .9

CONTROLLING WITH CLOSED LOOP SYSTEM.........................................................12

PART I.12

THEORETICAL PART..........................................................................................................................................................................13

EXPERIMENTAL PART.......................................................................................................................................................................13

Part A: LOAD TORQUE CONSTANT..................................................................................................................................................13

Part B: CONTROL SPEED...................................................................................................................................................................15

PART II...16

EXPERIMENTAL PART......................................................................................................................................................................17

CONCLUSION..19

GENERAL CONCLUSION...... 20

INTRODUCTION

Direct current (dc) motor has variable characteristics and is

used extensively in variable-speed drives. Dc motors can

provide a high starting torque and it is also possible to obtain

speed control over wide range. The methods of speed control

are normally simpler and less expensive than those of ac

CONTROLLINGDC MOTOR

drives. Dc motor plays a significant role in modern industrial

drives. Both series and separately excited dc motor are

normally used in variable-speed drives, but series motors are

traditionally employed for traction applications and require

more

maintenance

than

do

ac

motors.

With

recent

advancement in power conversion, control techniques, and

microcomputer, the ac motor drives are becoming increasingly

competitive with dc motor drives. Although the future trend is

toward ac drives, dc drives are currently used in many

industries. It might be a few decades before the dc drives are

completely replaced by ac drives.

Direct-current motors are used also in and position-control

systems where good dynamic response and steady-state

performance are required. Examples are in robotic drives,

printers, machine tools, process rolling mills, paper and textile

industries, and many others. Control of a dc motor, especially of

the separately excited type, is very straightforward, mainly

because of the incorporation of the commentator within the

motor. The commentator brush allows the motor-developed

torque to be proportional to the armature current if the field

current is held constant. Classical control theories are then

easily applied to the design of the torque and other control

loops of a drive system.

CONTROLLINGDC MOTOR

DCMOTORS

THEORY OF OPERATION:

The invention of the electrical motor comes simply from the

phenomenon that: a current carrying conductor will create a

force when placed in a magnetic field; the direction of the force

is perpendicular to the both, magnetic field and current.

An electrical motor uses this force in such a way to cause a

rotating motion; this can be achieved by placing a wire in loop

(coil) called armature windings that can rotate about an axis in

a magnetic field, with a comutator and brushes to supply

current to the armature as shown in Figure(1).

Figure -1Electrical motor

Operation representation

So whenever the rotor turns half revolution, the current

flow will change direction in the armature windings which

maintain the rotating force in the same direction.

One of the most important operating parameters is the

torque, which is directly proportional to the magnetic field and

the armature current; the motor torque can be expressed as:

T K IT A

(1.1)

Where:

CONTROLLINGDC MOTOR

T = motor torque

KT = a constant based on the motor construction

IA = armature current

= magnetic flux

Also another motor parameter can be seen when the motor

is running, that opposes the line voltage and its effect to cancel

out some of the line voltage, so the actual voltage available to

the armature is:

V A V in CEMF IA V

in

CEMF

(1.2)

RA

Where:

VA = actual voltage available to the armature

Vin = line voltage supplied to the motor

CEMF = voltage generated within the motor

RA

armature

resistance

Mathematical model:

Before we can control a system we must understand in

mathematical term how the system behaves without control,

CONTROLLINGDC MOTOR

this is called system modelling and it is done to obtain the

motor transfer function.

The basic characteristics that affect servo motors are; the

inertial load J on the out put shaft (rotor+ load), and the

viscous friction on the motor bearings referred as a constant b

which is found to be proportional to the shaft speed.

So using Newtons law we get:

T t ( ) J JbT t( )

i

(1.3

)

Where:

: The shaft position

J: The load moment of inertia (load + rotor)

B:

viscous friction constant

From eq (1.1) we get:

Jb K IT A( )t

(1.

4)

So its transfer function is:

s js(

b)

(1.5

)

CONTROLLINGDC MOTOR

Relationship between Torque and Speed

The fact that the field flux of a PM motor remains constant regardless of speed

makes for a very linear torque-speed curve. This is very desirable for control

applications because it simplifies the control equations. Figure -2- shows a

typical PM motor symbol and torque-speed curve. Notice that the curves are

straight lines for both speed and current. The absence of field coils is apparent in

the schematic [Figure

-2 (a)], which shows

the applied voltage

feeding only the

armature. The PM

motor is easily

reversed by reversing

the polarity of the applied voltage. The torquespeed curve can be used to predict

the performance of a motor under any load condition.

Figure -2A permanentant Motor.

Feedback Control Principles :

Broadly speaking, control systems can be classified into two groups: open-loop

and closed-loop. In an open-loop system [Figure-3-(a)], no feedback is used, so

the controller must independently determine what signal to send to the actuator.

The trouble with this approach is that the controller never actually knows if the

actuator did what it was supposed to do.

Figure -3Open- and closed Loop systems.

CONTROLLINGDC MOTOR

PERFORMANCE CRITERIA:

Performance criteria are various measurable parameters that indicate how good

(or bad) the control system is. These are divided into transient (moving) and

steady-state (not changing) parameters.

The exact path the controlled variable takes when going from one position to the

next is called its transient response. Consider the behavior of the robot arm

whose response is shown in Figure -4-; it is directed to move from 0 to 30, as

shown by the dashed line. This type of command (changing instantaneously

from one position to another) is called a step change. The actual response of the

system is shown as a solid line. As you can see, there is a difference between the

ideal path of the arm and the one it took. One major consideration is how fast

the system picks up speed (called rise time). The real arm simply cannot move

fast enough to follow the ideal path.

Rise time (T) is usually defined as the time it takes for the controlled variable to

go from 10 to 90% of the way to its new position. Another transient parameter is

overshoot.

Once the arm starts moving, its momentum will keep it going right on past

where it was supposed to stop. Overshoot can be reduced by the controller but

usually at the expense of a longer rise time. Settling time (Ts) refers to the time

it takes for the response to settle down to within some small percentage

(typically 2-5%) of its final value. In this case, it is the time it takes for the

oscillations to die out. Rise time, settling time, and overshoot are all related; a

change in one will cause a change in the others.

CONTROLLINGDC MOTOR

The steady-state error (ESS) of the system is simply the final position error,

which is the difference between where the controlled variable is and where it

should be. In

Figure -4-, ESS is shown as the position error after the oscillations have died

out. This error is the result of friction, loading, and feedback-sensor accuracy. A

sophisticated controller can reduce steady-state error to practically zero.

Figure-4Transient

Response.

PROPORTIONAL

+ INTEGRAL

CONTROLLER:

Many control systems

use a combination of

the three types of

feedback already discussed: Proportional + Integral

(PI) Control. The

foundation of the system is proportional control. Adding integral control

provides a means to eliminate steady-state error but may increase overshoot.

The response of the PI system can be described by Equation 11.6, which simply

adds together the three components required:

Another form of this obtained by factoring out KP from each term, is

Where

Output PI = output of the PI controller

KP = proportional control gain

KI = integral control gain (often seen as 1/TI)

E = error (deviation from the set point)

CONTROLLINGDC MOTOR

(E T) = sum of all past errors (area under the error time

curve) E/ t = rate of change of error (slope of the error curve)

Analog PI Controller:

CONTROLLING WITH OPEN LOOP SYSTEM

In this part we are dealing with speed torque control system

.we will have to see different relationship between them .we

will have then to plot the speed , the armature current and the

torque and we will see the behaviour of the torque with respect

to the current since there is related to the current .

Using XY graph we will plot the wm versus the torque in order

to seen the influence of the variation of the speed on the

torque .MATLAB SIMULINK is used as tool.

EXPERIMENTAL PART:

CONTROLLINGDC MOTOR

a)

Designingthecontrolsystem

:

b) Graphs out of the scope:

10

CONTROLLINGDC MOTOR

Remark:

From the simulation result we remark that the

speed increases until reaches the steady state conditions

and remains constant, and the torque is proportional to

the current, but practically this is not true because after

few minutes of running the parameter of the motor will

change, and this will effect on the torque-speed

11

CONTROLLINGDC MOTOR

characteristics. For this reason this system not useful and

not used in applications which implies to use another type

of system which is the closed loop system.

c) Speed torque plot :

CONTROLLING WITH CLOSED LOOP SYSTEM

PART I:

In this part we are dealing with the control of the speed and the

torque of the Dc motor using a feedback control system and a

12

CONTROLLINGDC MOTOR

DC chopper .This feedback and DC chopper will help us to

overcome the offset error during the control.

MATLAB is used as tool.

THEORETICAL PART:

In many industrial applications it is required to convert a fixed

voltage dc source into a variable voltage dc source .A dc

chopper converts directly from dc to dc and it is known as a dc

to dc converter .Choppers are widely used for traction motor

control in electric automobiles, trolley cars They provide

smooth acceleration control, high efficiency and fast dynamic

response. Choppers can be used in regenerative braking of dc

motors to return energy back in to the supply.

In our work dc chopper are used as dc to dc converter in ON

OFF feedback control system in order to control the speed and

torque of the Dc machine .The operation of the Step Down

chopper with a freewheeling diode explain the use of chopper

in ON OFF feedback control system. Therefore the operation of

the chopper can be divided in to two modes .During mode 1,

the chopper is switched on and the current flows from the

supply to the load .During mode 2, the chopper is switched off

and the load current continues to flow through freewheeling

diode.

In our case since we are controlling the speed, the ON or OFF

are activated by the difference between the measured value

compared to the set point .Therefore if there is an error the

controller is ON and a signal is outputted from the chopper to

the DC machine .Otherwise the controller is off and no output

from the chopper.

EXPERIMENTAL PART:

13

CONTROLLINGDC MOTOR

PartA: LOAD TORQUE CONSTANT

In this experiment the load torque is fixed and we give to the

speed two values (initial value and final value) the we see the

behaviour of the torque when the speed controller is trying to

overcome the error in order to reach the desired final value.

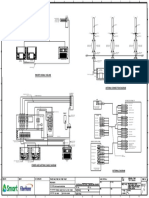

a) Designing the control system:

d) Graph

14

CONTROLLINGDC MOTOR

Remark: As it can be seen from the resulting graph the

torque is remarkably affected by the speed error

.Therefore when there s difference between the set point

and the measured speed values the torque is destabilized

and will return on its fixed value when the error will be

corrected by the controller and the speed at its desired

final value.

NB.-Initial speed value is fixed at 80 rad/s

-final speed value is fixed at 160 rad/s

-The load torque is fixed at 5 N.m

15

CONTROLLINGDC MOTOR

PartB: CONTROL SPEED

In this part the speed is fixed and we vary the load torque and

then we see variation of the seep with respect to the torque.

a) Designing the control system:

16

CONTROLLINGDC MOTOR

b) Graph:

Remark: In this part we see the influence of the torque in

the variation of the speed. Therefore as it has been

verified mathematically the speed is inversely proportional

to the torque.

PART II:

In this part we are going to improve the feedback speed control

system seen in previous part just by adding PI controller in the

feedback loop in order to try to remove the offset in speed

control

EXPERIMENTAL PART:

17

CONTROLLINGDC MOTOR

a)

Designingthecontrolsystem

:

b)Graph(speed and torque):

18

CONTROLLINGDC MOTOR

CONCLUSION:

We have seen in our experimentation work two types of

controlling a dc motor with following conclude:

A. In part one we were controlling the speed and torque of the

dc machine using a closed loop system. From this, as shown

on XY graph we have shown the relationship between the

speed and the torque.

From here we have to specify the advantages of using

MOSFET in this closed loop control system. Therefore MOSFET

is a voltage controlled device with infinite input impedance

which means that if a voltage is applied the input current to

19

CONTROLLINGDC MOTOR

the MOSFET will be very low; thus it doesnt require much

power .And it is also very simply driven

B. In this part we dealt with a simple feedback controlled system

which controls the speed. The step down chopper has been

used for this effect. This kind of system is not enough to

control a signal which contains many oscillations (where in

addition to the error there is an offset to the signal). That why

there is a need to add a PI controllers in the feedback loop in

order to overcome this offset.

C. The PI controller has an advantage in control system since it

helps us to correct continuously the error without oscillations.

Today Fasy-logic controllers are built up to replace the PI

controller because of its advantages since it doesnt need

transfer function to be implemented.

The control of the torque needs to know how the current is

varying since the torque is related to the current .The current

transformer could be used for this purpose.

GENERAL CONCLUSION

DC motors are widely used in applications requiring accurate speed controlfor

Example, in servo systems. Having developed a circuit model and analysis methods

for the DC generator, we can extend these results to DC motors, since these are in

effect DC generators with the roles of input and output reversed.

The closed-loop controller is a very common means of keeping motor speed at the

required "set point" under varying load conditions. It is also able to keep the speed at

the set point value where for example, the set point is ramping up or down at a

defined rate. The essential addition to the previous system is a means for the current

speed to be measured.

MATLAB/SIMULINK is/was used because of the short learning curve that we

require to start using it, its wide distribution, and its general-purpose nature. This

20

CONTROLLINGDC MOTOR

demonstrate the advantages of using MATLAB for analyzing power system steady

state behavior and its capabilities for simulating transients in power systems and

power electronics, including control system dynamic behavior.

According to the literature review and the results of this work, it is possible to outline

the most favorable simulation environment for electrical machines, circuit and control

systems. A fundamental assumption for doing so is that the emphasis of the

simulation will be/is on the operation of the whole system and the interaction between

the components, as well as on the behavior and design of each component separately.

Therefore, the best solution must contain two or three different tools operating firmly

together.

REFERENCE

[1]. P.C. Sen, Principles of Electric Machines and Power Electronics (2ndEdition), John

WILEY and Sons Inc., 1989

[2]. Power Electronics Hand Book by MUHAMMAD H. RASHID

[3]. Pricinples and applications of electrical engineering.

21

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Periodic Table & PeriodicityDocument22 pagesPeriodic Table & PeriodicityMike hunkNo ratings yet

- Rbs/Bts Signal Cabling: DF PanelDocument1 pageRbs/Bts Signal Cabling: DF PanelMayuSalanggaNo ratings yet

- Christopher Saint, Judy Saint-IC Mask Design - Essential Layout TechniquesDocument481 pagesChristopher Saint, Judy Saint-IC Mask Design - Essential Layout TechniquesPraveenNo ratings yet

- Bts SystemDocument8 pagesBts Systemrashm006ranjanNo ratings yet

- 24 Electrical PowerDocument172 pages24 Electrical PowerNurlan CebrayilzadeNo ratings yet

- Ee101 Basics of Electrical Engineering (End - SP19)Document2 pagesEe101 Basics of Electrical Engineering (End - SP19)soronaj532No ratings yet

- Serial + Crack READ MEDocument2 pagesSerial + Crack READ MEtoza74100% (1)

- Ele GenDocument10 pagesEle Gensanju08388458No ratings yet

- Frequency Ranges: H5: 518.000-542.000 MHZDocument5 pagesFrequency Ranges: H5: 518.000-542.000 MHZJNo ratings yet

- SLC Wiring Manual-51253Document80 pagesSLC Wiring Manual-51253teum3250% (8)

- Application of NanomatetialsDocument5 pagesApplication of NanomatetialsGinopragathishNo ratings yet

- Raychem ES EU1007 XLTraceFlowMaintenance enDocument2 pagesRaychem ES EU1007 XLTraceFlowMaintenance enSINIŠA PRETKOVIĆNo ratings yet

- Catalog Kocom 2011Document14 pagesCatalog Kocom 2011jeckie2No ratings yet

- Ch. 11: Liquids and Intermolecular Forces: - GasesDocument22 pagesCh. 11: Liquids and Intermolecular Forces: - GasesJozel Bryan Mestiola TerrìbleNo ratings yet

- STB 11 NK 50 ZDocument16 pagesSTB 11 NK 50 ZLEB 280No ratings yet

- Artificial Transmission Line Dec 16Document33 pagesArtificial Transmission Line Dec 16Arindam SenNo ratings yet

- MM850102-03 UniCal RTDDocument43 pagesMM850102-03 UniCal RTDctmtectrolNo ratings yet

- Butt Fusion Machines Small-Medium - V2 - LowDocument12 pagesButt Fusion Machines Small-Medium - V2 - LowViorel TomaNo ratings yet

- Envivio G6 Series DS-2015-05 r01Document3 pagesEnvivio G6 Series DS-2015-05 r01saefulNo ratings yet

- Napolcom Exam ReviewerDocument15 pagesNapolcom Exam ReviewerIrene FriasNo ratings yet

- MPCW2201SP 6-30-2020 PDFDocument1,229 pagesMPCW2201SP 6-30-2020 PDFMaximiliano AndrésNo ratings yet

- SMB/4144/R: Strategic Business Plan (SBP)Document5 pagesSMB/4144/R: Strategic Business Plan (SBP)ytumayNo ratings yet

- V-Log/V-Gamut: Reference ManualDocument7 pagesV-Log/V-Gamut: Reference ManualPufa DjuartonoNo ratings yet

- Tdoct5999a UsaDocument100 pagesTdoct5999a UsambidNo ratings yet

- Lecture 2 - Modern Computer SystemsDocument44 pagesLecture 2 - Modern Computer SystemsKisarach PhilipsNo ratings yet

- Assignment PDFDocument2 pagesAssignment PDFKapil JoshiNo ratings yet

- D Ia 16e 0409 FG-100 FF Z PDFDocument2 pagesD Ia 16e 0409 FG-100 FF Z PDFsharky1673No ratings yet

- Pinout Connector MercedesDocument4 pagesPinout Connector MercedesEasydiag Quikcar50% (2)

- Humble Homemade Hifi - ModulusDocument7 pagesHumble Homemade Hifi - ModulusmerrickNo ratings yet

- Message Authentication For Can Bus and Autosar Software ArchitectureDocument135 pagesMessage Authentication For Can Bus and Autosar Software ArchitecturebitzabladeNo ratings yet